Molecular Orientation Behavior of Lyotropic Liquid Crystal–Carbon Dot Hybrids in Microfluidic Confinement

Abstract

:1. Introduction

2. Results

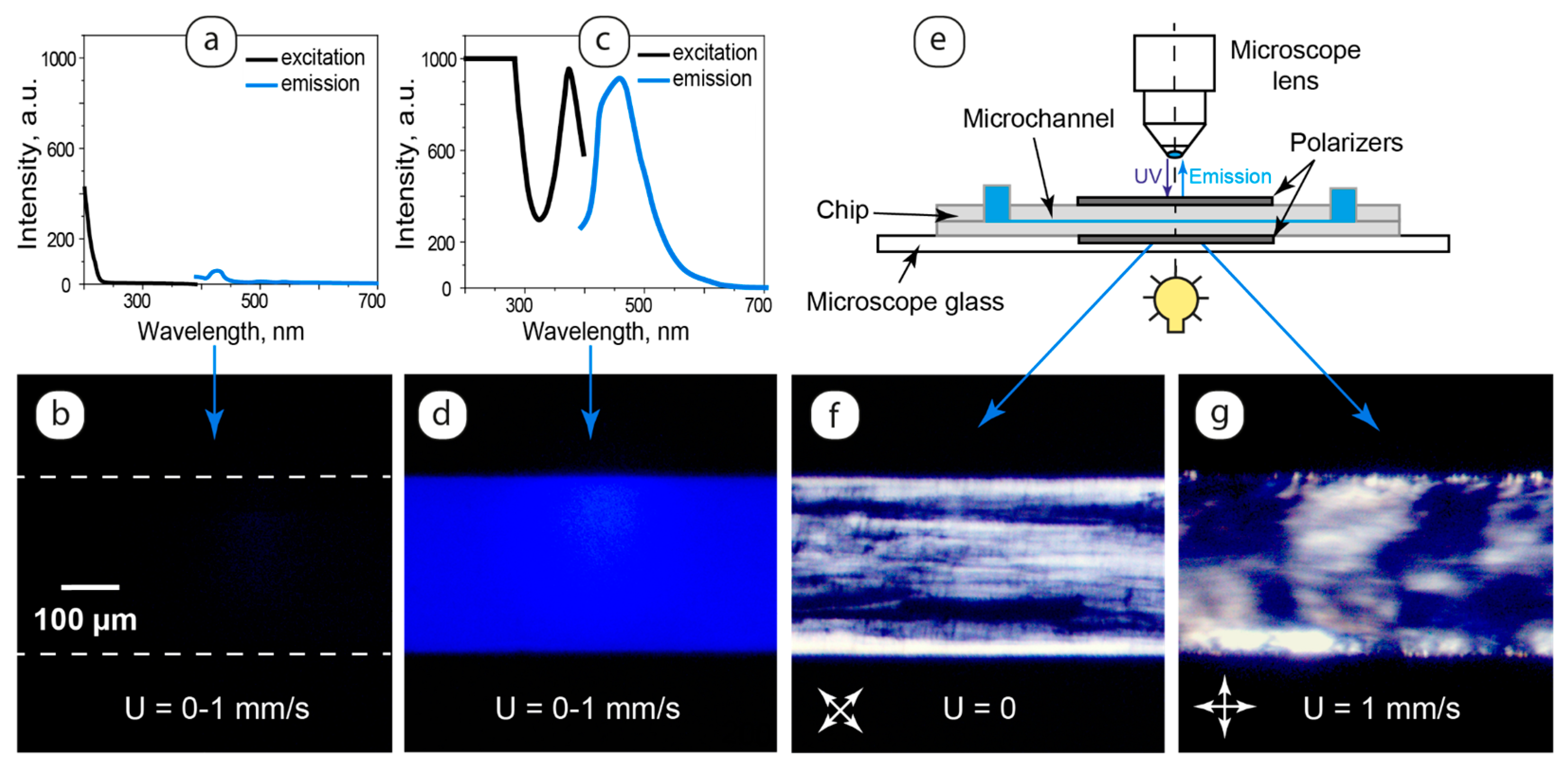

2.1. Preliminary Characterization of the LLC and Composite

2.2. Molecular Orientation and Optical Properties of Static LLC and Carbon Dot Composites in Microchannels

2.3. Impact of the Shear on the Molecular Arrangement in Microfluidic LLC and Composite Media

2.4. Luminescence of Anisotropic LLC–Carbon Dot Systems in Confinement

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Methods

4.3. Fabricating Microfluidic Devices and Preparing the Experimentsal Setup

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Q.; Zhu, J.C.; Li, Z.X.; Chen, X.S.; Jiang, Y.X.; Luo, Z.W.; Wang, P.; Xie, H.L. Luminescent Liquid Crystals Based on Carbonized Polymer Dots and Their Polarized Luminescence Application. ACS Appl. Mater. Interfaces 2021, 13, 26522–26532. [Google Scholar] [CrossRef] [PubMed]

- Sengupta, A.; Herminghaus, S.; Bahr, C. Liquid crystal microfluidics: Surface, elastic and viscous interactions at microscales. Liq. Cryst. Rev. 2014, 2, 73–110. [Google Scholar] [CrossRef]

- Kim, J.-W.; Oh, Y.; Lee, S.; Kim, S.-H. Thermochromic Microcapsules Containing Chiral Mesogens Enclosed by Hydrogel Shell for Colorimetric Temperature Reporters. Adv. Funct. Mater. 2022, 32, 2107275. [Google Scholar] [CrossRef]

- Jung, Y.D.; Khan, M.; Park, S.Y. Fabrication of temperature- and pH-sensitive liquid-crystal droplets with PNIPAM-b-LCP and SDS coatings by microfluidics. J. Mater. Chem. B 2014, 2, 4922–4928. [Google Scholar] [CrossRef]

