Comprehensive Evaluation of Resilience for Qinling Tunnel Group Operation Safety System Based on Combined Weighting and Cloud Model

Abstract

:1. Introduction

2. Data Basis and Statistics

2.1. An Analysis of the Distribution Characteristics

2.2. Analysis of Risk Factors for Traffic Accidents in Tunnel Groups

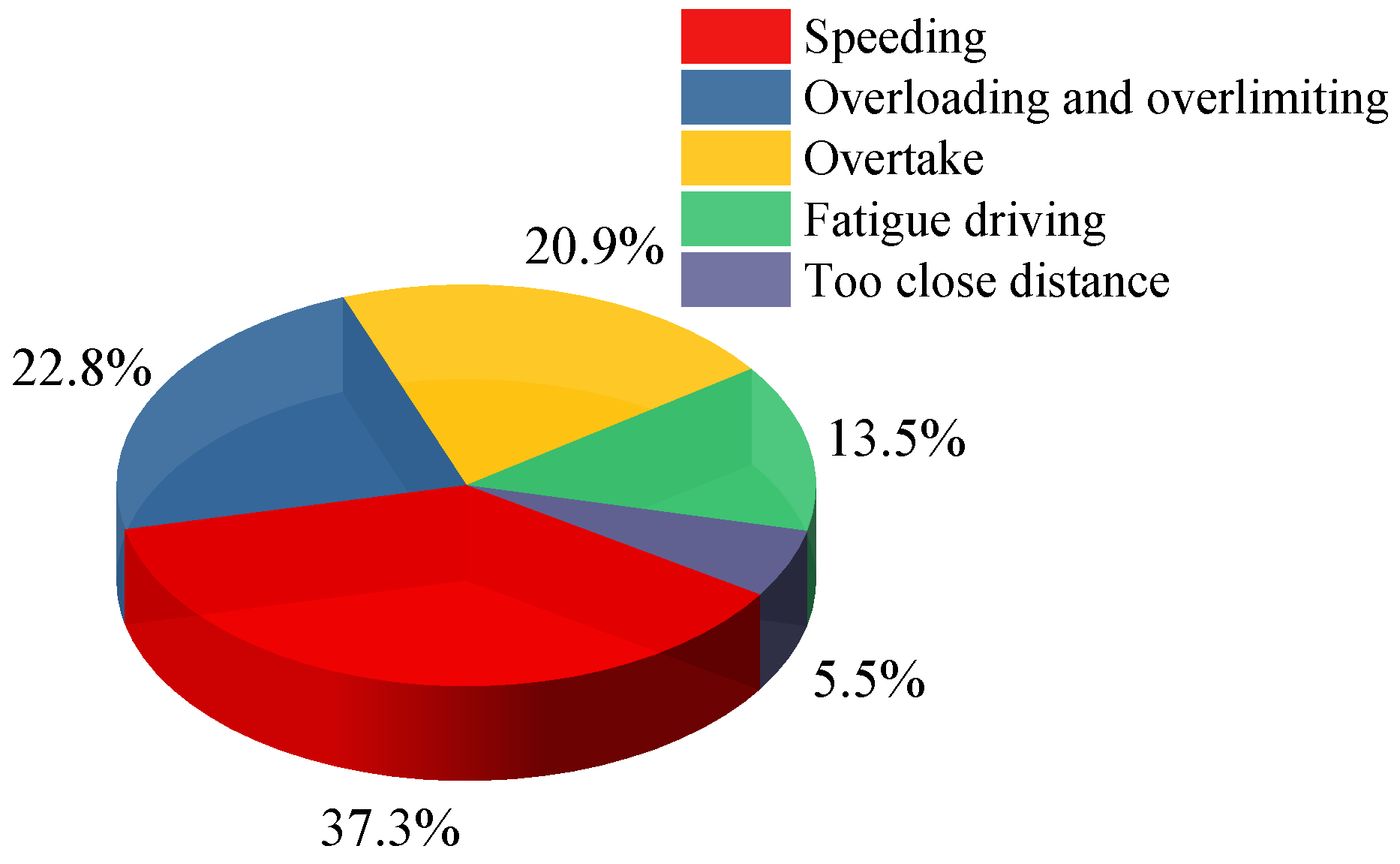

2.2.1. Human Factor Analysis

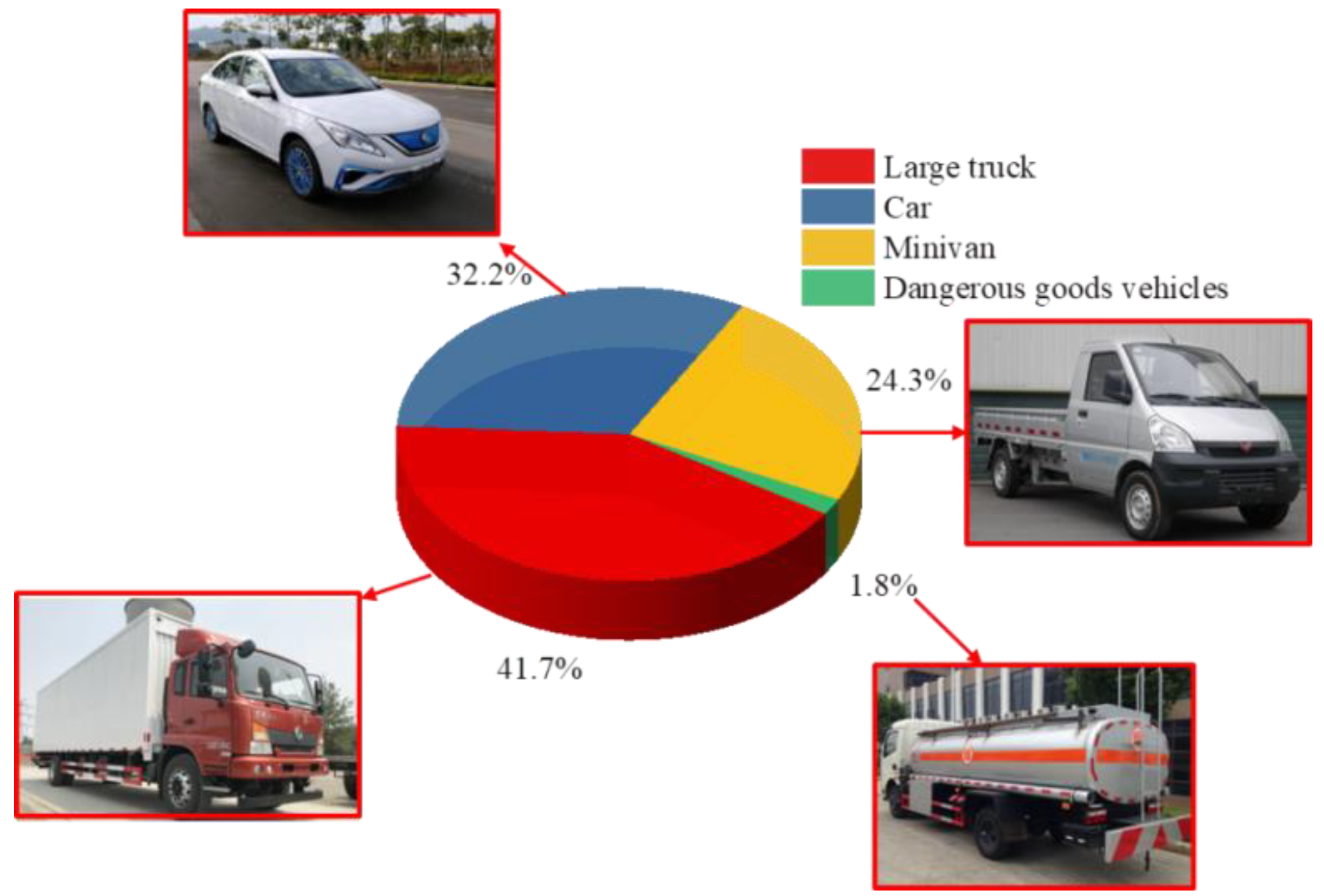

2.2.2. Vehicle Factor Analysis

- (1)

- The type of vehicle involved in a traffic accident

- (2)

- Traffic volume

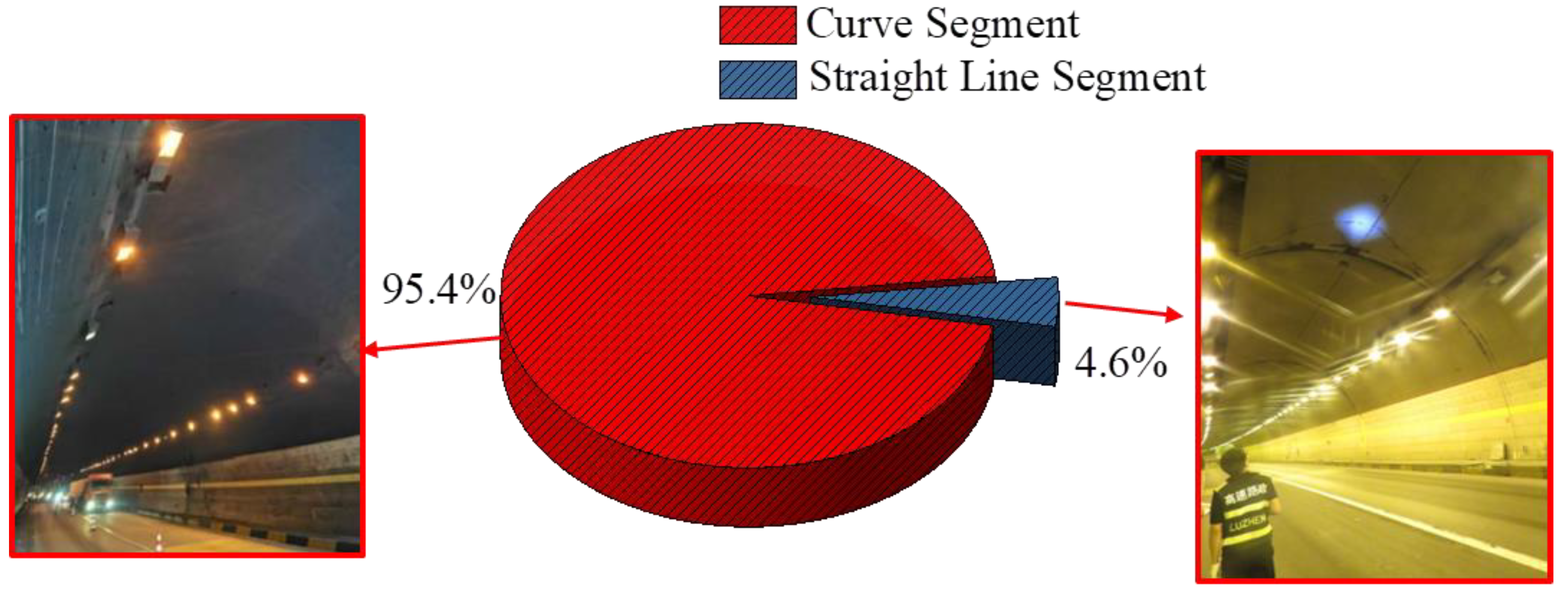

2.2.3. Road Factor Analysis

- (1)

