Evaluating the Non-Invasive Measurement of Apple Aroma Using Electronic Nose Device through Comparison with Direct Mass Spectrometry, Sugar Content, and Ripeness Measurements

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specifications of the E-Nose Device and Aroma Measurement Procedure

2.2. Direct Mass Spectrometry Analysis

2.3. Repeatability and Intermediate Precision of the E-Nose Device

2.4. Determination of Sugar Contents and Ripeness

2.5. Statistical Analysis

3. Results and Discussion

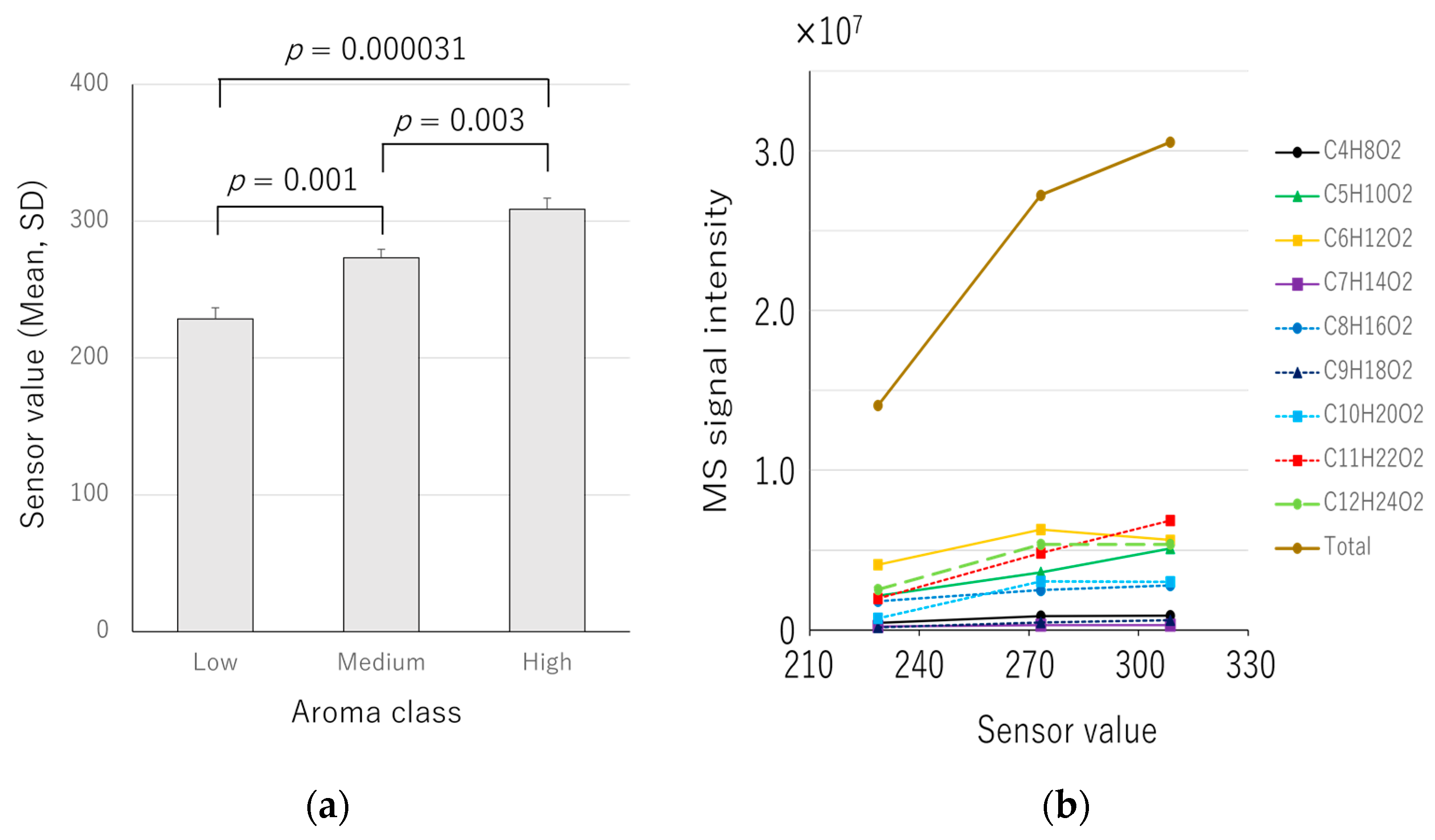

3.1. Comparison of Mass Spectrometry Intensity and E-Nose Values for Apple Aroma

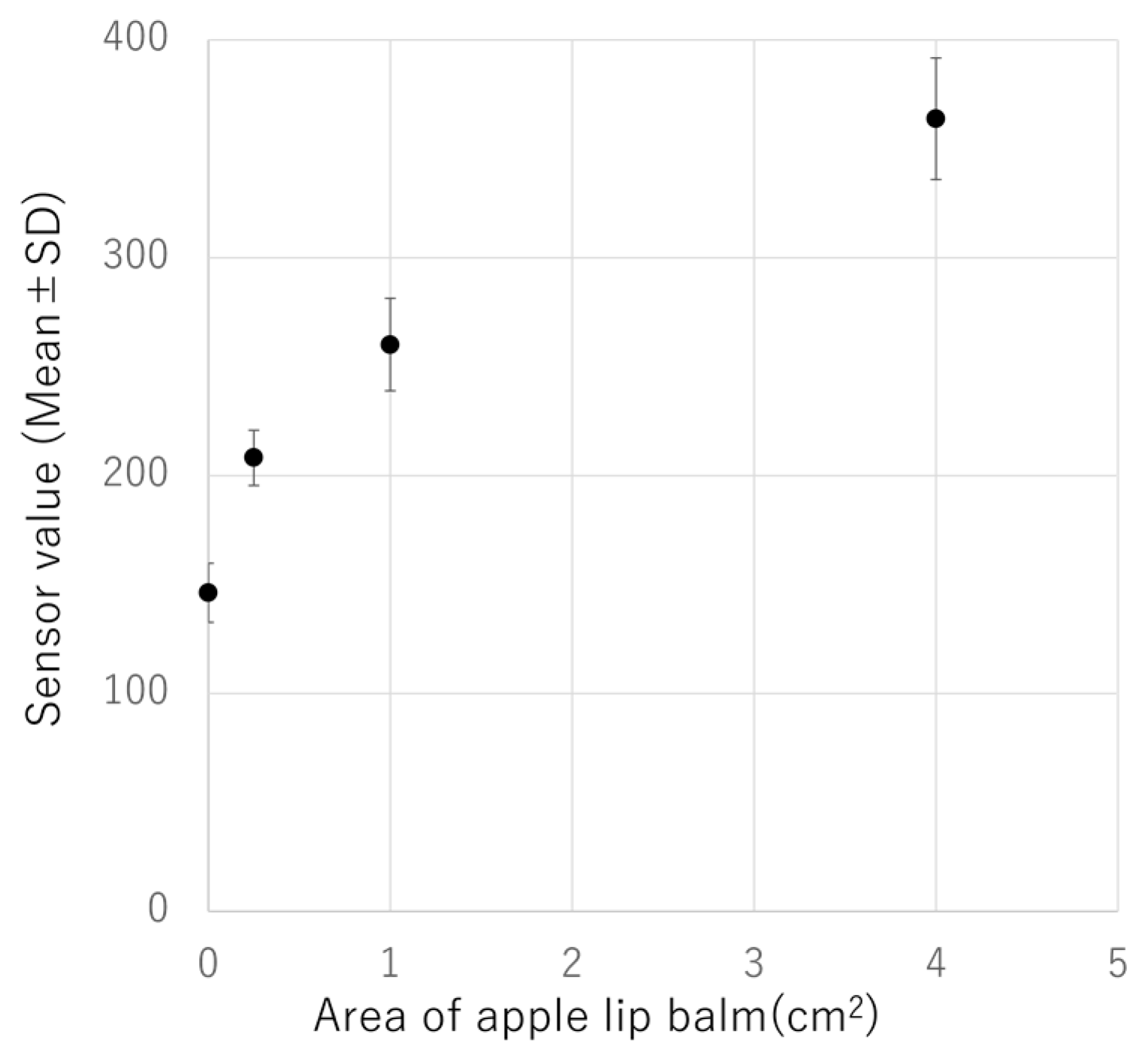

3.2. Repetability and Intermediate Precision of the E-Nose Measurement

3.3. Comparison of the Value of E-Nose Sensor with Sugar Contents or Ripeness

4. Conclusions

5. Patents

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karakaya, D.; Ulucan, O.; Turkan, M. Electronic Nose and Its Applications: A Survey. Int. J. Autom. Comput. 2020, 17, 179–209. [Google Scholar] [CrossRef]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- Oyenihi, A.B.; Belay, Z.A.; Mditshwa, A.; Caleb, O.J. “An apple a day keeps the doctor away”: The potentials of apple bioactive constituents for chronic disease prevention. J. Food Sci. 2022, 87, 2291–2309. [Google Scholar] [CrossRef] [PubMed]

