The Impact of Suspension Fertilizers Based on Waste Phosphorus Salts from Polyol Production on the Yield of Maize Intended for Green Fodder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Research Methodology

2.2. Statistical Analysis

3. Results

3.1. Meteorological Conditions during the Field Experiment

- P—monthly sum of atmospheric precipitation (mm);

- Σt—monthly sum of air temperatures > 0 °C.

3.2. Results of Field Tests

3.2.1. Dry Matter Content

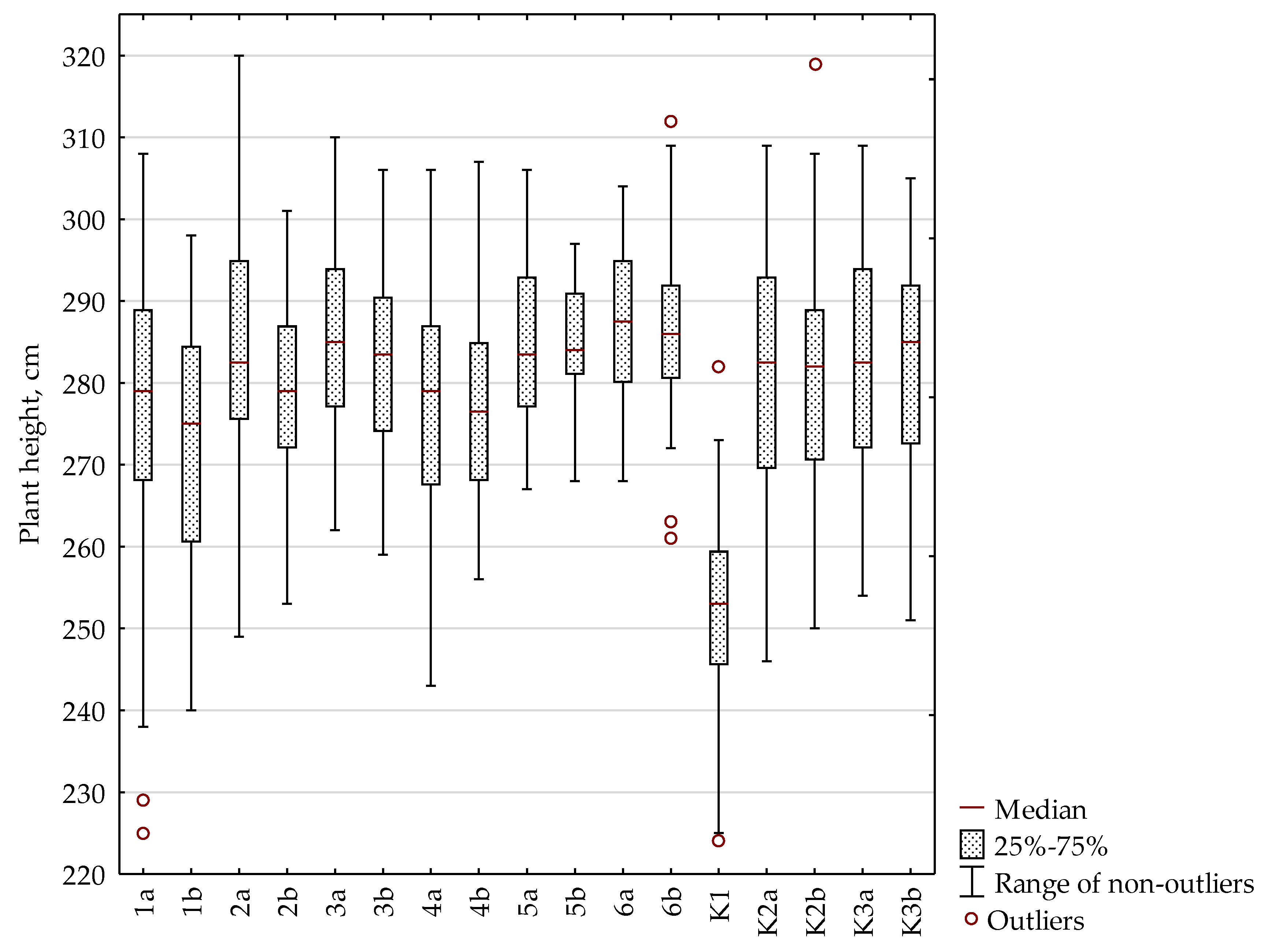

3.2.2. Maize Plant Height

3.2.3. The Ratio of the Weight of the Cob to the Weight of the Green Fodder

3.2.4. Cobs on the Plant

3.2.5. Number of Rows of Grains in the Cob

4. Discussion

- Choice of variety

- Selection of the earliness of the variety

- Influence of climatic conditions

- Optimal date for sowing corn

- Proper sowing depth of corn seeds

- Sowing density and its impact on yield

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Erenstein, O.; Jaleta, M.; Sonder, K.; Mottaleb, K.; Prasanna, B.M. Global maize production, consumption and trade: Trends and R&D implications. Food Secur. 2022, 14, 1295–1319. [Google Scholar]

