Study on Static Mechanical Properties and Numerical Simulation of Coral Aggregate Seawater Shotcrete with Reasonable Mix Proportion

Abstract

:1. Introduction

2. Materials and Experiment Procedure

2.1. Raw Materials and Mix Proportion

2.2. Specimen Preparation and Basic Physical Properties

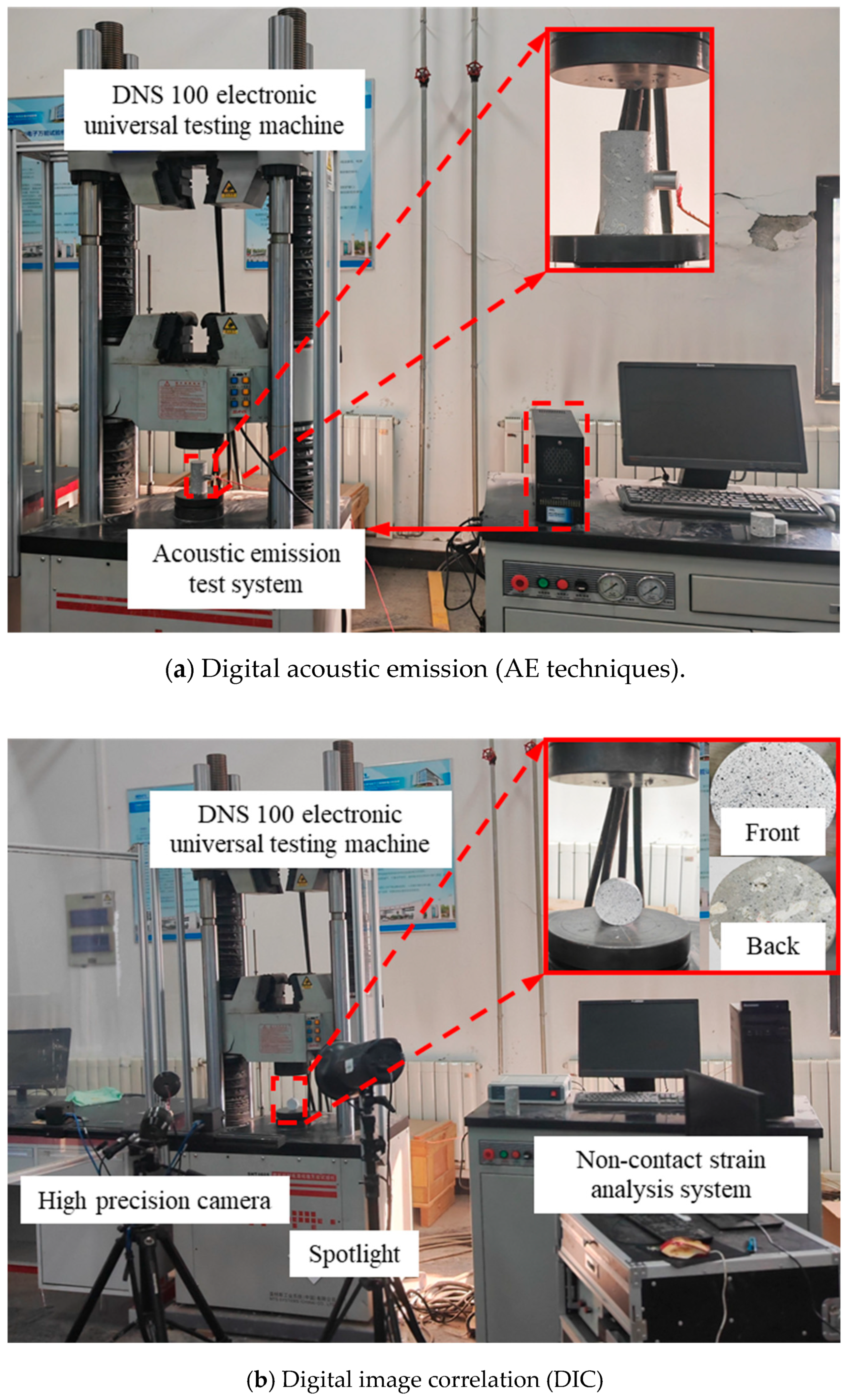

2.3. Quasi-Static Tests

3. Experiment Results and Discussion

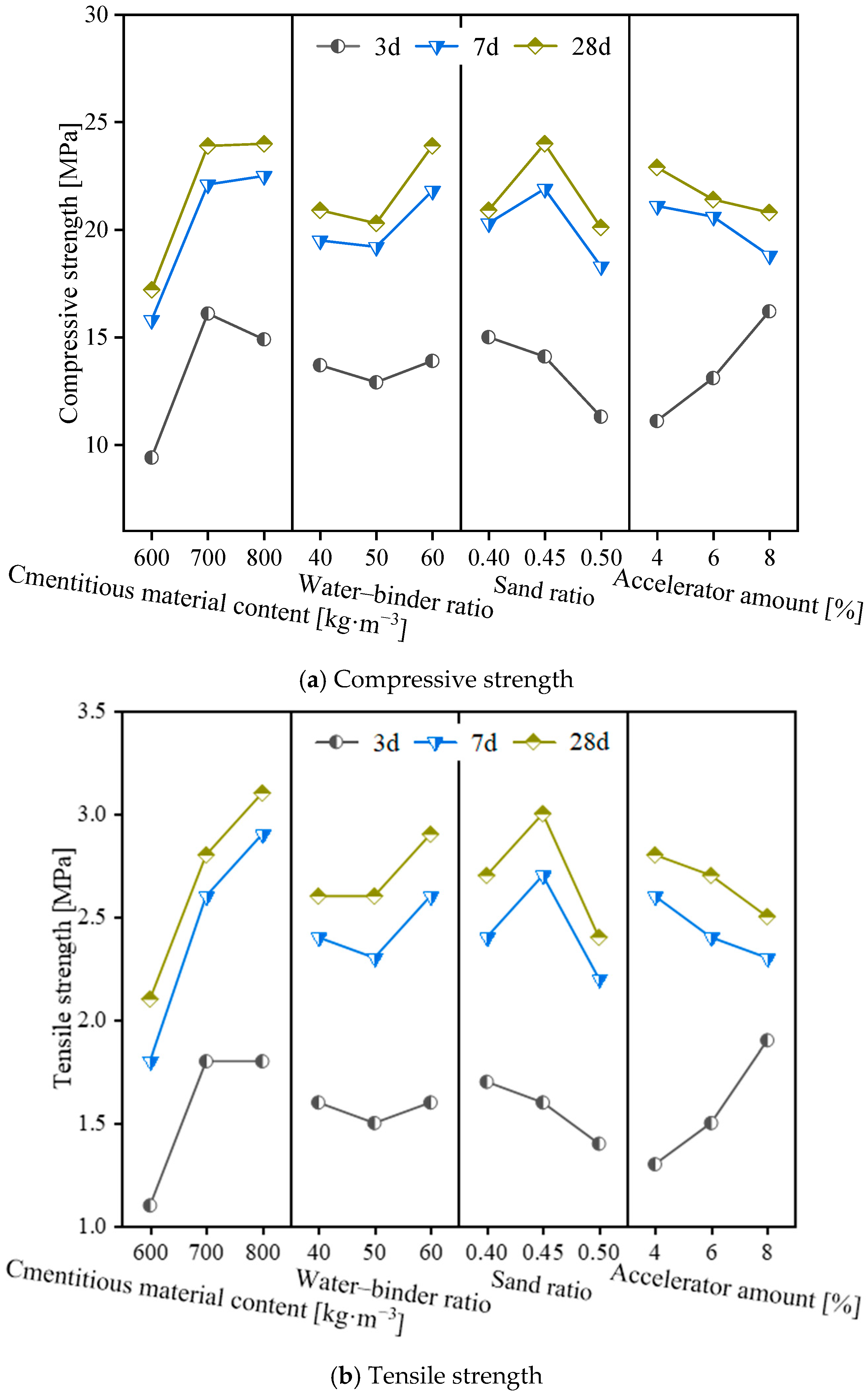

3.1. The Optimal Mix Proportion of CASS

3.2. Strength and Failure Behavior under Uniaxial Compression

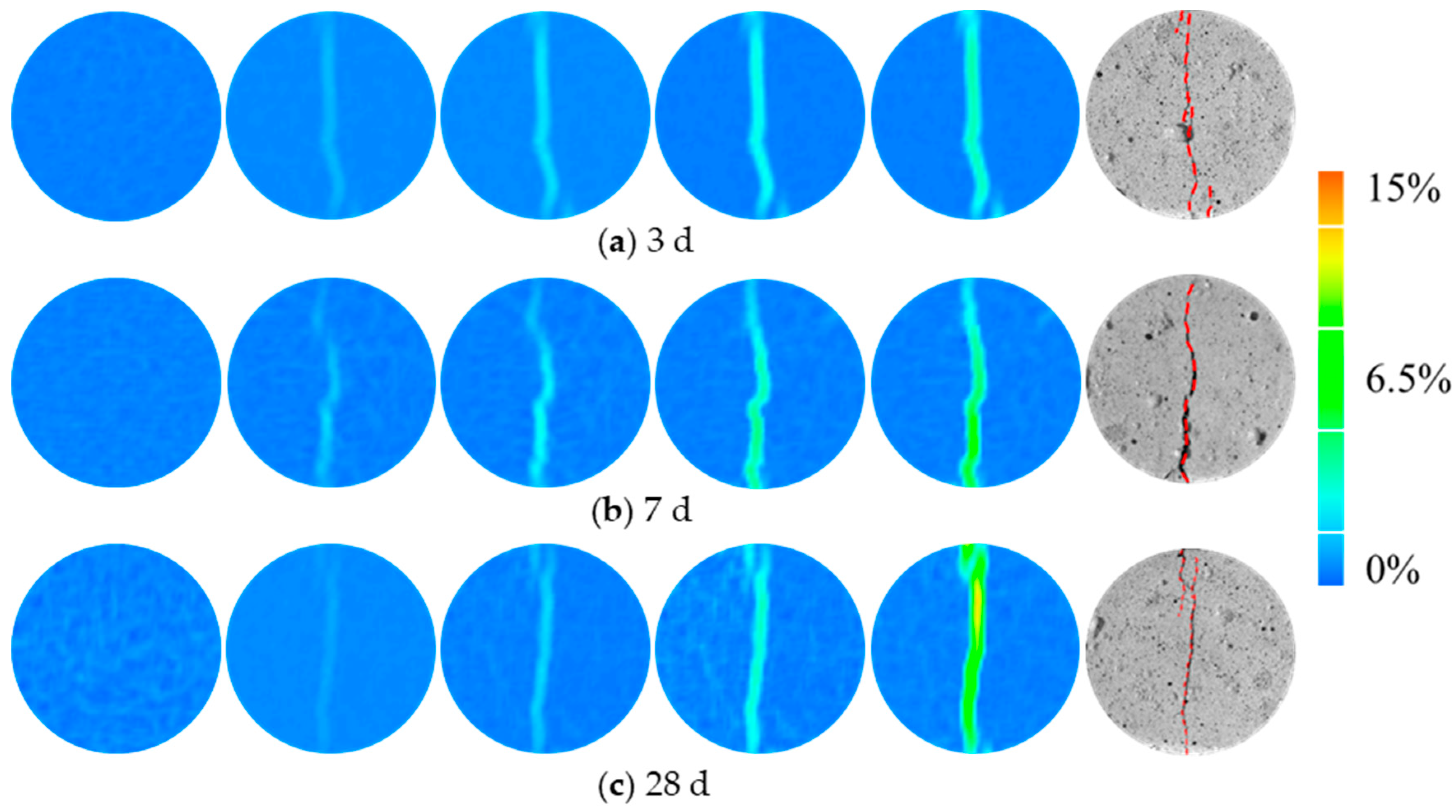

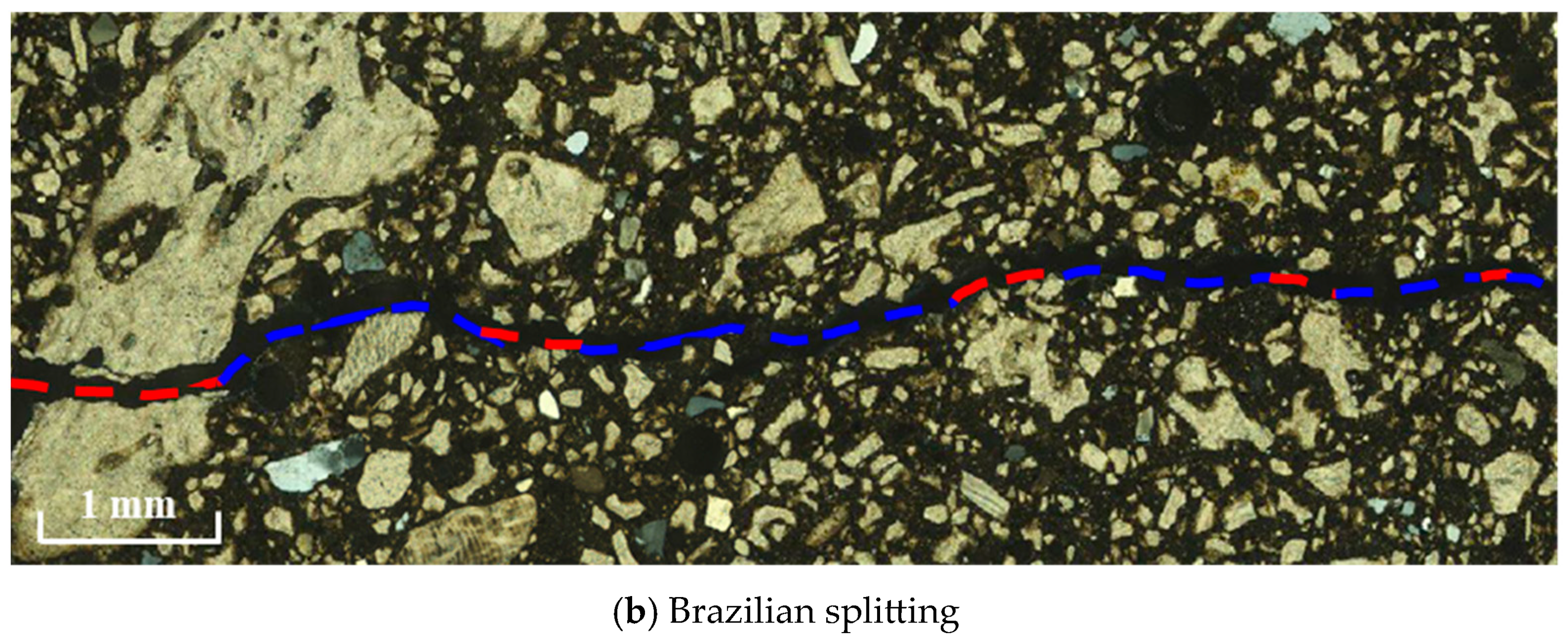

3.3. Strength and Failure Behavior under Splitting Tensile

3.4. Comparative Analysis of Static Mechanical Properties

4. Numerical Simulation

4.1. Modeling Process

- (1)