- Baietto, M.; Wilson, A.D. Electronic-Nose Applications for Fruit Identification, Ripeness and Quality Grading. Sensors 2015, 15, 899–931. [Google Scholar] [CrossRef] [PubMed]

- Zou, X.; Wang, C.; Luo, M.; Ren, Q.; Liu, Y.; Zhang, S.; Bai, Y.; Meng, J.; Zhang, W.; Su, S.W. Design of Electronic Nose Detection System for Apple Quality Grading Based on Computational Fluid Dynamics Simulation and K-Nearest Neighbor Support Vector Machine. Sensors 2022, 22, 2997. [Google Scholar] [CrossRef] [PubMed]

- Saevels, S.; Lammertyn, J.; Berna, A.Z.; Veraverbeke, E.A.; Di Natale, C.; Nicolaï, B.M. An electronic nose and a mass spectrometry-based electronic nose for assessing apple quality during shelf life. Postharvest Biol. Technol. 2004, 31, 9–19. [Google Scholar] [CrossRef]

- Saevels, S.; Lammertyn, J.; Berna, A.Z.; Veraverbeke, E.A.; Di Natale, C.; Nicolaï, B.M. Electronic nose as a non-destructive tool to evaluate the optimal harvest date of apples. Postharvest Biol. Technol. 2003, 30, 3–14. [Google Scholar] [CrossRef]

