Nano-Additives in Asphalt Binder: Bridging the Gap between Traditional Materials and Modern Requirements

Abstract

:1. Introduction

2. Materials

2.1. Asphalt Cement

2.2. Nanomaterials

2.3. Nanomaterial Addition Method

3. Experimental Tests

3.1. Consistency Properties

3.2. Storage Stability

3.3. Mass Loss

3.4. Rotational Viscosity

3.5. Dynamic Shear Rheometer

4. Results and Discussion

4.1. Consistency Test Results

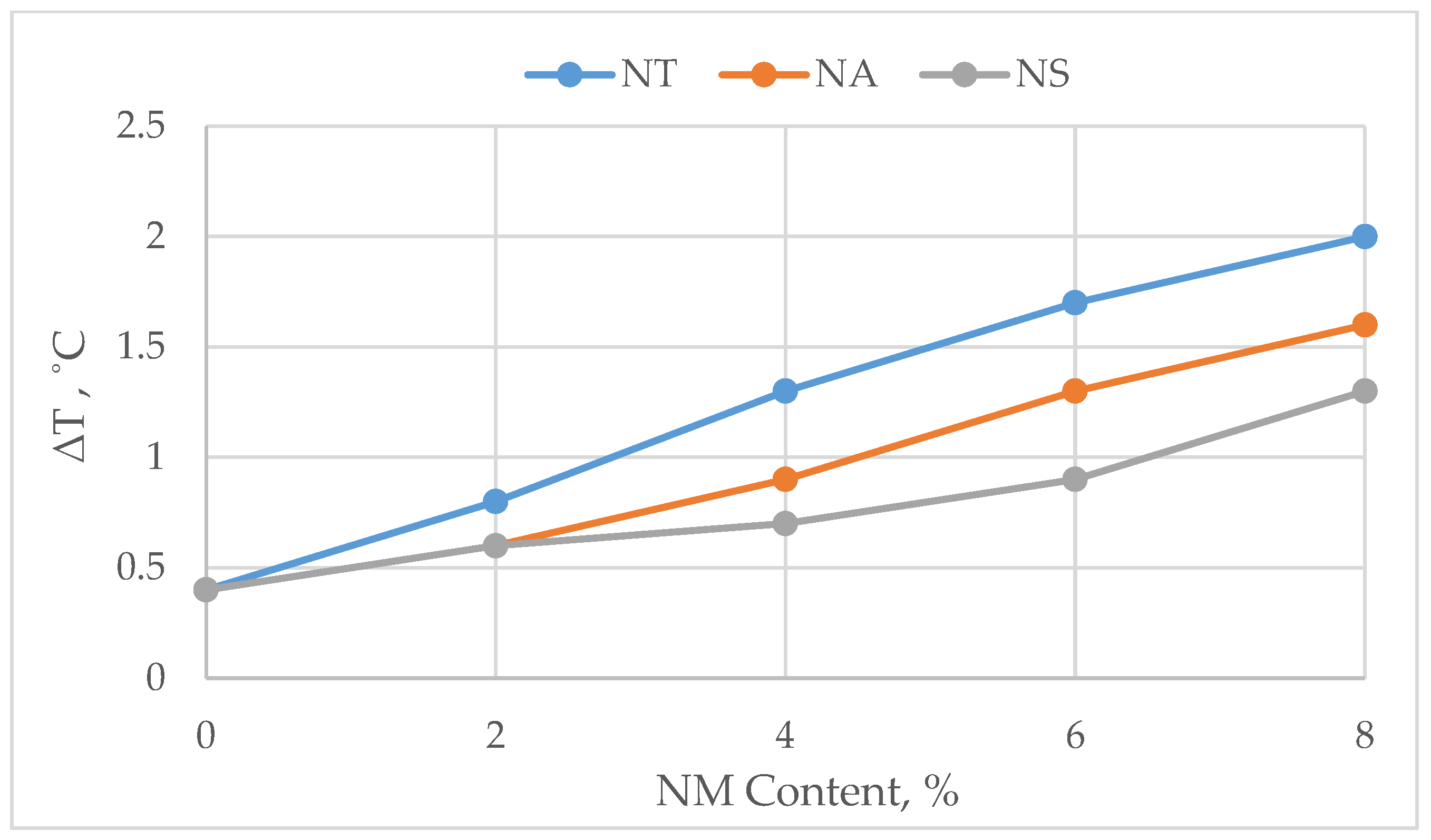

4.2. Storage Stability Results

4.3. Rotational Viscosity Results

4.4. Mass Loss due to Aging

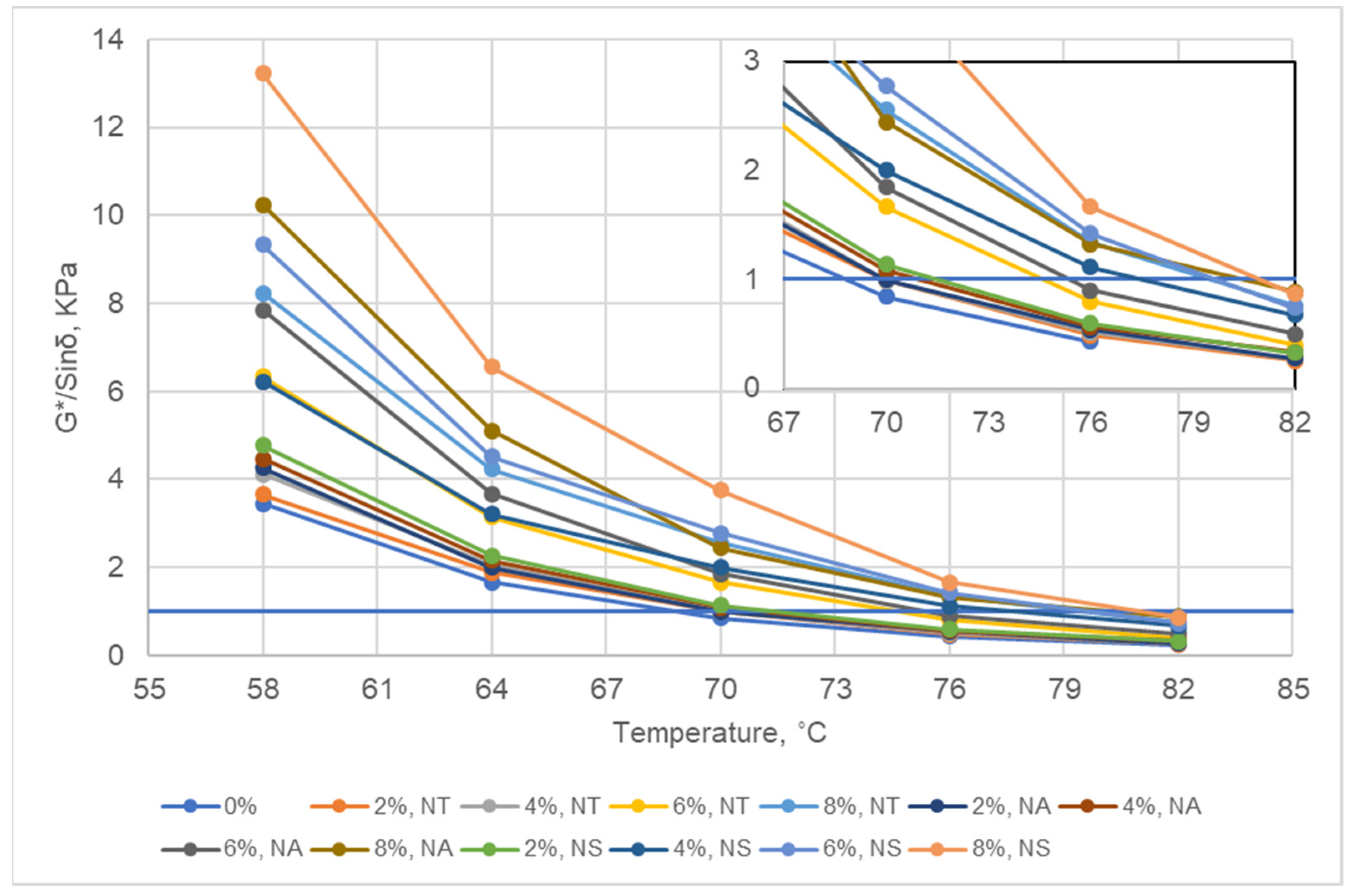

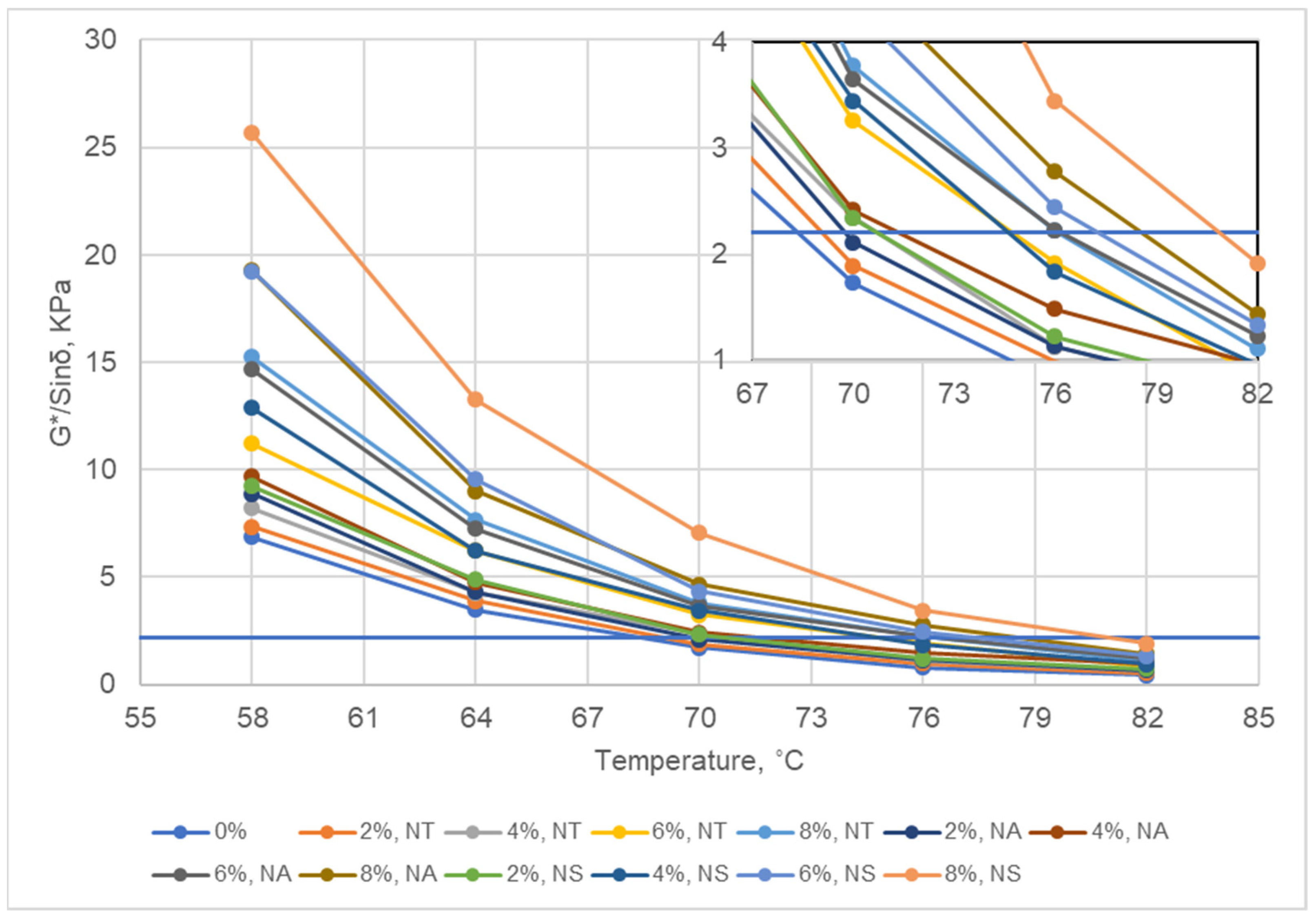

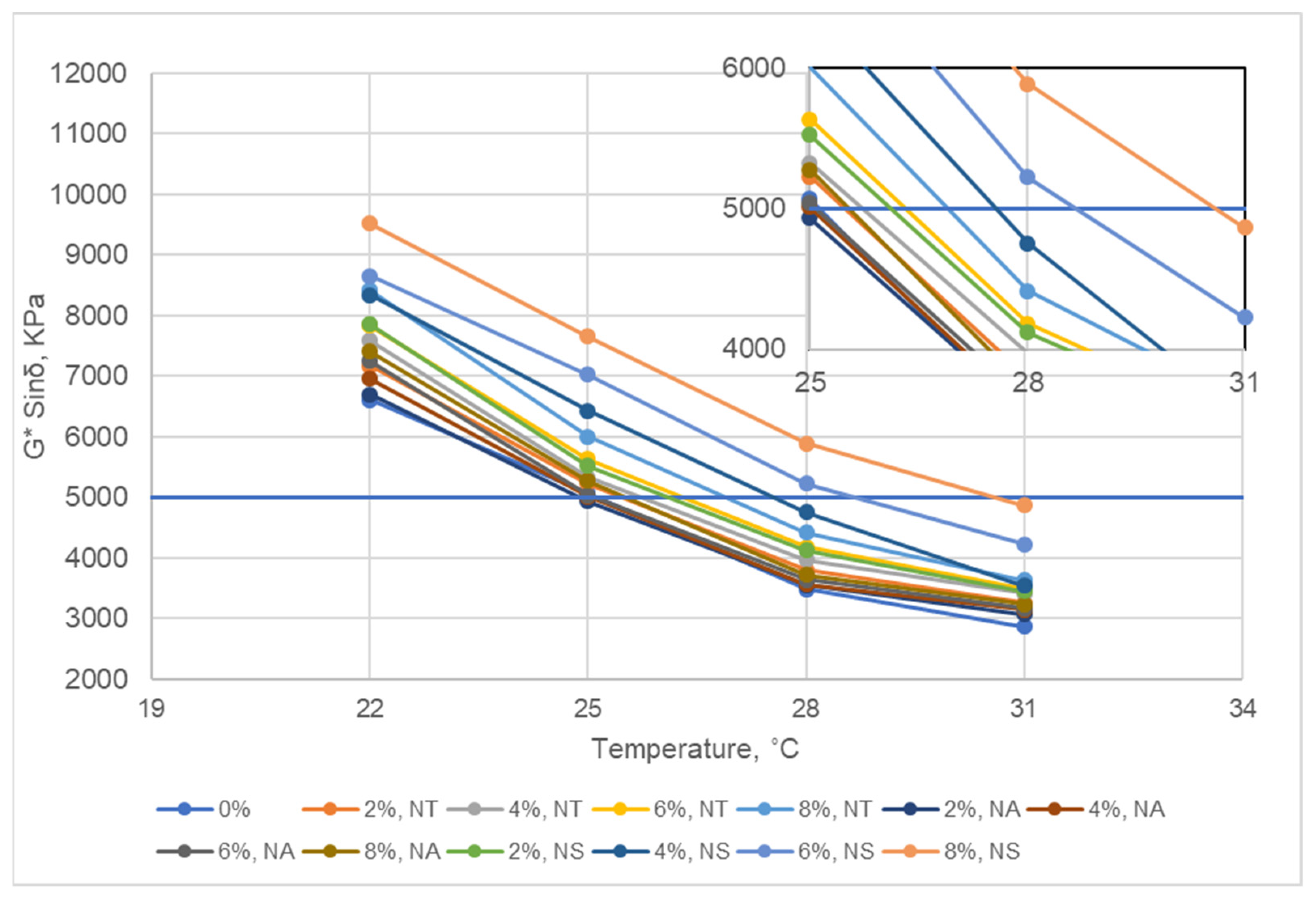

4.5. Rheological Properties

5. Optimal Nanomaterial Content

6. Conclusions