- Gollapelli, B.; Rama Raju Ganji, S.; Kumar Tatipamula, A.; Vallamkondu, J. Bio-derived chlorophyll dye doped cholesteric liquid crystal films and microdroplets for advanced anti-counterfeiting security labels. J. Mol. Liq. 2022, 363, 119952. [Google Scholar] [CrossRef]

- Bao, P.; Paterson, D.A.; Harrison, P.L.; Miller, K.; Peyman, S.; Jones, J.C.; Sandoe, J.; Evans, S.D.; Bushby, R.J.; Gleeson, H.F. Lipid coated liquid crystal droplets for the on-chip detection of antimicrobial peptides. Lab Chip 2019, 19, 1082–1089. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Li, W.; Wang, X.; Xie, Y.; Li, Y.; Wu, Z. Functional Liquid Crystal Core/Hydrogel Shell Microcapsules for Monitoring Live Cells in a 3D Microenvironment. Anal. Chem. 2023, 95, 2750–2756. [Google Scholar] [CrossRef] [PubMed]

- Otón, E.; Otón, J.; Caño-García, M.; Escolano, J.; Quintana, X.; Geday, M.A. Rapid detection of pathogens using lyotropic liquid crystals. Opt. Express 2019, 27, 10098–10107. [Google Scholar] [CrossRef] [PubMed]

- Norouzi, S.; Martinez Gonzalez, J.A.; Sadati, M. Chiral Liquid Crystal Microdroplets for Sensing Phospholipid Amphiphiles. Biosensors 2022, 12, 313. [Google Scholar] [CrossRef]

- Paterson, D.A.; Du, X.; Bao, P.; Parry, A.A.; Peyman, S.A.; Sandoe, J.A.; Evans, S.D.; Luo, D.; Bushby, R.J.; Jones, J.C. Chiral nematic liquid crystal droplets as a basis for sensor systems. Mol. Syst. Des. Eng. 2022, 7, 607–621. [Google Scholar] [CrossRef]

- Khan, M.; Liu, S.; Qi, L.; Ma, C.; Munir, S.; Yu, L.; Hu, Q. Liquid crystal-based sensors for the detection of biomarkers at the aqueous/LC interface. TrAC Trends Anal. Chem. 2021, 144, 116434. [Google Scholar] [CrossRef]