- Jia, W.; Liang, G.; Tian, H.; Sun, J.; Wan, C. Electronic Nose-Based Technique for Rapid Detection and Recognition of Moldy Apples. Sensors 2019, 19, 1526. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, F.; Okazaki, K.; Kashimura, T.; Ohwaki, Y.; Tatsuki, M.; Sawada, A.; Ito, T.; Miyazawa, T. Profiles and Physiological Mechanisms of Sensory Attributes and Flavor Components in Watercored Apple. Nippon. Shokuhin Kagaku Kogaku Kaishi 2016, 63, 101–116. [Google Scholar] [CrossRef]

- Bowen, A.J.; Blake, A.; Tureček, J.; Amyotte, B. External preference mapping: A guide for a consumer-driven approach to apple breeding. J. Sens. Stud. 2019, 34, e12472. [Google Scholar] [CrossRef]

- Yahia, E.M. Apple Flavor. In Horticultural Reviews; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1994; pp. 197–234. [Google Scholar]

- Komthong, P.; Hayakawa, S.; Katoh, T.; Igura, N.; Shimoda, M. Determination of potent odorants in apple by headspace gas dilution analysis. LWT-Food Sci. Technol. 2006, 39, 472–478. [Google Scholar] [CrossRef]

- Tanaka, F.; Hayakawa, F.; Tatsuki, M. Flavor and Texture Characteristics of ‘Fuji’ and Related Apple (Malus domestica L.) Cultivars, Focusing on the Rich Watercore. Molecules 2020, 25, 1114. [Google Scholar] [CrossRef] [PubMed]