- Stage I: To reproduce laboratory findings, we selected, categorized, and 3D-scanned corals used for mixing in PFC. Initially, a concrete specimen model with only spherical particles was created based on the established gradation. Subsequently, larger particles were randomly replaced with coral debris shapes based on volume equivalence. This process culminated in a realistic concrete structure model, which was preloaded with isotropic stress to simulate initial conditions.

- (2)

- Stage II: Mineral components were divided according to the concrete structure model, CASS mix proportions, and grading curves. Red particles, sized between 0.45 and 0.6 mm, symbolized silica fume, while yellow particles of 0.6 to 1 mm diameter represented cement mortar. The coral debris in the model was filled with blue particles of 0.45 to 0.6 mm. The model also incorporated the random distribution of red silica fume particles within coral clusters to enhance specimen compactness, as detailed in the enlarged view of Figure 14 (Stage III).

- (3)

- Stage III: Models were constructed with dimensions matching laboratory specimens (Φ50 × 100 mm and Φ50 × 25 mm) by refining the Stage II model. Contact between different particles was accounted for, assigning different values. Figure 14 (Stage III) shows the contact distribution, color-coded to indicate six distinct contact types: cement mortar to cement mortar (F-F), silica fume to silica fume (S-S), coral debris to coral debris (C-C), cement mortar to coral debris (F-C), cement mortar to silica fume (F-S), and coral debris to silica fume (C-S). The micro-parameter assignment endowed the numerical specimens with defined bearing strength, finalizing the CASS model building.

