Research on Slurry Flowability and Mechanical Properties of Cemented Paste Backfill: Effects of Cement-to-Tailings Mass Ratio and Mass Concentration

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

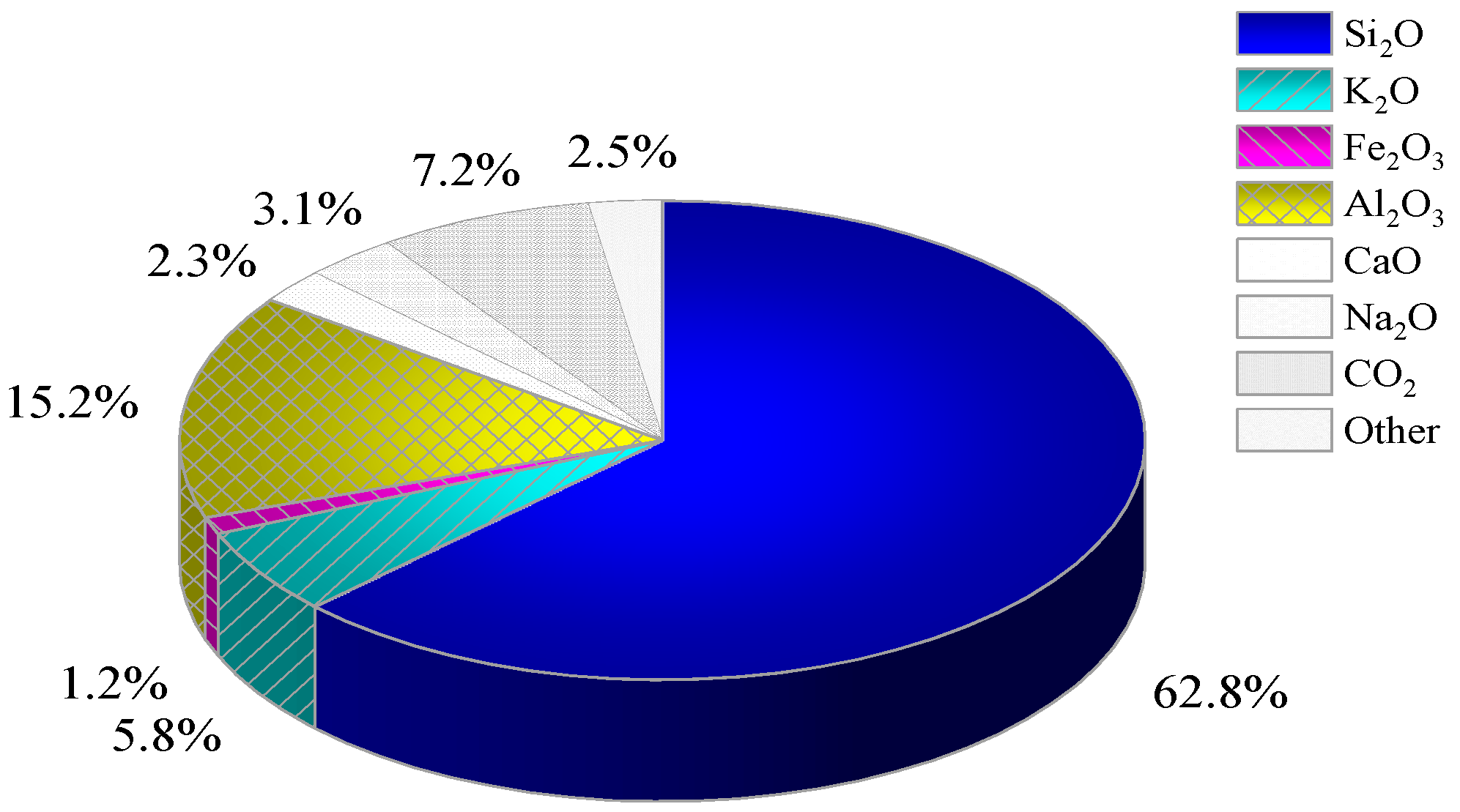

2.1.1. Filling Aggregate

2.1.2. Cementitious Material

2.1.3. Mixing Water

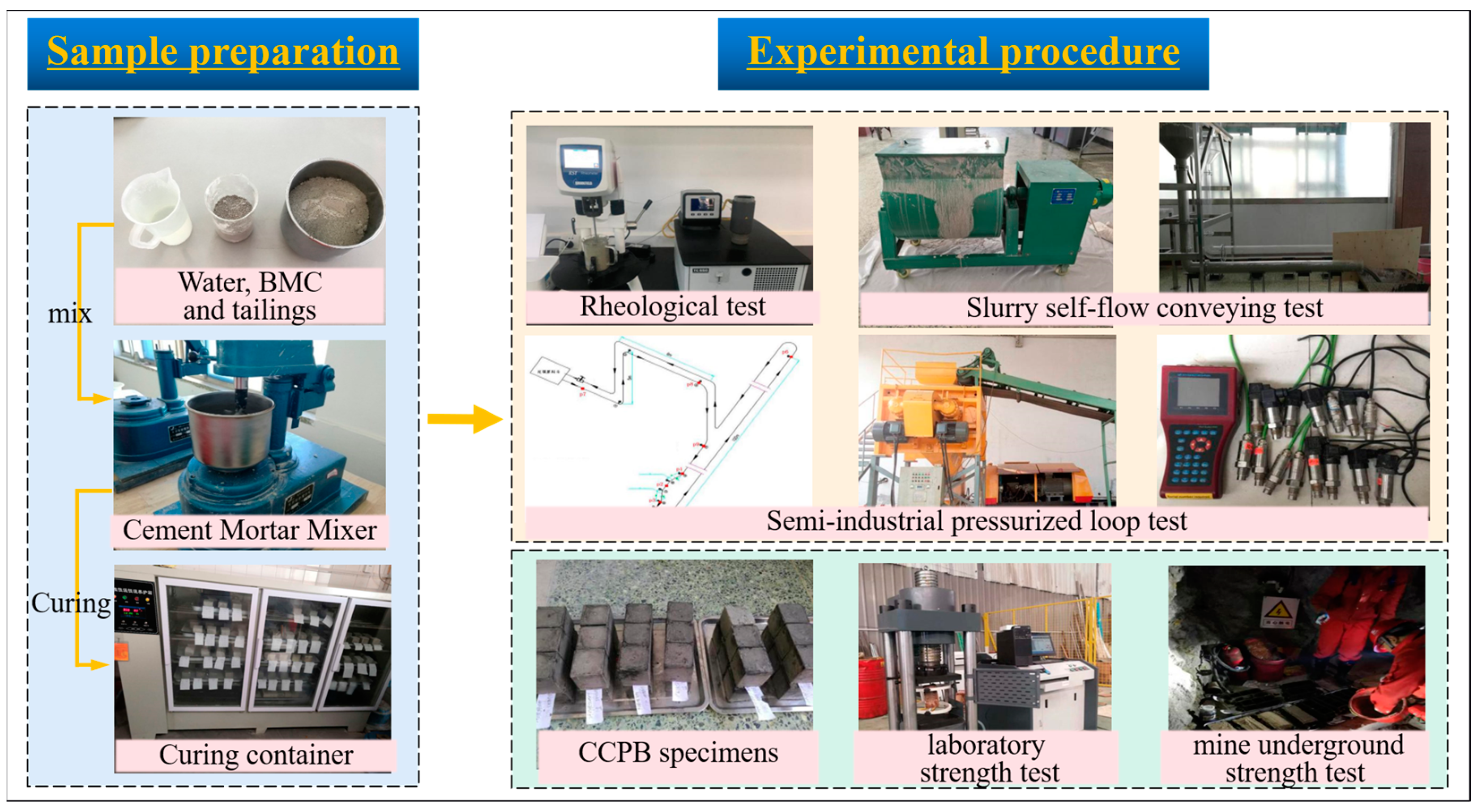

2.2. Sample Preparation

2.3. Experimental Procedure

2.3.1. Filling Slurry Transportation Test

- Rheological testing: The rheological characterization of total tailings paste was carried out with a variable shear method to obtain the rheological parameters of the total tailings paste. The CSR mode of the rheometer was selected for the test, and the maximum shear rate was 100 s−1. Considering the dynamic equilibrium state of the slurry during the test process, the test was set for a certain time (1200 s) of constant shear. The specific loading path was that the shear rate was incremented from 0 s−1 to 100 s−1, then decremented to 0 s−1 after the shear rate was steady at 100 s−1.

