Use of Recycled Plastic Fibers to Control Shrinkage and Desiccation Cracking in Clayey Soils

Abstract

:1. Introduction

2. Fundamentals and Background

2.1. Desiccation Cracking of Soils

2.2. Quantification of Soil Cracking

2.3. Soil Reinforcement with Plastic Fibers

2.4. Suction in Reinforced Fiber Soil

2.5. The Environmental Benefits of Plastic Reuse

3. Materials and Methods

3.1. Characteristics of the Recycled Plastic Fibers

3.2. Soil Characteristics

3.3. Sample Preparation

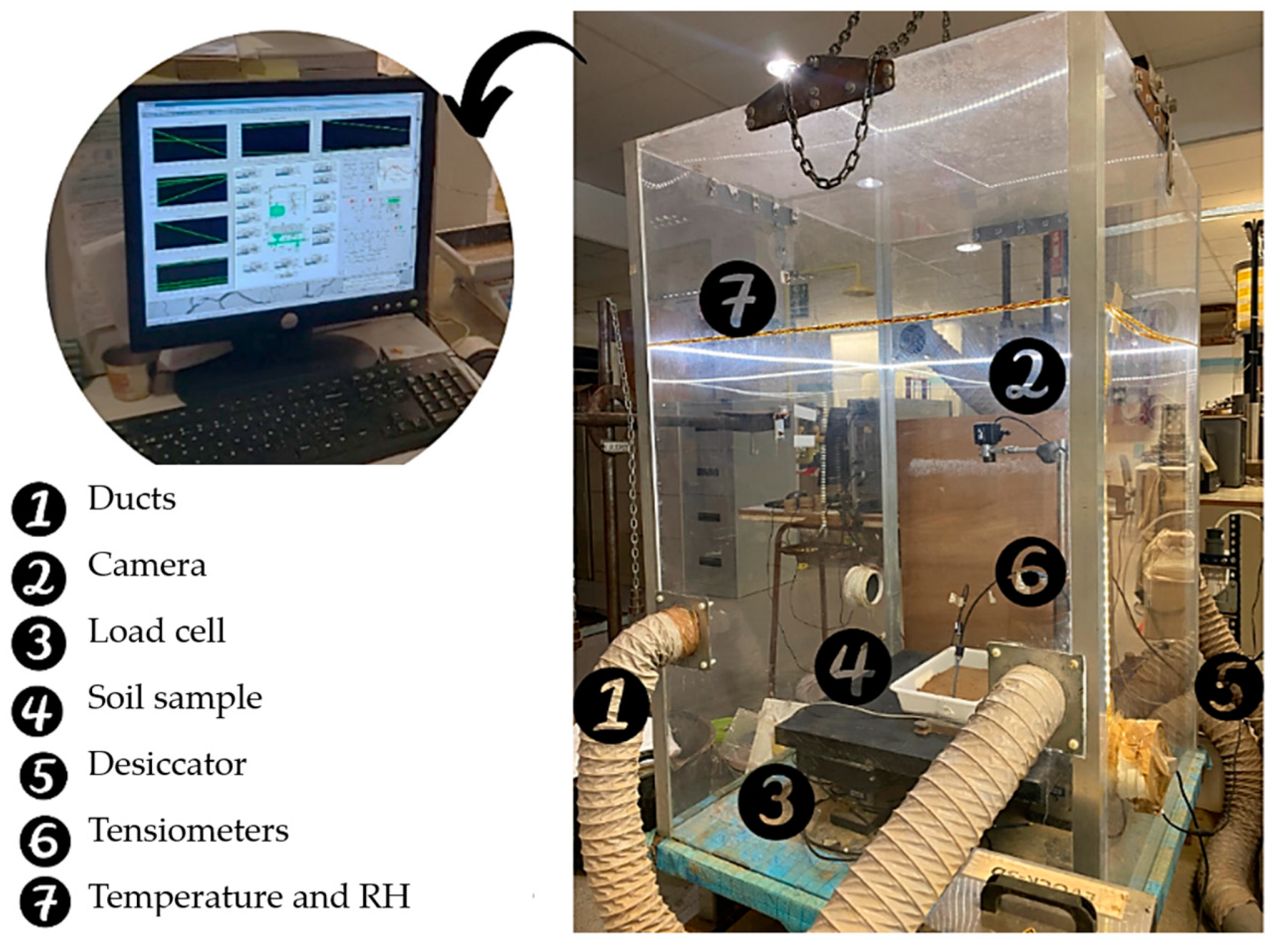

3.4. Desiccation in the Environmental Chamber and Suction Measurement

3.5. Image Analysis

4. Results and Discussion

4.1. Conditions of Induced Desiccation

4.2. Visual Assessment during Desiccation: Qualitative Analysis

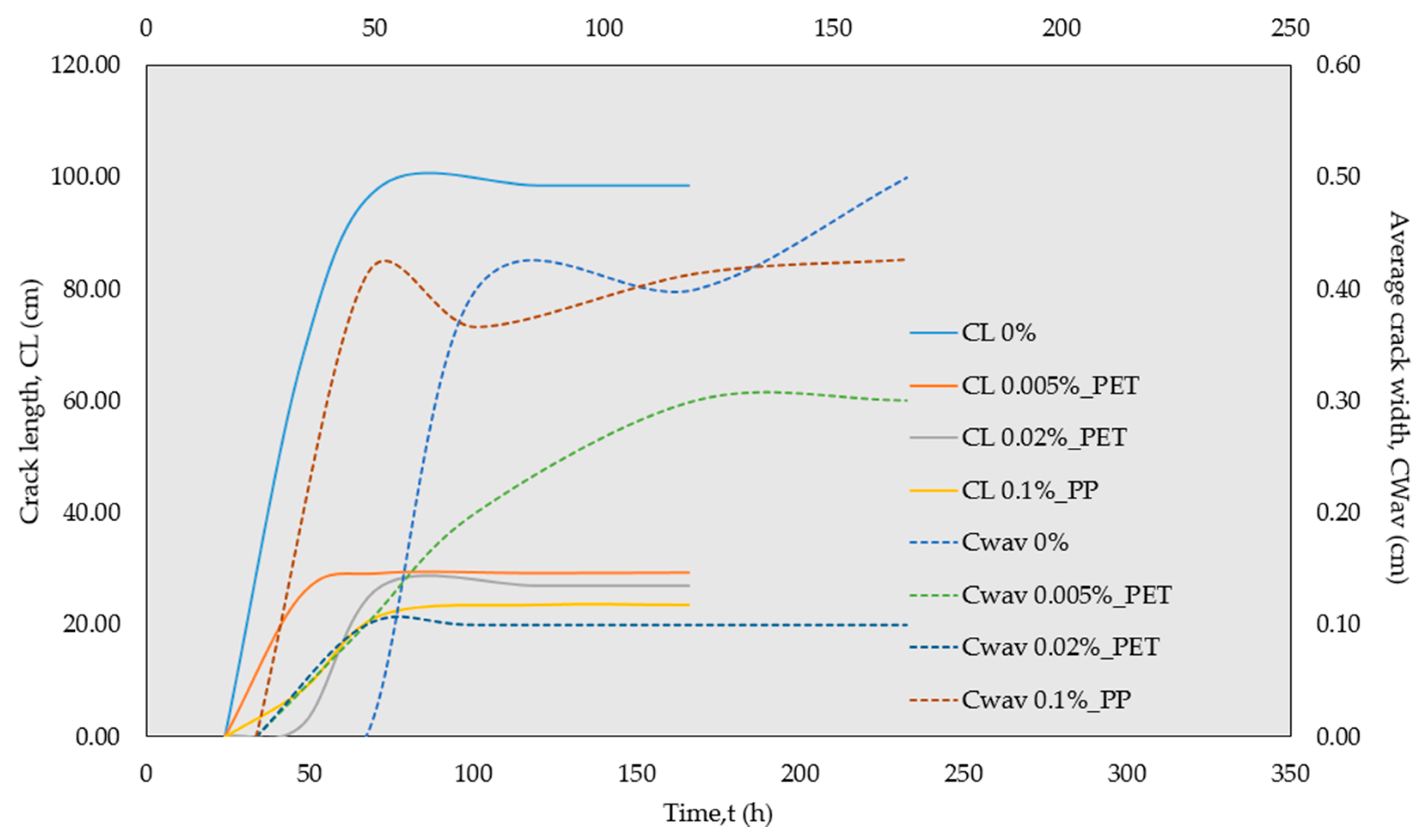

4.3. Effect of Plastic Fibers on the Quantitative Parameters of Soil Cracking and Shrinkage