4.2. Calibration of Micro-Parameters

4.3. Simulated Results and Discussion

- (1)

- Stage A: With the load increasing from 0 to 0.25Pmax, exceeding the contact parameter, cracks and fragments emerge. During this stage, the integrity of the numerical specimen is comparatively superior;

- (2)

- Stage B: In this stage, axial load increases from 0.25Pmax to 0.5Pmax, and a small number of cracks and damage are observed within the numerical specimen, along with the sporadic appearance of fragments. However, the number of cracks and fragments retains a low level;

- (3)

- Stage C: As the axial load increased from 0.5Pmax to 0.75Pmax, the number of cracks inside the specimen further increased, the cracks in the numerical specimen began to hook up with each other and penetrate through, and the damage inside the model further accumulates;

- (4)

- Stage D: With the axial load increased from 0.75Pmax to Pmax, the number of cracks increased rapidly, and the large fragment field started to appear along the direction of the main crack extension, as shown by the red box in Figure 16b;

- (5)

- Failure: The specimen transitioned into the macroscopic rupture phase, characterized by a steep increase in cracks and fragments. A large fragment field marked by red boxes occurred in the area of crack penetration;

- (1)

- Stage A: With the load increasing from 0 to 0.25Pmax, the specimen began to be subjected to an external load. Stress concentration and fragment field began to form around the upper and lower loading points. Due to the low-stress concentration, only a small number of cracks and fragments occur;

- (2)

- Stage B: The stress concentration around the loading points gradually increased with the load increasing from 0.25Pmax to 0.5Pmax, resulting in the initiation of fresh cracks and the propagation of original cracks. Then, with the slow growth of the number of cracks and fragments, the high-stress concentration region inside the specimen gradually propagated from the loading points to the center;

- (3)

- Stage C: As the load increased from 0.5Pmax to 0.75Pmax, the crack propagation path and fragment field began propagating to the center of the specimens, forming the main crack path and fragment field.

- (4)

- Stage D: When the load increases from 0.75Pmax to Pmax, the load on the specimens reaches the maximum value. The relatively large number of cracks leads to significant particle displacement around the loading points, and the main crack gradually propagates to the specimen’s center. The specimen was on the threshold entry to the splitting failure stage, and the number of cracks and fragments increased relatively rapidly.

- (5)

- Failure: Before the specimen was destroyed, the crack propagation rate and the number of cracks increased rapidly. At the moment of failure, the specimen was divided into two large fragments by the main crack propagating along the connection line between the upper and lower loading points.

5. Conclusions

- (1)

- The optimal mix proportion of CASS consists of 700 kg/m3 of cementitious materials content, a water–binder ratio of 0.45, a sand ratio of 60%, and a dosage of 8% for the accelerator amount.

- (2)

- Tensile failure is the primary failure mechanism of uniaxial compression and Brazilian splitting. Among them, the main failure form of the Brazilian split is the two ends crack initiation and spread to the central. Meanwhile, the specimens of CASS exhibit an increased brittleness with longer curing age.

- (3)

- Compared to OASS, the CASS with an optimal mix proportion has approximately equal early strength but low later strength. The early strength of CASS increases rapidly, but the later strength increases slowly. However, the strength of OASS increases evenly. The filling and water bag effect on coral pores makes a high early strength of specimens, but the unfilled pores in the specimens are also the reason for the low later strength.

- (4)

- A novel numerical three-dimensional model based on PFC was proposed to simulate the static mechanical properties of CASS. The multi-level division and quantitative description of cracks are realized. The failure in CASS under uniaxial compression and Brazilian splitting tests is primarily experienced within the cement mortar and bonding surface between the cement mortar and aggregate (coral debris).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Howdyshell, P.A. The Use of Coral as an Aggregate for Portland Cement Concrete Structures; DTIC Document; Construction Engineering Research Laboratory: Champaign, IL, USA, 1974. [Google Scholar]

- Vines, F.R. Experience with use of coral detritus as concrete as concrete aggregate in Western Samoa. Aust. Road Res. 1982, 12, 17–28. [Google Scholar]

- Ehlert, R.A. Coral concrete at Bikini Atoll. Concr. Int. 1991, 13, 19–24. [Google Scholar]

- Kaushik, S.; Islam, S. Suitability of seawater for mixing structural concrete exposed to a marine environment. Cem. Concr. Compos. 1995, 17, 177–185. [Google Scholar] [CrossRef]

- Zentar, R.; Dubois, V.; Abriak, N.E.; Ballivy, G. Mechanical behaviour and environmental impacts of a test road built with marine dredged sediments. Resour. Conserv. Recycl. 2008, 52, 947–954. [Google Scholar] [CrossRef]

- Dubois, V.; Abriak, N.E.; Zentar, R.; Ballivy, G. The use of marine sediments as a pavement base material. Waste Manag. 2009, 29, 774–782. [Google Scholar] [CrossRef] [PubMed]

- Limeira, J.; Etxeberria, M.; Agulló, L.; Molina, D. Mechanical and durability properties of concrete made with dredged marine sand. Constr. Build. Mater. 2011, 25, 4165–4174. [Google Scholar] [CrossRef]

- Bayrak, B.; Çelebi, O.; Öz, A.; Ustabas, I.; Kaplan, G.; Aydın, A.C. Effect of aluminosilicate precursors and curing regime on physico-mechanical durability and microstructural characteristics of coral geopolymers (Cor-Geo): Cleaner production for coral islands. Constr. Build. Mater. 2023, 407, 133596. [Google Scholar] [CrossRef]

- Tenza-Abril, A.J.; Benavente, D.; Pla, C.; Baeza-Brotons, F.; Valdes-Abellan, J.; Solak, A.M. Statistical and experimental study for determining the influence of the segregation phenomenon on physical and mechanical properties of lightweight concrete. Constr. Build. Mater. 2020, 238, 117642. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Huang, J.J.; Wang, D.J.; Liu, Y.F.; Zhao, Z.J.; Liu, J.P. Experimental study on hygrothermal characteristics of coral sand aggregate concrete and aerated concrete under different humidity and temperature conditions. Constr. Build. Mater. 2020, 230, 117034. [Google Scholar] [CrossRef]

