Building a Greener Future: Advancing Concrete Production Sustainability and the Thermal Properties of 3D-Printed Mortars

Abstract

:1. Introduction

2. Three-Dimensional Concrete Printing Prerequisites

3. Waste Availability

3.1. Impact of Waste Addition on Concrete Performance—The Current Situation

3.2. Alternative Binders—A More Sustainable Approach

3.3. A Thermal Perspective

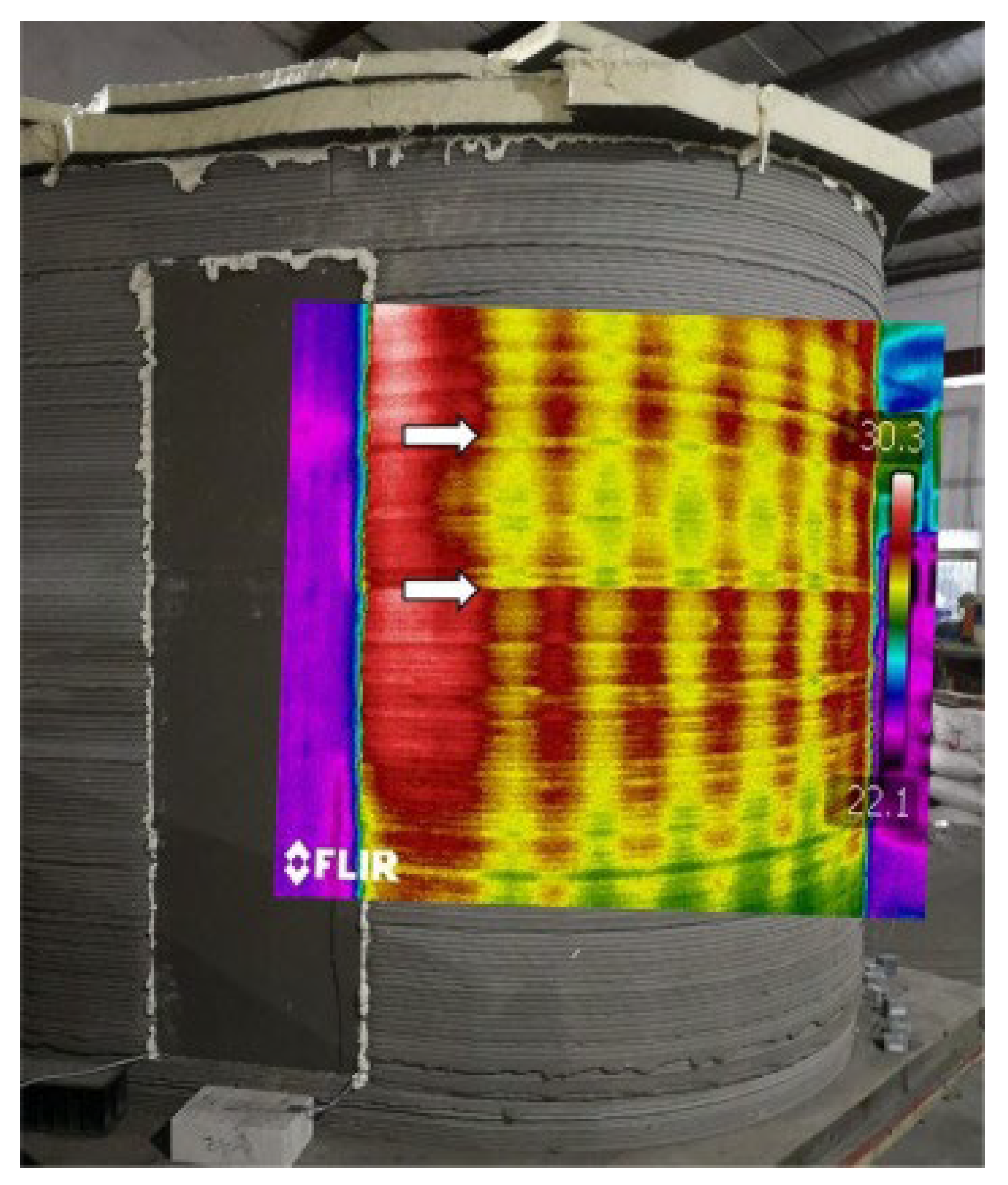

3.3.1. Case Studies

3.3.2. Future Challenges

- Some 3D-printed elements have voids in their structure, and therefore, filling them with recycled thermal insulation materials would be a viable option;

- Extruding different materials at the same time, side by side, in a layer-by-layer process, with, for example, a layer of mortar, to provide structural strength and a layer of thermal insulation to improve thermal and acoustic performance (“sandwich wall”);

- Changing the composition of the already conceived mortars and incorporating low-conductivity additives to improve its thermal properties while improving other aspects (mechanical, rheological, and printability aspects, for instance).

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Bonoli, A.; Zanni, S.; Serrano-Bernardo, F. Sustainability in building and construction within the framework of circular cities and European New Green Deal. The contribution of concrete recycling. Sustainability 2021, 13, 2139. [Google Scholar] [CrossRef]

- Brambilla, G.; Lavagna, M.; Vasdravellis, G.; Castiglioni, C.A. Environmental benefits arising from demountable steel-concrete composite floor systems in buildings. Resour. Conserv. Recycl. 2019, 141, 133–142. [Google Scholar] [CrossRef]

- Norouzi, M.; Chàfer, M.; Cabeza, L.F.; Jiménez, L.; Boer, D. Circular economy in the building and construction sector: A scientific evolution analysis. J. Build. Eng. 2021, 44, 102704. [Google Scholar] [CrossRef]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; 2020/98 Final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Imbabi, M.S.; Carrigan, C.; McKenna, S. Trends and developments in green cement and concrete technology. Int. J. Sustain. Built Environ. 2012, 1, 194–216. [Google Scholar] [CrossRef]

- D’Agostino, D.; Mazzarella, L. What is a nearly zero energy building? Overview, implementation and comparison of definitions. J. Build. Eng. 2019, 21, 200–212. [Google Scholar] [CrossRef]

- Szmigiera, M. Total Global Research and Development (R&D) Spending on Automotive from 2017 to 2019. Available online: https://www.statista.com/statistics/1102932/global-research-and-development-spending-automotive (accessed on 28 February 2024).