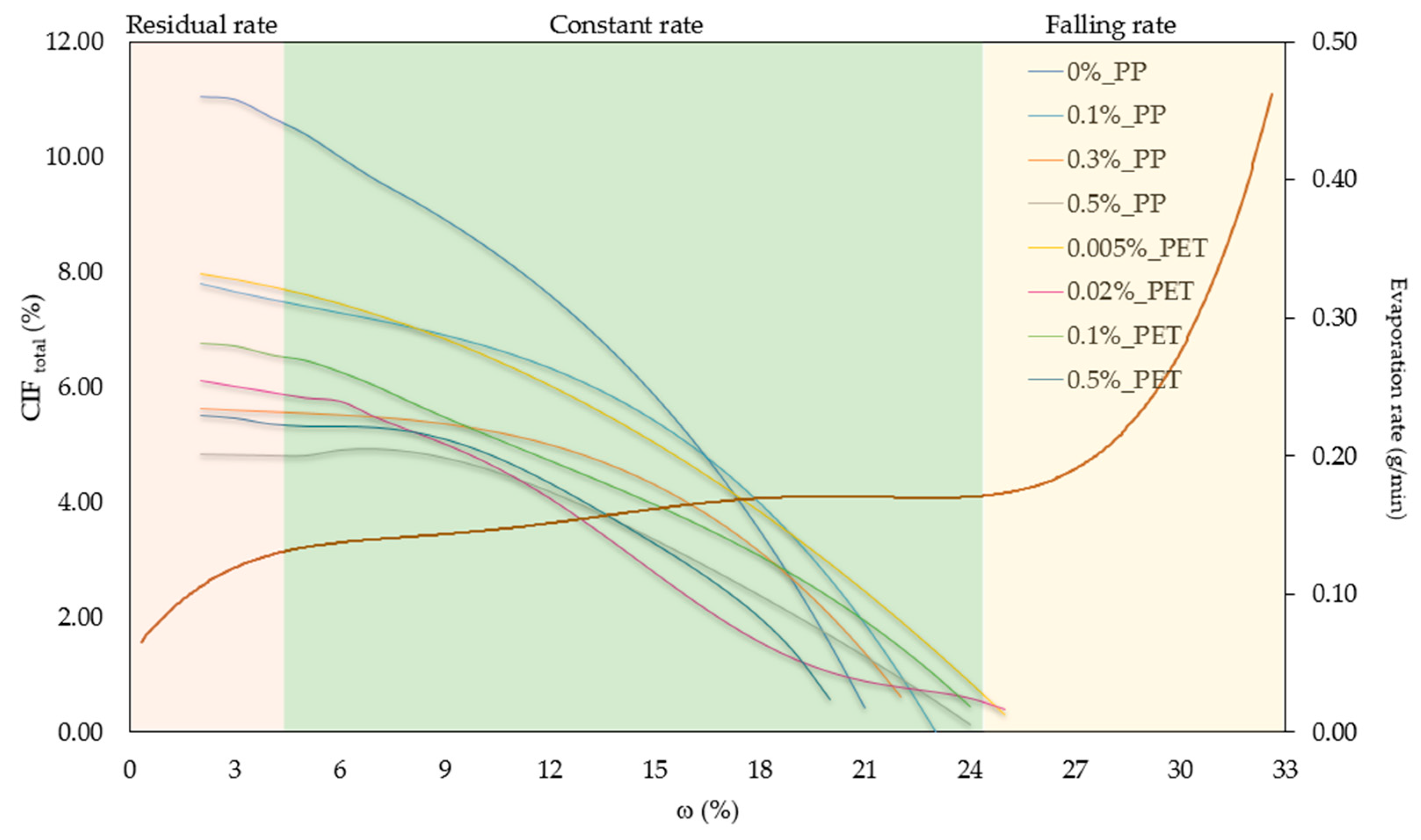

4.4. Effect of Plastic Fibers on the Soil Retention Curve

4.5. Environmental Benefits and Considerations for Recycled Plastic Fiber Soil Reinforcement

- (i)

- Goal 9 seeks to build resilient infrastructure, promote sustainable industrialization and innovative designs for durable solutions, and develop more efficient recycling methods and material specifications.