- Younis, A.; Ebeada, U.; Suraneni, P.; Nanni, A. Short-term flexural performance of seawater-mixed recycled-aggregate GFRP-reinforced concrete beams. Compos. Struct. 2020, 236, 111860. [Google Scholar] [CrossRef]

- Korichi, B.; Zazi, N.; Delbrel, S.; Ngo, K.; Chopart, J.P. Microstructural, morphological characterization and corrosion behavior of sand cast AlSi10Cu(Fe) alloy in chloride solution. Chem. Pap. 2022, 76, 2947–2967. [Google Scholar] [CrossRef]

- Arumugam, R.A.; Ramamurthy, K. Study of compressive strength characteristics of coral aggregate concrete. Mag. Concr. Res. 1996, 48, 141–148. [Google Scholar] [CrossRef]

- Tan, Y.S.; Yu, H.F.; Mi, R.J.; Zhang, Y. Compressive strength evaluation of coral aggregate seawater concrete (CAC) by non-destructive techniques. Eng. Struct. 2018, 176, 293–302. [Google Scholar] [CrossRef]

- Castagnetti, C.; Rossi, P.; Righi, S.; Cattini, S.; Simonini, R.; Rovati, L.; Capra, A. Potentialities of the combined use of underwater fluorescence imagery and photogrammetry for the detection of fine-scale changes in marine bioconstructors. Front. Mar. Sci. 2024, 10, 1305807. [Google Scholar] [CrossRef]

- Salvador, R.P.; Cavalaro, S.H.P.; Cincotto, M.A.; Figueiredo, A.D. Parameters controlling early age hydration of cement pastes containing accelerators for shotcrete. Cement. Concr. Res. 2016, 89, 230–248. [Google Scholar] [CrossRef]

- Steindl, F.R.; Mittermayr, F.; Sakoparnig, M.; Juhart, J.; Briendl, L.; Lindlar, B.; Ukrainczyk, N.; Dietzel, M.; Kusterle, W.; Galan, I. On the porosity of low-clinker shotcrete and accelerated pastes. Constr. Build. Mater. 2023, 368, 130461. [Google Scholar] [CrossRef]

- Freddi, A.; Salmon, M. Introduction to the Taguchi Method. In Design Principles and Methodologies. Springer Tracts in Mechanical Engineering; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Berger, P.D.; Maure, R.E.; Celli, G.B. Introduction to Taguchi methods. In Experimental Design; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Sharifi, E.; Sadjadi, S.J.; Aliha, M.R.M.; Moniri, A. Optimization of high-strength self-consolidating concrete mix design using an improved Taguchi optimization method. Constr. Build. Mater. 2020, 236, 117547. [Google Scholar] [CrossRef]

- Neuner, M.; Cordes, T.; Drexel, M.; Hofstetter, G. Time-Dependent Material Properties of Shotcrete: Experimental and Numerical Study. Materials 2017, 10, 1067. [Google Scholar] [CrossRef] [PubMed]

- Hammera, A.L.; Thewesa, M.; Galler, R. Time-dependent material behaviour of shotcrete-New empirical model for the strength development and basic experimental investigations. Tunn. Undergr. Space Technol. 2020, 99, 103238. [Google Scholar] [CrossRef]

- Lyu, B.C.; Wang, A.G.; Zhang, Z.H.; Liu, K.W.; Xu, H.Y.; Shi, L.; Sun, D.S. Coral aggregate concrete: Numerical description of physical, chemical and morphological properties of coral aggregate. Cem. Concr. Compos. 2019, 100, 25–34. [Google Scholar] [CrossRef]

- Mohajerani, A.; Rodrigues, D.; Ricciuti, C.; Wilson, C. Early-age strength measurement of shotcrete. J. Mater. 2015, 2015, 470160. [Google Scholar] [CrossRef]

- Lee, M.J.; Park, G.K. Investigation of constitutive models of HPFRCC subjected to static and dynamic loadings. Compos. Struct. 2023, 324, 117525. [Google Scholar] [CrossRef]

- Verma, V.; Kumar, U.; Ghosh, S.; Gurnani, L.; Mukhopadhyay, A. Developing intragranular zirconia-reinforced alumina possessing vastly improved mechanical and tribological properties. J. Am Ceram. Soc. 2024, 107, 760–776. [Google Scholar] [CrossRef]

- Mazzucco, G.; Majorana, C.E.; Salomoni, V.A. Numerical simulation of polypropylene fibres in concrete materials under fire conditions. Comput. Struct. 2015, 154, 17–28. [Google Scholar] [CrossRef]

- Mukhtara, F.; El-Tohfa, A. A review on fracture propagation in concrete: Models, methods, and benchmark tests. Eng. Fract. Mech. 2023, 281, 109100. [Google Scholar] [CrossRef]

- Tomporowski, D.; Nitka, M.; Tejchman, J. Application of the 3D DEM in the modelling of fractures in pre-flawed marble specimens during uniaxial compression. Eng. Fract. Mech. 2023, 277, 108978. [Google Scholar] [CrossRef]

- Karam, M.S.; Nakamura, H.; Yamamoto, Y.; Tahir, M.; Hameed, R. Mesoscopic evaluation of the bond behavior of concrete with deformed rebar subjected to passive confinement employing 3D discrete model. Eng. Fract. Mech. 2024, 295, 109790. [Google Scholar] [CrossRef]

- Engelke, L.; Brendel, L.; Wolf, D.E. Microstructure evolution during sintering: Discrete element method approach. J. Am. Ceram. Soc. 2023, 106, 5022–5032. [Google Scholar] [CrossRef]

