Study on Multiple Effects of Self-Healing Properties and Thermal Characteristics of Asphalt Pavement

Abstract

:1. Introduction

2. Materials and Methods

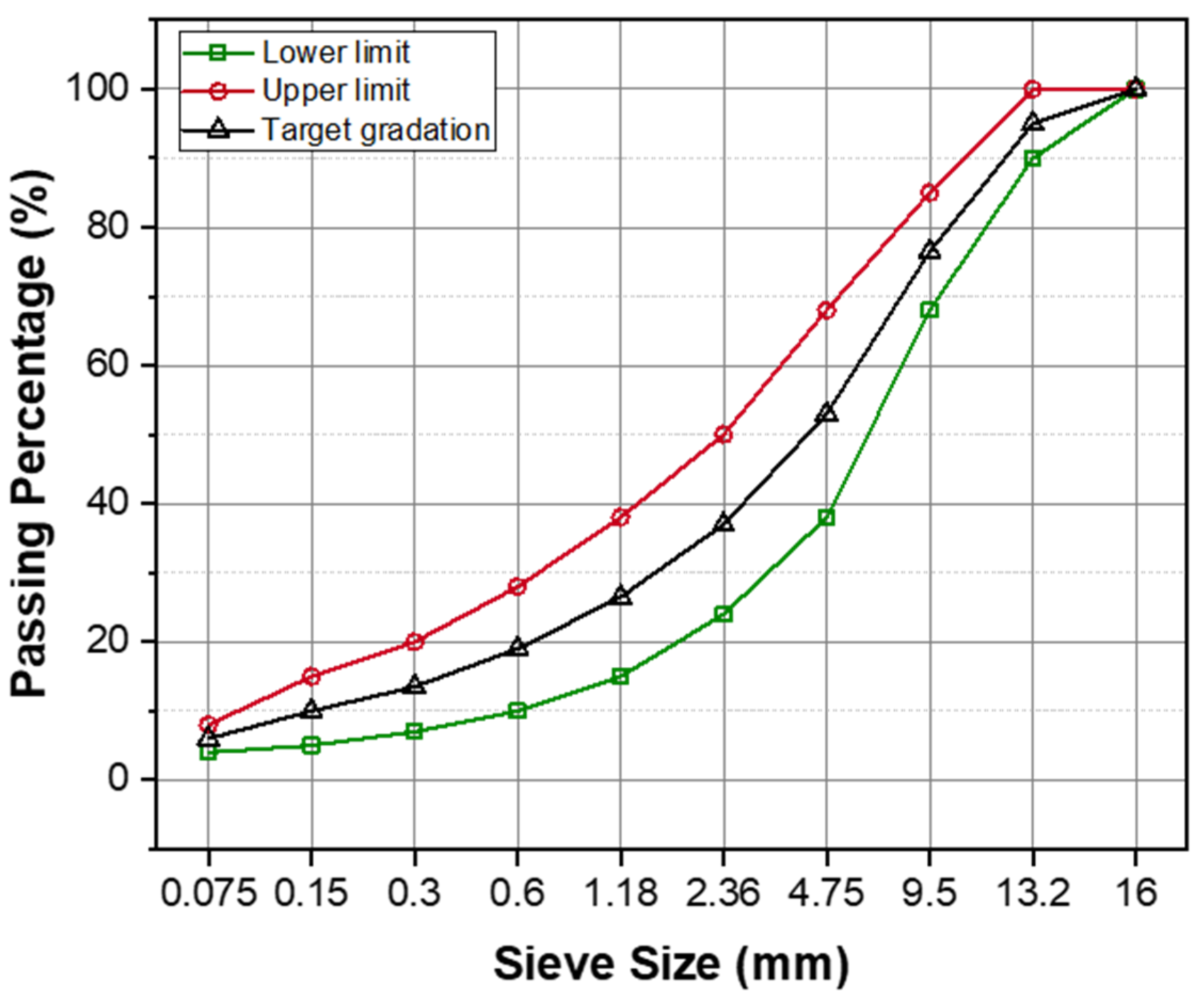

2.1. Materials

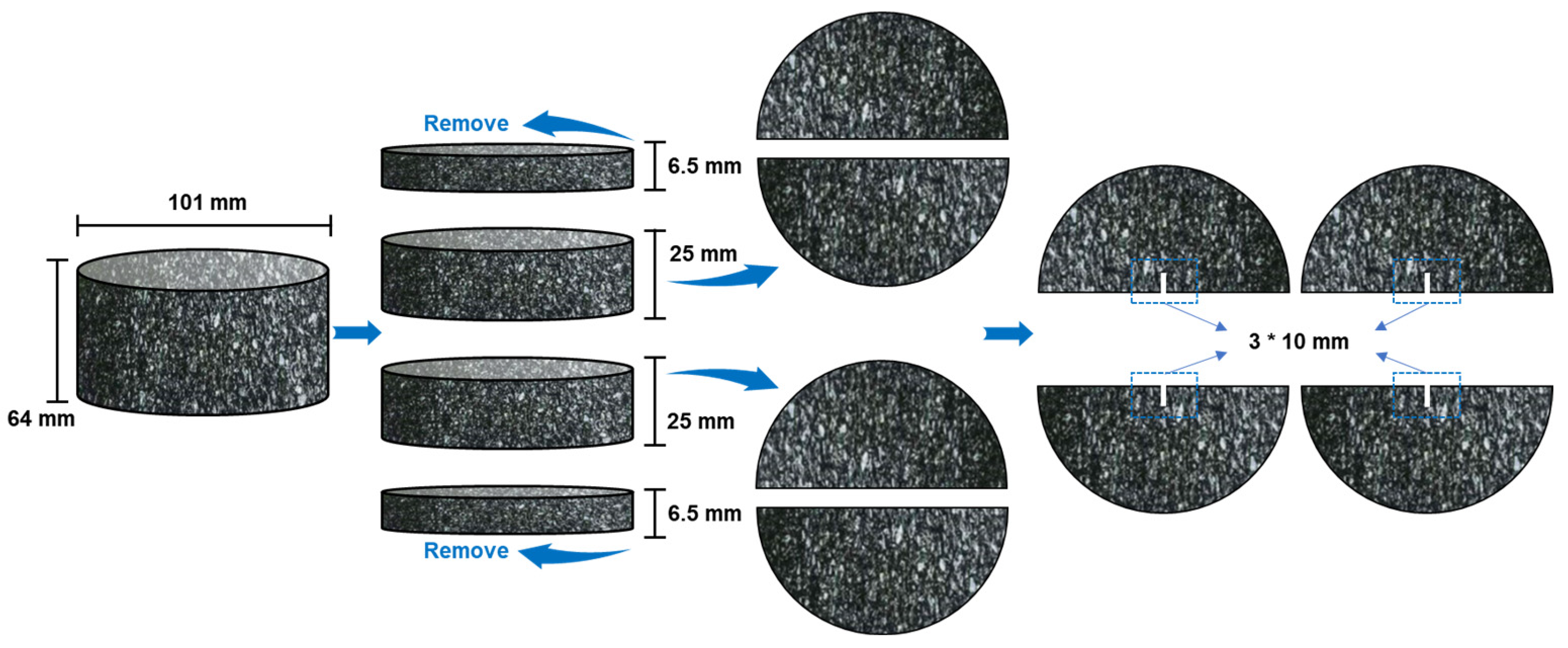

2.2. Sample Preparation

2.3. Three-Point Bending Test

2.4. Microwave Healing Test

3. Results and Discussion

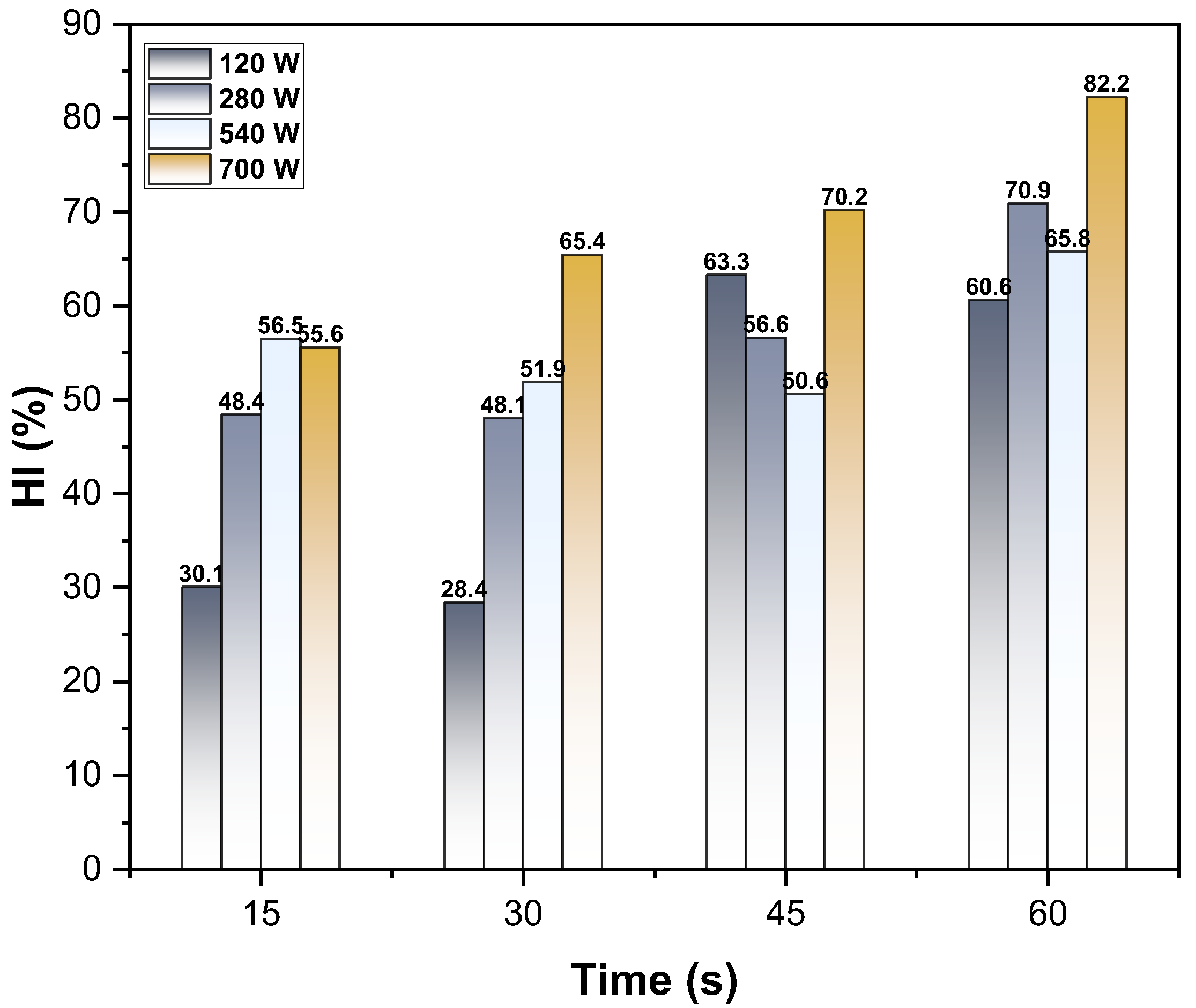

3.1. Healing Effect of Asphalt Mixtures