- (ii)

- Goal 12 is to ensure sustainable consumption and production. Reusing plastic reduces the need for new raw materials in both soil stabilization and plastic manufacturing, helping to conserve non-renewable natural resources (target 12.2). Additionally, target 12.5 aims to significantly reduce waste generation through the prevention, reduction, recycling, and reuse of materials and products. Hence, recycling plastics to produce fibers reduces solid waste and pollutants by diverting them from landfills or incinerators.

- (iii)

- Goal 13 is to take action to combat climate change and its impacts. Soil reinforcement with recycled plastic fibers strengthens the ability to adapt to drought-related hazards and their effects on infrastructure.

5. Conclusions

5.1. Effectiveness of Recycled Plastic Fibers in the Reduction of Soil Cracking and Shrinkage

5.2. Suction Behavior of Reinforced Soil

5.3. Environmental Benefits

6. Recommendations

- (a)

- The optimum fiber content was determined through image analysis in terms of the maximum efficiency in crack reduction and volumetric changes. It is necessary to complement this with conventional tests to verify that the reinforced soil provides high-density and strength properties.

- (b)

- Investigating soils over a wide range of plasticity indices is important, since soil plasticity is a critical factor in determining the behavior of fine reinforced soils.

- (c)

- We observed that shrinkage progressed with time and was most pronounced in samples with low fiber content. Therefore, the influence of edge conditions on shrinkage should be thoroughly investigated.

- (d)

- In our qualitative evaluation of the samples, fiber size showed some relevance. Therefore, fiber size and the scaling effect should be addressed in more detail.

- (e)

- While 2D imaging provides valuable information and simplifies dimensionality, it does not fully capture the three-dimensional features of soil cracking for more complex analyses, such as pore size and distribution with fiber size, length, and content. Therefore, further efforts should be made to develop more advanced 3D analyses for a more complete representation of fiber-reinforced soil behavior.

- (f)

- The results obtained from the suction measurements suggest that despite the structural change of the soil due to the interaction between the particles and the fibers, there is no appreciable change in the hydraulic parameters of the plastic fiber reinforced soil, but further investigations are needed to confirm this.

- (g)

- We recommend full-scale physical modeling in natural soil exposed to natural environment in instrumented field tests. This extension would allow the inclusion of larger soil fiber masses to study the influence of other parameters on stresses, deformations, and soil cracking: compaction, suction, edge effects, depth, and weather parameters. For these field tests, it is suggested to follow the recommendations on fiber addition, mixing, and compaction methods that have been found to be satisfactory in providing a reasonably random distribution of fibers in other types of soils [45,70,71,72].

- (h)

- Finally, studies should be conducted to evaluate the potential adverse effects of synthetic fibers as soil reinforcement. For example, future investigations of plastic-modified soils should consider testing for water leachability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Feng, S.; Fu, Q. Expansion of global drylands under a warming climate. Atmos. Chem. Phys. 2013, 13, 10081–10094. [Google Scholar] [CrossRef]

- Berg, A.; Findell, K.; Lintner, B.; Giannini, A.; Seneviratne, S.I.; van den Hurk, B.; Lorenz, R.; Pitman, A.; Hagemann, S.; Meier, A.; et al. Land–atmosphere feedback amplify aridity increase over land under global warming. Nat. Clim. Chang. 2016, 6, 869–874. [Google Scholar] [CrossRef]

- Louati, F.; Trabelsi, H.; Jamei, M.; Taibi, S. Impact of wetting-drying cycles and cracks on the permeability of compacted clayey soil. Eur. J. Environ. Civ. Eng. 2018, 25, 696–721. [Google Scholar] [CrossRef]

- Guo, L.; Chen, G.; Ding, L.; Zheng, L.; Gao, J. Numerical simulation of full desiccation process of clayey soils using an extended DDA model with soil suction consideration. Comput. Geotech. 2023, 153, 105107. [Google Scholar] [CrossRef]

- Kandalai, S.; John, N.J.; Patel, A. Effects of Climate Change on Geotechnical Infrastructures—State of the art. Environ. Sci. Pollut. Res. 2023, 30, 16878–16904. [Google Scholar] [CrossRef] [PubMed]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/publications/transforming-our-world-2030-agenda-sustainable-development-17981 (accessed on 5 February 2024).

