1. Introduction

Natural fibers have been widely used for composite materials since ancient times, when straws and other plant-based fibers were used for bricks and other building materials [

1]. These fibers are also called lignocellulosic fibers and are composed of cellulose, hemicellulose, and lignin, with minor components including waxes, pectins, and extractives [

2]. Natural fibers have known advantages, including low cost, low density, non-hazardous nature, zero carbon footprint, and good mechanical properties, as well as high biodegradability, low emission of toxic substances, and wide availability [

2].

Some cement-based composites reinforced by natural fibers have consolidated applications, including in fences, linings, tiles, sealing parts, and masonry. The growing interest in their use in different kinds of affordable cement composite materials for construction has especially increased since the prohibition of asbestos by the European Union [

3].

The literature reports improvements in various mechanical properties of fiber–cement due to the incorporation of natural fibers, encompassing flexural and compressive strength, ductility, reduced cracking, and increased toughness [

4]. There are also reports on decreased density and thermal conductivity as the fiber content increases [

5].

The major drawbacks related to a wider-spread dissemination of natural fibers in commercial products are related to their high moisture absorption and heterogeneity, leading to a large scatter in properties. Other negative characteristics include low durability, high hygroscopicity and permeability, and low thermal resistance compared to synthetic fibers [

4]. Furthermore, they are usually poorly bonded to the composite matrix, compromising matrix/fiber stress transfer [

1,

6,

7].

In this context, Toledo Filho et al. [

8] reported the precipitation of inorganic particles based on silica fume and/or blast-furnace slag on the surface of vegetable fibers (coconut and sisal), which was followed by alkaline hydrolysis of amorphous regions from cellulose. Similarly, Wei et al. [

9] exposed the occurrence of voids in the cement matrix due to the migration of hydration products from the cement to the surface of sisal fibers. These effects may cause fiber embrittlement, making it more susceptible to fractures or matrix pullout due to mechanical stresses, reducing its efficiency as a reinforcement for circumventing the brittleness of cement matrices.

To mitigate this degradation, pozzolanic additions have been employed to reduce the alkalinity of the cementitious medium, along with chemical and physical processes that can be adopted to modify the surface of the fibers for protection [

4]. Pozzolans chemically react with alkali ions released during cement hydration, such as NaOH and KOH, forming non-expansive compounds that can fill the pores of the cementitious composite, enhancing mechanical strength and durability by reducing the cement’s aggressiveness towards natural fibers [

10]. On the other hand, fiber treatments aim to partially seal them, hindering the deposition of Ca(OH)

2 on their surface [

11].

Hybrid-fiber systems have the potential to address some of the limitations of natural fiber-reinforced cements. According to Mahdi et al. [

12], a strong and stiff synthetic fiber improves the first crack stress and ultimate strength, while natural fibers, relatively flexible and ductile, enhance toughness and strain capacity in the post-cracking zone. They also emphasized the importance of combining a large fiber, which can arrest propagating macrocracks and improve fracture toughness, with a smaller and smoother fiber, which bridges microcracks, controls growth, delays coalescence, and increases tensile strength. Another possible synergistic action occurs when a fiber improves mechanical properties, while the other enhances fresh and early-age properties, such as plastic shrinkage.

Among the recent reports in the literature, Mahdi et al. [

12] evaluated the mechanical properties of polypropylene macro-fiber blended recycled cardboard concrete. The processed cardboard exhibited desirable rheological and mechanical properties, making it a suitable fine-aggregate replacement. The recycled polypropylene fibers enhanced flexural and tensile strength, and the mixture was considered suitable for real-world applications.

Alwesabi et al. [

13] studied the mechanical properties of hybrid concretes with various contents of micro-steel fibers (0–1%) and polypropylene fibers (0–1%), with and without crumb rubber. The hybrid concrete with 0.1% polypropylene fibers and 0.9% micro-steel fibers showed the highest compressive and splitting tensile strengths and elastic modulus. Moreover, the presence of 1% micro-steel fibers significantly enhanced flexural strength of concrete, while 1% polypropylene fibers negatively influenced the overall properties.

He et al. [

14] investigated the mechanical performance of hybrid concrete mixtures with different contents of steel and polypropylene fibers. The hybrid fibers exhibited an excellent coupling effect on mechanical properties, performing better than the isolated steel and polypropylene fibers. Among the hybrid concretes, the one containing 1.5% steel fibers and 0.9% polypropylene fibers exhibited the best mechanical properties.

Wang and Aslani [

15] investigated cementitious composites incorporating carbon nanofibers and hybridizing carbon fibers. They concluded that although carbon nanofibers can contribute to the mechanical properties of cementitious composites, hybrid reinforcement was more effective in enhancing the compressive and flexural strength. According to them, the large fiber helped to impede the progression of macrocracks, while the carbon nanofibers served to span microcracks, regulating their expansion.