- Pessoa, S.; Guimarães, A.S.; Lucas, S.S.; Simões, N. 3D printing in the construction industry—A systematic review of the thermal performance in buildings. Renew. Sustain. Energy Rev. 2021, 141, 110794. [Google Scholar] [CrossRef]

- Adesina, A. Overview of the influence of waste materials on the thermal conductivity of cementitious composites. Clean. Eng. Technol. 2021, 2, 100046. [Google Scholar] [CrossRef]

- Sakir, S.; Raman, S.N.; Safiuddin, M.; Kaish, A.B.M.A.; Mutalib, A.A. Utilization of by-products and wastes as supplementary cementitious materials in structural mortar for sustainable construction. Sustainability 2020, 12, 3888. [Google Scholar] [CrossRef]

- Khoshnevis, B. Automated construction by contour crafting—Related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Adaloudis, M.; Bonnin Roca, J. Sustainability tradeoffs in the adoption of 3D concrete printing in the construction industry. J. Clean. Prod. 2021, 307, 127201. [Google Scholar] [CrossRef]

- Allouzi, R.; Al-Azhari, W.; Allouzi, R. Conventional construction and 3D printing: A comparison study on material cost in Jordan. J. Eng. 2020, 2020, 1424682. [Google Scholar] [CrossRef]

- Adams, D.W.; Turner, C.J. Implicit slicing method for additive manufacturing processes. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017; pp. 1–14. [Google Scholar]

- Enkvist, P.A.; Klevnäs, P. The Circular Economy a Powerful Force for Climate Mitigation; Material Economics: Stockholm, Sweden, 2018. [Google Scholar]

- Lyu, F.; Zhao, D.; Hou, X.; Sun, L.; Zhang, Q. Overview of the development of 3D-printing concrete: A review. Appl. Sci. 2021, 11, 9822. [Google Scholar] [CrossRef]

- Rushing, T.S.; Stynoski, P.B.; Barna, L.A.; Al-Chaar, G.K.; Burroughs, J.F.; Shannon, J.D.; Kreiger, M.A.; Case, M.P. Investigation of concrete mixtures for additive construction. In 3D Concrete Printing Technology; Sanjayan, J.G., Nazari, A., Nematollahi, B., Eds.; Elsevier: Victoria, Australia, 2019; pp. 137–160. [Google Scholar]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Li, Z.; Hojati, M.; Wu, Z.; Piasente, J.; Ashrafi, N.; Duarte, J.P.; Nazarian, S.; Bilén, S.G.; Memari, A.M.; Radlińska, A. Fresh and hardened properties of extrusion-based 3D-printed cementitious materials: A review. Sustainability 2020, 12, 5628. [Google Scholar] [CrossRef]

- Ma, G.; Sun, J.; Wang, L.; Aslani, F.; Liu, M. Electromagnetic and microwave absorbing properties of cementitious composite for 3D printing containing waste copper solids. Cem. Concr. Compos. 2018, 94, 215–225. [Google Scholar] [CrossRef]

- Sambucci, M.; Biblioteca, I.; Valente, M. Life cycle assessment (LCA) of 3D concrete printing and casting processes for cementitious materials incorporating ground waste tire rubber. Recycling 2023, 8, 15. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability region for 3D concrete printing using slump and slump flow test. Compos. B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Zhang, C.; Hou, Z.; Chen, C.; Zhang, Y.; Mechtcherine, V.; Sun, Z. Design of 3D printable concrete based on the relationship between flowability of cement paste and optimum aggregate content. Cem. Concr. Compos. 2019, 104, 103406. [Google Scholar] [CrossRef]

- Paritala, S.; Singaram, K.K.; Bathina, I.; Khan, M.A.; Jyosyula, S.K.R. Rheology and pumpability of mix suitable for extrusion-based concrete 3D printing—A review. Constr. Build. Mater. 2023, 402, 132962. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; Van Tittelboom, K.; De Schutter, G. Evaluating the influence of aggregate content on pumpability of 3D printable concrete. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, Online, 6–9 July 2020; pp. 333–341. [Google Scholar]

- Wang, L.; Ye, K.; Wan, Q.; Li, Z.; Ma, G. Inclined 3D concrete printing: Build-up prediction and early-age performance optimization. Addit. Manuf. 2023, 71, 103595. [Google Scholar] [CrossRef]

- Yang, L.; Sepasgozar, S.M.E.; Shirowzhan, S.; Kashani, A.; Edwards, D. Nozzle criteria for enhancing extrudability, buildability and interlayer bonding in 3D printing concrete. Autom. Constr. 2023, 146, 104671. [Google Scholar] [CrossRef]

- Sergis, V.; Ouellet-Plamondon, C.M. Automating mix design for 3D concrete printing using optimization methods. Digit. Discov. 2022, 1, 645–657. [Google Scholar] [CrossRef]

- Mogra, M.; Asaf, O.; Sprecher, A.; Amir, O. Design optimization of 3D printed concrete elements considering buildability. Eng. Struct. 2023, 294, 116735. [Google Scholar] [CrossRef]

- Vantyghem, G.; Steeman, M.; De Corte, W.; Boel, V. Design optimization for 3D concrete printing: Improving structural and thermal performances. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, Online, 6–9 July 2020; pp. 720–727. [Google Scholar]

- Jiang, X.; Li, Y.; Yang, Z.; Li, Y.; Xiong, B. Harnessing path optimization to enhance the strength of three-dimensional (3D) printed concrete. Buildings 2024, 14, 455. [Google Scholar] [CrossRef]

- Banfill, P.F.G. The rheology of fresh cement and concrete—A review. In Proceedings of the 11th International Cement Chemistry Congress, Durban, South Africa, 11–16 May 2003. [Google Scholar]

- Lu, B.; Weng, Y.; Li, M.; Qian, Y.; Leong, K.F.; Tan, M.J.; Qian, S. A systematical review of 3D printable cementitious materials. Constr. Build. Mater. 2019, 207, 477–490. [Google Scholar] [CrossRef]

- Zhang, C.; Deng, Z.; Chen, C.; Zhang, Y.; Mechtcherine, V.; Sun, Z. Predicting the static yield stress of 3D printable concrete based on flowability of paste and thickness of excess paste layer. Cem. Concr. Compos. 2022, 129, 104494. [Google Scholar] [CrossRef]

- Nerella, V.N.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos. 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Tripathi, A.; Nair, S.A.O.; Neithalath, N. A comprehensive analysis of buildability of 3D-printed concrete and the use of bi-linear stress-strain criterion-based failure curves towards their prediction. Cem. Concr. Compos. 2022, 128, 104424. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, C.; Liu, H.; Zhang, Z.; He, C.; Liu, S.; Zhang, R.; Wang, Y.; Bai, G. Study on the rheology and buildability of 3D printed concrete with recycled coarse aggregates. J. Build. Eng. 2021, 42, 103030. [Google Scholar] [CrossRef]

- Gomaa, M.; Jabi, W.; Veliz Reyes, A.; Soebarto, V. 3D printing system for earth-based construction: Case study of cob. Autom. Constr. 2021, 124, 103577. [Google Scholar] [CrossRef]

- Ahmed, G.H. A review of “3D concrete printing”: Materials and process characterization, economic considerations and environmental sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Suiker, A.S.J.; Wolfs, R.J.M.; Lucas, S.M.; Salet, T.A.M. Elastic buckling and plastic collapse during 3D concrete printing. Cem. Concr. Res. 2020, 135, 106016. [Google Scholar] [CrossRef]

- Arunothayan, A.R.; Nematollahi, B.; Ranade, R.; Khayat, K.H.; Sanjayan, J.G. Digital fabrication of eco-friendly ultra-high performance fiber-reinforced concrete. Cem. Concr. Compos. 2022, 125, 104281. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Figueiredo, S.C.; Çopuroğlu, O.; Veer, F.; Schlangen, E. Limestone and calcined clay-based sustainable cementitious materials for 3D concrete printing: A fundamental study of extrudability and early-age strength development. Appl. Sci. 2019, 9, 1809. [Google Scholar] [CrossRef]