- The SEM analysis highlights unique morphologies of the nanomaterials used. NT displays spherical clusters, suggesting efficient dispersion within asphalt. NA is characterized by irregular agglomerates, potentially influencing its interaction with the binder. NS reveals a dense arrangement of particles, indicative of a significant surface area, which is crucial for integrating with the asphalt binder. These morphological traits are fundamental in understanding the interaction of each nanomaterial with the asphalt matrix.

- NS-modified asphalt demonstrated the best storage stability with a 225% increase in ΔT at an 8% inclusion compared to a 400% increase for NT and a 300% increase for NA, highlighting NS’s superior homogeneity.

- All modified binders remained within acceptable viscosity limits after RTFO aging. NS had the highest average viscosity increase of 33% compared to neat asphalt, suggesting its significant impact on the binder’s viscosity.

- TiO2 reduced mass loss by 12% at a 2% dosage, demonstrating potential anti-aging properties. In contrast, Al2O3 and SiO2 increased the mass loss by 55.64% and 109.77%, respectively, at an 8% inclusion, affecting thermal stability differently.

- SiO2 markedly improved the rutting resistance, showing the highest rutting factor, making it effective for high-temperature performance and heavy traffic conditions.

- Nanomaterials increased the binder stiffness, with the G* sin δ values indicating a slightly higher risk of fatigue cracking. However, the benefits in rutting resistance may offset this risk.

- The optimal dosage for enhanced performance was identified as 6% for both NT and NA, while NS achieved the best balance of properties at a 4% inclusion rate. This suggests that a nuanced approach is required when selecting nanomaterial dosages to maximize the overall asphalt binder’s performance.

