Improvement of Geotechnical Properties of Clayey Soil Using Biopolymer and Ferrochromium Slag Additives

Abstract

:1. Introduction

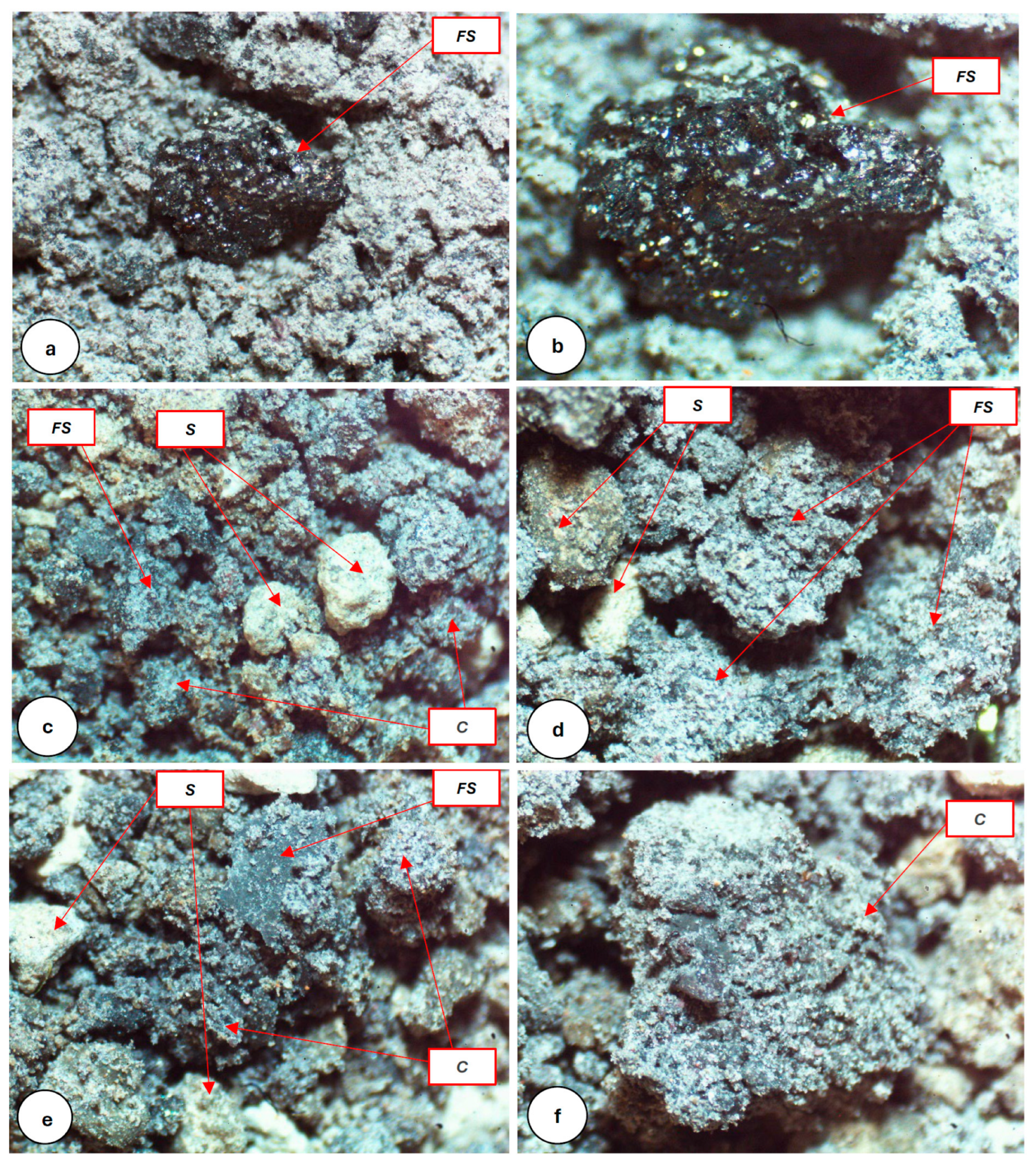

2. Materials and Methods

2.1. Material

2.2. Sample Preparation and Testing

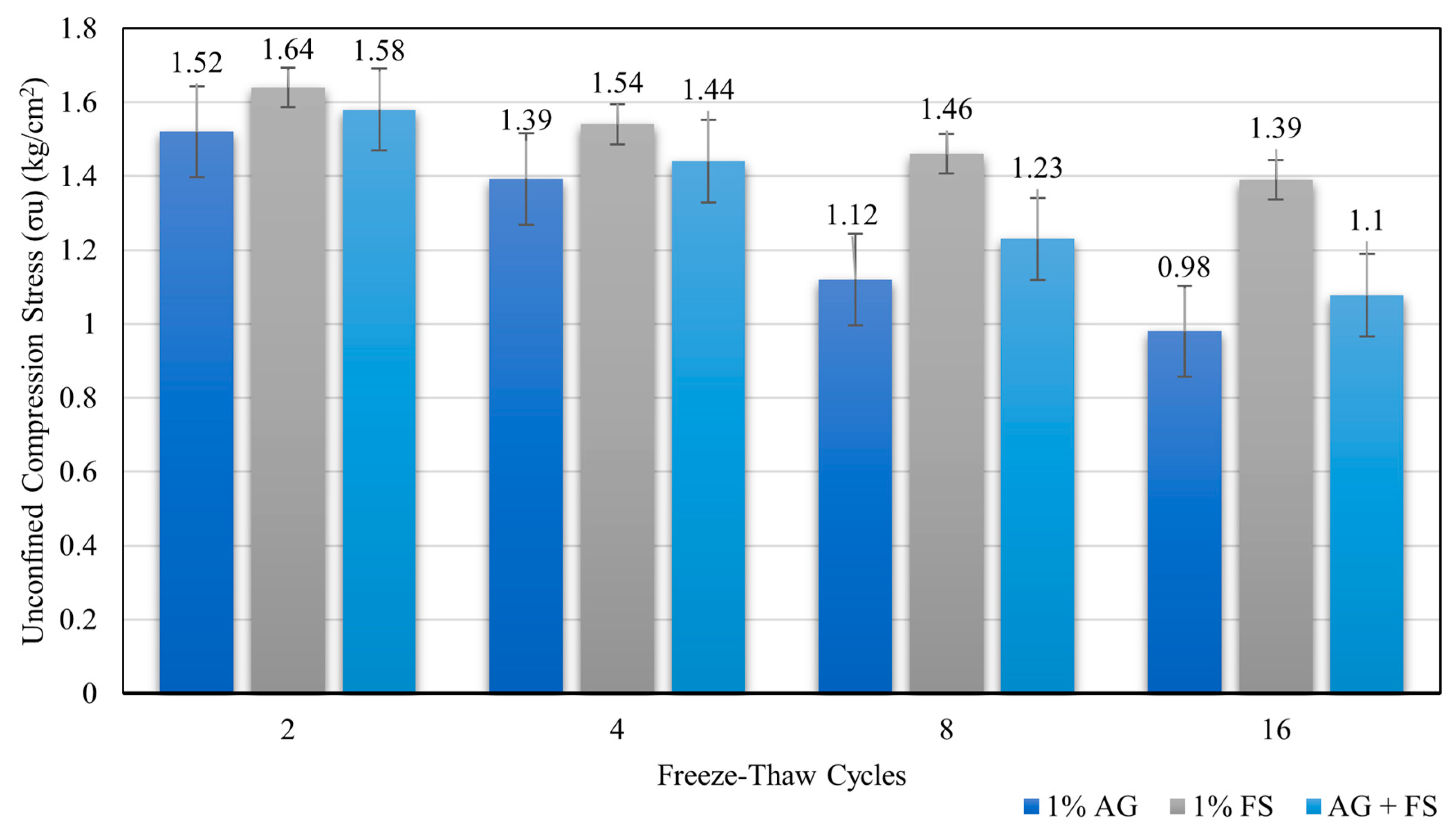

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brune, P.; Perucchio, R.; Ingraffea, A.R.; Jackson, M.D. The toughness of imperial Roman concrete. In Proceedings of the 7th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Jeju Island, Republic of Korea, 23–28 May 2010; pp. 38–45. [Google Scholar]

