Adobe Bricks of the Champagne Region (France): Characterization of a Chalky Raw Earth Construction Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Survey Location Specificity and Origin of Samples

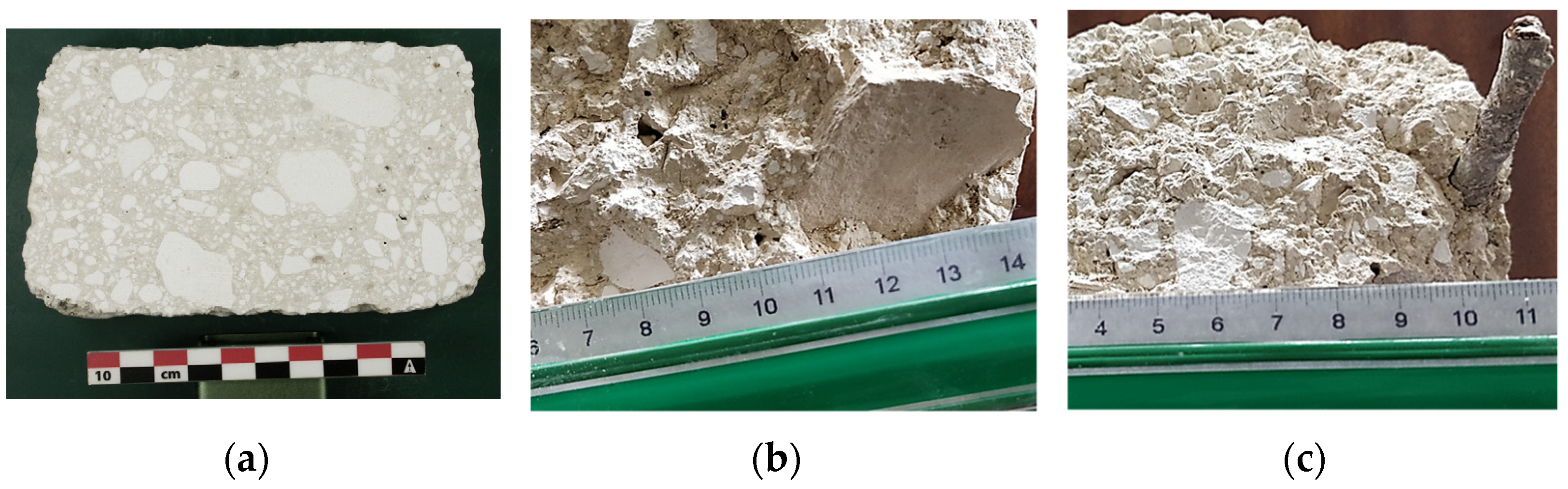

2.2. General Characteristics of Adobes

2.3. Particle Size Distribution

2.4. Methylene Blue Value (MBV1)

2.5. Compression Tests

2.6. Three-Point Flexural Tests

2.7. Thermal Analysis

2.8. Moisture Buffer Value (MBV2)

3. Results

3.1. Particle Size Distribution

3.2. Methylene Blue Value (MBV1)

3.3. Compression Tests

3.4. Three-Point Flexural Tests

3.5. Thermal Analysis

| (W/(m.K)) | (kJ/(kg.K)) | (10−6 m2/s) | |

|---|---|---|---|

| Adobe (present study) | 0.669 (0.033) | 1.109 (0.004) | 0.414 (0.019) |

| Wood oak | 0.17 | 1.6 | 0.15 |