None of these studies applied the Response Surface Methodology (RSM), which is a statistical and mathematical technique commonly used in experimental design and optimization. According to Cruz et al. [

16], RSM is particularly useful for studying the relationship between multiple independent variables and a response variable. In the work of Manral et al. [

17], RSM was applied with a face-centered central composite design to develop regression models, predicting the relationship between chemical treatment parameters for natural fibers using a quadratic model. The study identified chemical concentration as the most influential factor affecting mechanical properties of the developed composites and optimized input variables based on the predicted model within bounded response limits.

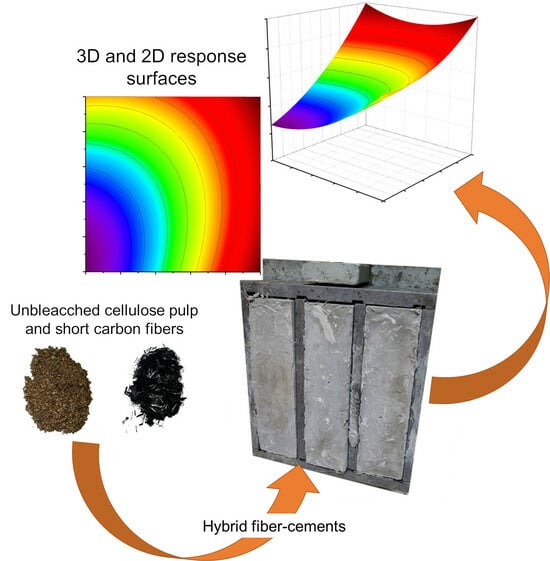

The current study aims to systematically analyze the interactive effects of varying contents of carbon fiber on the mechanical properties of a cellulose fiber-based composite through a comprehensive experimental design and mathematical approach utilizing RSM.

2. Materials and Methods

2.1. Raw Materials

The cement utilized in this study was Cauê brand high-initial-strength Portland cement (CPV-ARI), considered the purest form of cement, devoid of mineral additives that could potentially interact with the fibers. According to the ABNT NBR 16697/18 standard, CPV-ARI Portland cement is classified as having high initial strength, with a minimum compressive strength of 34 MPa at 7 days. This cement was produced at the factory located in Candiota, RS, Brazil.

Silica powder, commercially known as Silcca

® Nobre SC-1, from rice husk combustion was employed. This material is produced by Sílica Verde do Arroz Ltda (Alegrete, Brazil) and distributed by Grupo Pilecco Nobre Ltda. According to the manufacturer, it has a predominantly amorphous structure with the following composition: 91.48% SiO

2, 0.00% Al

2O

3, 0.05% Fe

2O

3, 0.32% MgO, 0.15% SO

3, 0.04% Na

2O, 0.36% CaO, 1.40% K

2O, 0.32% MnO, and 0.45% P

2O

5. Its specific gravity is 2.16 g/cm³, and its surface area is 21,000 m²/kg. Its pozzolanic activity index (ABNT NBR 5354) is 1.03, i.e., 103% compressive strength in relation to neat Portland cement. Its pozzolanicity, measured by the modified Chapelle method (ABNT NBR 15895), is 1379.37 mg of Ca(OH)

2 per g of material.

Figure 1 shows the particle size distribution curves for both the silica and cement used in this study, obtained using a set of standard sieves.

The cellulose fiber used in this study is from unbleached eucalyptus kraft pulp, which was generously donated by the Celulose Riograndense Company (CMPC) (Guaiba, Brazil). According to the producer, the unbleached eucalyptus pulp has a residual lignin content of 1.5–3 wt%. The carbon fibers utilized were 1 cm in length and cut from a unidirectional fabric (UC300 T700, 368 g/m2), supplied by E-Composites (Rio de Janeiro, Brazil).

Additionally, MC-PowerFlow 1180, a high-performance poly-carboxylic superplasticizer, was incorporated into all mixtures to enhance workability. This additive was produced by MC-Bauchemie Brasil, which is located in Vargem Grande Paulista/Brazil. It is a brown liquid form and has a density of 1.09 kg/L, compliant with the NBR 11768-3:2019 standard. It is categorized as a water-reducing admixture type 2—RA2 according to ABNT NBR 11768. The recommended dosage varies between 0.2% and 5.0% by weight of cement.

2.2. Fiber–Cement Manufacture

The fiber–cements were formulated with a fiber content ranging from 4% to 6% by mass relative to the binder. The specific fiber content varied depending on whether silica was included as part of the binder or not. All fiber–cement pastes were prepared with a water-to-cement (w/c) ratio of 0.47, consistent with recently published studies [

4,

11,

18].

Table 1 presents the composition of the produced composites.