- Delatte, N.J. Lessons from Roman cement and concrete. J. Prof. Issues Eng. Educ. Pract. 2001, 127, 109–115. [Google Scholar] [CrossRef]

- Jang, J. A Review of the Application of Biopolymers on Geotechnical Engineering and the Strengthening Mechanisms between Typical Biopolymers and Soils. Adv. Mater. Sci. 2020, 2020, 1465709. Available online: https://www.hindawi.com/journals/amse/2020/1465709/abs/ (accessed on 19 November 2023). [CrossRef]

- Jayapal, J.; Boobathiraja, S.; Thanaraj, M.S.; Priyadarshini, K. Weak soil stabilization using different admixtures—A comparative study. Adv. Mater. Sci. Eng. 2020, 3, 57–63. [Google Scholar]

- Chen, H.; Wang, Q. The behavior of organic matter in the process of soft soil stabilization using cement. Bull. Eng. Geol. Environ. 2006, 65, 445–448. [Google Scholar] [CrossRef]

- Saadeldin, R.; Siddiqua, S. Geotechnical characterization of a clay–cement mix. Bull. Eng. Geol. Environ. 2013, 72, 601–608. [Google Scholar] [CrossRef]

- Basu, D.; Misra, A.; Puppala, A.J. Sustainability and geotechnical engineering: Perspectives and review. Can. Geotech. J. 2015, 52, 96–113. [Google Scholar] [CrossRef]

- Kumar, S.; Thomas, B.S.; Gupta, V.; Basu, P.; Shrivastava, S. Sandstone wastes as aggregate and its usefulness in cement concrete—A comprehensive review. Renew. Sustain. Energy 2018, 81, 1147–1153. [Google Scholar] [CrossRef]

- Terzaghi, K. Theoretical Soil Mechanics; John Wiley and Sons Inc.: New York, NY, USA, 1943. [Google Scholar]

- Cetin, H.; Fener, M.; Gunaydin, O. Geotechnical properties of tire-cohesive clayey soil mixtures as a fill material. Eng. Geol. 2006, 88, 110–120. [Google Scholar] [CrossRef]

- Marks, B.D. Sodium-Chloride and Sodium-Chloride-Lime Treatment of Cohesive Oklahoma Soils. Ph.D. Thesis, Oklahoma State University, Stillwater, OK, USA, 1970. [Google Scholar]

- Etim, R.K.; Attah, I.C.; Ekpo, D.U.; Usanga, I.N. Evaluation on stabilization role of lime and cement in expansive black clay—Oyster shell ash composite. Transp. Infrastruct. Geotechnol. 2021, 9, 729–763. [Google Scholar] [CrossRef]

- Okagbue, C.O.; Onyeobi, S.U.T. Potential of Marble Dust to Stabilise Red Tropical Soils for Road Construction. Eng. Geol. 1999, 53, 371–380. [Google Scholar]

- Bağrıaçık, B. Utilization of alkali-activated construction demolition waste for sandy soil improvement with large-scale laboratory experiments. Constr. Build. Mater. 2021, 302, 124173. [Google Scholar] [CrossRef]

- Yılmaz, A.; Karaşahin, M. Mechanical properties of ferrochromium slag in granular layers of flexible pavements. Mater. Struct. 2010, 43, 309–317. [Google Scholar] [CrossRef]