- Sang, Y.; Han, J.; Zhao, T.; Duan, P.; Liu, M. Circularly Polarized Luminescence in Nanoassemblies: Generation, Amplification, and Application. Adv. Mater. 2020, 32, e1900110. [Google Scholar] [CrossRef] [PubMed]

- Grell, M.; Bradley, D.D.C. Polarized Luminescence from Oriented Molecular Materials. Adv. Mater. 1999, 11, 895–905. [Google Scholar] [CrossRef]

- O’Neill, M.; Kelly, S.M. Liquid Crystals for Charge Transport, Luminescence, and Photonics. Adv. Mater. 2003, 15, 1135–1146. [Google Scholar] [CrossRef]

- Deng, Y.; Wang, M.; Zhuang, Y.; Liu, S.; Huang, W.; Zhao, Q. Circularly polarized luminescence from organic micro-/nano-structures. Light Sci. Appl. 2021, 10, 76. [Google Scholar] [CrossRef] [PubMed]

- Zinna, F.; Di Bari, L. Lanthanide circularly polarized luminescence: Bases and applications. Chirality 2015, 27, 1–13. [Google Scholar] [CrossRef] [PubMed]

- El-Brolsy, H.; Hanafy, N.A.N.; El-Kemary, M.A. Fighting Non-Small Lung Cancer Cells Using Optimal Functionalization of Targeted Carbon Quantum Dots Derived from Natural Sources Might Provide Potential Therapeutic and Cancer Bio Image Strategies. Int. J. Mol. Sci. 2022, 23, 13283. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.; Bodas, D. High-quality quantum dots for multiplexed bioimaging: A critical review. Adv. Colloid Interface Sci. 2020, 278, 102137. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.; Kumar, S.; Malik, P. Recent trends and insights into carbon dots dispersed liquid crystal composites. J. Mol. Liq. 2023, 384, 122225. [Google Scholar]

- Gollapelli, B.; Suguru Pathinti, R.; Vallamkondu, J. Carbon Quantum Dots doped Cholesteric Liquid Crystal Films and Microdroplets for Anti-Counterfeiting. ACS Appl. Nano Mater. 2022, 5, 11912–11922. [Google Scholar] [CrossRef]

- Chen, H.Q.; Wang, X.Y.; Bisoyi, H.K.; Chen, L.J.; Li, Q. Liquid Crystals in Curved Confined Geometries: Microfluidics Bring New Capabilities for Photonic Applications and Beyond. Langmuir 2021, 37, 3789–3807. [Google Scholar] [CrossRef] [PubMed]

- Sevim, S.; Sorrenti, A.; Franco, C.; Furukawa, S.; Pané, S.; Demello, A.J.; Puigmartí-Luis, J. Self-assembled materials and supramolecular chemistry within microfluidic environments: From common thermodynamic states to non-equilibrium structures. Chem. Soc. Rev. 2018, 47, 3788–3803. [Google Scholar] [CrossRef] [PubMed]

- Čopar, S.; Kos, Ž.; Emeršič, T.; Tkalec, U. Microfluidic control over topological states in channel-confined nematic flows. Nat. Commun. 2020, 11, 59. [Google Scholar] [CrossRef] [PubMed]

- Crespo, M.; Majumdar, A.; Ramos, A.M.; Griffiths, I.M. Solution landscapes in nematic microfluidics. Phys. D Nonlinear Phenom. 2017, 351–352, 1–13. [Google Scholar] [CrossRef]

- Sengupta, A.; Tkalec, U.; Bahr, C. Nematic textures in microfluidic environment. Soft Matter 2011, 7, 6542–6549. [Google Scholar] [CrossRef]

- Anderson, T.G.; Mema, E.; Kondic, L.; Cummings, L.J. Transitions in Poiseuille flow of nematic liquid crystal. Int. J. Non-Linear Mech. 2015, 75, 15–21. [Google Scholar] [CrossRef]

- Wiese, O.; Marenduzzo, D.; Henrich, O. Microfluidic flow of cholesteric liquid crystals. Soft Matter 2016, 12, 9223–9237. [Google Scholar] [CrossRef]