- Usmanov, D.T.; Hiraoka, K.; Wada, H.; Matsumura, M.; Sanada-Morimura, S.; Nonami, H.; Yamabe, S. Non-proximate mass spectrometry using a heated 1-m long PTFE tube and an air-tight APCI ion source. Anal. Chim. Acta 2017, 973, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Fujioka, K. Comparison of Cheese Aroma Intensity Measured Using an Electronic Nose (E-Nose) Non-Destructively with the Aroma Intensity Scores of a Sensory Evaluation: A Pilot Study. Sensors 2021, 21, 8368. [Google Scholar] [CrossRef] [PubMed]

- Fujioka, K. Aroma Measuring Devices for Measuring the Aroma of Agricultural and Livestock Products from Below. Available online: https://www.naro.go.jp/project/results/4th_laboratory/rcait/2020/rcait20_s01.html (accessed on 5 March 2024). (In Japanese)

- Ministry of Health, Labour and Welfare of Japan. Guideline for Validation of Test Methods for Pesticide Residues in Food. Available online: https://www.nihs.go.jp/food/_src/sc877/validation_guideline.pdf (accessed on 5 March 2024). (In Japanese)

- Qin, L.; Wei, Q.; Kang, W.; Zhang, Q.; Sun, J.; Liu, S. Comparison of Volatile Compounds in ‘Fuji’ Apples in the Different Regions in China. Food Sci. Technol. Res. 2017, 23, 79–89. [Google Scholar] [CrossRef]

- Ozaki, A.; Kishi, E.; Kaneko, R.; Ooshima, T.; Shimizu, M.; Kawamura, Y. Validation Study on Headspace-GC Analytical Method for Residual Volatile Substances in Food Contact Polystyrene and Its Application for Surveillance (1998–2014). Food Hyg. Saf. Sci. 2015, 56, 166–172. [Google Scholar] [CrossRef] [PubMed]

- Goto, S.; Kudo, S. Effect of Defoliation Time on Fruit Quality of ‘Fuji’ Apples. Tohoku Agric. Res. 2014, 67, 77–78. [Google Scholar]

- Shimizu, T.; Hattori, Y.; Ogami, S.; Imayoshi, Y.; Moriya, S.; Okada, K.; Sawamura, Y.; Abe, K. Identification of aroma compounds responsible for apple flavor via palatability score prediction in tree-based regression models. LWT 2024, 192, 115737. [Google Scholar] [CrossRef]

- Yumoto, M.; Kawata, Y.; Abe, T.; Matsuyama, T.; Wada, S. Non-destructive mid-IR spectroscopy with quantum cascade laser can detect ethylene gas dynamics of apple cultivar ‘Fuji’ in real time. Sci. Rep. 2021, 11, 20695. [Google Scholar] [CrossRef] [PubMed]

- Qi, W.; Wang, H.; Zhou, Z.; Yang, P.; Wu, W.; Li, Z.; Li, X. Ethylene Emission as a Potential Indicator of Fuji Apple Flavor Quality Evaluation Under Low Temperature. Hortic. Plant J. 2020, 6, 231–239. [Google Scholar] [CrossRef]

| Molecules | MW | Low | Medium | High | p-Value | |||

|---|---|---|---|---|---|---|---|---|

| Average | SD | Average | SD | Average | SD | |||

| C4H8O2 | 89.0597 | 446,425.0 | 41,647.57 | 858,083.0 # | 101,785.00 | 901,960.3 # | 60,553.19 | 0.554 |

| C5H10O2 | 103.0754 | 2,142,152.0 | 374,563.86 | 3,613,496.3 | 652,776.12 | 5,090,150.3 # | 771,583.74 | 0.003 * |

| C6H12O2 | 117.091 | 4,082,257.0 | 427,804.85 | 6,282,441.3 # | 475,569.82 | 5,623,528.3 # | 239,404.42 | 0.001 * |

| C7H14O2 | 131.1067 | 213,769.7 | 21,742.91 | 290,570.0 # | 24,511.42 | 299,218.7 # | 14,073.09 | 0.004 * |

| C8H16O2 | 145.1223 | 1,787,431.0 | 168,114.28 | 2,489,897.3 # | 215,742.40 | 2,777,455.0 # | 187,333.04 | 0.002 * |

| C9H18O2 | 159.138 | 166,709.0 | 8951.05 | 469,390.0 # | 61,167.42 | 616,414.3 # | 89,630.53 | 0.0003 * |

| C10H20O2 | 173.1536 | 716,778.3 | 128,842.77 | 3,041,954.7 # | 577,358.99 | 3,015,308.0 # | 613,751.16 | 0.002 * |

| C11H22O2 | 187.1693 | 1,967,774.0 | 547,087.39 | 4,809,816.3 # | 1,011,165.44 | 6,857,352.7 # | 1,288,562.06 | 0.003 * |