- Gencel, O.; Munir, M.J.; Kazmi, S.M.S.; Sutcu, M.; Erdogmus, E.; Velasco, P.M.; Quesada, D.E. Recycling industrial slags in production of fired clay bricks for sustainable manufacturing. Ceram. Int. 2021, 47, 30425–30438. [Google Scholar] [CrossRef]

- Gu, F.; Zhang, Y.; Tu, Y.; Wu, X.; Zhu, Y.; Yuyang Long, Y.; Shen, D. Assessing magnesia effect on preparing refractory materials from ferrochromium slag. Ceram. Int. 2022, 48, 13100–13107. [Google Scholar] [CrossRef]

- Ren, Y.; Ren, Q.; Wu, X.; Zheng, J.; Hai, O. Recycling of solid wastes ferrochromium slag for preparation of eco-friendly high-strength spinel–corundum ceramics. Mater. Chem. Phys. 2020, 239, 122060. [Google Scholar] [CrossRef]

- Topaloglu, S.; Cetin, A.; Dayioglu, A.Y.; Aydilek, A.H. Laboratory Testing of Ferrochrome Slag as an Aggregate in Porous Pavements. Geotech. Test. J. 2024, 47, GTJ20220249. [Google Scholar] [CrossRef]

- Lind, B.B.; Fallman, A.M.; Larsson, L.B. Environmental impact of ferrochrome slag in road construction. Waste Manag. 2001, 21, 255–264. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, A. Investigation of the environmental impacts of slag wastes used in the pavement base layers. J. Grad. Sch. Nat. Appl. Sci. Mehmet Akif Ersoy Univ. 2017, 8, 123–134. [Google Scholar]

- Kartal, G.; Güven, A.; Kahvecioğlu, Ö.; Timur, S. Environmental Effects of Metals-II. Met. J. 2003, 137, 46–51. Available online: https://www.metalurji.org.tr/dergi/dergi137/d137_4651.pdf (accessed on 19 September 2023).

- Piatak, N.M.; Parsons, M.B.; Seal II, R.R. Characteristics and environmental aspects of slag: A review. Appl. Geochem. 2015, 57, 236–266. [Google Scholar] [CrossRef]

- Sahu, N.; Biswas, A.; Kapure, G. A Short Review on Utilization of Ferrochromium Slag. Miner. Process. Extr. Metall. Rev. 2016, 37, 211–219. Available online: https://www.tandfonline.com/doi/abs/10.1080/08827508.2016.1168415 (accessed on 21 October 2023). [CrossRef]

- Ashraf, M.S.; Azahar, S.B.; Yusof, N.Z. Soil Improvement Using MICP and Biopolymers: A Review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Melaka, Malaysia, 2017; Volume 226. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of problematic soils with biopolymer—An environmentally friendly soil stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Biju, M.S.; Arnepalli, D.N. Biopolymer-modified soil: Prospects of a promising green technology. Lect. Notes Civ. Eng. 2019, 16, 163–169. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Tran, A.T.P.; Lee, S.; Kwon, Y.M.; Im, J.; Cho, G.C. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp. Geotech. 2020, 24, 100385. [Google Scholar] [CrossRef]

- Chen, C.; Peng, Z.; Gu, J.; Peng, Y.; Huang, X.; Wu, L. Exploring environmentally friendly biopolymer material effect on soil tensile and compressive behavior. Int. J. Environ. Res. Public Health 2020, 17, 9032. [Google Scholar] [CrossRef] [PubMed]

- Arabani, M.; Shalchian, M.M. A review of the use of bio-based substances in soil stabilization. Environ. Dev. Sustain. 2023, 2023, 1–53. [Google Scholar] [CrossRef]

- Al-Jabri, K. Research on the use of Ferro-Chrome slag in civil engineering applications. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018. [Google Scholar] [CrossRef]

- Das, B.B. Characterization of Ferrochrome slag As an Embankment and Pavement Material. Master’s Thesis, National Institute of Technology, Rourkela, India, 2014. Available online: http://ethesis.nitrkl.ac.in/6593/ (accessed on 7 October 2023).