- Tunnel structural problems

- (2)

- Linear

- (3)

- Road condition

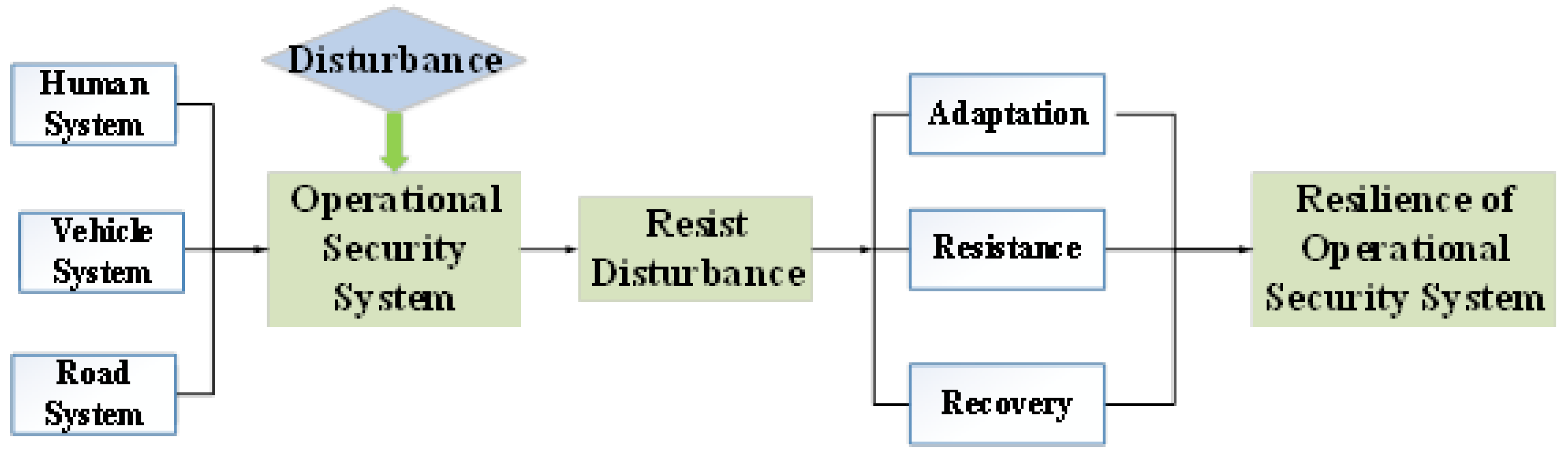

3. Resilience of Operation Safety System for Expressway Tunnel Group

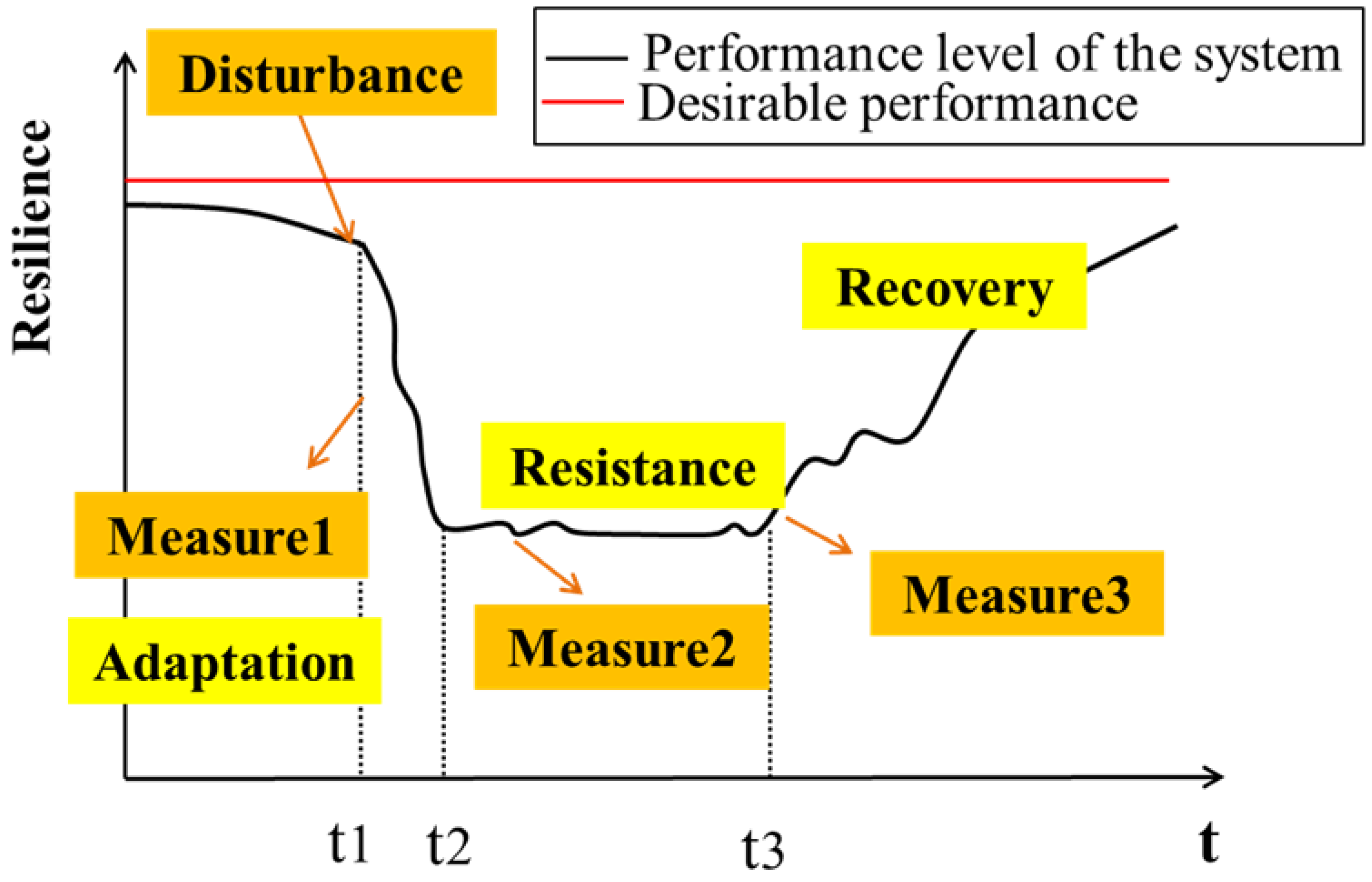

3.1. Conceptual Model of Resilience for Safety System of Expressway Tunnel Group Operation

3.2. Classification of Operational Safety Evaluation Indicators for Expressway Tunnel Group

4. Methodology

4.1. Analytical Hierarchy Process

4.2. Calculating Objective Weights via the Entropy Weight Method

- (1)

- The number of existing projects to be evaluated is assumed to be m, and the number of evaluation indicators is n. The original data matrix for forming the corresponding evaluation indicators of the project to be evaluated is as follows:where aij is the evaluation value of the jth evaluation indicator under the ith evaluation project.

- (2)

- The raw measurement data of each evaluation indicator are classified and normalized.If the evaluation indicator is a positive indicator, it is normalized to the following:If the evaluation indicator is a reverse indicator, it is normalized to the following:The decision matrix after standardization can be expressed as follows:

- (3)

- The proportion can be calculated as follows:

- (4)

- The entropy is given by the following:

- (5)

- The entropy weight can be expressed as follows:

4.3. Calculate the Final Weight Using the Combination Weighting Method

4.4. Cloud Model

5. Case Study

5.1. Example Introduction

5.2. Result Analysis

5.3. Safety Improvement Measures

6. Discussion

7. Conclusions

- This study performs a statistical analysis on traffic accidents within the Qinling Tunnel Group, delineating their distribution patterns and identifying risk factors associated with human, vehicle, and road elements.

- A resilience model for the highway tunnel group’s operational safety system was developed, incorporating a comprehensive set of indicators, grading criteria, and evaluation tiers based on traffic data analysis.