| C12H24O2 | 201.1849 | 2,528,008.0 | 570,220.21 | 5,359,085.3 # | 802,980.68 | 5,358,540.0 # | 459,690.10 | 0.002 * |

| Total | — | 13,604,879.0 | 2,133,274.22 | 26,356,651.3 | 3,459,975.26 | 29,637,967.3 | 3,087,390.22 | 0.001 * |

| Area of Apple Lip Balm (cm2) | Sensor Values (Mean) | Repeatability (RSD%) | Intermediate Precision (RSD%) |

|---|---|---|---|

| 0 | 146.2 | 1.36 | 9.96 |

| 0.25 | 208.2 | 4.98 | 6.23 |

| 1 | 260.1 | 7.81 | 8.21 |

| 4 | 363.7 | 6.25 | 7.88 |

| Apples | E-Nose Values (Mean) | Standard Deviation | RSD% | Sugar Content (%) | Ripeness (%) |

|---|---|---|---|---|---|

| A | 240.3 | 6.03 | 2.51 | 12.4 | 59.7 |

| B | 317.3 | 11.72 | 3.69 | 12.8 | 76.3 |

| C | 308.0 | 11.27 | 3.66 | 13.0 | 63.7 |

| D | 290.0 | 11.00 | 3.79 | 13.7 | 85.0 |

| E | 258.0 | 9.54 | 3.70 | 11.5 | 73.3 |

| F | 272.3 | 7.37 | 2.71 | 12.4 | 78.0 |

| G | 269.0 | 5.29 | 1.97 | 11.3 | 66.7 |

| H | 258.3 | 5.69 | 2.20 | 15.5 | 76.3 |

| I | 223.3 | 3.51 | 1.57 | 11.4 | 74.7 |

| J | 336.7 | 32.08 | 9.53 | 14.7 | 80.7 |

| K | 320.7 | 10.69 | 3.33 | 14.5 | 85.3 |

| L | 234.3 | 16.26 | 6.94 | 14.7 | 63.3 |

| M | 289.3 | 7.09 | 2.45 | 13.4 | 55.3 |

| N | 213.0 | 4.00 | 1.88 | 14.5 | 68.7 |

| O | 223.7 | 10.02 | 4.48 | 14.0 | 70.3 |

| P | 207.7 | 9.07 | 4.37 | 14.5 | 77.7 |

| Q | 253.0 | 2.00 | 0.79 | 12.1 | 79.7 |

| R | 237.7 | 4.51 | 1.90 | 13.6 | 76.7 |

| S | 285.0 | 19.52 | 6.85 | 12.4 | 36.3 |

| T | 218.3 | 12.42 | 5.69 | 13.6 | 69.7 |

| Mean | 262.8 | 9.95 | 3.70 | 13.3 | 70.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fujioka, K. Evaluating the Non-Invasive Measurement of Apple Aroma Using Electronic Nose Device through Comparison with Direct Mass Spectrometry, Sugar Content, and Ripeness Measurements. Sensors 2024, 24, 3114. https://doi.org/10.3390/s24103114

Fujioka K. Evaluating the Non-Invasive Measurement of Apple Aroma Using Electronic Nose Device through Comparison with Direct Mass Spectrometry, Sugar Content, and Ripeness Measurements. Sensors. 2024; 24(10):3114. https://doi.org/10.3390/s24103114

Chicago/Turabian StyleFujioka, Kouki. 2024. "Evaluating the Non-Invasive Measurement of Apple Aroma Using Electronic Nose Device through Comparison with Direct Mass Spectrometry, Sugar Content, and Ripeness Measurements" Sensors 24, no. 10: 3114. https://doi.org/10.3390/s24103114