- Hussein, A.H.; Muhauwiss, F.M.; Hassan, N.A.; Theyab, A.F. Evaluating the shear strength of agar gum-treated gypseous soil. In Smart Geotechnics for Smart Societies; CRC Press: Boca Raton, FL, USA, 2023; pp. 498–504. [Google Scholar] [CrossRef]

- Jang, C.; Yang, B.; Hong, W.; Ahn, J.; Jung, J. Soil Improvement Using Agar Gum Polymer for Seismic Liquefaction Mitigation. Soil Dyn. Earthq. Eng. 2024, 177, 108405. Available online: https://www.sciencedirect.com/science/article/pii/S0267726123006504 (accessed on 18 February 2024). [CrossRef]

- Patla, S.; Mondal, S.; Choudhary, A. On Improving the Performance of Silty Soil by Treating with Ferrochrome Slag: An Experimental Study. In Proceedings of the Indian Geotechnical Conference 2019: IGC-2019 Volume II; Springer: Singapore, 2021; Available online: https://link.springer.com/chapter/10.1007/978-981-33-6370-0_29 (accessed on 18 November 2023).

- Schmidt, G.C. Stratigraphic Nomenclature for the Adana Region Petroleum District VII; Petroleum Administration Bulletin: Ankara, Turkey, 1961; Volume 6, pp. 47–63. [Google Scholar]

- McHugh, D.J. A Guide to the Seaweed Industry; FAO Fisheries Technical Paper 441; Food and Agriculture Organization of the United Nations: Rome, Italy, 2003. [Google Scholar]

- Blakemore, W.R.; Harpell, A.R. Food Stabilizers, Thickeners and Gelling Agents; Blackwell Publishing: Oxford, UK, 2009. [Google Scholar]

- ASTM D 2487-06; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). Annual Book of ASTM Standards: West Conshohocken, PA, USA, 2010. Available online: http://www.astm.org/cgi-bin/resolver.cgi?D2487-06 (accessed on 25 September 2023).

- ASTM D 4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM D 854-23; Standard Test Method for Specific Gravity of Soils by the Water Displacement Methos. ASTM: Philadelphia, PA, USA, 2023.

- ASTM D 698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lb/ft3 (600 kN-m/m3)). ASTM: West Conshohocken, PA, USA, 2021. Available online: http://www.astm.org/cgi-bin/resolver.cgi?D698-12R21 (accessed on 4 December 2023).

- Flórez, M.; Cazón, P.; Vázquez, M. Selected Biopolymers’ Processing and Their Applications: A Review. Polymers 2023, 15, 641. [Google Scholar] [CrossRef] [PubMed]

- ASTM D 2166-06; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: West Conshohocken, PA, USA, 2006.

- ASTM D 3080-04; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM: West Conshohocken, PA, USA, 2012. Available online: http://www.astm.org/cgi-bin/resolver.cgi?D3080-04 (accessed on 6 December 2023).

- Annagür, H.M.; Çetin, M.Y. Performance and Geotechnical Properties of the Aggregates Used for the Turkish Trans-European Motorway Truck Escape Ramps. Transp. Infrastruct. Geotechnol. 2023, 1–25. [Google Scholar] [CrossRef]

- Ghazavi, M.; Roustaie, M. The influence of freeze- thaw cycles on the unconfined compressive strength of fiber-reinforced clay. Cold Reg. Sci. Technol. 2010, 61, 125–131. [Google Scholar] [CrossRef]

- Liu, J.; Wang, T.; Tian, Y. Experimental study of the dynamic properties of cement- and lime-modified clay soils subjected to freeze-thaw cycles. Cold Reg. Sci. Technol. 2010, 61, 29–33. [Google Scholar] [CrossRef]