The processing of the composites followed the methodology described in Aramburu et al. [

18]. For the molding of the test specimens, cellulose fibers were first mixed with water and allowed to soak for approximately 5 min until complete saturation. Subsequently, manual pre-mixing of cement with silica was performed, and this mixture was combined with hydrated cellulose using a vertical-axis and planetary movement mortar mixer operating at 140 rpm for 3 min. The electromechanical mortar mixer was supplied by Contenco, a equipament manufacter located in São José da Lapa, Brazil. Carbon fibers were then added to the mixture, followed by homogenization at 220 rpm for an additional 2 min. During this homogenization, the superplasticizer additive was gradually introduced while the equipment was still running, resulting in approximately 5 min of overall mixing time. The cementitious paste was deposited into steel molds in two stages, each followed by a compaction process using a vibrating table. Steel molds and the vibrating table where also provided by Contenco. Upon reaching the consistency for demolding, the test specimens were demolded after air curing for 5 days and subjected to a pressurized curing process in an autoclave for a period of 8 h, following the procedure described by Tawfik and Abd-El-Razik [

19].

Specimens were molded according to ASTM C305 (2014), using 40 mm × 40 mm × 160 mm prism molds for mechanical testing. The material was divided into two layers and compacted on a vibrating table. Specimens for fracture toughness testing were pre-notched with an 8 mm thick rod positioned transversely in the middle of the length, while still fresh. Upon reaching the desired consistency, the test specimens were demolded and subjected to curing under pressure in an autoclave at a maximum pressure of 1.5 kgf/cm² for 8 h using a Phoenix AV autoclave (model AV-18), following the procedure described in Tawfik and Abd-El-Razik [

19]. The

Figure 2 illustrates the processing flow of composites and the fiber-cement formulation.

2.3. Characterization of Fiber–Cement Composites

The mechanical performance of the fiber–cement samples was assessed using flexural tests as per ASTM C348. Six specimens, each measuring 40 mm × 40 mm × 160 mm (width × height × length), underwent characterization in an EMIC model DL 30000 universal testing machine operating at a loading speed of 50 N/s and a span (L) of 100 mm. For compression tests, the two halves of each flexural specimen were utilized. Prism compression plates measuring 40 mm × 40 mm were employed, loading at 500 N/s to determine the compressive stress (σ

c) in accordance with ASTM C348-21. For fracture toughness (Kc) assessment, six test specimens with an 8 mm notch were used. Subsequently, flexural testing was conducted with a span (L) of 120 mm, following the ISO 12135 standard [

20].

2.4. Mathematical Treatment

Response Surface Methodology (RSM) comprises a collection of statistical and mathematical techniques utilized for experimental design. One of its key attributes is the ability to establish genuine functional correlations between a response variable and an array of independent variables. The resulting equation is typically a first-order polynomial model, delineating a linear relationship between the response and independent variables [

21].

In this study, the RSM approach was employed to predict the flexural, compressive, and toughness properties of samples containing different contents of fibers. All mathematical procedures were implemented using Origin

® 2021 software. Equation (1) illustrates the interaction among the process parameters (cellulose and carbon fiber contents). To construct the RSM model, a three-dimensional predictive framework was established. The equation used for this purpose is based on a 2D quadratic polynomial (for flexural and compressive properties), with the orthogonal distance regression serving as the interaction algorithm (Equation (1)). For toughness, a planar function was employed to fit the response surface, using the Levenberg–Marquardt interaction algorithm (Equation (2)) [

16].

Here, Z represents the predicted response, namely flexural strength (MPa), compressive strength (MPa), or fracture toughness (MPa·m1/2), while x and y denote the parameter levels associated with cellulose and carbon fiber contents (% by weight), respectively.

3. Results

3.1. Flexural Strength

The surface displayed in

Figure 3 is a visual representation of all the points that satisfy Equation (3), and higher carbon fiber content resulted in higher levels of flexural strength. The carbon fiber content must be above 5% to yield the highest levels of flexural strength (above 17 MPa). The observed increase in flexural strength with carbon content can be attributed to the high tensile strength and stiffness of carbon fibers, which contribute significantly to the overall mechanical properties of composites [

4]. As the concentration of carbon fibers increases in the composites, the reinforcing effect becomes more pronounced, enhancing the resistance to bending or flexural loading [

22].

The observed plateau in flexural strength between 1.2% and 3.6% carbon fiber content indicates that, in this range, variations in cellulose fiber content do not significantly impact flexural strength. This implies that there is a threshold of carbon fiber content regarding flexural strength. This has important implications for composite formulation and design. For applications where flexural strength requirements fall within the range of 10 to 12 MPa, it may be possible to maintain up to 3.6% cellulose fiber content to ensure suitable performance. However, to achieve these strength levels, a minimum carbon fiber content of 2.4% is necessary. Such evaluations enable more efficient material utilization and cost-effective production. Indeed, by identifying the optimal balance between cellulose and carbon fiber content, manufacturers can tailor composite formulations to meet specific performance criteria while minimizing the use of expensive or environmentally impactful materials.