- Tang, C.S.; Zhu, C.; Cheng, Q.; Zeng, H.; Xu, J.J.; Tian, B. Desiccation cracking of soils: A review of investigation approaches, underlying mechanisms, and influencing factors. Earth Sci. Rev. 2021, 216, 103586. [Google Scholar] [CrossRef]

- Zeng, H.; Tang, C.S.; Cheng, Q.; Zhu, C.; Yin, L.Y.; Shi, B. Drought induced soil desiccation cracking behavior with consideration of basal friction and layer thickness. Water Resour. Res. 2020, 567, e2019WR026948. [Google Scholar] [CrossRef]

- Puppala, J.; Musenda, C. Effects of fiber reinforcement on strength and volumen change behavior of expansive soils. In Proceedings of the 79th Annual Meeting, Washington, DC, USA, 9–13 January 2000. [Google Scholar] [CrossRef]

- Malekzadeh, M.; Huriye, B. Hydro-mechanical behavior of polypropylene fiber reinforced expansive soils. KSCE J. Civ. Eng. 2014, 18, 2028–2033. [Google Scholar] [CrossRef]

- Li, J.H.; Zhang, L.M. Study of desiccation crack initiation and development at ground surface. Eng. Geol. 2011, 123, 347–358. [Google Scholar] [CrossRef]

- Sanchez, M.; Atique, A.; Kim, S.; Romero, E.; Zielinski, M. Exploring desiccation cracks in soils using a 2D profile laser device. Acta Geotech. 2013, 8, 583–596. [Google Scholar] [CrossRef]

- Tay, Y.Y.; Stewart, D.I.; Cousens, T.W. Shrinkage and desiccation cracking in bentonite-sand landfill liners. Eng. Geol. 2001, 60, 263–274. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Liu, C.; Zhao, L.; Wang, B. Influencing factors of geometrical structure of surface shrinkage cracks in clayey soils. Eng. Geol. 2008, 101, 204–217. [Google Scholar] [CrossRef]

- Miller, C.J.; Mi, H.; Yesiller, N. Experimental analysis of desiccation crack propagation in clay liners. JAWRA 1998, 34, 677–686. [Google Scholar] [CrossRef]

- Yesiller, N.; Miller, C.J.; Inci, G.; Yaldo, K. Desiccation and cracking behavior of three compacted landfill liner soils. Eng. Geol. 2000, 57, 105–121. [Google Scholar] [CrossRef]

- Prat, P.C.; Ledesma, A.; Lakshmikantha, M.R. Size effect in the cracking of drying soil. In Fracture of Nano and Engineering Materials and Structures; Springer: Berlin/Heidelberg, Germany, 2006; pp. 1373–1374. [Google Scholar]

- Hallet, P.D.; Newson, T.A. Describing soil crack formation using elastic–plastic fracture mechanics. Eur. J. Soil Sci. 2005, 56, 31–38. [Google Scholar] [CrossRef]

- Amarasiri, A.L.; Kodikara, J.K.; Costa, S. Numerical modelling of desiccation cracking. Int. J. Numer. Anal. Methods Geomech. 2011, 35, 82–96. [Google Scholar] [CrossRef]

- Zeng, H.; Tang, C.S.; Cheng, Q.; Inyang, H.I.; Rong, D.Z.; Lin, L.; Shi, B. Coupling effects of interfacial friction and layer thickness on soil desiccation cracking behavior. Eng. Geol. 2019, 260, 105220. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Liu, C.; Gao, L.; Inyang, H.I. Experimental investigation of the desiccation cracking behavior of soil layers during drying. J. Mater. Civ. Eng. 2011, 23, 873–878. [Google Scholar] [CrossRef]

- Shrestha, A.; Jotisankasa, A.; Chaiprakaikeow, S.; Pramusandi, S.; Soralump, S.; Nishimura, S. Determining shrinkage cracks based on the small-strain shear modulus–suction relationship. Geosciences 2019, 9, 362. [Google Scholar] [CrossRef]