| Plain brick | 1.10 | 0.9 | 0.61 |

| Plain concrete | 2.1 | 1.0 | 0.83 |

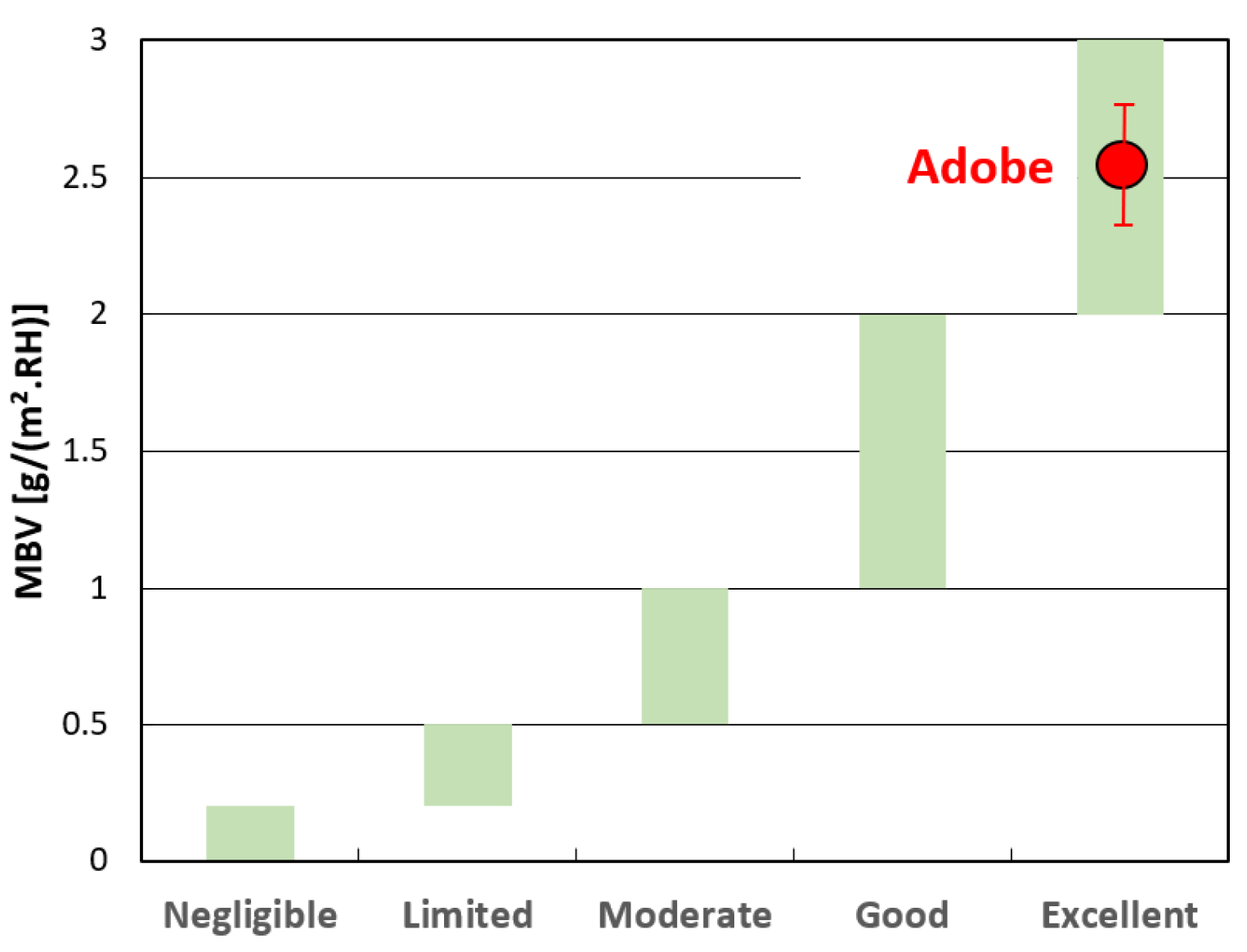

3.6. Moisture Buffer Value (MBV2)

3.7. Simulation of Adobe Integration within a Practical Eco-Friendly Vertical Wall

| Designation | Thickness e (m) | Thermal Conductivity λ (W/m.K) | |

|---|---|---|---|

| ① | Hemp concrete outside coating | 0.05 | 0.095 (*) |

| ② | Fully bio-sourced insulation | 0.16 | 0.09 (**) |

| ③ | Earth-based inside coating | 0.015 | 0.67 |

| ④ | Adobe (present study) | TBD, | 0.67 |

4. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme. 2022 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. 2022, Volume 224. Available online: https://globalabc.org/sites/default/files/2022-11/FULL%20REPORT_2022%20Buildings-GSR_1.pdf (accessed on 15 April 2024).