- Rashad, A. Cementitious materials and agricultural wastes as natural fine aggregate replacement in conventional mortar and concrete. J. Build. Eng. 2016, 5, 119–141. [Google Scholar] [CrossRef]

- Puzatova, A.; Shakor, P.; Laghi, V. Large-scale 3D printing for construction application by means of robotic arm and gantry 3D printer: A review. Buildings 2022, 12, 2023. [Google Scholar] [CrossRef]

- Tramontin Souza, M.; Maia Ferreira, I.; Guzi de Moraes, E.; Senff, L.; Arcaro, S.; Castro Pessôa, J.R.; Ribeiro, M.J.; Novaes de Oliveira, A.P. Role of chemical admixtures on 3D printed Portland cement: Assessing rheology and buildability. Constr. Build. Mater. 2022, 314, 125666. [Google Scholar] [CrossRef]

- European Comission. Eurostat Waste Generation 2018; European Comission: Brussels, Belgium, 2021; Volume 3, pp. 1–12. [Google Scholar]

- Gálvez-Martos, J.L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- EPA. Advancing Sustainable Materials Management: 2018 Fact Sheet; EPA: Washington, DC, USA, 2020. [Google Scholar]

- López Ruiz, L.A.; Roca Ramón, X.; Gassó Domingo, S. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Hadavand, B.; Imaninasab, R. Assessing the influence of construction and demolition waste materials on workability and mechanical properties of concrete using statistical analysis. Innov. Infrastruct. Solut. 2019, 4, 29. [Google Scholar] [CrossRef]

- Pashkevic, M.A. Chapter 1—Classification and environmental impact of mine dumps. In Assessment, Restoration and Reclamation of Mining Influenced Soils; Academic Press: Cambridge, MA, USA, 2017; pp. 1–32. [Google Scholar]

- Araujo, F.S.M.; Taborda-Llano, I.; Nunes, E.B.; Santos, R.M. Recycling and reuse of mine tailings: A review of advancements and their implications. Geosciences 2022, 12, 319. [Google Scholar] [CrossRef]

- Aznar-Sánchez, J.A.; García-Gómez, J.J.; Velasco-Muñoz, J.F.; Carretero-Gómez, A. Mining waste and its sustainable management: Advances in worldwide research. Minerals 2018, 8, 284. [Google Scholar] [CrossRef]

- Vallero, D.A.; Blight, G. Mine waste: A brief overview of origins, quantities, and methods of storage. In Waste; Elsevier: Amsterdam, The Netherlands, 2019; pp. 129–151. [Google Scholar]

- Piatak, N.M.; Parsons, M.B.; Seal, R.R. Characteristics and environmental aspects of slag: A review. Appl. Geochem. 2015, 57, 236–266. [Google Scholar] [CrossRef]

- Gayana, B.C.; Karra, R.C. Sustainable use of mine waste and tailings with suitable admixture as aggregates in concrete pavements—A review. Adv. Concr. Constr. 2018, 6, 221–243. [Google Scholar] [CrossRef]

- Lam, E.J.; Zetola, V.; Ram, Y.; Montofr, Í.L. Making paving stones from copper mine tailings as aggregates. Int. J. Environ. Res. Public Health 2020, 17, 2448. [Google Scholar] [CrossRef] [PubMed]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Vatopoulos, K.; Tzimas, E. Assessment of CO2 capture technologies in cement manufacturing process. J. Clean. Prod. 2012, 32, 251–261. [Google Scholar] [CrossRef]

- Mahmood, R.A.; Kockal, N.U. Cementitious materials incorporating waste plastics: A review. SN Appl. Sci. 2020, 2, 2072. [Google Scholar] [CrossRef]

- Alyousef, R.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P.; Alabduljabbar, H. Potential use of recycled plastic and rubber aggregate in cementitious materials for sustainable construction: A review. J. Clean. Prod. 2021, 329, 129736. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef] [PubMed]

- Ritchie, H.; Roser, M. Plastic Pollution. Available online: https://ourworldindata.org/plastic-pollution (accessed on 18 February 2021).

- Plastics Europe. Conversio Market & Strategy GmbH Plastics—The Facts 2019; Plastics Europe: Brussels, Belgium, 2019. [Google Scholar]

- Krasinikova, N.; Stepanov, S.; Makarov, D. Cement stone, modified by chemical water treatment sludge. IOP Conf. Ser. Mater. Sci. Eng. 2020, 890, 012099. [Google Scholar] [CrossRef]

- Rabie, G.M.; El-Halim, H.A. Influence of using dry and wet wastewater sludge in concrete mix on its physical and mechanical properties. Ain Shams J. 2019, 10, 705–712. [Google Scholar] [CrossRef]

- Jannat, N.; Hussien, A.; Abdullah, B.; Cotgrave, A. Application of agro and non-agro waste materials for unfired earth blocks construction: A review. Constr. Build. Mater. 2020, 254, 119346. [Google Scholar] [CrossRef]

- Sharma, G.; Kaur, M.; Punj, S.; Singh, K. Biomass as a sustainable resource for value-added modern materials: A review. Biofuels Bioprod. Biorefining 2020, 14, 673–695. [Google Scholar] [CrossRef]

- Buitrago, B.; Jaramillo, F.; Gomez, M. Some properties of natural fibers (sisal, pineapple, and banana) in comparison to man-made technical fibers (aramide, glass, carbon). J. Nat. Fibers 2015, 12, 357–367. [Google Scholar] [CrossRef]

- Ataie, F.F.; Riding, K.A. Influence of agricultural residue ash on early cement hydration and chemical admixtures adsorption. Constr. Build. Mater. 2016, 106, 274–281. [Google Scholar] [CrossRef]

- Raheem, A.A.; Ikotun, B.D. Incorporation of agricultural residues as partial substitution for cement in concrete and mortar—A review. J. Build. Eng. 2020, 31, 101428. [Google Scholar] [CrossRef]

- Al-Mansour, A.; Chow, C.L.; Feo, L.; Penna, R.; Lau, D. Green concrete: By-products utilization and advanced approaches. Sustainability 2019, 11, 5145. [Google Scholar] [CrossRef]

- Dey, D.; Srinivas, D.; Panda, B.; Suraneni, P.; Sitharam, T.G. Use of industrial waste materials for 3D printing of sustainable concrete: A review. J. Clean. Prod. 2022, 340, 130749. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly ash properties, characterization, and applications: A review. J. King Saud Univ. Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Xu, W.; Lo, T.; Wang, W.; Ouyang, D.; Wang, P.; Xing, F. Pozzolanic reactivity of silica fume and ground rice husk ash as reactive silica in a cementitious system: A comparative study. Materials 2016, 9, 146. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Khayat, K.H.; Shi, C. Changes in rheology and mechanical properties of ultra-high performance concrete with silica fume content. Cem. Concr. Res. 2019, 123, 105786. [Google Scholar] [CrossRef]