- Awika, J.M. Major cereal grains production and use around the world. In Advances in Cereal Science: Implications to Food Processing and Health Promotion; American Chemical Society: Washington, DC, USA, 2011; Volume 1089, pp. 1–13. ISBN 9780841226364. [Google Scholar]

- Florası, T.; Ot, Y.; Kaydı, T. Sustainable Weed Management in Maize (Zea mays L.) Production: A Review in Perspective of Southern Asia. Turkish J. Weed Sci. 2018, 21, 36–38. [Google Scholar]

- Wang, J.; Hu, X. Research on corn production efficiency and influencing factors of typical farms: Based on data from 12 corn-producing countries from 2012 to 2019. PLoS ONE 2021, 16, e0254423. [Google Scholar] [CrossRef] [PubMed]

- Gwirtz, J.A.; Garcia-Casal, M.N. Processing maize flour and corn meal food products. Ann. N. Y. Acad. Sci. 2014, 1312, 66–75. [Google Scholar] [CrossRef]

- Rabbani, B.; Safdary, A.J. Effect of sowing date and plant density on yield and yield components of three maize (Zea mays L.) genotypes in Takhar climatic conditions of Afghanistan. Cent. Asian J. Plant Sci. Innov. 2021, 2, 109–120. [Google Scholar] [CrossRef]

- Skowera, B.; Puła, J. Global maize production, utilization, and consumption. Acta Agrophysica 2014, 3, 171–177. [Google Scholar]

- Shiferaw, B.; Prasanna, B.M.; Hellin, J.; Bänziger, M. Crops that feed the world 6. Past successes and future challenges to the role played by maize in global food security. Food Secur. 2011, 3, 307–327. [Google Scholar] [CrossRef]

- Gheith, E.M.S.; El-Badry, O.Z.; Lamlom, S.F.; Ali, H.M.; Siddiqui, M.H.; Ghareeb, R.Y.; El-Sheikh, M.H.; Jebril, J.; Abdelsalam, N.R.; Kandil, E.E. Maize (Zea mays L.) Productivity and Nitrogen Use Efficiency in Response to Nitrogen Application Levels and Time. Front. Plant Sci. 2022, 13, 941343. [Google Scholar] [CrossRef]

- García-Chávez, I.; Meraz-Romero, E.; Castelán-Ortega, O.; Zaragoza-Esparza, J.; Avalos, J.O.; Jiménez, L.E.R.; González-Ronquillo, M. Corn silage, a systematic review of the quality and yield in different regions around the world. Cienc. Tecnol. Agropecu. 2022, 23, 1–23. [Google Scholar] [CrossRef]

- Gul, H.; Rahman, S.; Shahzad, A.; Gul, S.; Qian, M.; Xiao, Q.; Liu, Z. Maize (Zea mays L.) Productivity in Response to Nitrogen Management in Pakistan. Am. J. Plant Sci. 2021, 12, 1173–1179. [Google Scholar] [CrossRef]

- Bogucka, B.; Szempliński, W.; Wróbel, E. Nawożenie azotem a plon kukurydzy uprawianej na ziarno w warunkach północno-wschodniej Polski. Acta Sci. Pol. Agric. 2008, 7, 21–30. [Google Scholar]

- Khan, N.A.; Yu, P.; Ali, M.; Cone, J.W.; Hendriks, W.H. Nutritive value of maize silage in relation to dairy cow performance and milk quality. J. Sci. Food Agric. 2015, 95, 238–252. [Google Scholar] [CrossRef]

- Gołębiewska, M.; Wróbel, E. Nawożenie azotem a plon i jakość roślin kukurydzy z przeznaczeniem na zakiszenie. Biul. Inst. Hod. i Aklim. Roślin 2010, 256, 117–132. [Google Scholar] [CrossRef]

- Szempliński, W.; Bogucka, B.; Wróbel, E. Przydatność mieszańców kukurydzy o zróżnicowanej wczesności do uprawy na kiszonkę w warunkach województwa warmińsko-mazurskiego. Acta Sci. Pol. Agric. 2009, 8, 57–68. [Google Scholar]

- Guyader, J.; Baron, V.S.; Beauchemin, K.A. Corn forage yield and quality for silage in short growing season areas of the canadian prairies. Agronomy 2018, 8, 164. [Google Scholar] [CrossRef]

- Galassi, G.; Malagutti, L.; Rapetti, L.; Crovetto, G.M.; Zanfi, C.; Capraro, D.; Spanghero, M. Digestibility, metabolic utilisation and effects on growth and slaughter traits of diets containing whole plant maize silage in heavy pigs. Ital. J. Anim. Sci. 2017, 16, 122–131. [Google Scholar] [CrossRef]