- Lloret, A.; Olivella, S. Crack initiation in drying soils. In Proceedings of the Second International Conference on Unsaturated Soils; International Academic Publishers: Beijing, China, 1998; pp. 497–502. [Google Scholar]

- Towner, G. The mechanics of cracking of drying clays. J. Agric. Engng. 1987, 36, 115–124. [Google Scholar] [CrossRef]

- Colina, H.; Roux, S. Experimental model of cracking induced by drying shrinkage. Eur. Phys. J. E 2000, 1, 189–194. [Google Scholar] [CrossRef]

- Ávila, G. Estudio de la Retracción y el Agrietamiento de Arcillas. Aplicación a la Arcilla de Bogotá. Ph. D. Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2004. [Google Scholar]

- Liu, C.; Tang, C.; Sun, K.; Li, H.; Xu, S.; Leng, T. Review on the mechanism and theoretical model of desiccation cracking in clay soil. J. Eng. Geol. 2018, 262, 296–308. [Google Scholar] [CrossRef]

- Julina, M.; Thyagaraj, T. Quantification of desiccation cracks using X-ray tomography for tracing shrinkage path of compacted expansive soil. Acta Geotech. 2019, 4, 35. [Google Scholar] [CrossRef]

- Al-Jeznawi, D.; Sanchez, M.; Al-Taie, A.J. Using image analysis technique to study the effect of boundary and environment conditions on soil cracking mechanism. Geotech. Geol. Eng. 2021, 39, 25–36. [Google Scholar] [CrossRef]

- Lin, L.; Tang, C.; Cheng, Q.; Zeng, H.; Shi, B. Desiccation cracking behavior of soils based on digital image correlation technique. Chin. J. Geotech. Eng. 2019, 41, 1311–1318. [Google Scholar]

- Shit, P.K.; Bhunia, G.S.; Maiti, R. Soil crack morphology analysis using image processing techniques. MESE 2015, 14, 35. [Google Scholar] [CrossRef]

- Liu, C.; Tang, C.S.; Shi, B.; Suo, W.B. Automatic quantification of crack patterns by image processing. Comput. Geosci. 2013, 57, 77–80. [Google Scholar] [CrossRef]

- Baer, J.U.; Kent, T.F.; Anderson, S.H. Image analysis and fractal geometry to characterize soil desiccation cracks. Geoderma 2009, 154, 153–163. [Google Scholar] [CrossRef]

- Peng, X.; Horn, R.; Peth, S.; Smucker, A. Quantification of soil shrinkage in 2D by digital image processing of soil surface. Soil Tillage Res. 2006, 91, 173–180. [Google Scholar] [CrossRef]

- Singh, S.; Rout, S.; Tiwari, A. Quantification of desiccation cracks using image analysis technique. Int. J. Geotech. Eng. 2018, 12, 383–388. [Google Scholar] [CrossRef]

- Auvray, R.; Rosin-Paumier, S.; Abdallah, A.; Masrouri, F. Quantification of soft soil cracking during suction cycles by image processing. Eur. J. Environ. Civ. Eng. 2013, 18, 11–32. [Google Scholar] [CrossRef]

- Lakshmikantha, R.M.; Prat, P.; Ledesma, A. Boundary effects in the desiccation of soil layers with controlled environmental conditions. Geotech. Test. J. 2018, 41, 675–697. [Google Scholar] [CrossRef]

- Colombi, T.; Kirchgessner, N.; Seskog, D.; Alexandersson, S.; Larsbo, M.; Keller, T. A time-lapse imaging platform for quantification of soil crack development due to simulated root water uptake. Soil Tillage Res. 2021, 205, 104769. [Google Scholar] [CrossRef]

- Tang, C.S.; Zhu, C.; Leng, T.; Shi, B.; Cheng, Q.; Zeng, H. Three-dimensional characterization of desiccation cracking behavior of compacted clayey soil using X-ray computed tomography. Eng. Geol. 2019, 255, 1–10. [Google Scholar] [CrossRef]