- The analytic hierarchy process was employed to assign subjective weights, while the entropy weight method was utilized for objective weights. A combined weighting approach determined the overall indicator weights. Subsequently, a cloud model facilitated the quantification of the operational safety resilience, enabling a synthesis of quantitative and qualitative insights for enhanced accuracy.

- To bolster the operational security system’s resilience, targeted improvement strategies were formulated, addressing its adaptation, resistance, and recovery.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Editorial Department of China Journal of Highway and Transport. A review of academic research on traffic tunnel engineering in China·2022. China J. Highw. Transp. 2022, 35, 1–40. [Google Scholar]

- Sun, H.; Wang, Q.; Zhang, P.; Zhong, Y.; Yue, X. Spatialtemporal Characteristics of Tunnel Traffic Accidents in China from 2001 to Present. Adv. Civ. Eng. 2019, 2019, 4536414. [Google Scholar] [CrossRef]

- Pervez, A.; Huang, H.; Han, C.; Wang, J.; Li, Y. Revisiting freeway single tunnel crash characteristics analysis: A six-zone analytic approach. Accid. Anal. Prev. 2020, 142, 105542. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Wang, J.; Zhang, X.; Gu, D.; Yang, Y.; Zhu, H. Analysis of the causes of traffic accidents and identification of accident-prone points in long downhill tunnel of mountain expressways based on data mining. Sustainability 2022, 14, 8460. [Google Scholar] [CrossRef]

- Li, S.; Huang, S.; Wang, J.; He, S. Analysis of Factors Affecting the Over-Representation of Sequential Crashes in Freeway Tunnels: Using Rule-Based Data Mining Method. J. Adv. Transp. 2023, 2023, 7128408. [Google Scholar] [CrossRef]

- Luo, Q.; Liu, C. Exploration of road closure time characteristics of tunnel traffic accidents: A case study in Pennsylvania, USA. Tunn. Undergr. Space Technol. 2023, 132, 104894. [Google Scholar] [CrossRef]