- Amin, M.E.M.H. Effect of different nitrogen sources on growth, yield and quality of fodder maize (Zea mays L.). J. Saudi Soc. Agric. Sci. 2011, 10, 17–23. [Google Scholar] [CrossRef]

- Bogusz, P. The Possibility of Using Waste Phosphates from the Production of Polyols for Fertilizing Purposes. Molecules 2022, 27, 5632. [Google Scholar] [CrossRef]

- Bogusz, P.; Rusek, P.; Brodowska, M.S. Suspension Fertilizers Based on Waste Phosphates from the Production of Polyols. Molecules 2022, 27, 7916. [Google Scholar] [CrossRef] [PubMed]

- Skowera, B.; Puła, J. Skrajne Warunki Pluwiometryczne w Okresie Wiosennym na Obszarze Polski w Latach 1971-2000. Acta Agrophysica 2004, 3, 171–177. [Google Scholar]

- Rutkowski, J. Technologia Uprawy Kukurydzy–od Siewu do Zbioru; Warmińsko-Mazurski Ośrodek Doradztwa Rolniczego: Olsztyn, Poland, 2018. [Google Scholar]

- Bereś, P.; Mrówczyński, M.; Roślin, I.O. Metodyka Integrowanej Ochrony i Produkcji Kukurydzy dla Doradców: Opracowanie Zbiorowe; Michalski, T., Ed.; Instytut Ochrony Roślin-Państwowy Instytut Badawczy: Poznań, Poland, 2016; ISBN 9788364655234. [Google Scholar]

- Zhao, M.; Feng, Y.; Shi, Y.; Shen, H.; Hu, H.; Luo, Y.; Xu, L.; Kang, J.; Xing, A.; Wang, S.; et al. Yield and quality properties of silage maize and their influencing factors in China. Sci. China Life Sci. 2022, 65, 1655–1666. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Gerbens-Leenes, W. The water footprint of global food production. Water 2020, 12, 2696. [Google Scholar] [CrossRef]

- Ferreira, G.; Brown, A.N.; Ferreira, G.; Brown, A.N. Environmental factors affecting corn quality for silage production. In Advances in Silage Production and Utilization; BoD-Books on Demand: Norderstedt, Germany, 2016; pp. 1–15. [Google Scholar]

- Bereś, P.; Mrówczyński, M.; Korbas, M.; Kierzek, R.; Węgorek, P.; Sulewska, H.; Szulc, P.; Siódmiak, J. Metodyka Integrowanej Ochrony Kukurydzy dla Producentów; Michalski, T., Ed.; Instytut Ochrony Roślin: Poznań, Poland, 2013; ISBN 978-83-89867-97-1. [Google Scholar]

- Sawan, Z.M. Climatic variables: Evaporation, sunshine, relative humidity, soil and air temperature and its adverse effects on cotton production. Inf. Process. Agric. 2018, 5, 134–148. [Google Scholar] [CrossRef]

- Koca, Y.O.; Canavar, Ö. The Effect of Sowing Date on Yield and Yield Components and Seed Quality of Corn (Zea mays L.). 2014; Volume LVII, pp. 227–231. Available online: https://agronomyjournal.usamv.ro/pdf/2014/art40.pdf (accessed on 15 April 2024).

- Kamara, A.Y.; Ekeleme, F.; Chikoye, D.; Omoigui, L.O. Planting date and cultivar effects on grain yield in dryland corn production. Agron. J. 2009, 101, 91–98. [Google Scholar] [CrossRef]

- Testa, G.; Reyneri, A.; Blandino, M. Maize grain yield enhancement through high plant density cultivation with different inter-row and intra-row spacings. Eur. J. Agron. 2016, 72, 28–37. [Google Scholar] [CrossRef]

- Rahmani, A.; Alhossini, M.; Khorasani, S. Effect of Planting Date and Plant Densities on Yield and Yield Components of Sweet Corn (Zea mays L. var saccharata). Am. J. Exp. Agric. 2016, 10, 1–9. [Google Scholar] [CrossRef]

- Sharratt, B.S.; McWilliams, D.A. Microclimatic and rooting characteristics of narrow-row versus conventional-row corn. Agron. J. 2005, 97, 1129–1135. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, X.; Lu, W.; Li, F.; Ma, C. Improved Quality of Corn Silage When Combining Cellulose-Decomposing Bacteria and Lactobacillus buchneri during Silage Fermentation. Biomed Res. Int. 2019, 2019, 4361358. [Google Scholar] [CrossRef]

- Gurmu, S.; Biya, M.; Yadete, E. Effect of NP Fertilizer Rates and Plant Population Density on Late Maturing Maize Variety at Jimma and Buno-Bedele Zone, Southwestern Ethiopia. J. Environ. Earth Sci. 2020, 10, 1–9. [Google Scholar] [CrossRef]