- Xi, J.; Liu, J.; Yang, K.; Zhang, S.; Han, F.; Sha, J.; Zheng, X. Role of silica fume on hydration and strength development of ultra-high performance concrete. Constr. Build. Mater. 2022, 338, 127600. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-high-performance concrete (UHPC): A state-of-the-art review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef]

- Tzevelekou, T.; Lampropoulou, P.; Giannakopoulou, P.P.; Rogkala, A.; Koutsovitis, P.; Koukouzas, N.; Petrounias, P. Valorization of slags produced by smelting of metallurgical dusts and lateritic ore fines in manufacturing of slag cements. Appl. Sci. 2020, 10, 4670. [Google Scholar] [CrossRef]

- Diaz-Loya, I.; Juenger, M.; Seraj, S.; Minkara, R. Extending supplementary cementitious material resources: Reclaimed and remediated fly ash and natural pozzolans. Cem. Concr. Compos. 2019, 101, 44–51. [Google Scholar] [CrossRef]

- Melichar, J.; Žižková, N.; Brožovský, J.; Mészárosová, L.; Hermann, R. Study of the interaction of cement-based materials for 3D printing with fly ash and superabsorbent polymers. Buildings 2022, 12, 2008. [Google Scholar] [CrossRef]

- Salleh, N.; Jamalulail, N.S.; Hamid, N.A.A.; Jamellodin, Z.; Majid, M.A.; Suliman, N.H. New technology in 3D concrete printing by using ground granulated blast-furnace slag: A review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1200, 012007. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.; Guo, F.; Wang, Y.; Tang, S. Pore structural and fractal analysis of the influence of fly ash and silica fume on the mechanical property and abrasion resistance of concrete. Fractals 2021, 29, 2140003. [Google Scholar] [CrossRef]

- Wang, L.; Jin, M.; Wu, Y.; Zhou, Y.; Tang, S. Hydration, shrinkage, pore structure and fractal dimension of silica fume modified low heat Portland cement-based materials. Constr. Build. Mater. 2021, 272, 121952. [Google Scholar] [CrossRef]

- Wang, B.; Zhai, M.; Yao, X.; Wu, Q.; Yang, M.; Wang, X.; Huang, J.; Zhao, H. Printable and mechanical performance of 3D printed concrete employing multiple industrial wastes. Buildings 2022, 12, 374. [Google Scholar] [CrossRef]

- Bagcal, O.; Baccay, M. Influence of agricultural waste ash as pozzolana on the physical properties and compressive strength of cement mortar. J. Appl. Eng. Sci. 2019, 9, 29–36. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Camões, A.; Branco, F.G. Valorisation of wood fly ash on concrete. Resour. Conserv. Recycl. 2019, 145, 292–310. [Google Scholar] [CrossRef]

- Gabrijel, I.; Jelčić Rukavina, M.; Štirmer, N. Influence of wood fly ash on concrete properties through filling effect mechanism. Materials 2021, 14, 7164. [Google Scholar] [CrossRef]

- Hidalgo, S.; Soriano, L.; Monzó, J.; Payá, J.; Font, A.; Borrachero, M.V. Evaluation of rice straw ash as a pozzolanic addition in cementitious mixtures. Appl. Sci. 2021, 11, 773. [Google Scholar] [CrossRef]

- Thiedeitz, M.; Schmidt, W.; Härder, M.; Kränkel, T. Performance of rice husk ash as supplementary cementitious material after production in the field and in the lab. Materials 2020, 13, 4319. [Google Scholar] [CrossRef] [PubMed]

- Samad, N.A.I.A.; Abdullah, S.R.; Ibrahim, M.; Shahidan, S.; Ismail, N. Initial properties of 3D printing concrete using rice husk ash (RHA) as partial cement replacement. IOP Conf. Ser. Earth Environ. Sci. 2022, 1022, 012055. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Kua, H.W.; Yu, L.N.; Chung, J.K.H. Fresh properties of cementitious materials containing rice husk ash for construction 3D printing. J. Mater. Civ. Eng. 2020, 32, 04020195. [Google Scholar] [CrossRef]

- Joshaghani, A. Chapter 8 Workability retention and mechanical properties of self-compacting concrete (SCC) with sugar-cane bagasse ash (SCBA) and rice husk ash (RHA). In Concrete and Concrete Structures: A Review and Directions for Research; Nova Science: Hauppauge, NY, USA, 2018. [Google Scholar]

- Jesus, M.; Teixeira, J.; Alves, J.L.; Pessoa, S.; Guimarães, A.S.; Rangel, B. Potential use of sugarcane bagasse ash in cementitious mortars for 3D printing. In Materials Design and Applications IV; da Silva, L.F.M., Ed.; Springer International Publishing: Cham, Switzerland, 2023; pp. 89–103. [Google Scholar]

- Lim, N.H.A.S.; Shaari, F.H.; Shaari, E.H.; Sam, A.R.M.; Khalid, N.H.A.; Ariffin, N.F.; Muthusamy, K. Properties of concrete containing bamboo waste as cement replacement. J. Comput. Theor. Nanosci. 2020, 17, 1306–1310. [Google Scholar] [CrossRef]

- Srikanth, K.; Kumar Jagarapu, D.C.; Venkat Das, T.; Jeelani, S.H.; Eluru, A. Evaluation of the effective mechanical properties of palm oil fuel ash based fiber reinforced concrete. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1136, 012041. [Google Scholar] [CrossRef]

- Rehman, A.U.; Lee, S.-M.; Kim, J.-H. Use of municipal solid waste incineration ash in 3D printable concrete. Process Saf. Environ. Prot. 2020, 142, 219–228. [Google Scholar] [CrossRef]

- Zhu, L.; Zhu, Z. Reuse of clay brick waste in mortar and concrete. Adv. Mater. Sci. Eng. 2020, 2020, 6326178. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.; Elmoaty, M.A.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Nawar, M.T. Beneficial role of glass wastes in concrete—A review. J. Eng. Sustain. Dev. 2018, 22, 136–144. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Gunasekara, C.; Fox, K.; Tran, P. 3D-printed concrete with recycled glass: Effect of glass gradation on flexural strength and microstructure. Constr. Build. Mater. 2022, 314, 125561. [Google Scholar] [CrossRef]

- López-Uceda, A.; Fernández-Ledesma, E.; Jiménez, J.R.; Fernández-Rodríguez, J.M. Performance of sustainable mortars made with filler from different construction by-products. Materials 2022, 15, 2636. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Srivastava, V. Ceramic waste in concrete—A review. In Proceedings of the Recent Advances on Engineering, Technology and Computational Sciences (RAETCS), Allahabad, India, 6–8 February 2018. [Google Scholar]

- Sáez, I.F.; Van den Heede, P.; De Belie, N.; De Rojas, M.I.S.; Medina, C. Carbonation of concrete with construction and demolition waste based recycled aggregates and cement with recycled content. Constr. Build. Mater. 2020, 234, 117336. [Google Scholar] [CrossRef]

- Yang, H.; Che, Y. Recycling of aggregate micro fines as a partial replacement for fly ash in 3D printing cementitious materials. Constr. Build. Mater. 2022, 321, 126372. [Google Scholar] [CrossRef]