- Mollon, G.; Zhao, J. 3D generation of realistic granular samples based on random fields theory and Fourier shape descriptors. Comput. Methods Appl. Mech. Eng. 2014, 279, 46–65. [Google Scholar] [CrossRef]

- Invernizzi, S.; Lacidogna, G.; Carpinteri, A. Particle-based numerical modeling of AE statistics in disordered materials. Meccanica 2013, 48, 211–220. [Google Scholar] [CrossRef]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Stahl, M.; Konietzky, H. Discrete element simulation of ballast and gravel under special consideration of grain-shape, grain-size and relative density. Granul. Matter 2011, 13, 417–428. [Google Scholar] [CrossRef]

- Shang, J.; Zhao, Z.; Hu, J.; Handley, K. 3D Particle-based DEM investigation into the shear behaviour of incipient rock joints with various geometries of rock bridges. Rock Mech. Rock Eng. 2018, 51, 3563–3584. [Google Scholar] [CrossRef]

- Shang, J.; Yokota, Y.; Zhao, Z.; Dang, W. DEM simulation of mortar-bolt interface behaviour subjected to shearing. Constr. Build. Mater. 2018, 185, 120–137. [Google Scholar] [CrossRef]

- Song, Z.Y.; Konietzky, H.; Herbst, M. Three-dimensional particle model based numerical simulation on multi-level compressive cyclic loading of concrete. Constr. Build. Mater. 2019, 225, 661–677. [Google Scholar] [CrossRef]

- Asadi, M.S.; Rasouli, V.; Barla, G. A Laboratory Shear Cell Used for Simulation of Shear Strength and Asperity Degradation of Rough Rock Fractures. Rock Mech. Rock Eng. 2013, 46, 683–699. [Google Scholar] [CrossRef]

- Li, X.B.; Zou, Y.; Zhou, Z.L. Numerical Simulation of the Rock SHPB Test with a Special Shape Striker Based on the Discrete Element Method. Rock Mech. Rock Eng. 2014, 47, 1693–1709. [Google Scholar] [CrossRef]

- Haeri, H.; Sarfarazi, V. Numerical simulation of tensile failure of concrete using Particle Flow Code (PFC). Comput. Concr. 2016, 18, 39–51. [Google Scholar] [CrossRef]

- Lian, C.Q.; Yan, Z.G.; Beecham, S. Numerical simulation of the mechanical behaviour of porous concrete. Eng. Comput. 2011, 28, 984–1002. [Google Scholar] [CrossRef]

- Saksala, T. Numerical modeling of concrete fracture processes under dynamic loading: Meso-mechanical approach based on embedded discontinuity finite elements. Eng. Fract. Mech. 2018, 201, 282–297. [Google Scholar] [CrossRef]

- Potapov, S.; Masurel, A.; Marin, P.; Daudeville, L. Mixed DEM/FEM modeling of advanced damage in reinforced concrete structures. J. Eng. Mech. 2016, 143, 04016110. [Google Scholar] [CrossRef]

- Fang, Q.; Zhang, J.H.; Zhang, Y.D.; Gong, Z.M.; Chen, L.; Liu, J.C. 3D numerical investigation of cement mortar with microscopic defects at high strain rates. J. Mater. Civ. Eng. 2016, 28, 04015155. [Google Scholar] [CrossRef]

- Dai, L.Z.; Long, D.X.; Wang, L. Meso-scale modeling of concrete cracking induced by 3D corrosion expansion of helical strands. Comput. Struct. 2021, 254, 106615. [Google Scholar] [CrossRef]

- Ma, H.Y.; Wu, Z.Y.; Yu, H.F.; Zhang, J.H.; Yue, C.J. Experimental and three-dimensional mesoscopic investigation of coral aggregate concrete under dynamic splitting-tensile loading. Mater. Struct. 2020, 53, 12. [Google Scholar] [CrossRef]

- Jia, M.K.; Xu, W.X.; Zhu, Z.G. Numerical study on the excluded volumes of realistic 3D non convex particles. Powder Technol. 2019, 349, 52–58. [Google Scholar] [CrossRef]

- GB/T 14684-2011; Technical Specification for Lightweight Aggregate Concrete. Chinese National Standard: Beijing, China, 2011.

- ASTM D1141-2003; Standard Specification for Chemical Requirements for Utility Water Used in the Production of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2003.

- JGJ 51-2002; Technical Specification for Lightweight Aggregate Concrete. China Architecture & Building Press: Beijing, China, 2002.

- JGJ/T 372-2016; Technical Specification for Application of Shotcrete. China Architecture & Building Press: Beijing, China, 2016.

- EN 12620:2012; Aggregates and Aggregate Preparation for Testing. Standard, European Committee for Standardization: Brussels, Belgium, 2012.

- Khanlari, G.R.; Heidari, M.; Sepahigero, A.A.; Fereidooni, D. Quantification of strength anisotropy of metamorphic rocks of the Hamedan province, Iran, as determined from cylindrical punch, point load and Brazilian tests. Eng. Geol. 2014, 169, 80–90. [Google Scholar] [CrossRef]

- Thériault, F.; Noël, M.; Sanchez, L. Simplified approach for quantitative inspections of concrete structures using digital image correlation. Eng. Struct. 2022, 252, 113725. [Google Scholar] [CrossRef]

- Yang, L.Y.; Xie, H.Z.; Zhang, D.B.; Zhang, F.; Lin, C.Y.; Fang, S.Z. Acoustic emission characteristics and crack resistance of basalt fiber reinforced concrete under tensile load. Constr. Build. Mater. 2021, 312, 125442. [Google Scholar] [CrossRef]

- Nie, Y.J.; Su, H.J.; Yu, L.Y.; Feng, Y.J.; Wang, W.B. Bonding fracture and deformation behaviors of sandstone-concrete interface subjected to different temperatures under three-point bending. Int. J. Geomech. 2023, 23, 04023020. [Google Scholar] [CrossRef]

- Deresse, N.E.; VanSteen, C.; Soete, J.; Sarem, M.; Vanhulst, J.; Wevers, M.; François, S. Fracture mode analysis of cementitious mortars by simultaneous application of 4D-XCT and acoustic emission technique. Constr. Build. Mater. 2024, 419, 135486. [Google Scholar] [CrossRef]

- ASTM 3967-16; Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2016.