- Ferreira, G.; Alfonso, M.; Depino, S.; Alessandri, E. Effect of planting density on nutritional quality of green-chopped corn for silage. J. Dairy Sci. 2014, 97, 5918–5921. [Google Scholar] [CrossRef]

- Morris, T.F.; Murrell, T.S.; Beegle, D.B.; Camberato, J.J.; Ferguson, R.B.; Grove, J.; Ketterings, Q.; Kyveryga, P.M.; Laboski, C.A.M.; McGrath, J.M.; et al. Strengths and limitations of Nitrogen rate recommendations for corn and opportunities for improvement. Agron. J. 2018, 110, 1–37. [Google Scholar] [CrossRef]

| Basic Composition NPK | 9.5-4-11 | 9.5-6-11 | 0 | ||||||||||

| P, % | 4 | 6 | 0 | ||||||||||

| P source | Waste | Fosdar | Waste | Fosdar | 0 | ||||||||

| Type of fertilizer | NPK | NPK S Mg | NPK S Mg micro | NPK | NPK | NPK S Mg | NPK S Mg micro | NPK | 0 | ||||

| Fertilizer | 1 | 2 | 3 | K2 | 4 | 5 | 6 | K3 | K1 | ||||

| N dose | a b | a b | a b | a b | a b | a b | a b | a b | 0 | ||||

| Years | Months | Avg. | |||||

|---|---|---|---|---|---|---|---|

| IV | V | VI | VII | VIII | IX | ||

| I | 6.4 | 12.6 | 19.7 | 22.3 | 17.3 | 12.8 | 15.2 |

| II | 5.9 | 12.8 | 19.4 | 19.4 | 20.5 | 10.8 | 13.1 |

| III | 8.2 | 12.9 | 17.4 | 20.0 | 21.0 | 17.6 | 16.1 |

| Avg. | 6.8 | 12.8 | 18.8 | 20.6 | 19.6 | 13.7 | |

| Avg. 2011–2020 | 9.5 | 14.4 | 18.5 | 20.1 | 19.7 | 14.7 | |

| Years | Months | Avg. | |||||

|---|---|---|---|---|---|---|---|

| IV | V | VI | VII | VIII | IX | ||

| I | 49.1 | 55.7 | 43.2 | 43.0 | 231.7 | 62.1 | 80.7 |

| II | 53.2 | 36.3 | 38.7 | 111.8 | 52.3 | 112.3 | 67.4 |

| III | 57.9 | 66.0 | 60.0 | 84.7 | 46.4 | 28.5 | 57.3 |

| Avg. | 53.4 | 52.7 | 47.3 | 79.8 | 110.1 | 67.6 | |

| Avg. 2011–2020 | 40.8 | 80.3 | 64.3 | 91.3 | 54.9 | 60.2 | |

| Color Coding | k-Factor Range | Description |

|---|---|---|

| k ≤ 0.4 | Extremely dry conditions | |

| 0.4 < k ≤ 0.7 | Very dry conditions | |

| 0.7 < k ≤ 1.0 | Dry conditions | |

| 1.0 < k ≤ 1.3 | Quite dry conditions | |

| 1.3 < k ≤ 1.6 | Optimal conditions | |

| 1.6 < k ≤ 2.0 | Quite humid conditions | |

| 2.0 < k ≤ 2.5 | Humid conditions | |

| 2.5 < k ≤ 3.0 | Very humid conditions | |

| k > 3.0 | Extremely humid conditions |

| Years | Months | |||||

|---|---|---|---|---|---|---|

| IV | V | VI | VII | VIII | IX | |

| I | 2.56 | 1.43 | 0.73 | 0.62 | 4.32 | 1.62 |

| II | 3.01 | 0.91 | 0.66 | 1.86 | 0.82 | 3.47 |

| III | 2.35 | 1.65 | 1.15 | 1.37 | 0.71 | 0.54 |

| Year | N dose, kg N/ha (C) | Source of Phosphorus in Fertilizer (A) | Control without Fertilization | |||||

|---|---|---|---|---|---|---|---|---|

| Polyol Waste | Fosdar (Control) | |||||||

| Percentage of P (B) | ||||||||

| 4% | 6% | Avg. | 4% | 6% | Avg. | |||

| I | 180 | 24.74 ab | 24.86 ab | 24.80 GH | 25.90 b | 26.13 b | 26.02 H | 19.27 c |

| 135 | 22.87 a | 24.98 ab | 23.93 H | 25.53 b | 25.72 b | 25.63 H | ||

| Avg. | 23.81 G | 24.92 GH | 25.71 H | 25.93 H | ||||

| Avg. | 24.36 G | 25.82 H | ||||||

| A–Ƞ2p = 51.57% B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| II | 180 | 23.41 ab | 23.48 ab | 23.45 G | 23.11 ab | 24.55 b | 23.83 G | 18.52 c |