- Guide RE2020 Réglementation Environnementale; Ministère de la Transition Écologique et de la Cohésion des Territoires: Paris, France, 2024. Available online: https://www.ecologie.gouv.fr/sites/default/files/guide_re2020_version_janvier_2024.pdf (accessed on 3 April 2024).

- Rollot, M.; Aubertin, C. L’architecture localement bio- et géo-sourcée de Christophe Aubertin: Régionaliste, biorégionaliste? Cah La Rech Arch. Urbaine Paysagère 2021, 11. Available online: https://dx.doi.org/10.4000/craup.6871 (accessed on 3 April 2024). [CrossRef]

- Rollot, M. Éléments vers une Éthique de L’habitation; Université Paris VIII: Saint-Denis, France, 2018. [Google Scholar]

- Hallauer, E. Du vernaculaire à la Déprise D’oeuvre: Urbanisme, Architecture, Design; Université Paris-Est: Champs-sur-Marne, France, 2017. [Google Scholar]

- Ventura, A.; Ouellet-Plamondon, C.; Röck, M.; Hecht, T.; Roy, V.; Higuera, P.; Lecompte, T.; Faria, P.; Hamard, E.; Morel, J.C.; et al. Environmental Potential of Earth-Based Building Materials: Key Facts and Issues from a Life Cycle Assessment Perspective. RILEM State-Art Rep. 2022, 35, 261–296. Available online: https://link.springer.com/chapter/10.1007/978-3-030-83297-1_8 (accessed on 3 April 2024).

- Mcgregor, F.; Heath, A.; Shea, A.; Lawrence, M. The Moisture Buffering Capacity of Unfired Clay Masonry. Build. Environ. 2014, 82, 599–607. [Google Scholar] [CrossRef]

- Roucan, S.; McGregor, F.; Fabbri, A.; Perlot-Bascoulès, C.; Morel, J.C. Indoor CO2 buffering potential of clay-based building materials. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012135. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/1078/1/012135 (accessed on 3 April 2024). [CrossRef]

- Fabbri, A.; Aubert, J.E.; Bras, A.A.; Faria, P.; Gallipoli, D.; Goffart, J.; McGregor, F.; Perlot-Bascoules, C.; Soudani, L. Hygrothermal and Acoustic Assessment of Earthen Materials. RILEM State-Art Rep. 2022, 35, 83–126. Available online: https://novaresearch.unl.pt/en/publications/hygrothermal-and-acoustic-assessment-of-earthen-materials (accessed on 3 April 2024).

- Walter, A.; Blake, B.; D’Offay-Mancienne, Y.; Perlot, O.M.C. Recyclability, Durability and water vapour adsorption of unstabilised and stabilised compressed earth bricks. Mater. Struct. 2020, 53, 149. [Google Scholar] [CrossRef]

- ADEME. Déchets Chiffres-clés-Edition. 2023. Available online: https://librairie.ademe.fr/dechets-economie-circulaire/6108-dechets-chiffres-cles-edition-2023.html (accessed on 3 April 2024).

- Hamard, E.; Lemercier, B.; Cazacliu, B.; Razakamanantsoa, A.; Morel, J.C. A new methodology to identify and quantify material resource at a large scale for earth construction—Application to cob in Brittany. Constr. Build. Mater. 2018, 170, 485–497. [Google Scholar] [CrossRef]

- Verron, L.; Hamard, E.; Cazacliu, B.; Razakamanantsoa, A.; Duc, M.; Vinceslas, T.; de Menibus, A.H.; Lemercier, B.; Ansaa-Asare, R.J.; Lecompte, T. Estimating and mapping the availability of earth resource for light earth building using a soil geodatabase in Brittany (France). Resour. Conserv. Recycl. 2022, 184, 106409. [Google Scholar] [CrossRef]

- Santos, M.M.; Hilton, A.; Poullain, P.; Hamard, E.; Mouraud, C. Rediscovered earth heritage becomes motor for local change-The Guérande Peninsula (France). In HERITAGE2022 International Conference on Vernacular Heritage: Culture, People and Sustainability; Universitat Politecnica de Valencia: Valencia, Spain, 2022; pp. 149–156. Available online: https://shs.hal.science/halshs-03844005 (accessed on 3 April 2024).

