Study on the Mechanism of Carbon Dioxide Miscible Fracturing Fluid Huff and Puff in Enhanced Oil Recovery

Abstract

1. Introduction

2. Experiment

2.1. Experimental Materials

- ①

- Oil sample: The crude oil utilized originated from the wellhead of the G fault block reservoir within the J Oilfield. Specifically, we employed a high-temperature, high-pressure sampler to separate the oil and water. Representative live oil samples were then established at 113.8 °C and 33 MPa by recombining the oil and gas samples according to the formation gas components and the production gas–oil ratio. The components of the gas were as follows: CH4 66.78%, C2H6 12.57%, C3H8 10.14%, C4H10 3.51%, CO2 5.01%, and N2 1.99%. Notably, the gas-to-oil ratio of this simulated crude oil stood at 91.2 m3/m3.

- ②

- Gas injected: CO2 gas with a purity of 99.999% was used.

- ③

- Fracturing fluid additives: The solubilizers and viscosity reducers employed belonged to the fracturing fluid series additives that are routinely used on site within the target reservoir. These additives were developed by the Oil Production Technology Research Institute of the Great Wall Drilling Engineering Technology Research Institute based on the fluid properties and reservoir characteristics of the G fault block within the J Oilfield. The concentration dosage for these additives was set to 10%.

- ④

- Slim tube: A slim tube with a length of 15 m and a diameter of 4.4 mm was used; this exhibited a permeability of 5800 mD and possessed a pore volume of 84.2 mL.

- ⑤

- Water: The water employed in this study was sourced directly from the target oil reservoir site. Prior to the experimentation, it underwent filtration using a 0.45 μm filter membrane, facilitated through a sand core funnel.

- ⑥

- Core: The core specimens utilized consisted of natural rock samples generously supplied by J OilField, China. These cores exhibited a permeability range spanning from 4 to 40 mD, and their additional properties are shown in Table 1.

2.2. Experimental Design

2.2.1. Experiment on Gas Injection Expansion

- ①

- Add a specified quantity of simulated crude oil into the PVT cylinder. Then, elevate the temperature and pressure to match the reservoir conditions. Precisely measure the resulting oil sample volume. Following this, perform degassing experiments to ascertain both the gas–oil ratio and the volume coefficient of the oil.

- ②

- Employ the stepwise pressure reduction method to establish the p–V relationship for the oil sample. At each stable pressure reduction stage, record the corresponding sample volume values. These data points collectively form the p–V relationship curve. The inflection point on this curve corresponds to the bubble point pressure.

- ③

- First, compute the required quantity of injected gas (ranging from 10 mol% to 60 mol%) for each stage, considering the composition of the original oil sample. Then, introduce CO2 gas into the PVT cylinder and pressurize it beyond the bubble point pressure. Agitate the sample thoroughly to achieve fluid uniformity. Next, execute the procedures outlined in ② to establish the corresponding p–V relationship curve. Calculate the essential properties, including the saturation pressure, density, and volume coefficient. Finally, employ a high-temperature and high-pressure formation fluid viscometer to measure viscosity.

- ④

- Following the gas injection experiment, reintroduce a specific quantity of simulated crude oil into the PVT cylinder after meticulously cleaning the latter. Additionally, incorporate 0.1 PV of fracturing fluid additives. Subsequently, replicate the procedures outlined in steps ① to ③. Observe and quantify the alterations in the high-pressure physical properties of the oil as well as the characteristic behavior of gas injection expansion.

2.2.2. Experiment on Minimum Miscibility Pressure

- ①

- Saturate the slim tube with dead oil under experimental temperature and pressure and accurately measure the pore volume (volume entering the pump).

- ②

- Displace dead oil within the thin tube with live oil until the produced gas–oil ratio at the outlet end matches that of the simulated oil.