| 135 | 22.45 a | 24.32 ab | 23.39 G | 22.99 ab | 23.99 ab | 23.49 G | ||

| Avg. | 22.93 G | 23.90 GH | 23.05 G | 24.27 H | ||||

| Avg. | 23.42 G | 23.66 G | ||||||

| A–s.i. B–Ƞ2p = 45.80% | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| III | 180 | 23.98 a | 24.43 a | 24.21 G | 24.80 a | 24.91 a | 24.85 G | 19.31 b |

| 135 | 23.05 a | 24.22 a | 23.64 G | 24.84 a | 25.08 a | 24.96 G | ||

| Avg. | 23.52 G | 24.33 GH | 24.82 GH | 24.99 H | ||||

| Avg. | 23.92 G | 24.91 H | ||||||

| A–Ƞ2p = 32.52% B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| Year | N Dose, kg N/ha (C) | Percentage of P (A) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 4% | 6% | ||||||||

| Type of Fertilizer (B) | |||||||||

| NPK | NPK S Mg | NPK S Mg Micro | Avg. | NPK | NPK S Mg | NPK S Mg Micro | Avg. | ||

| I | 180 | 24.74 ab | 25.71 a | 25.22 ab | 25.22 G | 24.86 ab | 25.14 ab | 25.71 a | 25.24 G |

| 135 | 22.87 b | 24.92 ab | 24.97 ab | 24.25 G | 24.98 ab | 24.67 ab | 25.55 ab | 25.07 G | |

| Avg. | 23.81 G | 25.31 GH | 25.10 GH | 24.92 GH | 24.91 GH | 25.63 H | |||

| Avg. | 24.74 G | 25.15 G | |||||||

| A–s.i. B–Ƞ2p = 26.72% | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| II | 180 | 23.41 a | 24.81 a | 24.08 a | 24.10 G | 23.48 a | 24.21 a | 24.76 a | 24.15 G |

| 135 | 22.45 a | 23.44 a | 24.10 a | 23.33 G | 24.32 a | 24.13 a | 24.44 a | 24.30 G | |

| Avg. | 22.93 G | 24.12 GH | 24.09 GH | 23.90 GH | 24.17 GH | 24.60 H | |||

| Avg. | 23.71 G | 24.22 G | |||||||

| A–s.i. B–Ƞ2p = 26.93% | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| III | 180 | 23.98 a | 23.90 a | 24.53 a | 24.14 GH | 24.43 a | 24.64 a | 25.59 a | 24.89 H |

| 135 | 23.05 a | 24.06 a | 23.30 a | 23.47 G | 24.22 a | 24.51 a | 25.10 a | 24.61 GH | |

| Avg. | 23.52 G | 23.98 GH | 23.91 GH | 24.33 GH | 24.57 GH | 25.35 H | |||

| Avg. | 23.80 G | 24.75 H | |||||||

| A–Ƞ2p = 27.45% B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| Year | N Dose, kg N/ha (C) | Source of Phosphorus in Fertilizer (A) | Control without Fertilization | |||||

|---|---|---|---|---|---|---|---|---|

| Polyol Waste | Fosdar (Control) | |||||||

| Percentage of P (B) | ||||||||

| 4% | 6% | Avg. | 4% | 6% | Avg. | |||

| I | 180 | 283.71 b | 280.67 ab | 282.19 GH | 287.42 b | 285.71 b | 286.56 H | 256.75 c |

| 135 | 272.29 a | 285.29 b | 278.79 G | 285.38 b | 282.54 ab | 283.96 GH | ||

| Avg. | 278.00 G | 282.98 GH | 286.40 H | 284.13 GH | ||||

| Avg. | 280.49 G | 285.26 H | ||||||

| A–Ƞ2p = 4.02% B–s.i.* | C–s.i. | A × B–Ƞ2p = 2.36% A × C–s.i. | B × C–Ƞ2p = 2.49% A × B × C–Ƞ2p = 3.28% | |||||

| II | 180 | 274.04 ab | 279.88 abc | 276.96 GH | 284.38 bc | 281.67 abc | 283.02 G | 254.38 d |

| 135 | 273.04 a | 273.38 ab | 273.21 H | 281.38 abc | 286.13 c | 283.75 G | ||

| Avg. | 273.45 G | 276.63 GH | 282.88 HI | 283.90 I | ||||

| Avg. | 275.08 G | 283.39 H | ||||||

| A–Ƞ2p = 9.13% B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| III | 180 | 272.21 a | 274.08 a | 273.15 G | 274.38 a | 278.17 a | 276.27 G | 243.08 b |

| 135 | 273.57 a | 275.29 a | 274.48 G | 276.83 a | 278.50 a | 277.67 G | ||

| Avg. | 272.94 G | 274.69 G | 275.60 G | 278.33 G | ||||

| Avg. | 273.81 G | 276.97 G | ||||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| Year | N Dose, kg N/ha (C) | Percentage of P (A) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 4% | 6% | ||||||||

