Preparation and Curing Mechanism of Modified Corn Straw by 3-Glycidyl Ether Oxypropyl Trimethoxysilane/Epoxy Resin Composites

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Experimental Instruments

2.3. Preparation of Samples

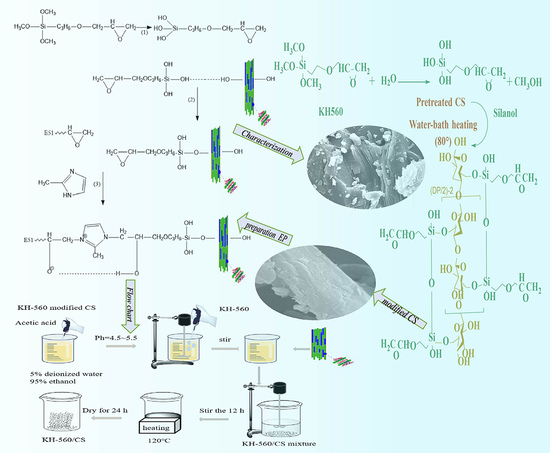

2.3.1. Surface Treatment of CS Particles with KH560

2.3.2. Preparation of Modified CS/E51 Composites (MCSECs)

2.4. Property Testing

3. Results and Discussion

3.1. Curing Mechanism Analysis

3.2. Micromorphology Analysis

3.3. Effects of Particle Sizes and Contents of KHCS on the Mechanical Properties of MCSEC

3.4. Dynamic Mechanical Analysis

3.5. Thermogravimetric Analysis

3.6. Mechanical Properties

3.7. Insulation Properties

3.8. Flame-Retardant Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Jayan, J.S.; Saritha, A.; Joseph, K. Innovative materials of this era for toughening the epoxy matrix: A review. Polym. Composite. 2018, 39, E1959–E1986. [Google Scholar] [CrossRef]

- Mohan, P. A Critical Review: The Modification, Properties, and Applications of Epoxy Resins. Polym. Plast. Tech. Mat. 2013, 52, 107–125. [Google Scholar] [CrossRef]

- Anoop, V.; Sankaraiah, S.; Jaisankar, S.N.; Chakraborty, S.; Mary, N.L. Enhanced mechanical, thermal and adhesion properties of polysilsesquioxane spheres reinforced epoxy nanocomposite adhesives. J. Adhesion. 2019, 97, 1–18. [Google Scholar]

- Paluvai, N.R.; Mohanty, S.; Nayak, S.K. Synthesis and modifications of epoxy resins and their composites: A review. Polym. Plast. Technol. 2014, 53, 1723–1758. [Google Scholar] [CrossRef]

- Venkatesan, G.; Jithin, P.R.; Rajan, T.V.; Pitchan, M.K.; Bhowmik, S.; Rane, R.; Mukherjee, S. Effect of titanium nitride coating for improvement of fire resistivity of polymer composites for aerospace application. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2018, 232, 1692–1703. [Google Scholar] [CrossRef]

- Chonkaew, W.; Sombatsompop, N.; Brostow, W. High impact strength and low wear of epoxy modified by a combination of liquid carboxyl terminated poly (butadiene-co-acrylonitrile) rubber and organoclay. Eur. Polym. J. 2013, 49, 1461–1470. [Google Scholar] [CrossRef]

- Kausar, A. Rubber toughened epoxy-based nanocomposite: A promising pathway toward advanced materials. J. Macromol. Sci. A 2020, 57, 499–511. [Google Scholar] [CrossRef]

- Abdollahi, H.; Salimi, A.; Barikani, M. Synthesis and architecture study of a reactive polybutadiene polyamine as a toughening agent for epoxy resin. J. Appl. Polym. Sci. 2016, 133, 44061. [Google Scholar] [CrossRef]

- Roudsari, G.M.; Mohanty, A.K.; Misra, M. Green approaches to engineer tough biobased epoxies: A review. ACS Sustain. Chem. Eng. 2017, 5, 9528–9541. [Google Scholar] [CrossRef]

- Teng, N.; Dai, J.Y.; Wang, S.P.; Hu, J.Y.; Liu, X.Q. Hyperbranched flame retardant for epoxy resin modification: Simultaneously improved flame retardancy, toughness and strength as well as glass transition temperature. Chem. Eng. J. 2022, 428, 131226. [Google Scholar] [CrossRef]

- Zhao, X.L.; Liu, Y.Y.; Weng, Y.X.; Li, Y.D.; Zeng, J.B. Sustainable epoxy vitrimers from epoxidized soybean oil and vanillin. ACS Sustain. Chem. Eng. 2020, 8, 15020–15029. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Gnanasekar, P.; Nair, S.S.; Farnood, R.; Yi, S.L.; Yan, N. Biobased Epoxy Synthesized from a Vanillin Derivative and Its Reinforcement Using Lignin-Containing Cellulose Nanofibrils. ACS Sustain. Chem. Eng. 2020, 8, 11215–11223. [Google Scholar]