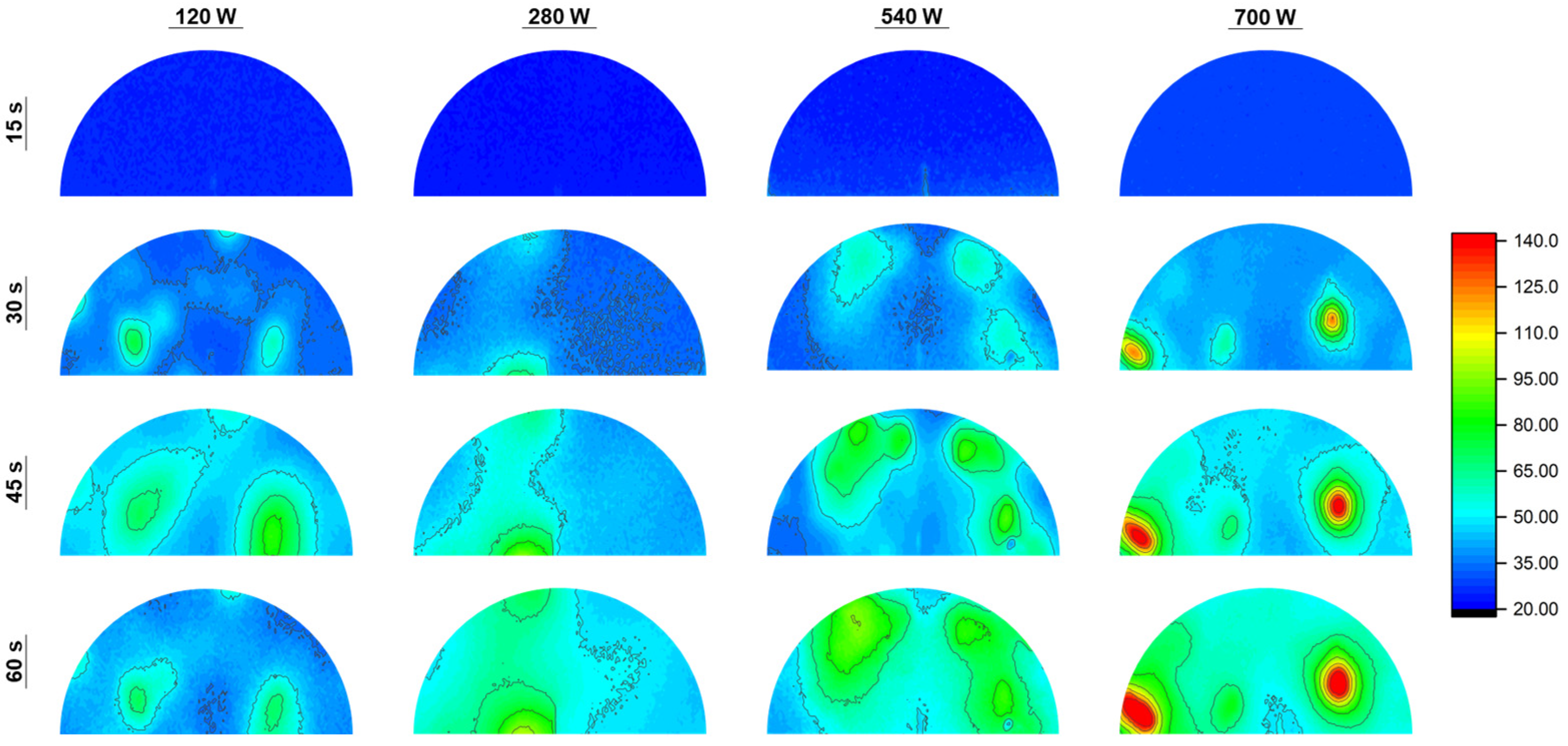

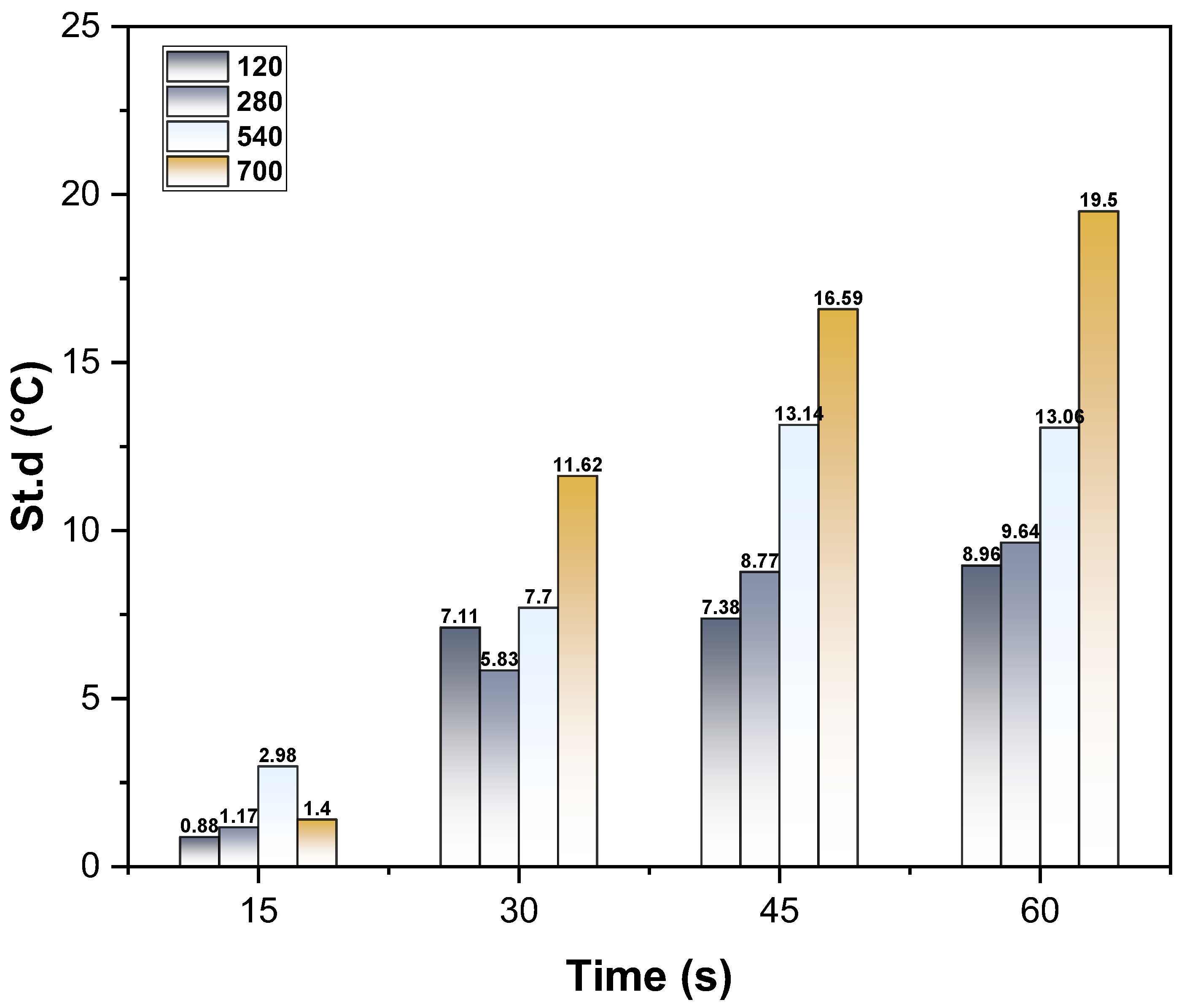

3.2. Thermal Transfer Characteristic

3.3. Crack Parameters of Asphalt Mixtures

4. Conclusions

- (1)

- Heating time and power that are too low are not enough to heal the asphalt mixture; on the contrary, 60 s heating time at 700 W power can restore the strength of the asphalt mixture to more than 80%.

- (2)

- There is a linear correlation between the healing level of the asphalt mixture