- ③

- Displace the live oil with CO2 gas at a constant rate and continue the injection process until 1.2 PV of gas is injected. Throughout this phase, record the amount of crude oil produced for every 0.1 PV of CO2 injected. Subsequently, calculate the corresponding degree of oil reserve recovery. Plot the relationship between the degree of reserve recovery and the amount of CO2 injected.

- ④

- Evaluate both the degree of reserve recovery and final recovery efficiency after changing the pressure and repeating the above steps. Specifically, the set experimental pressure should cover no fewer than three points when the final recovery efficiency is greater than 90% or less than 90%. Finally, plot the relationship between recovery efficiency and pressure. For trend lines of scatter points greater than and less than a 90% recovery efficiency, the pressure corresponding to the intersection is the MMP.

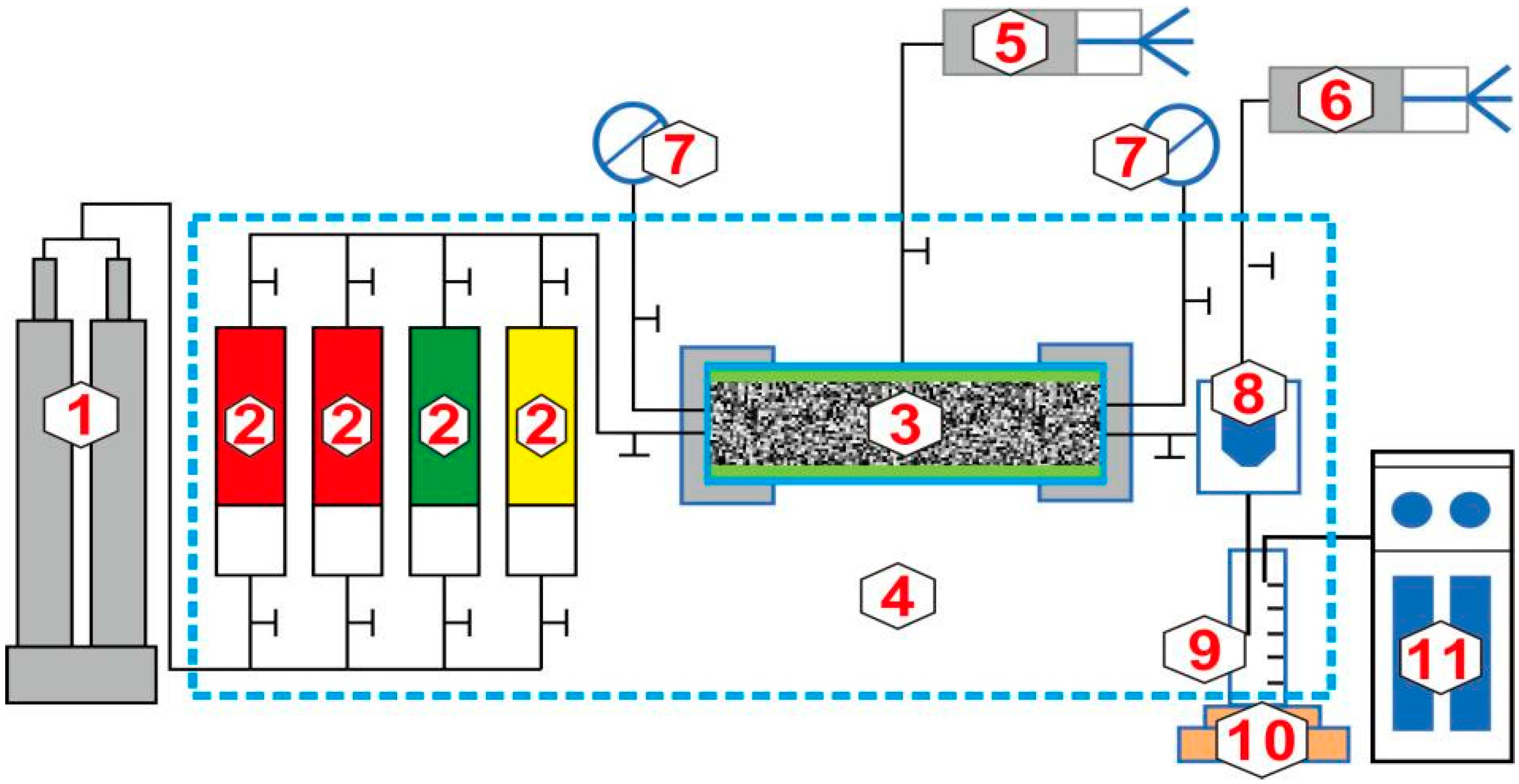

2.2.3. Experiment on CO2 Miscible Fracturing Huff and Puff

- ①

- Evacuate and pressurize the core to achieve formation water saturation. Next, prepare the core by introducing bound water using a gas-driving method. Determine the core’s irreducible water saturation through weight measurements before and after gas driving.

- ②

- Create a single-through fracture by splitting the core, thus mimicking the fracturing characteristics of the reservoir. Subsequently, load the core into the core holder and saturate it with dead oil.

- ③

- Displace the dead oil with live oil until the gas–oil ratio at the outlet matches that of the live oil, and then perform aging.

- ④

- Inject 0.1 PV of the fracturing fluid additive at a low flow rate and formation temperature. Then, displace the oil continuously with CO2 until the pressure reaches 55 MPa. Shut in the well after closing the valve and reopen it after the specified shut-in time. Gradually reduce the pressure by adjusting the back-pressure valve. Throughout this process, record the oil and gas production to evaluate recovery efficiency.