- Shen, Y.; Zheng, C.; Wu, F. Study on Traffic Accident Forecast of Urban Excess Tunnel Considering Missing Data Filling. Appl. Sci. 2023, 13, 6773. [Google Scholar] [CrossRef]

- Cui, L.; Sheng, Q.; Zhang, J.; Dong, Y.-K.; Guo, Z.-S. Evaluation of input geological parameters and tunnel strain for strain-softening rock mass based on GSI. Sci. Rep. 2022, 12, 20575. [Google Scholar] [CrossRef]

- Kim, J.; Kim, C.; Kim, G.; Kim, I.; Abbas, Q.; Lee, J. Probabilistic tunnel collapse risk evaluation model using analytical hierarchy process (AHP) and Delphi survey technique. Tunn. Undergr. Space Technol. 2022, 120, 104262. [Google Scholar] [CrossRef]

- Ye, F.; Han, X.; Qin, N.; Ouyang, A.; Liang, X.; Xu, C. Damage management and safety evaluation for operating highway tunnels: A case study of Liupanshan tunnel. Struct. Infrastruct. Eng. 2020, 16, 1512–1523. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, X.; Shi, L.; Liu, H. Influence of light zones on drivers’ visual fixation characteristics and traffic safety in extra-long tunnels. Traffic Inj. Prev. 2017, 18, 102–110. [Google Scholar] [CrossRef] [PubMed]

- Hyun, K.-C.; Min, S.; Choi, H.; Park, J.; Lee, I.-M. Risk analysis using fault-tree analysis (FTA) and analytic hierarchy process (AHP) applicable to shield TBM tunnels. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2015, 49, 121–129. [Google Scholar] [CrossRef]

- Luo, Y.; Gong, H.; Qu, D.; Zhang, X.; Tao, Y.; Li, X. Vibration velocity and frequency characteristics of surrounding rock of adjacent tunnel under blasting excavation. Sci. Rep. 2022, 12, 8453. [Google Scholar] [CrossRef] [PubMed]

- Lei, L.; Wang, F. The research on index system and method of high-speed railway tunnel operational safety evaluation. In Proceedings of the 2011 2nd IEEE International Conference on Emergency Management and Management Sciences, Beijing, China, 8–10 August 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 116–119. [Google Scholar]

- Liu, W.; Cai, L.; Chen, J.; Wang, Y.; Wu, H. Reliability analysis of operational metro tunnel based on a dynamic Bayesian copula model. J. Comput. Civ. Eng. 2020, 34, 05020002. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, R.; Chen, M.; Xiao, S. Research on Operational Safety Risk Assessment Method for Long and Large Highway Tunnels Based on FAHP and SPA. Appl. Sci. 2023, 13, 9151. [Google Scholar] [CrossRef]

- Shao, Y.; Xu, J. Understanding Urban resilience: A Conceptual Analysis Based on Integrated International Literature Review. Urban Plan. Int. 2015, 30, 48–54. [Google Scholar]

- Wei, Y.; Liang, J.; Deng, Y.; Dou, F.; Ning, Y.; Zhou, D.; Liu, J. Resilience Assessment of Beijing Subway Lines under Extreme Precipitation Weather. Appl. Sci. 2023, 13, 3964. [Google Scholar] [CrossRef]

- Qiao, W.; Ma, X.; Liu, Y.; Lan, H. Resilience assessment for the northern sea route based on a fuzzy Bayesian network. Appl. Sci. 2021, 11, 3619. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, F.; He, X.; Wang, B. Resilience Evaluation of Subway Tunnel Surrounding Rock Based on Euclidean Distance. Railw. Stand. Des. 2019, 63, 106–111. [Google Scholar]

- Khetwal, S.; Pei, S.; Gutierrez, M. A Data-Driven Approach for Direct Assessment and Analysis of Traffic Tunnel Resilience. In Information Technology in Geo-Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 168–177. [Google Scholar]

- Zheng, G.; Cheng, X.; Zhou, H.; Zhang, T.; Yu, X.; Diao, Y.; Wang, R.; Yi, F.; Zhang, W.; Guo, W. Evaluation and Control of Structural Resilience in Geotechnical and Underground Engineering. China Civ. Eng. J. 2022, 55, 1–38. [Google Scholar]

- Xu, C.; Hu, H.; Wang, H. A theoretical study on the resilience evaluation method of operational road tunnel systems. Appl. Sci. 2023, 13, 13279. [Google Scholar] [CrossRef]

- Lin, X.T.; Chen, X.; Su, D.; Han, K.; Zhu, M. An analytical model to evaluate the resilience of shield tunnel linings considering multistage disturbances and recoveries. Tunn. Undergr. Space Technol. 2022, 127, 104581. [Google Scholar] [CrossRef]

- Caliendo, C.; Russo, I.; Genovese, G. Resilience Assessment of a Twin-Tube Motorway Tunnel in the Event of a Traffic Accident or Fire in a Tube. Appl. Sci. 2022, 12, 513. [Google Scholar] [CrossRef]

- Liu, F.; Tang, C.; Zhang, Y.; Ma, T. Rockburst and microseismicity characteristics in the qinling water conveyance tunnel of the hanjiang-to-weihe river diversion project. Int. J. Rock Mech. Min. Sci. 2021, 148, 104973. [Google Scholar] [CrossRef]