and the heating time and power, and this relationship continues to exist as the heating cycle increases.

- (3)

- Asphalt mixture temperature uniformity can be observed in the heating process, and the temperature turns more uneven with the heating time and power increase.

- (4)

- The asphalt mixture does not have a healing behavior at the beginning of microwave radiation, but the effective healing area increases with time up to more than 80%.

- (5)

- Microwave heating can promote the recovery of the strength of asphalt mixtures. However, other crack parameters, including fracture energy, flexible index, and crack resistance index, all recovered at less than 50%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Q.; Li, Z.; Hu, W.; Meng, X.; Zhang, H. Driving comfort evaluation for manhole covers and pavement around manholes. Adv. Mater. Sci. Eng. 2019, 2019, 1293619. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Elseifi, M.A. New generation of wide-base tires: Impact on trucking operations, environment, and pavements. Transp. Res. Rec. 2007, 2008, 100–109. [Google Scholar] [CrossRef]

- Li, H.; Nyirandayisabye, R.; Dong, Q.; Niyirora, R.; Hakuzweyezu, T.; Zardari, I.A.; Nkinahamira, F. Crack damage prediction of asphalt pavement based on tire noise: A comparison of machine learning algorithms. Constr. Build. Mater. 2024, 414, 134867. [Google Scholar] [CrossRef]