3. Experimental Results and Analysis

3.1. Mechanism of Oil Production Increase

3.1.1. Interaction between CO2 and Crude Oil

3.1.2. Minimum Miscibility Pressure

3.2. Effect of Huff and Puff

3.2.1. Impact of Fracturing Fluid Additives

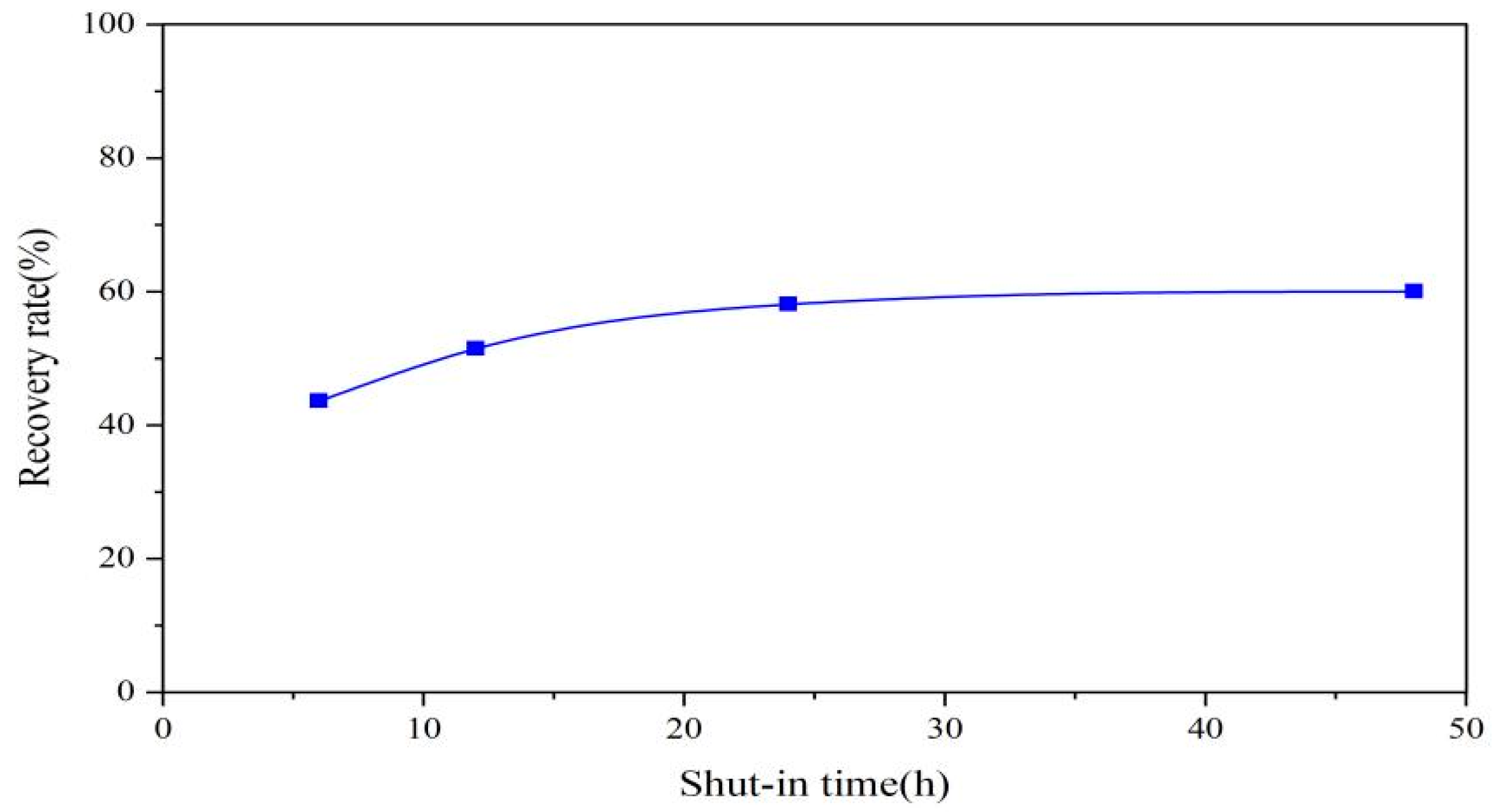

3.2.2. Impact of Shut-in Time

3.2.3. Impact of Permeability

3.2.4. Impact of Huff-and-Puff Patterns

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Y.; Fan, G.; Song, K.; Li, Y.; Chen, H.; Sun, H. The experimental research for reducing the minimum miscibility pressure of carbon dioxide miscible flooding. Renew. Sustain. Energy Rev. 2021, 145, 111091. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, T.; Pu, W.; Du, D.; Chen, Q.; Chen, B.; Li, J.; Huang, Y. Application status and research progress of CO2 fracturing fluid in petroleum engineering: A brief review. Petroleum 2024, 10, 1–10. [Google Scholar] [CrossRef]

- Torabi, F.; Firouz, A.Q.; Kavousi, A.; Asghari, K. Comparative evaluation of immiscible, near miscible and miscible CO2 huff-n-puff to enhance oil recovery from a single matrix-fracture system(experimental and simulation studies). Fuel 2012, 93, 443–453. [Google Scholar] [CrossRef]

- Rezk, M.G.; Foroozesh, J.; Zivar, D.; Mumtaz, M. CO2 storage potential during CO2 enhanced oil recovery in sandstone reservoirs. J. Nat. Gas Sci. Eng. 2019, 66, 233–243. [Google Scholar] [CrossRef]

- Seyyedi, M.; Sohrabi, M. Assessing the feasibility of improving the performance of CO2 and CO2–WAG injection scenarios by CWI. Ind. Eng. Chem. Res. 2018, 57, 11617–11624. [Google Scholar] [CrossRef]

- Johns, R.T.; Orr, F.M., Jr. Miscible gas displacement of multicomponent oils. SPE J. 1996, 1, 39–50. [Google Scholar] [CrossRef]