- Nanda, B.P.; Satapathy, A. An analysis of the sliding wear characteristics of epoxy-based hybrid composites using response surface method and neural computation. J. Nat. Fibers 2021, 18, 2077–2091. [Google Scholar] [CrossRef]

- Gan, Y.X. Effect of interface structure on mechanical properties of advanced composite materials. Int. J. Mol. Sci. 2009, 10, 5115–5134. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Bai, T.; Wang, D.; Yan, J.; Cheng, W.L.; Cheng, H.T.; Shi, S.Q.; Wang, G.; Han, G.P. Wetting mechanism and interfacial bonding performance of bamboo fiber reinforced epoxy resin composites. Compos. Sci. Technol. 2021, 213, 108951. [Google Scholar] [CrossRef]

- Mu, S.L.; Zhang, Y.Q.; Zhou, J.J.; Wang, B.X.; Wang, Z.K. Recyclable and mechanically robust palm oil-derived epoxy resins with reconfigurable shape-memory properties. ACS Sustain. Chem. Eng. 2020, 8, 5296–5304. [Google Scholar] [CrossRef]

- Yin, Q.F.; Yang, W.J.; Sun, C.J.; Di, M.W. Preparation and properties of lignin-epoxy resin composite. Bioresources 2012, 7, 5737–5748. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.J.; Xiong, Y.; Chen, Z.B.; Wang, H.Y.; Wu, Y.Z.; Zhang, X.W. Preparation and properties of corn stalks fiber/epoxy resin composite. Appl. Chem. Ind. 2009, 38, 799–802. (In Chinese) [Google Scholar]

- Qin, T.F.; Huang, L.H.; Li, G.Y. Effect of chemical modification on the properties of wood /polypropylene composites. J. Forest Res. JPN 2005, 16, 241–244. [Google Scholar]

- Cai, X.X.; Li, C.; Quo, C.D.; Peng, D. Renewable Coumarin-Derived Network as a Toughening Structure for Petroleum-Based Epoxy Resins. ACS Omega 2019, 4, 16080–16087. [Google Scholar] [CrossRef] [Green Version]

- Khare, K.S.; Khabaz, F.; Khare, R. Effect of carbon nanotube functionalization on mechanical and thermal properties of cross-linked epoxy–carbon nanotube nanocomposites: Role of strengthening the interfacial interactions. ACS Appl. Mater. Inter. 2014, 6, 6098–6110. [Google Scholar] [CrossRef]

- Kumar, S.; Krishnan, S.; Mohanty, S.; Nayak, S.K. Synthesis and characterization of petroleum and biobased epoxy resins: A review. Polym. Int. 2018, 67, 815–839. [Google Scholar] [CrossRef]

- Oksman, K.; Mathew, A.P.; Langstrom, R.; Nystrom, B.; Joseph, K. The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1847–1853. [Google Scholar] [CrossRef]

- Munir, K.S.; Wen, C.; Li, Y.C. Carbon nanotubes and graphene as nanoreinforcements in metallic biomaterials: A review. Adv. Biosyst. 2019, 3, 1800212. [Google Scholar] [CrossRef]

- Lubineau, G.; Rahaman, A. A review of strategies for improving the degradation properties of laminated continuous-fiber/epoxy composites with carbon-based nanoreinforcements. Carbon 2012, 50, 2377–2395. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Gunnarsson, M.; Bernin, D.; Hasani, M.; Lund, M.; Bialik, E. Direct Evidence for Reaction between Cellulose and CO2 from Nuclear Magnetic Resonance. ACS Sustain. Chem. Eng. 2021, 9, 14006–14011. [Google Scholar] [CrossRef]

- Oberlintner, A.; Likozar, B.; Novak, U. Hydrophobic functionalization reactions of structured cellulose nanomaterials: Mechanisms, kinetics and in silico multi-scale models. Carbohyd. Polym. 2021, 259, 117742. [Google Scholar] [CrossRef]

- Li, L.; Wu, Q.L.; Li, S.J.; Wu, P.Y. Study of the infrared spectral features of an epoxy curing mechanism. Appl. Spectrosc. 2008, 62, 1129–1136. [Google Scholar] [CrossRef]

- Ei-Hiti, G.A.; Alotaibi, M.H.; Ahmed, A.A.; Hamad, B.A.; Ahmed, D.S.; Ahmed, A.; Hashim, H.; Yousif, E. The Morphology and Performance of Poly(Vinyl Chloride) Containing Melamine Schiff Bases against Ultravillet Light. Molecules 2019, 24, 24040803. [Google Scholar]

- Sahoo, S.K.; Mohanty, S.; Nayak, S.K. Mechanical, thermal, and interfacial characterization of randomly oriented short sisal fibers reinforced epoxy composite modified with epoxidized soybean oil. J. Nat. Fibers 2017, 14, 357–367. [Google Scholar] [CrossRef]