- Further field testing and evaluations are recommended to ensure enhanced pavement performance and to confirm the technical viability and practical applicability of NT, NA, and NS in practical pavement applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-bayati, A.H.K.; Lateif, R.H. Evaluating the performance of high modulus asphalt concrete mixture for base course in Iraq. J. Eng. 2017, 23, 14–33. [Google Scholar] [CrossRef]

- Mirzamojeni, M.; Aghayan, I.; Behzadian, R. Evaluation of field aging effect on self-healing capability of asphalt mixtures. Constr. Build. Mater. 2023, 369, 130571. [Google Scholar] [CrossRef]

- Fusco, R.; Moretti, L.; Fiore, N.; D’Andrea, A. Behavior evaluation of bituminous mixtures reinforced with nano-sized additives: A review. Sustainability 2020, 12, 8044. [Google Scholar] [CrossRef]

- Al-Taher, M.; Hassanin, H.; Ibrahim, M.F.; Sawan, A.M. Comparative study of performance of modified asphalt mixtures using different traditional and nano additives. Int. J. Sci. Eng. Res. 2018, 9, 3. [Google Scholar]

- Korniejenko, K.; Nykiel, M.; Choinska, M.; Jexembayeva, A.; Konkanov, M.; Aruova, L. An Overview of Micro-and Nano-Dispersion Additives for Asphalt and Bitumen for Road Construction. Buildings 2023, 13, 2948. [Google Scholar] [CrossRef]

- Mohammed, A.M.; Abed, A.H. Enhancing asphalt binder performance through nano-SiO2 and nano-CaCO3 additives: Rheological and physical insights. Case Stud. Constr. Mater. 2023, 19, e02492. [Google Scholar] [CrossRef]

- Li, R.; Xiao, F.; Amirkhanian, S.; You, Z.; Huang, J. Developments of nano materials and technologies on asphalt materials-A review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Ali, M.; Albayati, A.H.K.; Wang, Y. A review of interface bonding testing techniques. J. Coeng. 2023, 29, 14–30. [Google Scholar] [CrossRef]