- Bai, G.; Wang, L.; Ma, G.; Sanjayan, J.; Bai, M. 3D printing eco-friendly concrete containing under-utilised and waste solids as aggregates. Cem. Concr. Compos. 2021, 120, 104037. [Google Scholar] [CrossRef]

- Skibicki, S.; Jakubowska, P.; Kaszyńska, M.; Sibera, D.; Cendrowski, K.; Hoffmann, M. Early-age mechanical properties of 3D-printed mortar with spent garnet. Materials 2021, 15, 100. [Google Scholar] [CrossRef] [PubMed]

- Gou, M.; Zhou, L.; Then, N.W.Y. Utilization of tailings in cement and concrete: A review. Sci. Eng. Compos. Mater. 2019, 26, 449–464. [Google Scholar] [CrossRef]

- Evdokimov, S.I.; Maslakov, M.P.; Evdokimov, V.S. Construction materials based on wastes from mining and metallurgical industries. Procedia Eng. 2016, 150, 1574–1581. [Google Scholar] [CrossRef]

- Kunt, K.; Meral, Y.; Dur, F.; Derun, E.M.; Pişkin, S. Utilization of bergama gold tailings as an additive in the mortar. CBU J. Sci. 2015, 11, 365–371. [Google Scholar] [CrossRef]

- Li, X.; Zhang, N.; Yuan, J.; Wang, X.; Zhang, Y.; Chen, F.; Zhang, Y. Preparation and microstructural characterization of a novel 3D printable building material composed of copper tailings and iron tailings. Constr. Build. Mater. 2020, 249, 118779. [Google Scholar] [CrossRef]

- Alfeehan, A.; Mohammed, M.; Jasim, M.; Fadehl, U.; Habeeb, F. Utilizing industrial metal wastes in one-way ribbed reinforced concrete panels Utilización de Desechos Metálicos Industriales En Los Paneles de Hormigón Armado Nervados Unidireccionales. Ing. Constr. 2020, 35, 246–256. [Google Scholar] [CrossRef]

- Patra, R.K.; Mukharjee, B.B. Influence of granulated blast furnace slag as fine aggregate on properties of cement mortar. Adv. Concr. Constr. 2018, 6, 611–629. [Google Scholar]

- Li, Y.; Wu, B.; Wang, R. A critical review on the use of copper slag (CS) as a substitute constituent in concrete. Constr. Build. Mater. 2021, 292, 123371. [Google Scholar] [CrossRef]

- Kanneboina, Y.Y.; Jothi Saravanan, T.; Kabeer, K.I.S.A.; Bisht, K. Valorization of lead and zinc slags for the production of construction materials—A review for future research direction. Constr. Build. Mater. 2023, 367, 130314. [Google Scholar] [CrossRef]

- Elseknidy, M.H.; Salmiaton, A.; Shafizah, I.N.; Saad, A.H. A study on mechanical properties of concrete incorporating aluminum dross, fly ash, and quarry dust. Sustainability 2020, 12, 9230. [Google Scholar] [CrossRef]

- Van Der Putten, J.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Development of 3D printable cementitious composites with the incorporation of polypropylene fibers. Materials 2021, 14, 4474. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, W.; Lim, C.W.; Akbar, A. Influence of elevated temperatures on the mechanical performance of sustainable-fiber-reinforced recycled aggregate concrete: A review. Buildings 2022, 12, 487. [Google Scholar] [CrossRef]

- Ning, X.; Li, J.; Li, Y. An explorative study into the influence of different fibers on the spalling resistance and mechanical properties of self-compacting concrete after exposure to elevated temperatures. Appl. Sci. 2022, 12, 12779. [Google Scholar] [CrossRef]

- Zhang, D.; Tan, K.H. Effect of various polymer fibers on spalling mitigation of ultra-high performance concrete at high temperature. Cem. Concr. Compos. 2020, 114, 103815. [Google Scholar] [CrossRef]

- Ahmad, J.; González-Lezcano, R.A.; Majdi, A.; Ben Kahla, N.; Deifalla, A.F.; El-Shorbagy, M.A. Glass fibers reinforced concrete: Overview on mechanical, durability and microstructure analysis. Materials 2022, 15, 5111. [Google Scholar] [CrossRef]

- Khalil, A.; Wang, X.; Celik, K. 3D printable magnesium oxide concrete: Towards sustainable modern architecture. Addit. Manuf. 2020, 33, 101145. [Google Scholar] [CrossRef]

- Henke, K.; Treml, S. Wood based bulk material in 3D printing processes for applications in construction. Eur. J. Wood Wood Prod. 2013, 71, 139–141. [Google Scholar] [CrossRef]

- Annappa, V.B. Green Cement Based Material Optimization for Additive Manufacturing in Construction. Master’s Thesis, Institute Polytechnic of Leiria (IPL), Leiria, Portugal, 2018. [Google Scholar]

- Jen, M. Improving the 3D printability of high volume fly ash mixtures via the use of nano attapulgite clay. Compos. Part B Eng. 2018, 165, 75–83. [Google Scholar] [CrossRef]

- Ma, G.; Salman, N.M.; Wang, L.; Wang, F. A novel additive mortar leveraging internal curing for enhancing interlayer bonding of cementitious composite for 3D printing. Constr. Build. Mater. 2020, 244, 118305. [Google Scholar] [CrossRef]

- Heng, G.; Ting, A.; Wei, Y.; Tay, D.; Qian, Y.; Tan, M.J. Utilization of recycled glass for 3D concrete printing: Rheological and mechanical properties. J. Mater. Cycles Waste Manag. 2019, 21, 994–1003. [Google Scholar] [CrossRef]

- Demyanenko, O.; Sorokina, E.; Kopanitsa, N.; Sarkisov, Y. Mortars for 3D printing. MATEC Web Conf. 2018, 143, 02013. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Qin, F.; Duan, Z. Mechanical behavior of 3D printed mortar with recycled sand at early ages. Constr. Build. Mater. 2020, 248, 118654. [Google Scholar] [CrossRef]

- Snellings, R. Assessing, understanding and unlocking supplementary cementitious materials. RILEM Tech. Lett. 2016, 1, 50–55. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Bhattacherjee, S.; Basavaraj, A.S.; Rahul, A.V.; Santhanam, M.; Gettu, R.; Panda, B.; Schlangen, E.; Chen, Y.; Copuroglu, O.; Ma, G.; et al. Sustainable materials for 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104156. [Google Scholar] [CrossRef]

- Zhang, R.; Arrigoni, A.; Panesar, D.K. Could reactive MgO cement be a green solution? The effect of CO2 mineralization and manufacturing route on the potential global warming impact. Cem. Concr. Compos. 2021, 124, 104263. [Google Scholar] [CrossRef]

- Gonçalves, T.; Silva, R.V.; de Brito, J.; Fernández, J.M.; Esquinas, A.R. Mechanical and durability performance of mortars with fine recycled concrete aggregates and reactive magnesium oxide as partial cement replacement. Cem. Concr. Compos. 2020, 105, 103420. [Google Scholar] [CrossRef]

- Sequeira, L.; Forero, J.; Bravo, M.; Evangelista, L.; de Brito, J. Durability of concrete with partial replacement of Portland cement by incorporating reactive magnesium oxide and fly ash. Materials 2023, 16, 2670. [Google Scholar] [CrossRef]