- Yu, T.; Ren, J.; Li, S.M.; Yuan, H.; Li, Y. Effect of fiber surface-treatments on the properties of poly (lactic acid)/ramie composites. Compos. Part A Appl. S. 2010, 41, 499–505. [Google Scholar] [CrossRef]

- Stark, W. Investigation of the curing behaviour of carbon fibre epoxy prepreg by Dynamic Mechanical Analysis DMA. Polym. Test. 2013, 32, 231–239. [Google Scholar] [CrossRef]

- Savonnet, E.; Grau, E.; Grelier, S.; Defoort, B.; Cramail, H. Divanillin-based epoxy precursors as DGEBA substitutes for biobased epoxy thermosets. ACS Sustain. Chem. Eng. 2018, 6, 11008–11017. [Google Scholar] [CrossRef]

- Raj, R.G.; Kokta, B.V. Composites of silane treated cellulosic fibers and high density polyethylene. Angew. Makromol. Chem. 1991, 189, 169–182. [Google Scholar] [CrossRef]

- Teng, N.; Dai, J.Y.; Wang, S.P.; Liu, X.L.; Hu, J.Y.; Yi, X.S.; Liu, X.Q. Hyperbranched flame retardant to simultaneously improve the fire-safety, toughness and glass transition temperature of epoxy resin. Eur. Polym. J. 2021, 157, 110638. [Google Scholar] [CrossRef]

- Athith, D.; Sanjay, M.R.; Gowda, T.G.Y.; Madhu, P.; Arpitha, G.R.; Yogesha, B.; Omri, M.A. Effect of tungsten carbide on mechanical and tribological properties of jute/sisal/E-glass fabrics reinforced natural rubber/epoxy composites. J. Ind. Text. 2018, 48, 713–737. [Google Scholar] [CrossRef]

- Guo, W.W.; Wang, X.; Huang, J.L.; Mu, X.W.; Cai, W.; Song, L.; Hu, Y. Phosphorylated cardanol-formaldehyde oligomers as flame-retardant and toughening agents for epoxy thermosets. Chem. Eng. J. 2021, 423, 130192. [Google Scholar] [CrossRef]

- Wang, X.; Niu, H.X.; Guo, W.W.; Song, L.; Hu, Y. Cardanol as a versatile platform for fabrication of bio-based flame-retardant epoxy thermosets as DGEBA substitutes. Chem. Eng. J. 2021, 421, 129738. [Google Scholar] [CrossRef]

- Meng, J.J.; Chen, P.F.; Yang, R.; Dai, L.L.; Yao, C.; Fang, Z.; Guo, K. Thermal stable honokiol-derived epoxy resin with reinforced thermal conductivity, dielectric properties and flame resistance. Chem. Eng. J. 2021, 412, 128647. [Google Scholar] [CrossRef]

| Sample | T5 | T10 | T50 | THRI/°C | Residual Carbon/% |

|---|---|---|---|---|---|

| E-51 | 392.72 | 409.88 | 443.09 | 207.24 | 11.49 |

| MCSEC-5 | 390.58 | 402.73 | 444.38 | 207.20 | 14.24 |

| MCSEC-10 | 370.26 | 396.04 | 445.22 | 203.47 | 15.71 |

| MCSEC-15 | 369.53 | 389.66 | 445.28 | 203.34 | 15.83 |

| MCSEC-20 | 339.86 | 379.78 | 445.89 | 197.70 | 17.67 |

| System | p HRR (W/g) | THR (KJ/g) |

|---|---|---|

| E-51 | 864.35 | 34.65 |

| MCSEC-5 | 852.33 | 34.18 |

| MCSEC-10 | 792.95 | 31.59 |

| MCSEC-15 | 607.14 | 28.19 |

| MCSEC-20 | 512.44 | 25.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, C.; Jiang, S.; Zhou, Y.; Gu, X.; Zhang, Y.; Kong, X. Preparation and Curing Mechanism of Modified Corn Straw by 3-Glycidyl Ether Oxypropyl Trimethoxysilane/Epoxy Resin Composites. Polymers 2022, 14, 5233. https://doi.org/10.3390/polym14235233

Lou C, Jiang S, Zhou Y, Gu X, Zhang Y, Kong X. Preparation and Curing Mechanism of Modified Corn Straw by 3-Glycidyl Ether Oxypropyl Trimethoxysilane/Epoxy Resin Composites. Polymers. 2022; 14(23):5233. https://doi.org/10.3390/polym14235233

Chicago/Turabian StyleLou, Chunhua, Siyu Jiang, Yongli Zhou, Xiaohua Gu, Yong Zhang, and Xianzhi Kong. 2022. "Preparation and Curing Mechanism of Modified Corn Straw by 3-Glycidyl Ether Oxypropyl Trimethoxysilane/Epoxy Resin Composites" Polymers 14, no. 23: 5233. https://doi.org/10.3390/polym14235233