This range of flexural strength surpasses that reported in most composite literature references [

11,

23,

24,

25,

26]. The parameters shown in

Table 2 confirm the suitability of the generated curves in relation to the experimental data. Good results using this methodology have also been reported by Poggiali et al. [

27] and Lima et al. [

28].

3.2. Compressive Strength

Regarding the compressive strength results (

Figure 4, Equation (4), and

Table 3), the highest levels (approaching 33 MPa) were achieved for carbon fiber content exceeding 4.8%. This magnitude of mean values presented is consistent with the literature [

29,

30,

31].

Again, there appears to be a plateau between 1.2% and 3.6% carbon fiber content, where there are no significant variations in compressive strength, which is within 25–26.5 MPa. In fiber-reinforced cementitious composites, such as fibrocement, the addition of carbon fibers typically enhances mechanical properties up to a certain threshold [

32]. This occurs since the fibers reinforce the material by bridging cracks and redistributing stress, thereby increasing strength [

33].

In practical terms for fibrocement design, this plateau implies that there is an optimal range of carbon fiber content to yield maximum compressive strength. Therefore, designers need to carefully consider the trade-off between carbon fiber content and mechanical properties when formulating fibrocement compositions. Operating within the plateau range ensures enhanced strength while avoiding unnecessary costs associated with excessive carbon fiber addition. Additionally, designers must balance other factors such as workability, durability, and cost-effectiveness to optimize the overall performance and economic viability of the fibrocement product.

Regarding the modeling of experimental values, here again it was possible to obtain fully adherent models for the compressive strength data, resulting in estimated values very similar to the experimental values.

3.3. Fracture Toughness

As for the fracture toughness results shown in

Figure 5, Equation (5), and

Table 4, the produced models satisfactorily estimated the experimental values, with R

2 levels above 0.99. The results indicate no further gain in properties for carbon fiber content above ≈3.6%, at which point it is possible to observe fracture toughness above 320 MPa·m

1/2. These results can again be justified considering that the carbon fibers enhance mechanical properties such as fracture toughness by providing reinforcement and bridging microcracks within the matrix. However, beyond a certain threshold, the effectiveness of the carbon fibers reaches a saturation point. This could be due to factors such as fiber–fiber interactions, fiber dispersion, or matrix-fiber bonding limitations. In practical terms for fibrocement design, these findings suggest that there is an optimal range of carbon fiber content for achieving maximum fracture toughness.

Below 3.6%, the lower the carbon fiber content, the lower the fracture toughness. This highlights the importance of carefully balancing fiber content to achieve the desired mechanical properties. Overall, understanding these relationships between carbon fiber content and fracture toughness is essential for optimizing fibrocement formulations and ensuring the structural integrity and performance of the final products.

4. Conclusions

The hybridization of carbon fibers with cellulose fibers can result in synergistic effects, wherein the combination of different fiber types yields superior mechanical properties compared to the individual components alone. Overall, the observed trend of increasing flexural strength with higher carbon fiber content underscores the effectiveness of hybridization strategies in optimizing the mechanical properties of cellulose fiber–cement composites. However, it is important to note that a pattern emerged where higher carbon fiber content resulted in higher levels of flexural strength, indicating that the carbon fiber content must exceed 5% to achieve peak flexural strength. The observed plateau in flexural strength between 1.2% and 3.6% carbon fiber content suggests an intriguing relationship between composite composition and mechanical properties, surpassing the range of flexural strength variation reported in most of the composite literature references [

34].

The highest levels of compressive strength (approaching 33 MPa) were attained for carbon fiber content exceeding 4.8%. Similarly, there appears to be a plateau between 1.2% and 3.6% carbon fiber content, where compressive strength values remain relatively constant, within 25–26.5 MPa. These results indicate no significant gain in properties for carbon fiber content above ≈3.6%, beyond which fracture toughness levels above 320 MPa·m1/2 were observed. Conversely, below 3.6% carbon fiber content, fracture toughness decreased with decreasing carbon fiber content.

The Response Surface Methodology (RSM) enabled the modeling of experimental data on flexural, compressive, and fracture toughness properties. This resulted in a response surface equation, offering broader insights and reducing experimental time and costs while ensuring statistical significance with high reliability. Additionally, it facilitated the estimation of results for untested experimental conditions, such as intermediate cellulose and carbon contents or reduced levels of both fibers, enhancing the comprehensiveness of the findings.

The authors’ future research endeavors may encompass optimizing hybridization ratios, exploring advanced modeling techniques, assessing real-world applications, and incorporating other sustainable materials to further enhance the mechanical properties and environmental sustainability of cellulose carbon fiber–cement composites.