- Ibrahim, K.A.; van Zijl, G.P.A.G.; Babafemi, A.J. Influence of limestone calcined clay cement on properties of 3D printed concrete for sustainable construction. J. Build. Eng. 2023, 69, 106186. [Google Scholar] [CrossRef]

- Chen, Y.; Figueiredo, S.C.; Yalçinkaya, Ç.; Çopuroğlu, O.; Veer, F.; Schlangen, E. The effect of viscosity-modifying admixture on the extrudability of limestone and calcined clay-based cementitious material for extrusion-based 3D concrete printing. Materials 2019, 12, 1374. [Google Scholar] [CrossRef] [PubMed]

- Geng, Z.; Tang, S.; Wang, Y.; Hubao, A.; He, Z.; Wu, K.; Wang, L. Stress relaxation properties of calcium silicate hydrate: A molecular dynamics study. J. Zhejiang Univ. Sci. A 2024, 25, 97–115. [Google Scholar] [CrossRef]

- Tang, S.; Wang, Y.; Geng, Z.; Xu, X.; Yu, W.; Hubao, A.; Chen, J. Structure, fractality, mechanics and durability of calcium silicate hydrates. Fractal Fract. 2021, 5, 47. [Google Scholar] [CrossRef]

- Singh, N.B.; Saxena, S.K.; Kumar, M.; Rai, S. Geopolymer cement: Synthesis, characterization, properties and applications. Mater. Today Proc. 2019, 15, 364–370. [Google Scholar] [CrossRef]

- Ariffin, M.A.M.; Bhutta, M.A.R.; Hussin, M.W.; Tahir, M.M.; Aziah, N. Sulfuric acid resistance of fly ash based geopolymer concrete. Constr. Build. Mater. 2013, 43, 80–86. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. 3D printing geopolymers: A review. Cem. Concr. Compos. 2022, 128, 104455. [Google Scholar] [CrossRef]

- Amran, M.; Abdelgader, H.S.; Onaizi, A.M.; Fediuk, R.; Ozbakkaloglu, T.; Rashid, R.S.M.; Murali, G. 3D-printable alkali-activated concretes for building applications: A critical review. Constr. Build. Mater. 2022, 319, 126126. [Google Scholar] [CrossRef]

- Nithya, M.; Muthukumaran, R. Recent trends in science and engineering. Additive manufacturing of geopolymer structures: A review. Proc. AIP Conf. Proc. 2022, 2393, 020044. [Google Scholar]

- Guimarães, A.S.; Delgado, J.M.P.Q.; Lucas, S.S. Advanced manufacturing in civil engineering. Energies 2021, 14, 4474. [Google Scholar] [CrossRef]

- Park, D. Multiscale Thermal Design for Buildings. PhD Thesis, Harvard University, Cambridge, MA, USA, 2016. [Google Scholar]

- Dhakar, E. Review on the impact of air entrapment on the properties of concrete structures. Int. Res. J. Eng. Technol. (IRJET) 2023, 10, 90–94. [Google Scholar]

- Singh, D.; Kansal, R. Experimental study of usage of discarded engine oil as an admixture in concrete. Int. Res. J. Eng. Technol. (IRJET) 2016, 3, 2729–2734. [Google Scholar]

- Hamad, B.S.; Rteil, A.A.; El-Fadel, M. Effect of used engine oil on properties of fresh and hardened concrete. Constr. Build. Mater. 2003, 17, 311–318. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Z.; Lv, C.; Meng, F.; Yang, Y. Preparation of waste cooking oil emulsion as shrinkage reducing admixture and its potential use in high performance concrete: Effect on shrinkage and mechanical properties. J. Build. Eng. 2020, 32, 101488. [Google Scholar] [CrossRef]

- Sharma, N.; Sharma, P. Effect of hydrophobic agent in cement and concrete: A review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1116, 012175. [Google Scholar] [CrossRef]

- Shah, H.A.; Yuan, Q.; Zuo, S. Air entrainment in fresh concrete and its effects on hardened concrete—A review. Constr. Build. Mater. 2021, 274, 121835. [Google Scholar] [CrossRef]

- Yaphary, Y.L.; Lam, R.H.W.; Lau, D. Reduction in cement content of normal strength concrete with used engine oil (UEO) as chemical admixture. Constr. Build. Mater. 2020, 261, 119967. [Google Scholar] [CrossRef]

- Chen, H.; Chow, C.L.; Lau, D. Recycling used engine oil in concrete: Fire performance evaluation. J. Build. Eng. 2023, 64, 105637. [Google Scholar] [CrossRef]

- Justnes, H.; Østnor, T.A.; Barnils Vila, N. Vegetable oils as water repellents for mortars. In Proceedings of the 1st International Conference of Asian Concrete Federation, Chiang Mai, Thailand, 28–29 October 2004; pp. 28–29. [Google Scholar]

- Bolobova, A.V.; Kondrashchenko, V.I. Use of yeast fermentation waste as a biomodifier of concrete (review). Appl. Biochem. Microbiol. 2000, 36, 205–214. [Google Scholar] [CrossRef]

- Weldu, Y.W.; Al-Ghamdi, S.G. Evaluating the environmental and economic sustainability of energy efficiency measures in buildings. IOP Conf. Ser. Earth Environ. Sci. 2019, 257, 012028. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Mattila, H. Moisture behavior of building insulation materials and good building practices. In Proceedings of the Conference Rakennusfysiikka 2017—Building Physics 2017, Tampere, Finland, 24–26 October 2017. [Google Scholar]

- Borges, A.; Flores-Colen, I.; de Brito, J. Physical and mechanical performance of cement-based renders with different contents of fly ash, expanded cork granules and expanded clay. Constr. Build. Mater. 2018, 191, 535–543. [Google Scholar] [CrossRef]

- Sisman, C.B.; Gezer, E.; Kocaman, I. Effects of organic waste (rice husk) on the concrete properties for farm buildings. Bulg. J. Agric. Sci. 2011, 17, 40–48. [Google Scholar]

- Wong, H.S.; Barakat, R.; Alhilali, A.; Saleh, M.; Cheeseman, C.R. Hydrophobic concrete using waste paper sludge ash. Cem. Concr. Res. 2015, 70, 9–20. [Google Scholar] [CrossRef]

- Tang Van, L.; Vu Kim, D.; Ngo Xuan, H.; Vu Dinh, T.; Bulgakov, B.; Bazhenova, S. Effect of aluminium powder on lightweight aerated concrete properties. E3S Web Conf. 2019, 97, 02005. [Google Scholar] [CrossRef]

- Kilincarslan, Ş.; Davraz, M.; Akça, M. The effect of pumice as aggregate on the mechanical and thermal properties of foam concrete. Arab. J. Geosci. 2018, 11, 289. [Google Scholar] [CrossRef]