- Huang, T.; Wang, Z.; Dong, H.; Qin, H.; Liu, H.; Cao, Z. Time-Temperature-Stress Equivalent Characteristics and Nonlinear Viscoelastic Model of Asphalt Mixture under Triaxial Compressive Stress State. J. Mater. Civ. Eng. 2024, 36, 04023543. [Google Scholar] [CrossRef]

- Jahanbakhsh, H.; Karimi, M.M.; Nejad, F.M.; Jahangiri, B. Viscoelastic-based approach to evaluate low temperature performance of asphalt binders. Constr. Build. Mater. 2016, 128, 384–398. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. Preparation and properties of high viscosity modified asphalt. Polym. Compos. 2017, 38, 936–946. [Google Scholar] [CrossRef]

- Atul Narayan, S.P.; Murali Krishnan, J.; Little, D.N.; Rajagopal, K.R. Mechanical behaviour of asphalt binders at high temperatures and specification for rutting. Int. J. Pavement Eng. 2017, 18, 916–927. [Google Scholar] [CrossRef]

- Pokorski, P.; Radziszewski, P.; Sarnowski, M. Study of high-temperature properties of asphalt mixtures used for bridge pavement with concrete deck. Materials 2021, 14, 4238. [Google Scholar] [CrossRef] [PubMed]

- Abouelsaad, A.; White, G. Review of asphalt mixture ravelling mechanisms, causes and testing. Int. J. Pavement Res. Technol. 2021, 15, 1448–1462. [Google Scholar] [CrossRef]

- Li, J.; Guo, W.; Meng, A.; Han, M.; Tan, Y. Investigation on the micro deformation mechanism of asphalt mixtures under high temperatures based on a self-developed laboratory test. Materials 2020, 13, 1791. [Google Scholar] [CrossRef]

- Office, J.E.; Cavalli, M.C.; Chen, D.; Chen, Q.; Chen, Y.; Falchetto, A.C.; Fang, M.; Gu, H.; Han, Z.; He, Z.; et al. Review of advanced road materials, structures, equipment, and detection technologies. J. Road Eng. 2023, 3, 370–468. [Google Scholar]

- Ishaq, M.A.; Giustozzi, F. Correlation between rheological tests on bitumen and asphalt low temperature cracking tests. Constr. Build. Mater. 2022, 320, 126109. [Google Scholar] [CrossRef]

- Zhang, F.; Sha, A.; Cao, Y.; Wang, W.; Song, R. Microwave heating moment, thermal characteristics, and structural variations of different steel slag asphalt mixtures suffered from freeze-thaw damage. Cold Reg. Sci. Technol. 2024, 217, 104028. [Google Scholar] [CrossRef]

- Al-Qudsi, A.; Falchetto, A.C.; Wang, D.; Büchler, S.; Kim, Y.S.; Wistuba, M.P. Finite element cohesive fracture modeling of asphalt mixture based on the semi-circular bending (SCB) test and self-affine fractal cracks at low temperatures. Cold Reg. Sci. Technol. 2020, 169, 102916. [Google Scholar] [CrossRef]

- Khawaja, H.; Tanveer, A. Review of low-temperature crack (LTC) developments in asphalt pavements. Int. J. Multiphysics 2018, 12, 169–187. [Google Scholar]

- Tang, J.; Fu, Y.; Ma, T.; Zheng, B.; Zhang, Y.; Huang, X. Investigation on low-temperature cracking characteristics of asphalt mixtures: A virtual thermal stress restrained specimen test approach. Constr. Build. Mater. 2022, 347, 128541. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, D.; Falchetto, A.C.; Cao, Y. Microwave deicing properties and carbon emissions assessment of asphalt mixtures containing steel slag towards resource conservation and waste reuse. Sci. Total Environ. 2024, 912, 169189. [Google Scholar] [CrossRef] [PubMed]

- Roimela, P.; Salmenkaita, S.; Maijala, P.; Saarenketo, T. Road analysis: A tool for cost-effective rehabilitation measures for Finnish roads. In Proceedings of the Eighth International Conference on Ground Penetrating Radar, Gold Coast, Australia, 27 April 2000; Volume 4084, pp. 107–112. [Google Scholar]

- Zhu, Z.; Cai, W.; Liu, W. Research on Disposal Parameters and Diffusion Path of Asphalt Pavement Crack Grouting. J. Munic. Technol. 2023, 41, 24–29+47. [Google Scholar]