| Type of Fertilizer (B) | |||||||||

| NPK | NPK S Mg | NPK S Mg Micro | Avg. | NPK | NPK S Mg | NPK S Mg Micro | Avg. | ||

| I | 180 | 283.71 a | 285.88 a | 287.92 a | 285.83 H | 280.67 ab | 283.87 a | 287.88 a | 284.14 GH |

| 135 | 272.29 b | 283.88 a | 287.75 a | 281.31 H | 285.29 a | 284.58 a | 286.50 a | 285.46 GH | |

| Avg. | 278.00 G | 284.88 H | 287.83 H | 282.98 GH | 284.23 H | 287.19 H | |||

| Avg. | 283.57 G | 284.80 G | |||||||

| A–s.i. B–Ƞ2p = 7.68% | C–s.i. | A × B–s.i. A × C–Ƞ2p = 2.10% | B × C–s.i. A × B × C–Ƞ2p = 3.31% | ||||||

| II | 180 | 274.00 ac | 280.71 abcd | 285.29 abd | 280.55 G | 279.88 abcd | 284.71 abd | 285.79 bd | 283.46 G |

| 135 | 273.04 c | 276.25 abc | 275.67 abc | 274.99 H | 273.38 c | 287.21 d | 284.71 abd | 281.76 G | |

| Avg. | 273.54 G | 278.48 GH | 280.48 HI | 276.63 GH | 285.96 I | 285.25 I | |||

| Avg. | 277.50 G | 282.61 H | |||||||

| A–Ƞ2p = 4.87% B–Ƞ2p = 8.87% | C–Ƞ2p = 2.16% | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| III | 180 | 272.21 a | 283.04 abc | 280.67 abc | 278.64 G | 274.08 ab | 286.13 abc | 288.83 c | 283.01 G |

| 135 | 273.67 ab | 275.67 abc | 282.50 abc | 277.28 G | 275.29 abc | 282.63 abc | 287.17 bc | 281.69 G | |

| Avg. | 278.94 G | 279.35 GHI | 281.58 HIJ | 274.69 GH | 284.38 IJ | 288.00 J | |||

| Avg. | 277.96 G | 282.35 H | |||||||

| A–Ƞ2p = 2.26% B–Ƞ2p = 9.34% | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| Year | N Dose, kg N/ha (C) | Source of Phosphorus in Fertilizer (A) | Control without Fertilization | |||||

|---|---|---|---|---|---|---|---|---|

| Polyol Waste | Fosdar (Control) | |||||||

| Percentage of P (B) | ||||||||

| 4% | 6% | Avg. | 4% | 6% | Avg. | |||

| I | 180 | 45.37 a | 45.68 a | 45.52 G | 44.97 a | 45.02 a | 44.99 G | 38.21 b |

| 135 | 45.60 a | 45.07 a | 45.34 G | 45.04 a | 45.81 a | 45.43 G | ||

| Avg. | 45.48 G | 45.38 G | 45.39 G | 45.03 G | ||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| II | 180 | 45.75 ab | 45.67 ab | 45.71 G | 47.91 b | 46.59 b | 47.25 G | 38.58 a |

| 135 | 45.99 ab | 46.23 ab | 46.11 G | 46.83 b | 44.95 ab | 45.89 G | ||

| Avg. | 45.87 G | 45.95 G | 47.37 G | 45.77 G | ||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| III | 180 | 45.43 a | 44.86 a | 45.15 AG | 45.47 a | 46.16 a | 45.81 G | 36.97 b |

| 135 | 45.36 a | 47.44 a | 46.40 G | 47.22 a | 45.45 | 46.34 G | ||

| Avg. | 45.39 G | 46.15 G | 46.35 G | 45.80 G | ||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| Year | N Dose, kg N/ha (C) | Percentage of P (A) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 4% | 6% | ||||||||

| Type of Fertilizer (B) | |||||||||

| NPK | NPK S Mg | NPK S Mg Micro | Avg. | NPK | NPK S Mg | NPK S Mg Micro | Avg. | ||

| I | 180 | 45.37 a | 46.21 a | 45.74 a | 45.77 G | 45.68 a | 46.05 a | 45.11 a | 45.61 G |

| 135 | 45.60 a | 45.34 a | 45.40 a | 45.45 G | 45.07 a | 46.20 a | 45.19 a | 45.49 G | |

| Avg. | 45.48 G | 45.77 G | 45.57 G | 45.38 G | 46.13 G | 45.15 G | |||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| II | 180 | 45.75 a | 45.20 a | 48.59 a | 46.51 G | 45.67 a | 46.83 a | 48.27 a | 46.92 G |

| 135 | 45.99 a | 45.38 a | 45.19 a | 45.52 G | 46.23 a | 45.38 a | 46.10 a | 45.90 G | |