- L-pipe self-flow test: A small-scale simulation test for L-type pipeline transportation was conducted according to a certain c/t ratio and mass concentration. The filling slurry was thoroughly mixed and poured into the upper hopper. Utilizing gravity, the slurry flowed downward through the L-type pipeline, which was connected to the hopper, and exited from the lower outlet. The vertical pipe height was h = 1.05 m; the horizontal pipe length was L = 2 m; the inner diameter of the pipeline was D = 0.1 m. By measuring the height of the stationary slurry column and other values, we could calculate the flow rate of the slurry transportation, the yield stress, the plastic viscosity coefficient, the shear stress of the wall of the pipe, the stowing gradient, and other related parameters.

- Semi-industrial loop test: The semi-industrial loop system simulates the filling slurry pipeline arrangement of the mine. It tests the pipeline pressure loss and flow properties of different mass concentrations and c/t slurry ratios in the process of pipeline transportation in the case of continuous pumping. The pipeline pressure data were processed using the weighted arithmetic average method to obtain the average value of the pressure , and the pressure loss of different pipeline sections was calculated accordingly.

2.3.2. Mechanical Properties Test

3. Results

3.1. Experimental Results

3.2. Analysis of the Slump and Bleeding Rate

3.2.1. Standard Curing Environment

3.2.2. Deep-Underground Curing Environment

3.3. Analysis of Slurry Flow Properties

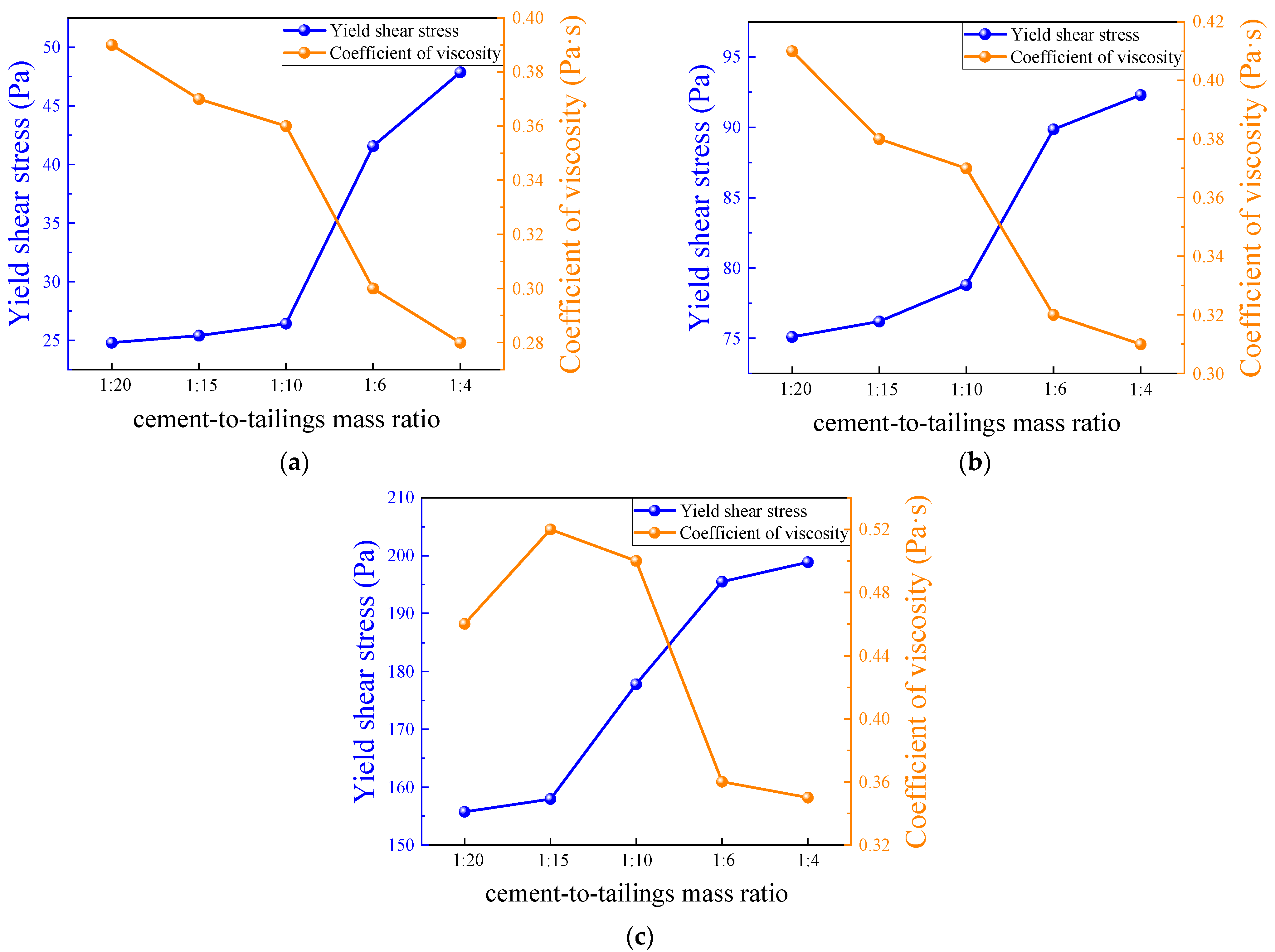

3.3.1. Rheological Test Results

3.3.2. L-Tube Self-Flow Simulation Experiment Results

3.3.3. Semi-Industrial Loop Test Experimental Results

3.4. Analysis of Mechanical Properties

3.4.1. Standard Curing Environment

3.4.2. Deep-Underground Curing Environment

4. Conclusions

- (1)

- When the c/t ratio is 1:4, the filling slurry with a mass concentration between 74% and 76% can be regarded as a paste, suitable for pipeline transportation in the mining industry.

- (2)

- The transportation resistance of the slurry is positively correlated with the c/t ratio and mass concentration, and as the flow rate declines, the range that can be reached by self-flow transportation of the filling slurry becomes narrower, and the stowing gradient also decreases.

- (3)