- Anupam, B.R.; Sahoo, U.C.; Chandrappa, A.K. A methodological review on self-healing asphalt pavements. Constr. Build. Mater. 2022, 321, 126395. [Google Scholar] [CrossRef]

- Agzenai, Y.; Pozuelo, J.; Sanz, J.; Perez, I.; Baselga, J. Advanced self-healing asphalt composites in the pavement performance field: Mechanisms at the nano level and new repairing methodologies. Recent Pat. Nanotechnol. 2015, 9, 43–50. [Google Scholar] [CrossRef]

- Roja, K.L.; Padmarekha, A.; Krishnan, J.M. Rheological investigations on warm mix asphalt binders at high and intermediate temperature ranges. J. Mater. Civ. Eng. 2018, 30, 04018038. [Google Scholar] [CrossRef]

- Karimi, M.M.; Amani, S.; Jahanbakhsh, H.; Jahangiri, B.; Alavi, A.H. Induced heating-healing of conductive asphalt concrete as a sustainable repairing technique: A review. Clean. Eng. Technol. 2021, 4, 100188. [Google Scholar] [CrossRef]

- Adam, Q.F.; Levenberg, E.; Ingeman-Nielsen, T.; Skar, A. Modeling the use of an electrical heating system to actively protect asphalt pavements against low-temperature cracking. Cold Reg. Sci. Technol. 2023, 205, 103681. [Google Scholar] [CrossRef]

- Liu, C.; Leng, L. Application of Microwave Heating Technology in Pothole Repair. J. Munic. Technol. 2023, 41, 42–46. [Google Scholar]

- Zhang, J.; Gao, L.; Dong, Z. Review on Materials and Technology of Multifunctional Maintenance of Asphalt Pavement. J. Munic. Technol. 2023, 41, 80–93. [Google Scholar]

- Zhang, L.; Zhang, Z.; Yu, W.; Miao, Y. Review of the Application of Microwave Heating Technology in Asphalt Pavement Self-Healing and De-icing. Polymers 2023, 15, 1696. [Google Scholar] [CrossRef]

- Wu, W.; Jiang, W.; Xiao, J.; Yuan, D.; Wang, T.; Ling, X. Investigation of LAS-based fatigue evaluation methods for high-viscosity modified asphalt binders with high-content polymers. Constr. Build. Mater. 2024, 422, 135810. [Google Scholar] [CrossRef]

- Gao, J.; Guo, H.; Wang, X.; Wang, P.; Wei, Y.; Wang, Z.; Huang, Y.; Yang, B. Microwave deicing for asphalt mixture containing steel wool fibers. J. Clean. Prod. 2019, 206, 1110–1122. [Google Scholar] [CrossRef]

- Fakhri, M.; Javadi, S.; Sedghi, R.; Sassani, A.; Arabzadeh, A.; Baveli Bahmai, B. Microwave induction heating of polymer-modified asphalt materials for self-healing and deicing. Sustainability 2021, 13, 10129. [Google Scholar] [CrossRef]

- Gulisano, F.; Gallego, J. Microwave heating of asphalt paving materials: Principles, current status and next steps. Constr. Build. Mater. 2021, 278, 121993. [Google Scholar] [CrossRef]

- Zhang, F.; Sha, A.; Cao, Y.; Wang, W.; Song, R.; Jiao, W. Characterization of Self-healing Properties of Asphalt Pavement Materials Containing Carbon Nanotubes: From the Binder and Mix Level based on Grey Relational Analysis. Constr. Build. Mater. 2023, 404, 133323. [Google Scholar] [CrossRef]

- Garcia, A.; Salih, S.; Gómez-Meijide, B. Optimum moment to heal cracks in asphalt roads by means electromagnetic induction. Constr. Build. Mater. 2020, 238, 117627. [Google Scholar] [CrossRef]

- Lu, D.; Jiang, X.; Leng, Z.; Huo, Y.; Wang, D.; Zhong, J. Electrically conductive asphalt concrete for smart and sustainable pavement construction: A review. Constr. Build. Mater. 2023, 406, 133433. [Google Scholar] [CrossRef]