- Kim, Y.G.; Park, S.; Kim, S.-H. Designing photonic microparticles with droplet microfluidics. Chem. Commun. 2022, 58, 10303–10328. [Google Scholar] [CrossRef] [PubMed]

- Takenaka, Y.; Škarabot, M.; Muševič, I. Nematic Liquid-Crystal Necklace Structure Made by Microfluidics System. Langmuir 2020, 36, 3234–3241. [Google Scholar] [CrossRef]

- Pilkington, C.P.; Contini, C.; Barritt, J.D.; Simpson, P.A.; Seddon, J.M.; Elani, Y. A microfluidic platform for the controlled synthesis of architecturally complex liquid crystalline nanoparticles. Sci. Rep. 2023, 13, 12684. [Google Scholar] [CrossRef]

- Kim, J.; Khan, M.; Park, S.Y. Glucose sensor using liquid-crystal droplets made by microfluidics. ACS Appl. Mater. Interfaces 2013, 5, 13135–13139. [Google Scholar] [CrossRef] [PubMed]

- Sengupta, A. Topological Microfluidics: Nematic Liquid Crystals and Nematic Colloids in Microfluidic Environment; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; p. 153. [Google Scholar]

- With, S.; Trebbin, M.; Bartz, C.B.; Neuber, C.; Dulle, M.; Yu, S.; Roth, S.V.; Schmidt, H.-W.; Förster, S. Fast diffusion-limited lyotropic phase transitions studied in situ using continuous flow microfluidics/microfocus-SAXS. Langmuir 2014, 30, 12494–12502. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Ong, I.L.H.; Sengupta, A. Time Dependent Lyotropic Chromonic Textures in Microfluidic Confinements. Crystals 2020, 11, 35. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, R.; Ge, B.; Yaqoob, Z.; So, P.T.C.; Bischofberger, I. Structures and topological defects in pressure-driven lyotropic chromonic liquid crystals. Proc. Natl. Acad. Sci. USA 2021, 118, e2108361118. [Google Scholar] [CrossRef] [PubMed]

- Ulaganathan, V.; Sengupta, A. Spatio-temporal programming of lyotropic phase transition in nanoporous microfluidic confinements. J. Colloid Interface Sci. 2023, 649, 302–312. [Google Scholar] [CrossRef] [PubMed]

- He, V.; Cadarso, V.J.; Seibt, S.; Boyd, B.J.; Neild, A. A novel droplet-based approach to study phase transformations in lyotropic liquid crystalline systems. J. Colloid Interface Sci. 2023, 641, 459–469. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Palomo, A.; Lutz-Bueno, V.; Cao, X.; Kadar, R.; Andersson, M.; Liebi, M. In Situ Visualization of the Structural Evolution and Alignment of Lyotropic Liquid Crystals in Confined Flow. Small 2021, 17, e2006229. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Dyett, B.P.; Zhai, J.; Strachan, J.B.; Drummond, C.J.; Conn, C.E. Formation of particulate lipid lyotropic liquid crystalline nanocarriers using a microfluidic platform. J Colloid Interface Sci 2023, 634, 279–289. [Google Scholar] [CrossRef]

- De Souza, J.F.; Pontes, K.d.S.; Alves, T.F.; Amaral, V.A.; Rebelo, M.d.A.; Hausen, M.A.; Chaud, M.V. Spotlight on biomimetic systems based on lyotropic liquid crystal. Molecules 2017, 22, 419. [Google Scholar] [CrossRef]

- Zhao, J.; Gulan, U.; Horie, T.; Ohmura, N.; Han, J.; Yang, C.; Kong, J.; Wang, S.; Xu, B.B. Advances in Biological Liquid Crystals. Small 2019, 15, e1900019. [Google Scholar] [CrossRef]

- Sarisozen, S.; Polat, N.; Mert Balci, F.; Guvenc, C.M.; Kocabas, C.; Yaglioglu, H.G.; Balci, S. Strong Coupling of Carbon Quantum Dots in Liquid Crystals. J. Phys. Chem. Lett. 2022, 13, 3562–3570. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Farheen; Sachdev, S.; Manori, S.; Bhardwaj, S.; Chitme, H.; Sharma, A.; Raina, K.K.; Shukla, R.K. Graphene quantum dot doped viscoelastic lyotropic liquid crystal nanocolloids for antibacterial applications. Soft Matter 2023, 19, 6589–6603. [Google Scholar] [CrossRef] [PubMed]