- Wang, X.; Lai, J.; Garnes, R.; Luo, Y. Support system for tunnelling in squeezing ground of qingling-daba mountainous area: A case study from soft rock tunnels. Adv. Civ. Eng. 2019, 2019, 8682535. [Google Scholar] [CrossRef]

- Xing, R.; Li, Z.; Cai, X.; Yang, Z.; Zhang, N.; Yang, T. Accident Rate Prediction Model for Urban Expressway Underwater Tunnel. Sustainability 2023, 15, 10730. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, S.; Tang, J.; Wu, P.; Tang, B. Exploring the Impacts of Driving Environment on Crashes in Tunnel-Bridge-Tunnel Groups: An Eight-Zone Analytic Approach. Sustainability 2021, 13, 2272. [Google Scholar] [CrossRef]

- Yuan, J. Analysis of Traffic Accident Characteristics and Safety Risk Assessment of Expressway Tunnels in Sichuan Province. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2018. [Google Scholar]

- Tichy, T.; Broz, J.; Belinova, Z.; Pirnik, R. Analysis of predictive maintenance for tunnel systems. Sustainability 2021, 13, 3977. [Google Scholar] [CrossRef]

- Wang, N.; Ren, Z.; Zhang, Z.; Fu, J. Evaluation and Prediction of Higher Education System Based on AHP-TOPSIS and LSTM Neural Network. Appl. Sci. 2022, 12, 4987. [Google Scholar] [CrossRef]

- Cai, X.; Lei, C.; Peng, B.; Tang, X.; Gao, Z. Road traffic safety risk estimation method based on vehicle onboard diagnostic data. J. Adv. Transp. 2020, 2020, 3024101. [Google Scholar] [CrossRef]

- Chen, X.; Li, X.; Zhu, H. Condition evaluation of urban metro shield tunnels in shanghai through multiple indicators multiple causes model combined with multiple regression method. Tunn. Undergr. Space Technol. 2019, 85, 170–181. [Google Scholar] [CrossRef]

- Deng, Y.; Song, L.; Zhou, J.; Xu, N.; Ni, G.; Wang, L. Analysis of Failures and Influence Factors of Critical Infrastructures: A Case of Metro. Adv. Civ. Eng. 2020, 2020, 2301276. [Google Scholar] [CrossRef]

- Wang, J.; Pervez, A.; Wang, Z.; Han, C.; Hu, L.; Huang, H. Crash analysis of chinese freeway tunnel groups using a five-zone analytic approach. Tunn. Undergr. Space Technol. 2018, 82, 358–365. [Google Scholar] [CrossRef]

- Bi, X.; Fan, Q.; He, L.; Zhang, C.; Diao, Y.; Han, Y. Analysis and Evaluation of Extreme Rainfall Trends and Geological Hazards Risk in the Lower Jinshajiang River. Appl. Sci. 2023, 13, 4021. [Google Scholar] [CrossRef]

- Zakeri, S.; Choupani, A.A. Operational evaluation of a throughabout to give priority to public transport at standard roundabouts. J. Adv. Transp. 2021, 2021, 1840040. [Google Scholar] [CrossRef]

- Yao, P.; Yu, Z.; Lv, Y.; Shi, B.; He, Y.; Wang, H.; Liu, D.; Wei, S. Safety level assessment of shield tunneling in water rich sandy pebble strata with large particle size. Sci. Rep. 2023, 13, 3854. [Google Scholar] [CrossRef] [PubMed]

- Bognár, F.; Benedek, P. A novel AHP-PRISM risk assessment method—An empirical case study in a nuclear power plant. Sustainability 2022, 14, 11023. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, L.; Suo, J. Comprehensive assessment on sustainable development of highway transportation capacity based on entropy weight and TOPSIS. Sustainability 2014, 6, 4685–4693. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, T.; Wang, X.; Lin, W.; Fong, S.; Chen, Z.; Xu, F.; Wu, L. An ambient air quality evaluation model based on improved evidence theory. Sci. Rep. 2022, 12, 5753. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Fan, Z.; Shen, S. Urban green space suitability evaluation based on the AHP-CV combined weight method: A case study of Fuping county, China. Sustainability 2018, 10, 2656. [Google Scholar] [CrossRef]

- Yu, H.; Liang, C.; Li, P.; Niu, K.; Du, F.; Shao, J.; Liu, Y. Evaluation of waterlogging risk in an urban subway station. Adv. Civ. Eng. 2019, 2019, 5393171. [Google Scholar] [CrossRef]

- Chang, Z.; Mei, H.; Yan, C.; Shi, Y.; Zhu, X.; Lu, Z.; Jia, Z. Health status evaluation of highway tunnel inverted arch based on variable weight and extension cloud model. Eng. Fail. Anal. 2024, 157, 107939. [Google Scholar] [CrossRef]

- Ministry of Transport, Engineering Quality Supervision Bureau. Analysis of the Safety Risk Assessment System and Guide for Highway Bridge and Tunnel Construction; People’s Transportation Publishing House: Beijing, China, 2011. [Google Scholar]