- Mileto, C.; Vegas, F.; Correia, M.; Carlos, G.; Dipasquale, L.; Mecca, S.; Achenza, M.; Rakotomamonjy, B.; Sánchez, N. The European Project “Versus+/Heritage for People”. Objectives and Methodology. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2020, XLIV-M-1–2020, 645–649. [Google Scholar] [CrossRef]

- Pelé-Peltier, A.; Charef, R.; Morel, J.C. Factors affecting the use of earth material in mainstream construction: A critical review. Build. Res. Inf. 2023, 51, 119–137. Available online: https://www.tandfonline.com/doi/abs/10.1080/09613218.2022.2070719 (accessed on 3 April 2024). [CrossRef]

- Morel, J.C.; Charef, R.; Hamard, E.; Fabbri, A.; Beckett, C.; Bui, Q.B. Earth as construction material in the circular economy context: Practitioner perspectives on barriers to overcome. Philos. Trans. R Soc. B 2021, 376, 20200182. Available online: https://royalsocietypublishing.org/doi/10.1098/rstb.2020.0182 (accessed on 3 April 2024). [CrossRef]

- Turmel, A. Répartition et Utilisation des Pierres et Géomatériaux de Construction Dans le Bâti du Pays Rémois-Analyse Spatiale et Propriétés Pétrophysiques. Ph.D. Thesis, Université de Reims Champagne-Ardenne, Reims, France, 2014. [Google Scholar]

- Fronteau, G.; Laratte, S.; Devos, A.; Pichard, C. L’emploi antique des géomatériaux à Reims/Durocortorum. Gallia 2022, 79, 47–59. Available online: http://journals.openedition.org/gallia/6583 (accessed on 3 April 2024). [CrossRef]

- Delencre, F. Terres et Pierres Pour Matières de Cultures: L’apparition et la Diffusion de Nouveaux Modes et Matériaux de Construction Dans le Nord-Est de la Gaule Romaine (IIème Siècle Avant J.-C.-IIème Siècle Après J.-C.). Ph.D. Thesis, Université de Bourgogne Franche-Comté, Besançon, France, 2017. [Google Scholar]

- Turmel, A.; Fronteau, G.; Chalumeau, L.; Deroin, J.P.; Essautier-Chuine, S.; Thomachot-Schneider, C.; De Kock, T.; Cnudde, V.; Barbin, V. GIS-based variability of building materials towards the Île-de-France cuesta (Paris Basin, France): Inventory, distribution, uses and relationship with the environment. Geol. Soc. London Spec. Publ. 2015, 416, 113–131. [Google Scholar] [CrossRef]

- Aras-Gaudry, A.; Fronteau, G.; Hamard, E. Rediscovering raw earth heritage of Champagne area (France): Cartography and typology of a specific adobe vernacular architecture. Mater. Today Proc. 2023, 14. [Google Scholar] [CrossRef]

- Royer, C. Champagne Ardenne: L’architecture Rurale Française; Die, A., Ed.; Eyrolles: Paris, France, 2001; Available online: https://www.eyrolles.com/BTP/Livre/champagne-ardenne-9782908730449/ (accessed on 15 April 2024).

- EN ISO 17892-4; Geotechnical Investigation and Testing Laboratory Testing of Soil. ISO: Geneva, Switzerland, 2018. Available online: https://www.boutique.afnor.org/fr-fr/norme/nf-en-iso-178924/reconnaissance-et-essais-geotechniques-essais-de-laboratoire-sur-les-sols-p/fa166662/80069 (accessed on 11 April 2024).

- Li, B.; Zhou, M.; Wang, J. Effect of the Methylene Blue Value of Manufactured Sand on Performances of Concrete. J. Adv. Concr. Technol. 2011, 9, 127–132. [Google Scholar]

- NF P94-068:1993; Mesure de la Quantité et de L’activité de la Fraction Argileuse. AFNOR: Saint-Denis, France, 1993.