- Tang, C.S.; Wang, D.; Zhu, C.; Zhou, Q.; Xu, S.; Shi, B. Characterizing drying-induced clayey soil desiccation cracking process using electrical resistivity method. Appl. Clay Sci. 2018, 181, 101–112. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Miller, C.J.; Rifai, S. Fiber reinforcement for waste containment soil liners. J. Environ. Eng. 2004, 130, 891–895. [Google Scholar] [CrossRef]

- Al Wahab, R.M. Using fibers to reduce tension cracks and shrink/swell in compacted clays. Proc. Geoenviron. 2000, 1995, 791–805. [Google Scholar]

- Shukla Sanjay, K. Fundamentals of Fiber-Reinforced Soil Engineering; Springer Nature Singapore Pte Ltd.: Singapore, 2017. [Google Scholar] [CrossRef]

- Chaduvula, U.; Viswanadham, B.V.S.; Kodikara, J. A study on desiccation cracking behavior of polyester fiber-reinforced expansive clay. Appl. Clay Sci. 2017, 142, 163–172. [Google Scholar] [CrossRef]

- Maheshwari, K.; Solanki, C.H.; Desai, A.K. Effect of polyester fibers on strength properties of clayey soil of high plasticity. Int. J. Sci. Eng. Res. 2013, 4, 486–491. [Google Scholar]

- Tang, C.S.; Wang, D.Y.; Cui, Y.J.; Shi, B.; Li, J. Tensile strength of fiber-reinforced soil. J. Mater. Civ. Eng. 2016, 28, 04016031. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Zhao, L.Z. Interfacial shear strength of fiber reinforced soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Abdi, M.R.; Parsapajouh, A.; Arjomand, M.A. Effects of random fiber inclusion on consolidation, hydraulic conductivity, swelling, shrinkage limit and desiccation cracking of clays. Int. J. Civ. Eng. 2008, 6, 284–292. [Google Scholar]

- Ziegler, S.; Leshchinsky, D.; Ling, H.I.; Perry, E.B. Effect of short polymeric fibers on crack development in clays. Soils Found. 1998, 38, 247–253. [Google Scholar] [CrossRef]

- OECD. Global Plastics Outlook: Policy Scenarios to 2060; OECD Publishing: Paris, France, 2022. [Google Scholar] [CrossRef]

- Alabi, O.A.; Ologbonjaye, K.I.; Awosolu, O.; Alalade, O.E. Public and environmental health effects of plastic wastes disposal: A review. J. Toxicol. Risk Assess. 2019, 5, 1–13. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent trends in recycling and reusing techniques of different plastic polymers and their composite materials. Sustain. Mater. Technol. 2022, 31, e00382. [Google Scholar] [CrossRef]

- Mohammad, S.I.; Jobaer, U.; Khaled, A. Plastic waste and carbon footprint generation due to the consumption of bottled waters in Saudi Arabia. Res. Dev. Mater. Sci. 2018, 5, RDMS.000604. [Google Scholar] [CrossRef]

- Dormer, A.; Finn, D.; Ward, P.; Cullen, J. Carbon footprint analysis in plastics manufacturing. J. Clean. Prod. 2013, 51, 133–141. [Google Scholar] [CrossRef]

- Hadad, K. Análisis de Compensación de Emisiones de CO2 por Medio de un Proyecto de Reciclaje de PET en ENKA de Colombia; Ingeniería de Procesos, Universidad Eafit: Medellín, Colombia, 2015. [Google Scholar]

- Rojas, M.; Sheinbaum, C.; Ledesma, M.T. Gases de invernadero generados de residuos sólidos. Rev. Cienc. Y Desarro. 2001, 51–59. [Google Scholar]

- ACI Committee 544. State-of-the-art report on fiber reinforced concrete—ACI 544.1R-96 (reapproved 2002). In ACI Manual of Concrete Practice, Part 6; ACI: Indianapolis, IN, USA, 2002. [Google Scholar]

- Cuadrado, A.; Encalada, D.; Ledesma, A.; Prat, P. Soil surface boundary condition in desiccating soils. In Proceedings of the XVII ECSMGE-2019, Geotechnical Engineering Foundation of the Future 2019, Reykjavik, Island, 1–6 September 2019. [Google Scholar] [CrossRef]

- Cordero, J.A. Experimental Analysis of Soil Cracking Due to Environmental Conditions. Ph. D. Thesis, Universidad Politécnica de Cataluña, Barcelona, Spain, 2019; 298p. [Google Scholar]