- Wen, X.; Nie, Y.; Du, Z.; Huang, L. Operational safety assessment of straddle-type monorail vehicle system based on cloud model and improved CRITIC method. Eng. Fail. Anal. 2022, 139, 106463. [Google Scholar] [CrossRef]

| No. | Accident Site | Accident Time | Accident Location | Accident Reason | Type of Accident Vehicle | Casualties |

|---|---|---|---|---|---|---|

| 1 | Qinling No.1 Tunnel | 16 May 2018 14:20 | K1159 + 100 m Xian direction | Overspeed | Car | 2 Injuries |

| 2 | Qinling No.2 Tunnel | 14 September 2018 13:30 | 1171 + 400 m Xian direction | Overloading | Large truck | 1 Injuries |

| 3 | Shuanglin Tunnel | 19 January 2019 19:53 | K1153 + 800 m Hanzhong direction | Overspeed | Car | 1 Injuries |

| 4 | Heichagou Tunnel | 31 January 2019 9:50 | K1148 + 100 m Hanzhong direction | Fatigue driving | Car | - |

| 5 | Guanyinshan Tunnel | 9 October 2019 19:10 | K1158 + 900 m Hanzhong direction | Too close interval | Car | 1 Injuries |

| 6 | Qinling No.3 Tunnel | 21 April 2020 22:56 | K1172 + 400 m Hanzhong direction | Overtake | Car | - |

| 7 | Xishuiliu No.2 Tunnel | 27 May 2020 21:52 | K1149 + 100 m Xian direction | Overspeed | Large truck | 2 Injuries |

| 8 | Qinling No.2 Tunnel | 26 November 2020 23:01 | K1165 + 510 m Hanzhong direction | Overspeed | Light truck | 2 Death |

| Accident Cause | Number of Accidents | The Proportion of Accidents (%) |

|---|---|---|

| Speeding | 115 | 37.3 |

| Overloading and overlimiting | 70 | 22.8 |

| Overtake | 64 | 20.9 |

| Fatigue driving | 42 | 13.5 |

| Too close interval | 17 | 5.5 |

| Type of Accident Vehicle | Number of Accidents | The Proportion of Accidents (%) |

|---|---|---|

| Large truck | 201 | 41.7 |

| Car | 155 | 32.2 |

| Light truck | 117 | 24.3 |

| Dangerous material vehicles | 9 | 1.8 |

| Year | Traffic Volume (10,000 Vehicles/Year) | Accident Rate (Times/Million Vehicles Kilometers) |

|---|---|---|

| 2015 | 847 | 0.456 |

| 2016 | 921 | 0.499 |

| 2017 | 1005 | 0.523 |

| 2018 | 1113 | 0.360 |

| 2019 | 1441 | 0.391 |

| 2020 | 1173 | 0.302 |

| 2021 | 1289 | 0.425 |

| Characteristics of the Accident Site | Number of Accidents | The Proportion of Accidents (%) |

|---|---|---|

| Curve section | 447 | 95.4 |

| Straight section | 21 | 4.6 |

| Tunnel Name | Accident Rate (Times/Million Vehicles Kilometers) | Reduction Rate (%) | |

|---|---|---|---|

| Before Measures | After Measures | ||

| Qinling No.1 Tunnel | 0.667 | 0.455 | 31.8 |

| Qinling No.2 Tunnel | 0.603 | 0.398 | 34.1 |

| Qinling No.3 Tunnel | 0.647 | 0.347 | 35.3 |

| Index Classification | Index Description | Index Influence | ||||

|---|---|---|---|---|---|---|

| Primary Index | Resilience Indicator | Low Resilience | Medium Resilience | Relatively High Resilience | High Resilience | |

| Human | Driving behavior R1 | High-risk driving behavior >75‱ | High-risk driving behavior 50–75‱ | High-risk driving behavior 25–50‱ | High-risk driving behavior <25‱ | − |

| Driving time R2 | 8:00 to 18:00 >80% | 8:00 to 18:00 60–80% | 8:00 to 18:00 40–60% | 8:00 to 18:00 <40% | − | |

| Vehicle | Traffic volume S1 | >1400 (10,000 vehicles/year) | 1200 (10,000 vehicles/year)–1400 (10,000 vehicles/year) | 1000 (10,000 vehicles/year)–1200 (10,000 vehicles/year) | <1000 (10,000 vehicles/year) | − |

| Vehicle type S2 | Large truck > 40% | Large truck 20–30% | Large truck 10–20% | Large truck < 10% | − | |

| Road | Tunnel condition T1 | Technical Condition Score < 55 | Technical Condition Score 55–70 | Technical Condition Score 70–85 | Technical Condition Score 85–100 | − |

| Tunnel spacing T2 | 0–200 m | 200–400 m | 400–600 m | >600 m | + | |

| Pavement condition T3 | Pavement grade 1 | Pavement grade 2 | Pavement grade 3 | Pavement grade 4 | + | |

| Plane alignment T4 | Number of curve segments > 2 | Number of curve segments 2 | Number of curve segments 1 | Number of curve segments 0 | − | |

| Evaluation Level | Ⅰ | II | III | IV |

|---|---|---|---|---|

| Level Description | Low resilience | Medium resilience | Relatively high resilience | High resilience |