- XP P13-901:2022; Blocs de Terre Comprimée Pour Murs et Cloisons: Définitions-Spécifications-Méthodes d’essais-Conditions de Réception. AFNOR: Saint-Denis, France, 2022.

- Abhilash, H.N.; Hamard, E.; Beckett, C.T.S.; Morel, J.C.; Varum, H.; Silveira, D.; Ioannou, I.; Illampas, R. Mechanical Behaviour of Earth Building Materials. In Testing and Characterisation of Earth-based Building Materials and Elements: State-of-the-Art Report of the RILEM TC 274-TCE; Fabbri, A., Morel, J.C., Aubert, J.E., Bui, Q.B., Gallipoli, D., Reddy, B.V.V., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 127–180. [Google Scholar] [CrossRef]

- Adorni, E.; Coïsson, E.; Ferretti, D. In Situ Characterization of Archaeological Adobe Bricks. Constr. Build. Mater. 2013, 40, 19. [Google Scholar] [CrossRef]

- Rode, C.; Peuhkuri, R.H.; Hansen, K.K.; Time, B.; Svennberg, K.; Arfvidsson, J.; Ojanen, T. NORDTEST Project on Moisture Buffer Value of Materials. In Proceedings of the AIVC 26th Conference: Ventilation in Relation to the Energy Performance of Buildings Air Infiltration and Ventilation, APA, Brussels, Belgium, 21–23 September 2005; pp. 47–52. [Google Scholar]

- Saïag, J.; Collin, P.Y.; Sizun, J.P.; Herbst, F.; Faÿ-Gomord, O.; Chateau Smith, C.; Caline, B.; Lasseur, É. Classifying chalk microtextures: Sedimentary versus diagenetic origin (Cenomanian–Santonian, Paris Basin, France). Sedimentology 2019, 66, 2976–3007. Available online: https://onlinelibrary.wiley.com/doi/full/10.1111/sed.12618 (accessed on 4 April 2024). [CrossRef]

- Faÿ-Gomord, O.; Descamps, F.; Tshibangu, J.P.; Vandycke, S.; Swennen, R. Unraveling chalk microtextural properties from indentation tests. Eng. Geol. 2016, 209, 30–43. [Google Scholar] [CrossRef]

- LCPC-SETRA; Réalisation des Remblais et des Couches de Forme (GTR)-Fascicule 1-Principes Généraux: Guide Technique-Fascicule 2: Annexes Techniques. CEREMA: Bagneux, France, 1992.

- Rojat, F.; Hamard, E.; Fabbri, A.; Carnus, B.; Mcgregor, F. Towards an Easy Decision Tool to Assess Soil Suitability for Earth Building. Constr. Build. Mater. 2020, 257, 119544. [Google Scholar] [CrossRef]

- NF EN ISO 10693:1995; Qualité du sol-Détermination de la Teneur en Carbonate-Méthode Volumétrique. AFNOR: Saint-Denis, France, 1995.

- Jiménez Delgado, M.C.; Guerrero, I.C. The selection of soils for unstabilised earth building: A normative review. Constr. Build. Mater. 2007, 21, 237–251. [Google Scholar] [CrossRef]

- Houben, H.; Guillaud, H. Earth Construction—A Comprehensive Guide, 2nd ed.; Intermediate Technology Publications: London, UK, 1996; Available online: https://www.scirp.org/reference/referencespapers?referenceid=3129844 (accessed on 4 April 2024).