- On the one hand, the pressure loss in the route of the straight pipe section shows an approximately linear growth pattern with the slurry flow rate. On the other hand, the pressure loss in the straight pipe section tends to grow with an increasing c/t ratio and mass concentration. In nine sets of semi-industrial loop test data, when the slurry c/t ratio increases to 1:4, the mass concentration rises to 76%, and the slurry flow rate reaches the maximum value of 1.334 m/s, the pressure loss in the route of the straight pipe section reaches the maximum value of 4.324 MPa/km.

- (4)

- The UCS of the CCPB in both the standard curing environment and the deep-underground curing environment improved with an increasing curing age, mass concentration, and c/t ratio. The UCS of the CCTB cured in a deep-underground curing environment is relatively stronger and possesses higher stresses when the c/t ratio is between intervals of 1:6 and 1:4. The filling slurry using BMC as the cementitious material can be better applied to the deep-underground environment of this mine.

- (5)

- Combined with the results of the slurry conveying experimental research and the comprehensive judgment of the mine’s economic benefits, when the whole tailings filling slurry is at c/t ratio of 1:4 and mass concentration of 74% or so, the slump, extension degree, bleeding rate, flow properties, and other indexes of the filling slurry satisfy the transportation and filling requirements, the filling body possesses a high strength and can well support the goaf.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, M.; Li, P.; Tan, W.; Ren, F. Key Engineering Technologies to Achieve Green, Intelligent, and Sustainable Development of Deep Metal Mines in China. Engineering 2021, 7, 1513–1517. [Google Scholar] [CrossRef]

- Ghorbani, Y.; Nwaila, G.T.; Zhang, S.E. Moving towards deep underground mineral resources: Drivers, challenges and potential solutions. Resour. Policy 2023, 80, 103222. [Google Scholar] [CrossRef]

- FU, J.; Song, W.; Tan, Y. Criterion of Local Energy Release Rate of Gob Destabilization in Deep Mines under Unloading Stress Path. Int. J. Min. Sci. Technol. 2017, 27, 1011–1017. [Google Scholar] [CrossRef]

- Xia, K.; Chen, C.; Liu, X.; Liu, X.; Yuan, J.; Dang, S. Assessing the stability of high-level pillars in deeply-buried metal mines stabilized using cemented backfill. Int. J. Rock. Mech. Min. 2023, 170, 105489. [Google Scholar] [CrossRef]

- Li, Y.; Fu, J.; Wang, K.; He, Z. Influence of shell ash on pore structure and mechanical characteristics of cemented tailings backfill. Constr. Build. Mater. 2024, 411, 134473. [Google Scholar] [CrossRef]