- Farina, A.; Kutay, M.E.; Anctil, A. Environmental assessment of asphalt mixtures modified with polymer coated rubber from scrap tires. J. Clean. Prod. 2023, 418, 138090. [Google Scholar] [CrossRef]

- Al-Azawee, E.T.; Latief, R.H. The feasibility of using styrene-butadiene-styrene (SBS) as modifier in Iraqi bituminous binder. J. Eng. Sci. Technol. 2020, 15, 1596–1607. [Google Scholar]

- Rondón-Quintana, H.A.; Ruge-Cárdenas, J.C.; Zafra-Mejía, C.A. Natural asphalts in pavements: Review. Sustainability 2023, 15, 2098. [Google Scholar] [CrossRef]

- Mohammed, F.A.; Latief, R.H.; Albayati, A.H.K. Assessment of traditional asphalt mixture performance using natural asphalt from sulfur springs. J. Coeng. 2024, 30, 54–73. [Google Scholar] [CrossRef]

- Wang, Y.; Latief, R.H.; Al-Mosawe, H.; Mohammad, H.K.; Albayati, A.; Haynes, J. Influence of iron filing waste on the performance of warm mix asphalt. Sustainability 2021, 13, 13828. [Google Scholar] [CrossRef]

- Li, J.; Tang, F. Effects of two metal nanoparticles on performance properties of asphalt binder and stone matrix asphalt mixtures containing waste high density polyethylene. Constr. Build. Mater. 2023, 401, 132787. [Google Scholar] [CrossRef]

- Hashim, S.; Al-Mosawe, H.; Mohammed, H. The Influence of Using Recycled Asphalt Pavement and Crumbed Rubber on Asphalt Pavement: A Review. Al-Nahrain J. Eng. Sci. 2023, 26, 74–82. [Google Scholar] [CrossRef]

- Lima, O.; Afonso, C.; Segundo, I.R.; Landi, S.; Homem, N.C.; Freitas, E.; Alcantara, A.; Branco, V.C.; Soares, S.; Soares, J.; et al. Asphalt binder “Skincare”? Aging evaluation of an asphalt binder modified by nano-TiO2. Nanomaterials 2022, 12, 1678. [Google Scholar] [CrossRef]

- Aljbouri, R.Q.; Albayati, A.H.K. Investigating the effect of nanomaterials on the marshall properties and durability of warm mix asphalt. Cogent Eng. 2023, 10, 2269640. [Google Scholar] [CrossRef]

- Diab, A.; You, Z.; Hossain, Z.; Zaman, M. Moisture susceptibility evaluation of nanosize hydrated lime-modified asphalt-aggregate systems based on surface free energy concept. Transp. Res. Rec. 2024, 2446, 52–59. [Google Scholar] [CrossRef]

- Yusoff, N.I.M.; Breem, A.A.S.; Alattug, H.N.M.; Ahmad, A.H.J. The effects of moisture susceptibility and ageing conditions on nano-silica/polymer-modified asphalt mixtures. Constr. Build. Mater. 2014, 72, 139–147. [Google Scholar] [CrossRef]

- Martínez-Toledo, C.; Valdés-Vidal, G.; Calabi-Floody, A.; González, M.E.; Reyes-Ortiz, O. Effect of biochar from oat hulls on the physical properties of asphalt binder. Materials 2022, 15, 7000. [Google Scholar] [CrossRef]

- Ghabchi, R. Effect of Lignin Type as an Additive on Rheology and Adhesion Properties of Asphalt Binder. Solids 2022, 3, 603–619. [Google Scholar] [CrossRef]

- Ji, H.; He, D.; Li, B.; Lu, G.; Wang, C. Evaluation of rheological and anti-aging properties of TPU/nano-TiO2 composite-modified asphalt binder. Materials 2022, 15, 3000. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Yan, K.; Liu, W. The effect of ultraviolet aging duration on the rheological properties of sasobit/SBS/Nano-TiO2-Modified asphalt binder. Appl. Sci. 2022, 12, 10600. [Google Scholar] [CrossRef]