- Birid, K.C. An Equation to Evaluate the Unconfined Compressive Strength of Rock from Splitting Tensile Strength Test Results. Geotech. Geol. Eng. 2016, 34, 391–401. [Google Scholar] [CrossRef]

- Quan, J.S.; Rong, G.; Xu, L.D.; Chen, Z.H. A three-dimensional grain-based model for studying the microscopic fracture behavior of granite. Comput. Geotech. 2023, 159, 105427. [Google Scholar] [CrossRef]

- Itasca Consulting Group Inc. PFC3D (3 Dimensional Particle Flow Code), version 6.0; Itasca Consulting Group Inc.: Minneapolis, MN, USA, 2020. [Google Scholar]

- Peng, Y.X.; Zhang, T.; Yu, L.Y.; Gao, J.L.Y.A.; Tian, W.L. Numerical investigation on the effect of intergranular contact bonding strength on the mechanical properties of granite using PFC3D-GBM. Int. J. Numer. Anal. Methods Geomech. 2023, 47, 694–716. [Google Scholar] [CrossRef]

- Rasmussen, L.L.; Min, K.B. Developments to the Bonded Block Modeling technique for Discrete Element simulation of transversely isotropic rocks. Int. J. Rock Mech. Min. Sci. 2023, 170, 105518. [Google Scholar] [CrossRef]

- Xu, Y.; Dai, F.; Xu, N.W.; Zhao, T. Numerical investigation of dynamic rock fracture toughness determination using a semi-circular bend specimen in split Hopkinson pressure bar testing. Rock Mech. Rock Eng. 2016, 49, 731–745. [Google Scholar] [CrossRef]

| Bulk Density (kg/m3) | Apparent Density (kg/m3) | Water Absorption (%) | Porosity (%) | Cylindrical Compressive Strength (MPa) |

|---|---|---|---|---|

| 894 | 1973 | 12.52 | 48.97 | 2.69 |

| Fineness Modulus | Bulk Density (kg/m3) | Apparent Density (kg/m3) | The Saturated Surface Dry Moisture Content (%) |

|---|---|---|---|

| 2.88 | 1138 | 2751 | 1.96 |

| NaCl (kg/m3) | MgCl·6H2O (kg/m3) | Na2SO4 (kg/m3) | CaCl2 (kg/m3) | KCl (kg/m3) |

|---|---|---|---|---|

| 24.5 | 11.1 | 4.1 | 1.2 | 0.7 |

| Mix | Cementitious Material Content (kg/m3) | Water–Binder Ratio | Sand Ratio (%) | Accelerator Amount (%) |

|---|---|---|---|---|

| Mix. 1 | 600 | 0.4 | 40 | 4 |

| Mix. 2 | 600 | 0.45 | 50 | 6 |

| Mix. 3 | 600 | 0.5 | 60 | 8 |

| Mix. 4 | 700 | 0.4 | 50 | 8 |

| Mix. 5 | 700 | 0.45 | 60 | 4 |

| Mix. 6 | 700 | 0.5 | 40 | 6 |

| Mix. 7 | 800 | 0.4 | 60 | 6 |

| Mix. 8 | 800 | 0.45 | 40 | 8 |

| Mix. 9 | 800 | 0.5 | 50 | 4 |

| Mix | Cementitious Material Content (kg/m3) | Cement (kg/m3) | Seawater (kg/m3) | Coral Sand (kg/m3) | Coral Debris (kg/m3) | Water Reducer (kg/m3) | Accelerating Agent (kg/m3) |

|---|---|---|---|---|---|---|---|

| Mix. 1 | 600 | 552 | 240 | 541 | 812 | 12 | 24 |

| Mix. 2 | 600 | 552 | 270 | 655 | 655 | 13.5 | 36 |

| Mix. 3 | 600 | 552 | 300 | 760 | 506 | 15 | 48 |

| Mix. 4 | 700 | 644 | 280 | 590 | 590 | 14 | 56 |

| Mix. 5 | 700 | 644 | 315 | 702 | 468 | 15.7 | 28 |

| Mix. 6 | 700 | 644 | 350 | 448 | 672 | 17.5 | 42 |

| Mix. 7 | 800 | 736 | 320 | 627 | 418 | 16 | 48 |

| Mix. 8 | 800 | 736 | 360 | 395 | 395 | 18 | 64 |

| Mix. 9 | 800 | 736 | 400 | 489 | 489 | 20 | 32 |

| Parameter | Mix. 1 | Mix. 2 | Mix. 3 | Mix. 4 | Mix. 5 | Mix. 6 | Mix. 7 | Mix. 8 | Mix. 9 |

|---|---|---|---|---|---|---|---|---|---|

| Slump (mm) | 90 | 105 | 125 | 120 | 135 | 165 | 125 | 155 | 190 |

| Rebound rate (%) | 16.99 | 11.7 | 12.92 | 11.72 | 7.04 | 8.22 | 14.61 | 9.67 | 14.97 |