- Li, P.; Cai, M. Challenges and new insights for exploitation of deep underground metal mineral resources. Trans. Nonferrous Met. Soc. China 2021, 31, 3478–3505. [Google Scholar] [CrossRef]

- Yin, S.; Shao, Y.; Wu, A.; Wang, H.; Liu, X.; Wang, Y. A systematic review of paste technology in metal mines for cleaner production in China. J. Clean. Prod. 2020, 247, 119590. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Wu, A. Effect of particle size distribution of tailings on pressure gradient and drag reduction characteristics of non-cemented paste considering wall slip. Case Stud. Constr. Mat. 2024, 20, e02792. [Google Scholar] [CrossRef]

- Yilmaz, T.; Ercikdi, B.; Deveci, H. Utilisation of construction and demolition waste as cemented paste backfill material for underground mine openings. J. Environ. Manag. 2018, 222, 250–259. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, L.; Yin, S.; Yan, Z.; Zhang, X. Multiphase slurry flow regimes and its pipeline transportation of underground backfill in metal mine: Mini review. Constr. Build. Mater. 2023, 402, 133014. [Google Scholar] [CrossRef]

- Shao, X.; Ning, J.; Tang, R.; Fang, Z.; Zhao, B.; Xu, B.; Tian, C.; Wang, W.; Wang, Z. Effect of temperature-rising inhibitor on the hydration and performance of cemented paste-filling material. Case Stud. Constr. Mat. 2023, 19, e02680. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Song, W.; Fu, J. Pore structure, mechanical behavior and damage evolution of cemented paste backfill. J. Mater. Res. Technol. 2022, 17, 2864–2874. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, J.; Song, W.; Kang, M.; Li, T.; Wang, N. Analysis on mechanical behavior and failure characteristics of layered cemented paste backfill (LCPB) under triaxial compression. Constr. Build. Mater. 2022, 324, 126631. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W.; Zhang, Y. Effect of rice husk ash (RHA) dosage on pore structural and mechanical properties of cemented paste backfill. J. Mater. Res. Technol. 2022, 17, 840–851. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W.; Zhang, Y.; Wang, Y. Mechanical behavior, acoustic emission properties and damage evolution of cemented paste backfill considering structural feature. Constr. Build. Mater. 2020, 261, 119958. [Google Scholar] [CrossRef]

- Niu, Y.; Cheng, H.; Wu, S.; Sun, J.; Wang, J. Rheological properties of cemented paste backfill and the construction of a prediction model. Case Stud. Constr. Mat. 2022, 16, e01140. [Google Scholar] [CrossRef]

- Dong, H.; Aziz, N.A.; Shafri, H.Z.M.; Ahmad, K.A.B. Computational fluid dynamics study on cemented paste backfill slurry: Review. Constr. Build. Mater. 2023, 369, 130558. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Yang, G.; Ruan, Z.; Wang, Z. Effect of cement-to-tailings ratio and flow rate on the wear performance of filling pipeline. Powder Technol. 2022, 397, 117027. [Google Scholar] [CrossRef]

- Feng, G.; Wang, Z.; Qi, T.; Du, X.; Guo, J.; Wang, H.; Shi, X.; Wen, X. Effect of velocity on flow properties and electrical resistivity of cemented coal gangue-fly ash backfill (CGFB) slurry in the pipeline. Powder Technol. 2022, 396, 191–209. [Google Scholar] [CrossRef]

- Yan, J.; Zhu, Z.; Liu, R.; Chen, M.; Shao, C.; Zhang, C.; Li, X. A multi-perspective study on the influence of physical and chemical properties of 5 types of fly ash on the performance of high-volume blended fly ash cementitious slurry. Constr. Build. Mater. 2024, 411, 134301. [Google Scholar] [CrossRef]

- Jiang, G.; Wu, A.; Wang, Y.; Li, J. The rheological behavior of paste prepared from hemihydrate phosphogypsum and tailing. Constr. Build. Mater. 2019, 229, 116870. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Xue, Z.; Gan, D.; Zhang, Y.; Liu, Z. Rheological behavior of ultrafine-tailings cemented paste backfill in high-temperature mining conditions. Constr. Build. Mater. 2020, 253, 119212. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Y.; Hao, Y. Experimental Study and Application of Rheological Properties of Coal Gangue-Fly Ash Backfill Slurry. Processes 2020, 8, 284. [Google Scholar] [CrossRef]