- Qi, J.L.; Zhang, J.M.; Zhu, Y.L. Influence of freezing–thawing on soil structure and its soils mechanics significance. Chin. J. Rock Mech. Eng. 2004, 22 (Suppl. S2), 2690–2694. [Google Scholar]

- Bağrıaçık, B.; Uslu, F.M.; Yiğittekin, E.S.; Delik, A.; Dinçer, S. The behavior of Bacillus sp. improved soils under the freeze-thaw effect. NOHU J. Eng. Sci. 2021, 10, 704–711. [Google Scholar]

- Mahmutluoğlu, B.; Bağrıaçık, B. Effect of glass waste sludge on the freezing-thawing behavior of clayey soils. Çukurova Univ. J. Fac. Eng. Archit. 2020, 35, 783–796. [Google Scholar] [CrossRef]

- Casagrande, A. Classification and identification of soils. Trans. ASCE 1948, 113, 901–930. [Google Scholar] [CrossRef]

- Mitchell, J.K. Fundamentals of Soil Behavior; John Wiley and Sons: New York, NY, USA, 1993. [Google Scholar]

- Liu, C.; Evett, J.B. Soil Properties: Testing, Measurement, and Evaluation; Prentice-Hall, Inc.: Upper Saddle River, NJ, USA, 2000. [Google Scholar]

- Cetin, H.; Soylemez, M. Soil-particle and pore orientations during drained and undrained shear of cohesive sandy silt–clay soil. Can. Geotech. J. 2004, 41, 1127–1138. [Google Scholar] [CrossRef]

| AG (%) | Liquid Limit (LL) | Plastic Limit (PL) | Plasticity Index (PI) | USCS Classification |

|---|---|---|---|---|

| 0% (Natural) | 42.19% | 25.63% | 16.56% | CL |

| 0.75% | 40.63% | 25.88% | 14.75% | CL |

| 0.85% | 40.38% | 25.97% | 14.41% | CL |

| 1.00% | 40.13% | 26.06% | 14.07% | CL |

| 1.15% | 39.88% | 26.15% | 13.73% | CL |

| FS (%) | ||||

| 0.25% | 41.94% | 25.69% | 16.25% | CL |

| 0.50% | 41.69% | 25.75% | 15.94% | CL |

| 0.75% | 41.44% | 25.81% | 15.63% | CL |

| 1.00% | 41.19% | 25.88% | 15.31% | CL |

| AG (%) | Optimum Water Content (%) | Dry Unit Weight (g/cm3) |

|---|---|---|

| 0 (clay soil) | 17.50 | 1.83 |

| 0.75 | 17.12 | 1.84 |

| 0.85 | 17.04 | 1.86 |

| 1 | 16.85 | 1.87 |

| 1.15 | 16.74 | 1.88 |

| FS (%) | ||

| 0.25 | 17.28 | 1.83 |

| 0.5 | 17.06 | 1.84 |

| 0.75 | 16.84 | 1.84 |

| 1 | 16.62 | 1.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çetin, M.Y.; Bağrıaçık, B.; Annagür, H.M.; Topoliński, S. Improvement of Geotechnical Properties of Clayey Soil Using Biopolymer and Ferrochromium Slag Additives. Polymers 2024, 16, 1306. https://doi.org/10.3390/polym16101306

Çetin MY, Bağrıaçık B, Annagür HM, Topoliński S. Improvement of Geotechnical Properties of Clayey Soil Using Biopolymer and Ferrochromium Slag Additives. Polymers. 2024; 16(10):1306. https://doi.org/10.3390/polym16101306

Chicago/Turabian StyleÇetin, Mustafa Yasin, Baki Bağrıaçık, Hatice Merve Annagür, and Szymon Topoliński. 2024. "Improvement of Geotechnical Properties of Clayey Soil Using Biopolymer and Ferrochromium Slag Additives" Polymers 16, no. 10: 1306. https://doi.org/10.3390/polym16101306