| Avg. | 45.87 G | 45.29 G | 46.89 G | 45.95 G | 46.10 G | 47.18 G | |||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| III | 180 | 45.43 a | 46.76 a | 44.79 a | 45.66 G | 44.86 a | 44.80 a | 46.20 a | 45.29 G |

| 135 | 45.36 a | 46.18 a | 45.75 a | 45.76 G | 47.44 a | 45.30 a | 46.67 a | 46.47 G | |

| Avg. | 45.39 G | 46.47 G | 45.27 G | 46.15 G | 45.05 G | 46.43 G | |||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| Year | N Dose, kg N/ha (C) | Source of Phosphorus in Fertilizer (A) | Control without Fertilization | |||||

|---|---|---|---|---|---|---|---|---|

| Polyol Waste | Fosdar (Control) | |||||||

| Percentage of P (B) | ||||||||

| 4% | 6% | Avg. | 4% | 6% | Avg. | |||

| I | 180 | 1.63 a | 1.83 a | 1.73 G | 1.79 a | 1.67 a | 1.73 G | 1.71 a |

| 135 | 1.67 a | 1.83 a | 1.75 G | 1.75 a | 1.88 a | 1.81 G | ||

| Avg. | 1.65 G | 1.83 G | 1.77 G | 1.77 G | ||||

| Avg. | 1.74 G | 1.77 H | ||||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i A × B × C–s.i. | |||||

| II | 180 | 1.50 a | 1.54 a | 1.52 G | 1.75 a | 1.79 a | 1.77 GH | 1.58 a |

| 135 | 1.83 a | 1.83 a | 1.83 H | 1.67 a | 1.63 a | 1.65 GH | ||

| Avg. | 1.67 G | 1.69 G | 1.71 G | 1.71 G | ||||

| Avg. | 1.68 G | 1.71 G | ||||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–Ƞ2p = 4.97% | B × C–s.i. A × B × C–s.i. | |||||

| III | 180 | 1.58 a | 1.33 a | 1.46 G | 1.46 a | 1.50 a | 1.48 G | 1.25 a |

| 135 | 1.33 a | 1.25 a | 1.29 G | 1.67 a | 1.33 a | 1.50 G | ||

| Avg. | 1.46 GH | 1.29 G | 1.56 H | 1.42 GH | ||||

| Avg. | 1.38 G | 1.49 G | ||||||

| A–s.i. B–Ƞ2p = 2.58% | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | |||||

| Year | N Dose, kg N/ha (C) | Percentage of P (A) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 4% | 6% | ||||||||

| Type of Fertilizer (B) | |||||||||

| NPK | NPK S Mg | NPK S Mg Micro | Avg. | NPK | NPK S Mg | NPK S Mg Micro | Avg. | ||

| I | 180 | 1.63 a | 1.67 a | 1.71 a | 1.67 G | 1.83 a | 1.88 a | 1.88 a | 1.86 G |

| 135 | 1.67 a | 1.79 a | 1.75 a | 1.74 G | 1.83 a | 1.67 a | 1.71 a | 1.74 G | |

| Avg. | 1.65 G | 1.73 G | 1.73 G | 1.83 G | 1.77 G | 1.79 G | |||

| Avg. | 1.70 G | 1.80 G | |||||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| II | 180 | 1.50 a | 1.67 a | 1.71 a | 1.62 G | 1.54 a | 1.67 a | 1.83 a | 1.68 G |

| 135 | 1.83 a | 1.46 a | 1.58 a | 1.63 G | 1.83 a | 1.63 a | 1.88 a | 1.78 G | |

| Avg. | 1.67 GH | 1.56 G | 1.65 GH | 1.69 GH | 1.65 GH | 1.85 H | |||

| Avg. | 1.63 G | 1.73 G | |||||||

| A–s.i. B–s.i. | C–Ƞ2p = 2.16% | A × B–s.i. A × C–s.i. | B × C–Ƞ2p = 3.69% A × B × C–s.i. | ||||||

| III | 180 | 1.58 ab | 1.38 ab | 1.78 b | 1.56 H | 1.33 ab | 1.17 a | 1.21 a | 1.24 H |

| 135 | 1.33 ab | 1.50 ab | 1.75 b | 1.53 H | 1.25 a | 1.50 ab | 1.33 ab | 1.36 GH | |

| Avg. | 1.46 GH | 1.44 G | 1.73 H | 1.29 G | 1.33 G | 1.27 G | |||

| Avg. | 1.30 G | 1.54 H | |||||||

| A–Ƞ2p = 6.55% B–s.i. | C–s.i. | A × B–Ƞ2p = 2.75% A × C–s.i. | B × C–Ƞ2p = 3.07% A × B × C–s.i. | ||||||

| Year | N Dose, kg N/ha (C) | Source of Phosphorus in Fertilizer (A) | Control without Fertilization | |||||