- Feys, D.; Verhoeven, R.; Schutter, G.D. Evaluation of Time Independent Rheological Models Applicable to Fresh Self-Compacting Concrete. Appl. Rheol. 2007, 17, 56244-1–56244-10. [Google Scholar] [CrossRef]

- Guo, Z.; Sun, X.; Zhang, X.; Qiu, J.; Jiang, H.; Zhao, Y.; Wu, P.; Zhang, Q. Effect of superplasticizer on rheology and thixotropy of superfine-tailings cemented paste backfill: Experiment and modelling. Constr. Build. Mater. 2022, 316, 125693. [Google Scholar] [CrossRef]

- Panchal, S.; Deb, D.; Sreenivas, T. Variability in rheology of cemented paste backfill with hydration age, binder and superplasticizer dosages. Adv. Powder Technol. 2019, 29, 2211–2220. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Pel, L.; Zhao, Y.; Zhu, Q.; Kwek, J.W.; Zhang, L.; Jiang, H.; Yang, J.; Qu, Z. A contribution to understanding the rheological measurement, yielding mechanism and structural evolution of fresh cemented paste backfill. Cem. Concr. Compos. 2023, 143, 105221. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Yu, Z.; Huang, P. Determination of mechanical, flowability, and microstructural properties of cemented tailings backfill containing rice straw. Constr. Build. Mater. 2020, 246, 118520. [Google Scholar] [CrossRef]

- Gao, R.; Zhou, K.; Zhou, Y.; Yang, C. Research on the fluid characteristics of cemented backfill pipeline transportation of mineral processing tailings. Alex. Eng. J. 2020, 59, 4409–4426. [Google Scholar] [CrossRef]

- Wang, X.; Guo, J.; Wu, A.; Wang, H.; Jiang, H.; Li, Z.; Qiu, Z. Wear characteristics of the pipeline transporting cemented paste backfill containing coarse aggregate. Constr. Build. Mater. 2024, 410, 134170. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Jiang, H.; Zhu, Q.; Kwek, J.W.; Ke, L.; Qu, Z. Experimental and modeling study on the transient flow and time-dependent yield stress of superfine-tailings cemented paste backfill. Constr. Build. Mater. 2023, 367, 130363. [Google Scholar] [CrossRef]

- Qi, C.; Chen, Q.; Fourie, A.; Zhang, Q. An intelligent modelling framework for mechanical properties of cemented paste backfill. Miner. Eng. 2018, 123, 16–27. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, Q.; Xiao, C.; Feng, Y.; Qiu, J.; Zhu, L.; Chen, Q. Investigation of flocculation behavior of tailings during settling-concentration: Influence of true density, particle size, and mud layer height. J. Mater. Res. Technol. 2023, 26, 6769–6781. [Google Scholar] [CrossRef]

- Ruan, Z.; Li, C.; Shi, C. Numerical simulation of flocculation and settling behavior of whole-tailings particles in deep-cone thickener. J. Cent. South. Univ. 2016, 23, 740–749. [Google Scholar] [CrossRef]

- Bharathan, B.; McGuinness, M.; Kuhar, S.; Kermani, M.; Hassani, F.P.; Sasmito, A.P. Pressure loss and friction factor in non-Newtonian mine paste backfill: Modelling, loop test and mine field data. Powder Technol. 2019, 344, 443–453. [Google Scholar] [CrossRef]

- Qi, C.; Guo, L.; Ly, H.; Le, H.V.; Pham, B.T. Improving pressure drops estimation of fresh cemented paste backfill slurry using a hybrid machine learning method. Constr. Build. Mater. 2024, 410, 134170. [Google Scholar] [CrossRef]

- Yang, X.; Xiao, B.; Gao, Q.; He, J. Determining the pressure drop of cemented Gobi sand and tailings paste backfill in a pipe flow. Constr. Build. Mater. 2020, 255, 119371. [Google Scholar] [CrossRef]

- Yan, Z.; Yin, S.; Chen, X.; Wang, L. Rheological properties and wall-slip behavior of cemented tailing-waste rock backfill (CTWB) paste. Constr. Build. Mater. 2022, 324, 126723. [Google Scholar] [CrossRef]

- Cheng, H.; Wu, S.; Li, H.; Zhang, X. Influence of time and temperature on rheology and flow performance of cemented paste backfill. Constr. Build. Mater. 2020, 231, 117117. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Time- and temperature-dependent rheological properties of cemented paste backfill that contains superplasticizer. Powder Technol. 2020, 360, 734–740. [Google Scholar] [CrossRef]