- Zhang, A.; Fan, Z.; Zhao, L. An investigation on phase behaviors and displacement mechanisms of gas injection in gas condensate reservoir. Fuel 2020, 268, 117373. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, M.; You, Q.; Fan, H.; Li, W.; Liu, Y.; Fang, J.; Zhao, G.; Jin, Z.; Dai, C. Smart mobility control agent for enhanced oil recovery during CO2 flooding in ultra-low permeability reservoirs. Fuel 2019, 241, 442–450. [Google Scholar] [CrossRef]

- Sambo, C.; Liu, N.; Shaibu, R.; Ahmed, A.A.; Hashish, R.G. A technical review of CO2 for enhanced oil recovery in unconventional oil reservoirs. J. Pet. Sci. Eng. 2023, 221, 111185. [Google Scholar] [CrossRef]

- Shi, Y.; Wu, B.; Wang, H.; Li, Y.; Liu, Z.; Xu, C.; Qin, J.; Li, Y.; Song, Z.; Liu, H. Insights into CO2 huff-n-puff mechanisms from laboratory experiment and single-well pilot test in the Lucaogou tight oil reservoir, Jimsar sag, China. Geoenergy Sci. Eng. 2024, 232, 212456. [Google Scholar] [CrossRef]

- Kalam, S.; Afagwu, C.; Al Jaberi, J.; Siddig, O.M.; Tariq, Z.; Mahmoud, M.; Abdulraheem, A. A review on non-aqueous fracturing techniques in unconventional reservoirs. J. Nat. Gas Sci. Eng. 2021, 95, 104223. [Google Scholar] [CrossRef]

- Wu, J.; Liu, B.; Liu, D.; Wang, C.; Li, Y.; Liu, G. Test of CO2 miscible fracturing and huff and puff. Spec. Oil Gas Reserv. 2022, 29, 126–131. [Google Scholar] [CrossRef]

- Bai, Z.; Song, K.; Fu, H.; Shi, Y.; Liu, Y.; Chen, Z. Effect of viscosity and heterogeneity on dispersion in porous media during miscible flooding processes. Adv. Geo-Energy Res. 2022, 6, 460–471. [Google Scholar] [CrossRef]

- Cai, M.; Su, Y.; Hao, Y.; Guo, Y.; Elsworth, D.; Li, L.; Li, D.; Li, X. Monitoring oil displacement and CO2 trapping in low-permeability media using NMR: A comparison of miscible and immiscible flooding. Fuel 2021, 305, 121606. [Google Scholar] [CrossRef]

- Kumar, N.; Sampaio, M.A.; Ojha, K.; Hoteit, H.; Mandal, A. Fundamental aspects, mechanisms and emerging possibilities of CO2 miscible flooding in enhanced oil recovery: A review. Fuel 2022, 330, 125633. [Google Scholar] [CrossRef]

- Lv, W.; Gong, H.; Dong, M.; Li, Y.; Sun, H.; Sun, Z.; Jiang, H. Potential of nonionic polyether surfactant-assisted CO2 huff-n-puff for enhanced oil recovery and CO2 storage in ultra-low permeability unconventional reservoirs. Fuel 2024, 359, 130474. [Google Scholar] [CrossRef]

- Wang, T.; Wang, L.; Meng, X.; Chen, Y.; Song, W.; Yuan, C. Key parameters and dominant EOR mechanism of CO2 miscible flooding applied in low-permeability oil reservoirs. Geoenergy Sci. Eng. 2023, 225, 211724. [Google Scholar] [CrossRef]

- Li, S.; Zhu, J.; Wang, Z.; Li, M.; Wei, Y.; Zhang, K. Chemical strategies for enhancing CO2-hydrocarbon miscibility. Sep. Purif. Technol. 2024, 337, 126436. [Google Scholar] [CrossRef]

- Alharthy, N.; Teklu, T.W.; Kazemi, H.; Graves, R.M.; Hawthorne, S.B.; Braunberger, J.; Kurtoglu, B. Enhanced oil recovery in liquid-rich shale reservoirs: Laboratory to field. SPE Reserv. Eval. Eng. 2017, 21, 137–159. [Google Scholar] [CrossRef]