- ASTM Committee D-18 on Soil and Rock. ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM Committee D-18 on Soil and Rock. ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM Committee D-18 on Soil and Rock. ASTM D4943-18; Standard Test Method for Shrinkage Factors of Cohesive Soils by the Water Submersion Method. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM Committee D-18 on Soil and Rock. ASTM D2487-17e1; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM Committee D-18 on Soil and Rock. ASTM C837-09; Standard Test Method for Methylene Blue Index of Clay. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM Committee D-18 on Soil and Rock. ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2021.

- Hernandez-Valerio, C.; Botero-Jaramillo, E.; Ossa-Lopez, A. Study of the dynamic behavior of fine soil reinforced with recycled polyethylene terephthalate (PET) fiber. DYNA New Technol. 2022, 9, 16. [Google Scholar] [CrossRef]

- Lakshmikantha, M.R.; Prat, P.C.; Ledesma, A. Image analysis for the quantification of a developing crack network on a drying soil. Geotech. Test. J. 2009, 32, 505–515. [Google Scholar] [CrossRef]

- Hoover, J.M.; Moeller, D.T.; Pitt, J.M.; Smith, S.G.; Wainaina, N.W. Performance of randomly oriented fiber—Reinforced roadway soils—A laboratory and field investigation. In Iowa DOT project report HR-211; Department of Civil Engineering, Engineering Research Institute, Iowa State University: Ames, IA, USA, 1982. [Google Scholar]

- Gray, D.H.; Al-Refeai, T.O. Behavior of fabric versus fiber-reinforced sand. J. Geotech. Eng. 1986, 112, 804–820. [Google Scholar] [CrossRef]

- White David, J.; Vennapusa, P. Low-Cost Rural Surface Alternatives: Literature Review and Recommendations; InTrans Proj. 11-402, Final Report; Center for Earthworks Engineering Research, Iowa State University: Ames, IA, USA, 2013. [Google Scholar]

| Fiber Type | L (mm) | D (μm) | Gs [59] | σt (MPa) [59] | E (MPa) [59] | εq (%) [59] | Tf (°F) [59] |

|---|---|---|---|---|---|---|---|

| PET | 50 | 15 | 0.92–0.96 | 76–586 | 4999 | 3–80 | 273 |

| PP | 13 | 31 | 0.9–0.91 | 138–689 | 3447–4826 | 15 | 330 |

| Index Properties | ||

| 2.7 | [62] | |

| 29 | [63] | |

| 17 | [63] | |

| 14 | [64] | |

| Plasticity index | 12 | [63] |

| Unified Soil Classification System (USCS) | CL | [65] |

| Number of additions of methylene blue (N) | 72 | [66] |

| Proctor compaction | ||

| 16 | [67] | |

| 17.8 | [67] | |

| Code | Fiber | RH | T |

|---|---|---|---|

| % | % | °C | |

| 0.005%_PET | 0.005 | 29.94 | 24.38 |

| 0.02%_PET | 0.02 | 30.56 | 20.75 |

| 0.1%_PET | 0.1 | 29.59 | 23.24 |

| 0.5%_PET | 0.5 | 29.72 | 22.35 |

| 0%_PP | 0 | 30 | 22 |

| 0.1%_PP | 0.1 | ||

| 0.3%_PP | 0.3 | ||

| 0.5%_PP | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández, C.; Beltrán, G.; Botero, E. Use of Recycled Plastic Fibers to Control Shrinkage and Desiccation Cracking in Clayey Soils. Sustainability 2024, 16, 3853. https://doi.org/10.3390/su16093853

Hernández C, Beltrán G, Botero E. Use of Recycled Plastic Fibers to Control Shrinkage and Desiccation Cracking in Clayey Soils. Sustainability. 2024; 16(9):3853. https://doi.org/10.3390/su16093853

Chicago/Turabian StyleHernández, Carolina, Gloria Beltrán, and Eduardo Botero. 2024. "Use of Recycled Plastic Fibers to Control Shrinkage and Desiccation Cracking in Clayey Soils" Sustainability 16, no. 9: 3853. https://doi.org/10.3390/su16093853