- Roshani, A.; Fall, M. Rheological properties of cemented paste backfill with nano-silica: Link to curing temperature. Cement Concrete Comp. 2020, 114, 103785. [Google Scholar] [CrossRef]

- Ouattara, D.; Yahia, A.; Mbonimpa, M.; Belem, T. Effects of superplasticizer on rheological properties of cemented paste backfills. Int. J. Miner. Process. 2017, 161, 28–40. [Google Scholar] [CrossRef]

- Deng, X.; Zhang, J.; Klein, B.; Zhou, N.; deWit, B. Experimental characterization of the influence of solid components on the rheological and mechanical properties of cemented paste backfill. Int. J. Miner. Process. 2017, 168, 116–125. [Google Scholar] [CrossRef]

- Yin, S.; Wu, A.; Hu, K.; Wang, Y.; Zhang, Y. The effect of solid components on the rheological and mechanical properties of cemented paste backfill. Miner. Eng. 2012, 35, 61–66. [Google Scholar] [CrossRef]

- Jiang, H.; Fall, M. Yield stress and strength of saline cemented tailings in sub-zero environments: Portland cement paste backfill. Int. J. Miner. Process. 2017, 160, 68–75. [Google Scholar] [CrossRef]

- Zhu, L.; Lyu, W.; Mao, X.; Zhao, Z.; Yang, D.; Zhang, H.; Wang, K.; Yang, P.; Zeng, H. Effect of solution pH and polyethylene oxide concentration on surface/ interface properties, flocculation and rheology of concentrated monodisperse ultrafine synthetic tailings slurry. Powder Technol. 2023, 430, 119002. [Google Scholar] [CrossRef]

- Ruan, Z.; Wu, A.; Bürger, R.; Betancourt, F.; Wang, Y.; Wang, Y.; Jiao, H.; Wang, S. Effect of interparticle interactions on the yield stress of thickened flocculated copper mineral tailings slurry. Powder Technol. 2021, 392, 278–285. [Google Scholar] [CrossRef]

- Wu, A.; Wang, Y.; Wang, H. Estimation model for yield stress of fresh uncemented thickened tailings: Coupled effects of true solid density, bulk density, and solid concentration. Int. J. Miner. Process. 2015, 143, 117–124. [Google Scholar] [CrossRef]

- Ouattara, D.; Belem, T.; Mbonimpa, M.; Yahia, A. Effect of superplasticizers on the consistency and unconfined compressive strength of cemented paste backfills. Constr. Build. Mater. 2018, 181, 59–72. [Google Scholar] [CrossRef]

- Fu, J.; Wang, K.; Wang, J. Internal pore evolution and early hydration characterization of fly ash cement backfill. J. Build. Eng. 2023, 72, 106716. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.; Song, W.; Fu, J. Effect of waste glass powder on pore structure, mechanical properties and microstructure of cemented tailings backfill. Constr. Build. Mater. 2023, 365, 130062. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Advances in rheological measurement and characterization of fresh cement pastes. Powder Technol. 2023, 429, 118903. [Google Scholar] [CrossRef]

| Physical Parameters | True Density (g/cm3) | Bulk Density (g/cm3) | Percentage of Void (%) | Natural Repose Angle (°) | ||

|---|---|---|---|---|---|---|

| Loose | Compacted | Loose | Compacted | |||

| The properties of tailings | 2.65 | 1.15 | 1.54 | 56.60 | 41.89 | 41.11 |

| Physical Parameters | True Density (g/cm3) | Bulk Density (g/cm3) | Percentage of Void (%) | Natural Repose Angle (°) | Specific Surface Area (m2/kg) | Initial Consolidation Time (h) | Final Consolidation Time (h) |

|---|---|---|---|---|---|---|---|

| BMC properties | 2.80 | 1.02 | 61.94 | 26.21 | 750 | 6 | 9 |

| C/t Ratio | Mass Concentration (%) | Bulk Density (N/m3) | Flow Speed (m/s) | Shear Stress on Tube Wall (pa) | Rheological Parameters | Flow Resistance (pa/m) | Stowing Gradient | |