- Wei, B.; Zhong, M.; Gao, K.; Li, X.; Zhang, X.; Cao, J.; Lu, J. Oil recovery and composition change of CO2 huff-n-puff and continuous injection modes in a variety of dual-permeability tight matrix-fracture models. Fuel 2020, 276, 117939. [Google Scholar] [CrossRef]

- Bai, H.; Zhang, Q.; Li, Z.; Li, B.; Zhu, D.; Zhang, L.; Lv, G. Effect of fracture on production characteristics and oil distribution during CO2 huff-n-puff under tight and lowpermeability conditions. Fuel 2019, 246, 117–125. [Google Scholar] [CrossRef]

- Yang, M.; Huang, S.; Zhao, F.; Sun, H.; Chen, X. Experimental investigation of CO2 huff-n-puff in tight oil reservoirs: Effects of the fracture on the dynamic transport characteristics based on the nuclear magnetic resonance and fractal theory. Energy 2024, 294, 130781. [Google Scholar] [CrossRef]

- GB/T 26981-2020; Analysis Method for Reservoir Fluid Physical Properties. State Administration for Market Regulation: Beijing, China, 2020.

- SY/T 6573-2016; Measurement Method for Minimum Miscibility Pressure by Slim Tube Test. National Energy Administration: Beijing, China, 2016.

- Su, Y.; Wang, C.; Li, L.; Hou, Z.; Fan, L.; Chen, Z. Behavior of CO2 pre-fracturing fluid in tight reservoir. Sci. Technol. Eng. 2021, 21, 3076–3081. [Google Scholar]

| Core | Length (cm) | Diameter (cm) | Permeability (mD) | Porosity (%) | Injection Medium | Shut-In Time | Huff-and-Puff Mode |

|---|---|---|---|---|---|---|---|

| 1-1 | 9.454 | 2.523 | 39.42 | 19.72 | CO2 + solubilizer | 6 | Same well |

| 1-2 | 9.835 | 2.525 | 38.58 | 19.27 | 12 | ||

| 1-3 | 9.637 | 2.521 | 39.15 | 19.31 | 24 | ||

| 1-4 | 9.646 | 2.523 | 38.97 | 18.96 | 48 | ||

| 2-1 | 9.832 | 2.520 | 11.85 | 17.02 | CO2 | 12 | Same well |

| 2-2 | 9.994 | 2.521 | 11.25 | 17.25 | CO2 + solubilizer | ||

| 2-3 | 9.705 | 2.522 | 11.48 | 17.31 | |||

| 2-4 | 9.924 | 2.523 | 12.07 | 17.59 | Different well | ||

| 3-1 | 9.841 | 2.532 | 4.54 | 12.72 | Same well |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Wang, C.; Gao, B.; Wang, T. Study on the Mechanism of Carbon Dioxide Miscible Fracturing Fluid Huff and Puff in Enhanced Oil Recovery. Processes 2024, 12, 1019. https://doi.org/10.3390/pr12051019

Xu S, Wang C, Gao B, Wang T. Study on the Mechanism of Carbon Dioxide Miscible Fracturing Fluid Huff and Puff in Enhanced Oil Recovery. Processes. 2024; 12(5):1019. https://doi.org/10.3390/pr12051019

Chicago/Turabian StyleXu, Shijing, Changquan Wang, Bin Gao, and Tiezheng Wang. 2024. "Study on the Mechanism of Carbon Dioxide Miscible Fracturing Fluid Huff and Puff in Enhanced Oil Recovery" Processes 12, no. 5: 1019. https://doi.org/10.3390/pr12051019

APA StyleXu, S., Wang, C., Gao, B., & Wang, T. (2024). Study on the Mechanism of Carbon Dioxide Miscible Fracturing Fluid Huff and Puff in Enhanced Oil Recovery. Processes, 12(5), 1019. https://doi.org/10.3390/pr12051019