- Khan, S.A.; Jassim, M.; Ilcan, H.; Sahin, O.; Bayer, I.R.; Sahmaran, M.; Koc, M. Sustainable 3D printing in the construction industry: Environmental benefits of comparative analysis of circular materials from waste and conventional construction methods. Case Stud. Constr. Mater. 2023, 18, e02059. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Montrelay, N.; Houessou, J.; Quéneudec, M. Effect of substitution of wood shavings by barley straws on the physico-mechanical properties of lightweight sand concrete. Constr. Build. Mater. 2014, 66, 247–258. [Google Scholar] [CrossRef]

- Muhammad Salman, N.; Ma, G.; Ijaz, N.; Wang, L. Importance and potential of cellulosic materials and derivatives in extrusion-based 3D concrete printing (3DCP): Prospects and challenges. Constr. Build. Mater. 2021, 291, 123281. [Google Scholar] [CrossRef]

- Tedjditi, A.K.; Ghomari, F.; Belarbi, R.; Cherif, R.; Boukhelf, F.; Bouhraoua, R.T. Towards understanding cork concrete behaviour: Impact of considering cork absorption during mixing process. Constr. Build. Mater. 2022, 317, 125905. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Development of lignocellulosic fiber reinforced cement composite panels using semi-dry technology. Cellulose 2021, 28, 3631–3645. [Google Scholar] [CrossRef]

- Boukhattem, L.; Boumhaout, M.; Hamdi, H.; Benhamou, B.; Ait Nouh, F. Moisture content influence on the thermal conductivity of insulating building materials made from date palm fibers mesh. Constr. Build. Mater. 2017, 148, 811–823. [Google Scholar] [CrossRef]

- Boussetoua, H.; Maalouf, C.; Lachi, M.; Belhamri, A.; Moussa, T. Mechanical and hygrothermal characterization of cork concrete composite: Experimental and modelling study. Eur. J. Environ. Civ. Eng. 2020, 24, 456–471. [Google Scholar] [CrossRef]

- Labib, W.A. Plant-based fibres in cement composites: A conceptual framework. J. Eng. Fibers Fabr. 2022, 17, 155892502210789. [Google Scholar] [CrossRef]

- Suazo, F.J.A.; Carregosa, J.D.C. Mechanical performance and healing process improvement of cement-coir pith particle composites by accelerated carbonation. Rev. Matéria 2020, 25, e-12669. [Google Scholar] [CrossRef]

- Teixeira, J.N.; Silva, D.W.; Vilela, A.P.; Savastano Junior, H.; de Siqueira Brandão Vaz, L.E.V.; Mendes, R.F. Lignocellulosic materials for fiber cement production. Waste Biomass Valorization 2020, 11, 2193–2200. [Google Scholar] [CrossRef]

- Ferraz, P.F.P.; Mendes, R.F.; Marin, D.B.; Paes, J.L.; Cecchin, D.; Barbari, M. Agricultural residues of lignocellulosic materials in cement composites. Appl. Sci. 2020, 10, 8019. [Google Scholar] [CrossRef]

- Palanisamy, M.; Kolandasamy, P.; Awoyera, P.; Gobinath, R.; Muthusamy, S.; Krishnasamy, T.R.; Viloria, A. Permeability properties of lightweight self-consolidating concrete made with coconut shell aggregate. J. Mater. Res. Technol. 2020, 9, 3547–3557. [Google Scholar] [CrossRef]

- He, J.; Kawasaki, S.; Achal, V. The utilization of agricultural waste as agro-cement in concrete: A review. Sustainability 2020, 12, 6971. [Google Scholar] [CrossRef]

- Ayed, R.; Bouadila, S.; Skouri, S.; Boquera, L.; Cabeza, L.F.; Lazaar, M. Recycling textile waste to enhance building thermal insulation and reduce carbon emissions: Experimentation and model-based dynamic assessment. Buildings 2023, 13, 535. [Google Scholar] [CrossRef]

- Ricciardi, P.; Cillari, G.; Carnevale Miino, M.; Collivignarelli, M.C. Valorization of agro-industry residues in the building and environmental sector: A review. Waste Manag. Res. 2020, 38, 487–513. [Google Scholar] [CrossRef] [PubMed]

- Massoudinejad, M.; Amanidaz, N.; Santos, R.M.; Bakhshoodeh, R. Use of municipal, agricultural, industrial, construction and demolition waste in thermal and sound building insulation materials: A review article. J. Environ. Health Sci. Eng. 2019, 17, 1227–1242. [Google Scholar] [CrossRef] [PubMed]

- CEN EN 12664:2001; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Dry and Moist Products of Medium and Low Thermal Resistance. Slovenski Inštitut za Standardizacijo: Ljubljana, Slovenia, 2001.

- CEN EN 12667:2001; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Products of High and Medium Thermal Resistance. Slovenski Inštitut za Standardizacijo: Ljubljana, Slovenia, 2001.

- ASTM C518-21; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2021.

- Záleská, M.; Pavlíková, M.; Pokorný, J.; Jankovský, O.; Pavlík, Z.; Černý, R. Structural, mechanical and hygrothermal properties of lightweight concrete based on the application of waste plastics. Constr. Build. Mater. 2018, 180, 1–11. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Nascimento, D.; Teixeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Tahir, M.M.; Sam, A.R.M. RETRACTED: The feasibility of Improving impact resistance and strength properties of sustainable concrete composites by adding waste metalized plastic fibres. Constr. Build. Mater. 2018, 169, 223–236. [Google Scholar] [CrossRef]

- Khern, Y.C.; Paul, S.C.; Kong, S.Y.; Babafemi, A.J.; Anggraini, V.; Miah, M.J.; Šavija, B. Impact of chemically treated waste rubber tire aggregates on mechanical, durability and thermal properties of concrete. Front. Mater. 2020, 7, 11. [Google Scholar] [CrossRef]

- Pczieczek, A.; Schackow, A.; Effting, C.; Dias, T.F.; Gomes, I.R. Properties of mortars containing tire rubber waste and expanded polystyrene (EPS). J. Urban Environ. Eng. 2018, 11, 219–225. [Google Scholar] [CrossRef]

- Tuladhar, R.; Yin, S. Sustainability of using recycled plastic fiber in concrete. In Use of Recycled Plastics in Eco-Efficient Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 441–460. [Google Scholar]

- Misri, Z.; Ibrahim, M.H.W.; Awal, A.S.M.A.; Desa, M.S.M.; Ghadzali, N.S. Review on factors influencing thermal conductivity of concrete incorporating various type of waste materials. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012141. [Google Scholar] [CrossRef]

- Alawneh, M.; Matarneh, M.; El-Ashri, S. The world’s first 3D–printed office building in Dubai. In Proceedings of the 2018 PCI Convention, Denver, CO, USA, 20–24 February 2018. [Google Scholar]

- Heimgartner, J. Apis Cor Company Finishes Printing a Concrete Residence Near Moscow. Available online: https://www.engineering.com/story/the-house-that-3d-printing-built (accessed on 17 February 2021).

- Saleem, F. World’s Largest 3D-Printed Building in Dubai. Available online: https://www.engineering.com/story/worlds-largest-3d-printed-building-in-dubai (accessed on 17 February 2021).