- Galeeva, A.I.; Selivanova, N.M.; Galyametdinov, Y.G. Wetting and adhesive properties of biopolymer-based organized condensed phases as drug delivery systems. Liq. Cryst. Their Appl. 2023, 23, 38–48. [Google Scholar] [CrossRef]

- Selivanova, N.M.; Galeeva, A.I.; Galyametdinov, Y.G. Chitosan/Lactic Acid Systems: Liquid Crystalline Behavior, Rheological Properties, and Riboflavin Release In Vitro. Int. J. Mol. Sci. 2022, 23, 13207. [Google Scholar] [CrossRef] [PubMed]

- Bezrukov, A.; Galyametdinov, Y. Tuning Molecular Orientation Responses of Microfluidic Liquid Crystal Dispersions to Colloid and Polymer Flows. Int. J. Mol. Sci. 2023, 24, 13555. [Google Scholar] [CrossRef]

- Bezrukov, A.; Galyametdinov, Y. Dynamic Flow Control over Optical Properties of Liquid Crystal-Quantum Dot Hybrids in Microfluidic Devices. Micromachines 2023, 14, 990. [Google Scholar] [CrossRef] [PubMed]

- Zana, R. Dynamics of Surfactant Self-Assemblies; CRC Press: Boca Raton, FL, USA, 2019; p. 537. [Google Scholar]

- Selivanova, N.M.; Galeeva, A.I.; Gubaydullin, A.T.; Lobkov, V.S.; Galyametdinov, Y.G. Mesogenic and luminescent properties of lyotropic liquid crystals containing Eu(III) and Tb(III) ions. J. Phys. Chem. B 2012, 116, 735–742. [Google Scholar] [CrossRef]

- Selivanova, N.M.; Galeeva, A.I.; Konov, A.B.; Gnezdilov, O.I.; Salikhov, K.M.; Galyametdinov, Y.G. Phase diagram of the liquid crystal system of water-decanol-lanthanum nitrate-decaethylene glycol monododecyl ether. Russ. J. Phys. Chem. A 2010, 84, 802–807. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, L.; Deng, Y.; Peng, K.; Yu, Y.; Zeng, X. A multi-color carbon quantum dots based on the coordinated effect of quantum size and surface defects with green synthesis. Ceram. Int. 2023, 49, 16647–16651. [Google Scholar] [CrossRef]

- Shabbir, H.; Tokarski, T.; Ungor, D.; Wojnicki, M. Eco Friendly Synthesis of Carbon Dot by Hydrothermal Method for Metal Ions Salt Identification. Materials 2021, 14, 7604. [Google Scholar] [CrossRef]

- Sarkar, S.; Banerjee, D.; Ghorai, U.K.; Das, N.S.; Chattopadhyay, K.K. Size dependent photoluminescence property of hydrothermally synthesized crystalline carbon quantum dots. J. Lumin. 2016, 178, 314–323. [Google Scholar] [CrossRef]

- Yue, J.; Li, L.; Cao, L.; Zan, M.; Yang, D.; Wang, Z.; Chang, Z.; Mei, Q.; Miao, P.; Dong, W.F. Two-Step Hydrothermal Preparation of Carbon Dots for Calcium Ion Detection. ACS Appl. Mater. Interfaces 2019, 11, 44566–44572. [Google Scholar] [CrossRef]

- Han, Z.; He, L.; Pan, S.; Liu, H.; Hu, X. Hydrothermal synthesis of carbon dots and their application for detection of chlorogenic acid. Luminescence 2020, 35, 989–997. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Zhu, S.; Xiang, S.; Zhao, X.; Zhang, J.; Zhang, H.; Fu, Y.; Yang, B. Investigation into the fluorescence quenching behaviors and applications of carbon dots. Nanoscale 2014, 6, 4676–4682. [Google Scholar] [CrossRef] [PubMed]