- Silveira, D.; Varum, H.; Costa, A.; Martins, T.; Pereira, H.; Almeida, J. Mechanical properties of adobe bricks in ancient constructions. Constr. Build. Mater. 2011, 28, 36–44. [Google Scholar] [CrossRef]

- Wu, F.; Li, G.; Li, H.N.; Jia, J.Q. Strength and stress-strain characteristics of traditional adobe block and masonry. Mater. Struct. Constr. 2013, 46, 1449–1457. Available online: https://link.springer.com/article/10.1617/s11527-012-9987-y (accessed on 4 April 2024). [CrossRef]

- Illampas, R.; Ioannou, I.; Charmpis, D.C. Experimental assessment of adobe masonry assemblages under monotonic and loading-unloading compression. Mater. Struct. 2016, 50, 79. Available online: http://www.ucy.ac.cy/dir/ (accessed on 18 March 2024). [CrossRef]

- Sánchez, A.; Varum, H.; Martins, T.; Fernández, J. Mechanical Properties of Adobe Masonry for the Rehabilitation of Buildings. Constr. Build. Mater. 2022, 333, 127330. [Google Scholar] [CrossRef]

- Doat, P.; Hays, A.; Houben, H.; Matuk, S.; Vitoux, F. Construire en Terre; Collection AnArchitec; CRAterre: Villefontaine, France, 1979; Available online: https://craterre.hypotheses.org/319 (accessed on 4 April 2024).

- Illampas, R.; Ioannou, I.; Charmpis, D.C. Adobe bricks under compression: Experimental investigation and derivation of stress–strain equation. Constr. Build. Mater. 2014, 53, 83–90. [Google Scholar] [CrossRef]

- Fratini, F.; Pecchioni, E.; Rovero, L.; Tonietti, U. The earth in the architecture of the historical centre of Lamezia Terme (Italy): Characterization for restoration. Appl. Clay Sci. 2011, 53, 509–516. [Google Scholar] [CrossRef]

- NZS 4298:2020; Materials and Construction for Earth Buildings. Standards New Zealand: Wellington, New Zealand, 2020. Available online: https://www.standards.govt.nz/shop/nzs-42982020/ (accessed on 4 April 2024).

- Standard for Earthen IRC Structures; Pima County Development Services (PCDS): Tucson, AZ, USA, 2012.

- New Mexico Earthen Building Materials Code; Construction Industries Division of the Regulation and Licensing Department (RLD): Santa Fe, Mexico, 2015.

- DIN 4108; Thermal Insulation and Energy Economy in Buildings. DIN CERTCO: Berlin, Germany, 2024. Available online: https://www.boutique.afnor.org/en-gb/standard/din-41084/thermal-insulation-and-energy-economy-in-buildings-part-4-hygrothermal-desi/eu167388/261822 (accessed on 4 April 2024).

- Rempel, A.R.; Rempel, A.W. Rocks, clays, water, and salts: Highly durable, infinitely rechargeable, eminently controllable thermal batteries for buildings. Geosciences 2013, 3, 63–101. [Google Scholar] [CrossRef]

- ASHRAE—American Society of Heating Refrigerating and Air-Conditioning Engineers. ASHRAE Handbook-Fundamentals; ASHRAE: Atlanta, GA, USA, 2021. [Google Scholar]

- Yuan, Z.M.; Li, M.; Ji, C.Y.; Li, L.; Jia, L.; Incecik, A. Steady hydrodynamic interaction between human swimmers. J. R. Soc. Interface 2019, 16, 20180768. [Google Scholar] [CrossRef]

- Saleh, M.A.E. Adobe as a thermal regulating material. Sol. Wind Technol. 1990, 7, 407–416. [Google Scholar] [CrossRef]

- Rode, C.; Peuhkuri, R.; Time, B.; Svennberg, K.; Ojanen, T. Moisture buffer value of building materials. ASTM Spec. Tech. Publ. 2007, 1495, 33–44. [Google Scholar]

- Harb, E.; Maalouf, C.; Bliard, C.; Tenpierik, M.; Lachi, M.; Bogard, F.; Polidori, G. Thermal performance of starch/beet-pulp composite bricks for building insulation at a wall scale. Case Stud. Constr. Mater. 2023, 18, e01851. [Google Scholar] [CrossRef]

- Costantine, G.; Maalouf, C.; Moussa, T.; Polidori, G. Experimental and Numerical Investigations of Thermal Performance of a Hemp Lime External Building Insulation. Build. Environ. 2018, 131, 140–153. [Google Scholar] [CrossRef]

- ISO 6946:2017; Composants et Parois de Bâtiments—Résistance Thermique et Coefficient de Transmission Thermique—Méthodes de Calcul. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/fr/standard/65708.html (accessed on 4 April 2024).