| The system’s weak anti-interference ability results in substantial losses when faced with interference. After interference occurs, effective rescue and repair become impossible, and it takes a considerable amount of time to restore a safe state. | The system possesses a specific capacity to resist interference, albeit resulting in moderate losses when faced with such interference. Once interference takes place, rescue measures can be implemented and maintenance can be performed, enabling the restoration of the tunnel group operation system to a safe state within a specified time frame. | The system boasts excellent resistance to interference, resulting in minimal damage to the system due to interferences. Moreover, it can efficiently carry out rescue operations and repair equipment, enabling the tunnel group operation system to be restored to a safe state in a brief time frame. | The system boasts excellent anti-interference capabilities, resulting in minimal losses in the presence of interference. Once interference occurs, prompt and efficient rescue measures can be implemented, enabling the tunnel group operation system to be swiftly restored to a secure state. |

| Scale | Mean |

|---|---|

| 1 | Both elements are equally important |

| 3 | The former is slightly more important than the latter |

| 5 | The former is obviously more important than the latter |

| 7 | The former is more important than the latter |

| 9 | The former is more important than the latter |

| 2, 4, 6, 8 | The middle of two adjacent judgments |

| Count backwards | Less important than the other element |

| Primary Index | Weight | Secondary Indicator | Weight | Relative Weight |

|---|---|---|---|---|

| Human R | 0.23 | Driving behavior R1 | 0.75 | 0.171 |

| Driving time R2 | 0.25 | 0.057 | ||

| Vehicle S | 0.18 | Traffic volume S1 | 0.8 | 0.146 |

| Vehicle type S2 | 0.2 | 0.036 | ||

| Road T | 0.59 | Tunnel condition T1 | 0.47 | 0.278 |

| Tunnel spacing T2 | 0.11 | 0.064 | ||

| Pavement condition T3 | 0.26 | 0.151 | ||

| Plane alignment T4 | 0.16 | 0.097 |

| Secondary Indicator | Driving Behavior R1 | Driving Time R2 | Traffic Volume S1 | Vehicle Type S2 |

|---|---|---|---|---|

| 2015 | 8 | 44 | 847 | 20 |

| 2016 | 9 | 47 | 921 | 27 |

| 2017 | 10 | 52 | 1005 | 40 |

| 2018 | 15 | 67 | 1113 | 31 |

| 2019 | 20 | 50 | 1441 | 29 |

| 2020 | 22 | 61 | 1173 | 38 |

| Secondary Indicator | Tunnel Condition T1 | Tunnel Spacing T2 | Pavement Condition T3 | Plane Alignment T4 |

|---|---|---|---|---|

| Qinling Tunnel No.1 | 82.7 | 538 | 4 | 9 |

| Qinling Tunnel No.2 | 79.8 | 120 | 3 | 6 |

| Qinling Tunnel No.3 | 78.1 | 645 | 3 | 7 |

| Guojiashan Tunnel | 79.2 | 824 | 4 | 8 |

| Zhujiaya Tunnel | 80.2 | 312 | 2 | 6 |

| Liangxin Tunnel | 76.7 | 674 | 3 | 7 |

| Primary Index | Weight | Secondary Indicator | Weight |

|---|---|---|---|

| Human R | 0.23 | Driving behavior R1 | 0.211 |

| Driving time R2 | 0.058 | ||

| Vehicle S | 0.18 | Traffic volume S1 | 0.141 |

| Vehicle type S2 | 0.024 | ||

| Road T | 0.59 | Tunnel condition T1 | 0.204 |

| Tunnel spacing T2 | 0.056 | ||

| Pavement condition T3 | 0.178 | ||

| Plane alignment T4 | 0.128 |

| Evaluation Level | Composite Evaluation Value | Safety Conditions | Countermeasure |

|---|---|---|---|

| Ⅰ | 66 ≥ D > 0 | Low resilience | Take immediate countermeasures |

| II | 80 ≥ D > 66 | Medium resilience | Take countermeasures as soon as possible |

| III | 90 ≥ D > 80 | Relatively high resilience | Prepare to take countermeasures |

| IV | 100 ≥ D > 90 | High resilience | Monitoring and observation |

| Primary Index | Secondary Indicator | Real Data | Indicator Description |

|---|---|---|---|

| Human (R) | Driving behavior (R1) | 37‱ | Relatively high resilience |

| Driving time (R2) | 47% | Relatively high resilience | |

| Vehicle (S) | Traffic volume (S1) | 847 | Low resilience |

| Vehicle type (S2) | 13% | Medium resilience | |

| Road (T) | Tunnel condition (T1) | 82.7 | Relatively high resilience |

| Tunnel spacing (T2) | 538 | Relatively high resilience | |

| Pavement condition (T3) | 3 | High resilience | |

| Plane alignment (T4) | 9 | Low resilience |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; He, Y. Comprehensive Evaluation of Resilience for Qinling Tunnel Group Operation Safety System Based on Combined Weighting and Cloud Model. Sustainability 2024, 16, 3937. https://doi.org/10.3390/su16103937

Liu H, He Y. Comprehensive Evaluation of Resilience for Qinling Tunnel Group Operation Safety System Based on Combined Weighting and Cloud Model. Sustainability. 2024; 16(10):3937. https://doi.org/10.3390/su16103937

Chicago/Turabian StyleLiu, Haiyang, and Yiyang He. 2024. "Comprehensive Evaluation of Resilience for Qinling Tunnel Group Operation Safety System Based on Combined Weighting and Cloud Model" Sustainability 16, no. 10: 3937. https://doi.org/10.3390/su16103937