- Capaccio, A.; Caserta, S.; Guido, S.; Rusciano, G.; Sasso, A. Dissolution of a surfactant-water lamellar phase investigated by combining time-lapse polarized light microscopy and confocal Raman spectroscopy. J. Colloid Interface Sci. 2020, 561, 136–146. [Google Scholar] [CrossRef]

- Müller, S.; Börschig, C.; Gronski, W.; Schmidt, C.; Roux, D. Shear-Induced States of Orientation of the Lamellar Phase of C12E4/Water. Langmuir 1999, 15, 7558–7564. [Google Scholar] [CrossRef]

- Govindaraju, T.; Bertics, P.J.; Raines, R.T.; Abbott, N.L. Using Measurements of Anchoring Energies of Liquid Crystals on Surfaces to Quantify Proteins Captured by Immobilized Ligands. J. Am. Chem. Soc. 2007, 129, 11223–11231. [Google Scholar] [CrossRef] [PubMed]

- Léon, A.; Bonn, D.; Meunier, J.; Al-Kahwaji, A.; Greffier, O.; Kellay, H. Coupling between Flow and Structure for a Lamellar Surfactant Phase. Phys. Rev. Lett. 2000, 84, 1335–1338. [Google Scholar] [CrossRef] [PubMed]

- Versluis, P.; van de Pas, J.C.; Mellema, J. Microstructure and Rheology of Lamellar Liquid Crystalline Phases. Langmuir 1997, 13, 5732–5738. [Google Scholar] [CrossRef]

- Izaki, Y.; Kurita, R.; Tanaka, H. Hidden linear defects in surfactant onions revealed by coalescence into lamellar layers. Phys. Rev. Res. 2021, 3, 043094. [Google Scholar] [CrossRef]

- Linge Johnsen, S.A.; Bollmann, J.; Lee, H.W.; Zhou, Y. Accurate representation of interference colours (Michel-Levy chart): From rendering to image colour correction. J. Microsc. 2018, 269, 321–337. [Google Scholar] [CrossRef] [PubMed]

- Brake, J.M.; Mezera, A.D.; Abbott, N.L. Active Control of the Anchoring of 4’-Pentyl-4-cyanobiphenyl (5CB) at an Aqueous−Liquid Crystal Interface by Using a Redox-Active Ferrocenyl Surfactant. Langmuir 2003, 19, 8629–8637. [Google Scholar] [CrossRef]

- Wang, B.; Abdulali-Kanji, Z.; Dodwell, E.; Horton, J.H.; Oleschuk, R.D. Surface characterization using chemical force microscopy and the flow performance of modified polydimethylsiloxane for microfluidic device applications. Electrophoresis 2003, 24, 1442–1450. [Google Scholar] [CrossRef] [PubMed]

- McDonald, J.C.; Duffy, D.C.; Anderson, J.R.; Chiu, D.T.; Wu, H.; Schueller, O.J.A.; Whitesides, G.M. Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 2000, 21, 27–40. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bezrukov, A.; Galeeva, A.; Krupin, A.; Galyametdinov, Y. Molecular Orientation Behavior of Lyotropic Liquid Crystal–Carbon Dot Hybrids in Microfluidic Confinement. Int. J. Mol. Sci. 2024, 25, 5520. https://doi.org/10.3390/ijms25105520

Bezrukov A, Galeeva A, Krupin A, Galyametdinov Y. Molecular Orientation Behavior of Lyotropic Liquid Crystal–Carbon Dot Hybrids in Microfluidic Confinement. International Journal of Molecular Sciences. 2024; 25(10):5520. https://doi.org/10.3390/ijms25105520

Chicago/Turabian StyleBezrukov, Artem, Aliya Galeeva, Aleksandr Krupin, and Yuriy Galyametdinov. 2024. "Molecular Orientation Behavior of Lyotropic Liquid Crystal–Carbon Dot Hybrids in Microfluidic Confinement" International Journal of Molecular Sciences 25, no. 10: 5520. https://doi.org/10.3390/ijms25105520