- Observation des Déchets issus de Chantiers du Bâtiment et des Travaux Publics; Observatoire Régional de la Prévention et de la Gestion des Déchets et de L’économie Circulaire: Toulouse, France, 2023.

- Goodhew, S.; Carfrae, J.; Hood-Cree, K.; Fox, M.; Boutouil, M.; Streiff, F. Building with earth: How we are working to revive an ancient, sustainable building technique. Constr. Res. Innov. 2019, 10, 105–108. Available online: https://www.tandfonline.com/doi/abs/10.1080/20450249.2019.1700077 (accessed on 4 April 2024). [CrossRef]

- Streiff, F.; Goodhew, S.; Morton, T.; Boutouil, M.; Guern, M.; Le Touati, K.; Rattier, R.; Hudson, A.; Louahlia, H.G. CobBauge—A Hybrid Walling Technique Combining Mechanical and Thermal Performance. In Proceedings of the LEHM 2020, the 8th International Conference on Building with Earth, Weimar, Germany, 30 October–1 November 2020. [Google Scholar]

| Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 | Average (SD) |

|---|---|---|---|---|---|---|---|---|

| (MPa) | 0.98 | 1.14 | 1.25 | 0.79 | 0.92 | 0.92 | 1.21 | 1.03 (0.17) |

| (%) | 4.85 | 4.57 | 6.08 | 4.21 | 4.27 | 6.40 | 4.25 | 4.95 (0.91) |

| Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 | Average (SD) |

|---|---|---|---|---|---|---|---|---|

| Width b (mm) | 145 | 138 | 145 | 129 | 138 | 134 | 152 | 140.1 (7.7) |

| Thickness h (mm) | 80 | 84 | 86 | 81 | 81 | 82 | 83 | 82.4 (2.1) |

| F (N) | 1832 | 1786 | 2242 | 1808 | 1390 | 1990 | 1749 | 1828 (258) |

| Flexural stress (MPa) | 0.49 | 0.45 | 0.52 | 0.53 | 0.38 | 0.55 | 0.41 | 0.48 (0.06) |

| Flexural strain (%) | 1.19 | 1.66 | 1.61 | 1.67 | 1.40 | 1.96 | 1.68 | 1.60 (0.24) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Polidori, G.; Aras-Gaudry, A.; Beaumont, F.; Bogard, F.; Murer, S.; Lachi, M.; Maalouf, C.; Moussa, T.; Bliard, C.; Fronteau, G.; et al. Adobe Bricks of the Champagne Region (France): Characterization of a Chalky Raw Earth Construction Material. Materials 2024, 17, 2307. https://doi.org/10.3390/ma17102307

Polidori G, Aras-Gaudry A, Beaumont F, Bogard F, Murer S, Lachi M, Maalouf C, Moussa T, Bliard C, Fronteau G, et al. Adobe Bricks of the Champagne Region (France): Characterization of a Chalky Raw Earth Construction Material. Materials. 2024; 17(10):2307. https://doi.org/10.3390/ma17102307

Chicago/Turabian StylePolidori, Guillaume, Adrien Aras-Gaudry, Fabien Beaumont, Fabien Bogard, Sébastien Murer, Mohammed Lachi, Chadi Maalouf, Tala Moussa, Christophe Bliard, Gilles Fronteau, and et al. 2024. "Adobe Bricks of the Champagne Region (France): Characterization of a Chalky Raw Earth Construction Material" Materials 17, no. 10: 2307. https://doi.org/10.3390/ma17102307

APA StylePolidori, G., Aras-Gaudry, A., Beaumont, F., Bogard, F., Murer, S., Lachi, M., Maalouf, C., Moussa, T., Bliard, C., Fronteau, G., & Hamard, E. (2024). Adobe Bricks of the Champagne Region (France): Characterization of a Chalky Raw Earth Construction Material. Materials, 17(10), 2307. https://doi.org/10.3390/ma17102307