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and limitations in 3D printing materials and technologies: A critical review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. 3D printed cork/polyurethane composite foams. Mater. Des. 2019, 179, 107905. [Google Scholar] [CrossRef]

- Bedarf, P. Foamwork. Available online: https://dbt.arch.ethz.ch/project/foamwork/ (accessed on 19 April 2022).

- He, Y.; Zhang, Y.; Zhang, C.; Zhou, H. Energy-saving potential of 3D printed concrete building with integrated living wall. Energy Build. 2020, 222, 110110. [Google Scholar] [CrossRef]

- Zapelloni, G.; García Rellán, A.; Bello Bugallo, P.M. Sustainable production of marine equipment in a circular economy: Deepening in material and energy flows, best available techniques and toxicological impacts. Sci. Total Environ. 2019, 687, 991–1010. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, J.; Li, Z.; Feng, X. Experimental study on the thermal performance of a 3D printed concrete prototype building. Energy Build. 2021, 241, 110965. [Google Scholar] [CrossRef]

- Karade, S.R.; Caldiera, F.; Irle, M.; Maher, K. Cork granules as lightweight aggregate. In Challenges of Concrete Construction: Volume 5, Sustainable Concrete Construction; Thomas Telford Publishing: London, UK, 2002; pp. 253–261. [Google Scholar]

- Pessoa, S.; Jesus, M.; Guimarães, A.S.; Lucas, S.S.; Simões, N. Upcoming challenges on the application of thermal insulation in 3D printed building elements. In Proceedings of the CEES 2021—International Conference on Construction, Energy, Environment and Sustainability, Coimbra, Portugal, 12–15 October 2021. [Google Scholar]

| Properties | Description | References |

|---|---|---|

| Flowability | Transportation of the paste from the mixer to the extruder | [28,29] |

| Pumpability | The ability of the material to be extruded without phase separation under pressure | [30,31] |

| Open time | Maintenance of the material’s consistency for good extrudability | [32,33] |

| Extrudability | Extrusion of the material in continuous and uniform filaments | |

| Buildability | Extrusion of the mortar in stacked layers and retention of the extruded shape | [34,35] |

| Mechanical strength | Compressive and flexural strength | [36,37] |

| Source | References | |

|---|---|---|

| Biomass-Based | Casting Process | 3DCP |

| Wood (power plants) | [93,94] | - |

| Rice husk | [95,96] | [97,98] |

| Sugarcane bagasse | [99] | [100] |

| Bamboo leaf | [101] | - |

| Other | ||

| Palm oil fuel (POFA) | [102] | - |

| Municipal/industrial waste (solids and sludges) | - | [103] |

| Waste | Optimum Replacement | Material Replaced or Reinforced | Concrete Properties | Reference |

|---|---|---|---|---|

| Magnesium oxide from waste brine | 3% | Cement | Good extrudability, flowability, and buildability, ↓ sorptivity | [128] |

| Fly ash (FA) and silica fume (SF) | 60:10% | Magnesium potassium phosphate cement | Variations on setting time, with good extrudability and buildability | [39] |

| Fly ash (FA) and granulated blast-furnace slag (S) | 0:60% | PC | The superior material efficiency index | [47] |

| Rice husk ash | 20% | PC | ↑ Workability than control | [97] |

| Municipal sludge waste ashes (fly and bottom) and nylon fibres (NF) | 7.5–10% FA 0.14% binder weight | PC | ↑ Buildability and yield stress ↓ Setting time, flowability, and interlayer bond | [103] |

| Recycled concrete (RA), ceramsite particles (CPs), and desert sand (DS) | Depending on particle size and distribution | Aggregates | Adequate flowability and extrudability ↑ Interlayer bond and can ↑ shrinkage | [112] |

| Wood chips from spruce with different binders | Chips/cement = 0.15 Water/cement = 0.80 | Aggregates | Density = 0.7 to 0.8 g/cm3 Mechanical strength is enough for non-structural applications | [129] |

| Stone sludge + Al-polishing waste + cork + eucalyptus ash + superplasticiser SIKA | 2:1 cement/stone sludge with superplasticiser Sika control 40 | Composite with concrete | Good flowability, extrudability, shape retention, buildability, and open time Conventional mortar ↑ early age strength development properties | [130] |

| Nano-attapulgite clay | 0.5% | Plasticizer | Compared with the control mixture ↑ Viscosity recovery and structural build-up | [131] |

| Cellulose fibre (CS) and limestone, silica fume (SF) | Ratio—0.15 HB-CSA: 0.85 OPC: 0.15 SF | Filler for application between layers | ↑ Printing interval, interlayer strength, and durability ↓ Voids and longitudinal flaws | [132] |

| Copper tailings | 30% | Sand | Favourable buildability and high mechanical strength | [24] |

| Copper and iron tailings | Mass ratio—1:4 | Water treated | ↑ Mechanical properties | [117] |

| Recycled glass | 10% | Sand | ↓ Mechanical properties ↑ Flowability | [133] |

| Thermally treated peat-based admixture (MT-600) | 0.5% of cement fraction [0.08–0.125] mm | Cement | ↑ Strength of hardened cement pastes at an early age (3 days) than reference composition | [134] |

| Polypropylene fibres | Lengths 3 (M3) and 6 mm (M6), 0.1 to 0.3% v/v | Aggregates | ↑ Workability ↑ Porosity (in the hardened state) ↑ Flexural strength (M6) ↓ Total free shrinkage (M3) | [123] |

| FA, SF, and ground granulated blast-furnace slag (GGBS) | 20 wt.% (FA), 15 wt.% (SF), and 10 wt.% (GGBS) | Cement | ↑ Compressive strength ↓ Flexural strength | [91] |

| Limestone aggregate micro-fines (AMFs) | 3% < AMF < 12% | FA | ↓ Flowability ↓ Extrudability ↑ Shape stability ↑ Green strength ↑ Compressive strength ↑ Flexural strength (after 60 days) | [111] |

| Spent garnet (SP) | SP ≤ 50% | Natural sand | ↓ Green strength ↓ Young’s modulus –Buildability | [113] |

| Recycled sand (RS) (crushed from waste concrete) | 25 and 50% (only tested values) | Natural sand | Change from plastic to solid material It affects early-age behaviour ↑ Buildability ↓ Open time | [135] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capêto, A.P.; Jesus, M.; Uribe, B.E.B.; Guimarães, A.S.; Oliveira, A.L.S. Building a Greener Future: Advancing Concrete Production Sustainability and the Thermal Properties of 3D-Printed Mortars. Buildings 2024, 14, 1323. https://doi.org/10.3390/buildings14051323

Capêto AP, Jesus M, Uribe BEB, Guimarães AS, Oliveira ALS. Building a Greener Future: Advancing Concrete Production Sustainability and the Thermal Properties of 3D-Printed Mortars. Buildings. 2024; 14(5):1323. https://doi.org/10.3390/buildings14051323

Chicago/Turabian StyleCapêto, Ana Paula, Manuel Jesus, Braian E. B. Uribe, Ana Sofia Guimarães, and Ana L. S. Oliveira. 2024. "Building a Greener Future: Advancing Concrete Production Sustainability and the Thermal Properties of 3D-Printed Mortars" Buildings 14, no. 5: 1323. https://doi.org/10.3390/buildings14051323