- Gallego, J.; del Val, M.A.; Contreras, V.; Páez, A. Heating asphalt mixtures with microwaves to promote self-healing. Constr. Build. Mater. 2013, 42, 1–4. [Google Scholar] [CrossRef]

- Dong, Y.S.; Hou, Y.; Wang, Z.F.; Qian, Z.Y. Self-healing performance of rollable asphalt mixture. J. Mater. Civ. Eng. 2019, 31, 04019117. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, H.; Liu, K.; Liu, H.; Zhang, X. Development of self-heating tack coat for bonding prefabricated rollable asphalt materials to existing pavement structure. Constr. Build. Mater. 2023, 409, 133937. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. People’s Communication Press: Beijing, China, 2011.

- JTG E42-2005; Test Methods of Aggregate for Highway Engineering. People’s Communication Press: Beijing, China, 2005.

- Mandal, T.; Ling, C.; Chaturabong, P.; Bahia, H.U. Evaluation of analysis methods of the semi-circular bend (SCB) test results for measuring cracking resistance of asphalt mixtures. Int. J. Pavement Res. Technol. 2019, 12, 456–463. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Jia, H.; Jing, H.; Chen, H.; Zhou, L.; Yuan, L.; Hoff, I. Characteristics and properties of asphalt mortar containing FO filler. Constr. Build. Mater. 2023, 392, 132039. [Google Scholar] [CrossRef]

- Lou, B.; Sha, A.; Barbieri, D.M.; Liu, Z.; Zhang, F. Microwave heating properties of steel slag asphalt mixture using a coupled electromagnetic and heat transfer model. Constr. Build. Mater. 2021, 291, 123248. [Google Scholar] [CrossRef]

- Zhu, H.; Yuan, H.; Liu, Y.; Fan, S.; Ding, Y. Evaluation of self-healing performance of asphalt concrete for macrocracks via microwave heating. J. Mater. Civ. Eng. 2020, 32, 04020248. [Google Scholar] [CrossRef]

- Banerjee, A.; de Fortier Smit, A.; Prozzi, J.A. The effect of long-term aging on the rheology of warm mix asphalt binders. Fuel 2012, 97, 603–611. [Google Scholar] [CrossRef]

- Bhasin, A.; Palvadi, S.; Little, D.N. Influence of aging and temperature on intrinsic healing of asphalt binders. Transp. Res. Rec. 2011, 2207, 70–78. [Google Scholar] [CrossRef]

- Bera, A.; Babadagli, T. Status of electromagnetic heating for enhanced heavy oil/bitumen recovery and future prospects: A review. Appl. Energy 2015, 151, 206–226. [Google Scholar] [CrossRef]

- Gao, J.; Sha, A.; Wang, Z.; Tong, Z.; Liu, Z. Utilization of steel slag as aggregate in asphalt mixtures for microwave deicing. J. Clean. Prod. 2017, 152, 429–442. [Google Scholar] [CrossRef]

- Amani, S.; Kavussi, A.; Karimi, M.M. Effects of aging level on induced heating-healing properties of asphalt mixes. Constr. Build. Mater. 2020, 263, 120105. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Hofko, B. A critical assessment of stiffness modulus and fatigue performance of plant produced asphalt concrete samples using various test methods. Road Mater. Pavement Des. 2021, 22, 2661–2673. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Sun, Y.; Kong, L.; Cannone Falchetto, A.; Yuan, D.; Wang, W. Study on Multiple Effects of Self-Healing Properties and Thermal Characteristics of Asphalt Pavement. Buildings 2024, 14, 1313. https://doi.org/10.3390/buildings14051313

Zhang F, Sun Y, Kong L, Cannone Falchetto A, Yuan D, Wang W. Study on Multiple Effects of Self-Healing Properties and Thermal Characteristics of Asphalt Pavement. Buildings. 2024; 14(5):1313. https://doi.org/10.3390/buildings14051313

Chicago/Turabian StyleZhang, Fan, Yuxuan Sun, Lingyun Kong, Augusto Cannone Falchetto, Dongdong Yuan, and Weina Wang. 2024. "Study on Multiple Effects of Self-Healing Properties and Thermal Characteristics of Asphalt Pavement" Buildings 14, no. 5: 1313. https://doi.org/10.3390/buildings14051313