|---|---|---|---|---|---|---|---|---|

| Yield Shear Stress (pa) | Coefficient of Viscosity (pa·s) | |||||||

| 1:4 | 72 | 18,222 | 2.78 | 126.09 | 47.86 | 0.28 | 5043.41 | 3.09 |

| 74 | 18,648 | 0.85 | 144.15 | 92.30 | 0.31 | 5765.87 | 2.76 | |

| 76 | 19,094 | 0.30 | 273.56 | 198.87 | 0.35 | 10,942.40 | 1.50 | |

| 1:6 | 72 | 18,194 | 2.77 | 121.91 | 41.57 | 0.30 | 4876.27 | 3.21 |

| 74 | 18,618 | 0.86 | 141.83 | 89.86 | 0.32 | 5673.17 | 2.81 | |

| 76 | 19,062 | 0.42 | 272.76 | 195.50 | 0.36 | 10,910.51 | 1.50 | |

| 1:10 | 72 | 18,169 | 2.05 | 94.28 | 26.43 | 0.36 | 3771.20 | 4.18 |

| 74 | 18,591 | 0.80 | 128.73 | 78.79 | 0.37 | 5149.33 | 3.13 | |

| 76 | 19,033 | 0.39 | 252.67 | 177.80 | 0.50 | 10,106.67 | 1.63 | |

| 1:15 | 72 | 18,156 | 1.98 | 92.47 | 25.40 | 0.37 | 3698.99 | 4.29 |

| 74 | 18,577 | 0.76 | 124.70 | 76.20 | 0.38 | 4988.16 | 3.26 | |

| 76 | 19,017 | 0.33 | 224.29 | 157.92 | 0.52 | 8971.52 | 1.84 | |

| 1:20 | 72 | 18,149 | 1.99 | 95.15 | 24.80 | 0.39 | 3806.19 | 4.18 |

| 74 | 18,569 | 0.78 | 125.72 | 75.10 | 0.41 | 5028.69 | 3.25 | |

| 76 | 19,009 | 0.35 | 220.48 | 155.70 | 0.46 | 8819.20 | 1.88 | |

| Design Mass Concentration (%) | Observe Mass Concentration (%) | Pumping Frequency (/min) | Flow Velocity (m/s) | Pressure Loss (MPa/km) | ||||

|---|---|---|---|---|---|---|---|---|

| Straight Pipe | 30° Tilt Downward | 30° Tilt Upward | Vertically Downward | Vertically Upward | ||||

| 72 | 71.87 | 14 | 0.676 | 2.126 | 0.611 | 0.611 | 0.443 | 20.138 |

| 15 | 0.984 | 2.947 | 0.683 | 0.683 | 0.580 | 21.268 | ||

| 21 | 1.397 | 3.531 | 1.042 | 1.042 | 0.626 | 22.061 | ||

| 74 | 73.49 | 12 | 0.634 | 2.598 | 0.653 | 0.653 | 0.530 | 21.156 |

| 14 | 0.963 | 3.221 | 0.817 | 0.817 | 0.691 | 22.056 | ||

| 19 | 1.355 | 3.890 | 1.246 | 1.246 | 0.776 | 22.662 | ||

| 76 | 75.56 | 11 | 0.613 | 3.061 | 0.838 | 0.838 | 0.631 | 21.934 |

| 14 | 0.963 | 3.713 | 1.076 | 1.076 | 0.743 | 22.515 | ||

| 18 | 1.334 | 4.324 | 1.321 | 1.321 | 0.902 | 23.370 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Fu, J.; Yang, J.; Wang, J. Research on Slurry Flowability and Mechanical Properties of Cemented Paste Backfill: Effects of Cement-to-Tailings Mass Ratio and Mass Concentration. Materials 2024, 17, 2222. https://doi.org/10.3390/ma17102222

Li Y, Fu J, Yang J, Wang J. Research on Slurry Flowability and Mechanical Properties of Cemented Paste Backfill: Effects of Cement-to-Tailings Mass Ratio and Mass Concentration. Materials. 2024; 17(10):2222. https://doi.org/10.3390/ma17102222

Chicago/Turabian StyleLi, Yan, Jianxin Fu, Jiguang Yang, and Jie Wang. 2024. "Research on Slurry Flowability and Mechanical Properties of Cemented Paste Backfill: Effects of Cement-to-Tailings Mass Ratio and Mass Concentration" Materials 17, no. 10: 2222. https://doi.org/10.3390/ma17102222