|---|---|---|---|---|---|---|---|---|

| Polyol Waste | Fosdar (Control) | |||||||

| Percentage of P (B) | ||||||||

| 4% | 6% | Avg. | 4% | 6% | Avg. | |||

| I | 180 | 14.33 ab | 13.83 ab | 14.08 G | 13.88 ab | 14.79 b | 14.33 G | 13.71 ab |

| 135 | 14.38 ab | 13.96 ab | 14.17 G | 14.13 ab | 13.33 a | 13.73 G | ||

| Avg. | 14.35 G | 13.90 G | 14.00 G | 14.06 G | ||||

| Avg. | 14.13 G | 14.03 G | ||||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–Ƞ2p = 1.91% A × B × C–Ƞ2p = 2.31% | |||||

| II | 180 | 14.13 a | 14.88 ab | 14.50 G | 14.83 ab | 15.33 ab | 15.08 G | 15.08 ab |

| 135 | 14.58 ab | 15.00 ab | 14.79 G | 15.71 b | 14.83 ab | 15.27 G | ||

| Avg. | 14.35 G | 14.94 GH | 15.27 H | 15.08 GH | ||||

| Avg. | 14.65 G | 15.18 H | ||||||

| A–Ƞ2p = 2.58% B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–Ƞ2p = 2.14% A × B × C–s.i. | |||||

| III | 180 | 13.96 ab | 14.29 abc | 14.13 G | 15.13 c | 14.67 abc | 14.90 H | 14.63 abc |

| 135 | 14.92 bc | 13.67 a | 14.29 GH | 14.46 abc | 14.54 abc | 14.50 GH | ||

| Avg. | 14.44 GH | 13.98 G | 14.79 H | 14.60 GH | ||||

| Avg. | 14.21 G | 14.70 H | ||||||

| A–Ƞ2p = 3.36% B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–Ƞ2p = 3.94% | |||||

| Year | N Dose, kg N/ha (C) | Percentage of P (A) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 4% | 6% | ||||||||

| Type of Fertilizer (B) | |||||||||

| NPK | NPK S Mg | NPK S Mg Micro | Avg. | NPK | NPK S Mg | NPK S Mg Micro | Avg. | ||

| I | 180 | 14.33 ab | 14.50 ab | 13.96 ab | 14.26 G | 13.83 a | 14.63 ab | 15.21 b | 14.56 G |

| 135 | 14.38 ab | 14.29 ab | 14.38 ab | 14.35 G | 13.96 ab | 14.54 ab | 14.54 ab | 14.35 G | |

| Avg. | 14.35 GH | 14.40 GH | 14.17 GH | 13.90 G | 14.58 GH | 14.87 H | |||

| Avg. | 14.31 G | 14.45 G | |||||||

| A–s.i. B–s.i. | C–s.i. | A × B–Ƞ2p = 3.17% A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| II | 180 | 14.13 a | 15.00 a | 14.92 a | 14.68 G | 14.88 a | 14.58 a | 14.08 a | 14.51 G |

| 135 | 14.58 a | 14.75 a | 14.92 a | 14.75 G | 15.00 a | 14.75 a | 14.33 a | 14.69 G | |

| Avg. | 14.35 G | 14.88 G | 14.92 G | 14.94 G | 14.67 G | 14.21 G | |||

| Avg. | 14.72 G | 14.60 G | |||||||

| A–s.i. B–s.i. | C–s.i. | A × B–Ƞ2p = 3.83% A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

| III | 180 | 13.96 a | 14.08 a | 14.38 a | 14.14 G | 14.29 a | 14.46 a | 13.92 a | 14.22 G |

| 135 | 14.92 a | 14.38 a | 14.67 a | 14.65 G | 13.67 a | 14.46 a | 14.38 a | 14.17 G | |

| Avg. | 14.44 G | 14.23 G | 14.52 G | 13.98 G | 14.46 G | 14.15 G | |||

| Avg. | 14.40 G | 14.19 G | |||||||

| A–s.i. B–s.i. | C–s.i. | A × B–s.i. A × C–s.i. | B × C–s.i. A × B × C–s.i. | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogusz, P.; Brodowska, M.S.; Rusek, P. The Impact of Suspension Fertilizers Based on Waste Phosphorus Salts from Polyol Production on the Yield of Maize Intended for Green Fodder. Agronomy 2024, 14, 1054. https://doi.org/10.3390/agronomy14051054

Bogusz P, Brodowska MS, Rusek P. The Impact of Suspension Fertilizers Based on Waste Phosphorus Salts from Polyol Production on the Yield of Maize Intended for Green Fodder. Agronomy. 2024; 14(5):1054. https://doi.org/10.3390/agronomy14051054

Chicago/Turabian StyleBogusz, Paulina, Marzena Sylwia Brodowska, and Piotr Rusek. 2024. "The Impact of Suspension Fertilizers Based on Waste Phosphorus Salts from Polyol Production on the Yield of Maize Intended for Green Fodder" Agronomy 14, no. 5: 1054. https://doi.org/10.3390/agronomy14051054