| Mix | Curing Age | |||

|---|---|---|---|---|

| 3 d | 7 d | 28 d | ||

| CS (MPa) | Mix. 1 | 8.70 | 16.28 | 16.97 |

| Mix. 2 | 9.06 | 16.92 | 17.83 | |

| Mix. 3 | 10.35 | 14.23 | 16.91 | |

| Mix. 4 | 19.84 | 19.86 | 20.75 | |

| Mix. 5 | 14.73 | 26.44 | 29.63 | |

| Mix. 6 | 13.84 | 20.10 | 21.17 | |

| Mix. 7 | 16.53 | 24.72 | 25.11 | |

| Mix. 8 | 18.50 | 22.21 | 24.59 | |

| Mix. 9 | 9.79 | 20.69 | 22.19 | |

| TS (MPa) | Mix. 1 | 0.96 | 1.89 | 2.05 |

| Mix. 2 | 0.97 | 1.94 | 2.36 | |

| Mix. 3 | 1.35 | 1.67 | 1.88 | |

| Mix. 4 | 2.24 | 2.36 | 2.58 | |

| Mix. 5 | 1.63 | 3.12 | 3.38 | |

| Mix. 6 | 1.61 | 2.29 | 2.49 | |

| Mix. 7 | 1.90 | 3.01 | 3.32 | |

| Mix. 8 | 2.14 | 2.91 | 3.15 | |

| Mix. 9 | 1.29 | 2.69 | 2.90 | |

| Curing Age | Cementitious Material Content | Water–Binder Ratio | Sand Ratio | Accelerator Amount | ||

|---|---|---|---|---|---|---|

| CS | 3 d | K1 | 9.4 | 15.0 | 13.7 | 11.1 |

| K2 | 16.1 | 14.1 | 12.9 | 13.1 | ||

| K3 | 14.9 | 11.3 | 13.9 | 16.2 | ||

| R | 6.77 | 3.70 | 0.97 | 5.16 | ||

| 7 d | K1 | 15.8 | 20.3 | 19.5 | 21.1 | |

| K2 | 22.1 | 21.9 | 19.2 | 20.6 | ||

| K3 | 22.5 | 18.3 | 21.8 | 18.8 | ||

| R | 6.73 | 3.52 | 2.64 | 2.37 | ||

| 28 d | K1 | 17.2 | 20.9 | 20.9 | 22.9 | |

| K2 | 23.9 | 24.0 | 20.3 | 21.4 | ||

| K3 | 24.0 | 20.1 | 23.9 | 20.8 | ||

| R | 6.73 | 3.93 | 3.63 | 2.18 | ||

| TS | 3 d | K1 | 1.1 | 1.7 | 1.6 | 1.3 |

| K2 | 1.8 | 1.6 | 1.5 | 1.5 | ||

| K3 | 1.8 | 1.4 | 1.6 | 1.9 | ||

| R | 0.73 | 0.28 | 0.12 | 0.62 | ||

| 7 d | K1 | 1.8 | 2.4 | 2.4 | 2.6 | |

| K2 | 2.6 | 2.7 | 2.3 | 2.4 | ||

| K3 | 2.9 | 2.2 | 2.6 | 2.3 | ||

| R | 1.03 | 0.44 | 0.27 | 0.25 | ||

| 28 d | K1 | 2.1 | 2.7 | 2.6 | 2.8 | |

| K2 | 2.8 | 3.0 | 2.6 | 2.7 | ||

| K3 | 3.1 | 2.4 | 2.9 | 2.5 | ||

| R | 1.03 | 0.54 | 0.30 | 0.24 |

| Microparameters | F-F | S-S | C-C | F-S | F-C | C-S |

|---|---|---|---|---|---|---|

| Tensile strength (MPa) | 32.76 | 32.76 | 18.72 | 32.76 | 18.72 | 18.72 |

| Cohesion strength (MPa) | 48 | 48 | 28.8 | 48 | 28.8 | 28.8 |

| Bonding activation gap (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Elastic modulus (GPa) | 8.5 | 8.5 | 21.25 | 8.5 | 14.45 | 14.45 |

| Stiffness ratio | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 |

| Friction angle (°) | 13 | 13 | 13 | 13 | 13 | 13 |

| Crack Types | Symbol | Proportion Symbol | |

|---|---|---|---|

| Tensile crack (Tc) | Cement mortar–Silica fume | Tfs | PTfs |

| Cement mortar–Cement mortar | Tff | PTff | |

| Cement mortar–Coral debris | Tfc | PTfc | |

| Silica fume–Silica fume | Tss | PTss | |

| Coral debris–Silica fume | Tcs | PTcs | |

| Coral debris–Coral debris | Tcc | PTcc | |

| Shear crack (Sc) | Cement mortar–Silica fume | Sfs | PSfs |

| Cement mortar–Cement mortar | Sff | PSff | |

| Cement mortar–Coral debris | Sfc | PSfc | |

| Silica fume–Silica fume | Sss | PSss | |

| Coral debris–Silica fume | Scs | PScs | |

| Coral debris–Coral debris | Scc | PScc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Y.; Yu, L.; Li, W.; Zhang, T.; Ma, L.; Wu, D.; Wu, C.; Zhou, L. Study on Static Mechanical Properties and Numerical Simulation of Coral Aggregate Seawater Shotcrete with Reasonable Mix Proportion. Materials 2024, 17, 2353. https://doi.org/10.3390/ma17102353

Peng Y, Yu L, Li W, Zhang T, Ma L, Wu D, Wu C, Zhou L. Study on Static Mechanical Properties and Numerical Simulation of Coral Aggregate Seawater Shotcrete with Reasonable Mix Proportion. Materials. 2024; 17(10):2353. https://doi.org/10.3390/ma17102353

Chicago/Turabian StylePeng, Yuxuan, Liyuan Yu, Wei Li, Tao Zhang, Linjian Ma, Dongyang Wu, Changan Wu, and Linjie Zhou. 2024. "Study on Static Mechanical Properties and Numerical Simulation of Coral Aggregate Seawater Shotcrete with Reasonable Mix Proportion" Materials 17, no. 10: 2353. https://doi.org/10.3390/ma17102353