- Hassan, M.M.; Mohammad, L.N.; Cooper, S.B.; Dylla, H. Evaluation of nano-titanium dioxide additive on asphalt binder aging properties. Transp. Res. Rec. 2011, 2207, 11–15. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Yu, J.; Shi, C.; Zhang, D. Influence of surface modification on physical and ultraviolet aging resistance of bitumen containing inorganic nanoparticles. Constr. Build. Mater. 2015, 98, 735–740. [Google Scholar] [CrossRef]

- Mubaraki, M.; Ali, S.I.A.; Ismail, A.; Yusoff, N.I.M. Rheological evaluation of asphalt cements modified with ASA polymer and Al2O3 nanoparticles. Procedia Eng. 2016, 143, 1276–1284. [Google Scholar] [CrossRef]

- Saltan, M.; Terzi, S.; Karahancer, S. Examination of hot mix asphalt and binder performance modified with nano silica. Constr. Build. Mater. 2017, 156, 976–984. [Google Scholar] [CrossRef]

- Chelovian, A.; Shafabakhsh, G. Laboratory evaluation of nano Al2O3 effect on dynamic performance of stone mastic asphalt. Int. J. Pavement Res. Technol. 2017, 10, 131–138. [Google Scholar] [CrossRef]

- Enieb, M.; Diab, A. Characteristics of asphalt binder and mixture containing nanosilica. Int. J. Pavement Res. Technol. 2017, 10, 148–157. [Google Scholar] [CrossRef]

- Shi, X.; Cai, L.; Xu, W.; Fan, J.; Wang, X. Effects of nano-silica and rock asphalt on rheological properties of modified bitumen. Constr. Build. Mater. 2018, 161, 704–714. [Google Scholar] [CrossRef]

- Qian, G.; Yu, H.; Gong, X.; Zhao, L. Impact of nano-TiO2 on the NO2 degradation and rheological performance of asphalt pavement. Constr. Build. Mater. 2019, 218, 53–63. [Google Scholar] [CrossRef]

- Buhari, R.; Abdullah, M.E.; Ahmad, M.K.; Zabidi, N.; Abu Bakar, S.K. Moisture susceptibility of modified asphalt concrete containing titanium dioxide. Int. J. Adv. Trends Comp. Sci. Eng. 2019, 8, 140–143. [Google Scholar] [CrossRef]

- Taherkhani, H.; Tajdini, M. Comparing the effects of nano-silica and hydrated lime on the properties of asphalt concrete. Constr. Build. Mater. 2019, 218, 308–315. [Google Scholar] [CrossRef]

- Günay, T.; Ahmedzade, P. Physical and rheological properties of nano-TiO2 and nanocomposite modified bitumens. Constr. Build. Mater. 2020, 243, 118208. [Google Scholar] [CrossRef]

- Karahancer, S. Effect of aluminum oxide nano particle on modified bitumen and hot mix asphalt. Pet. Sci. Technol. 2020, 38, 773–784. [Google Scholar] [CrossRef]

- Bhat, F.S.; Mir, M.S. Investigating the effects of nano Al2O3 on high and intermediate temperature performance properties of asphalt binder. Road Mater. Pavement Des. 2021, 22, 2604–2625. [Google Scholar] [CrossRef]

- Bhat, F.S.; Mir, M.S. A study investigating the influence of nano Al2O3 on the performance of SBS modified asphalt binder. Constr. Build. Mater. 2021, 271, 121499. [Google Scholar] [CrossRef]

- Masri, K.A.; Zali, N.S.S.M.; Jaya, R.P.; Seman, M.A.; Rosli, M.R.M. The influence of nano titanium as bitumen modifier in stone mastic asphalt. Adv. Mater. Sci. Eng. 2022, 2022, 4021618. [Google Scholar] [CrossRef]

- Alas, M.; Abba, S.I.; Ali, S.I.A.; Rahim, A.; Yusoff, N.I.M. Evaluating the performance of aluminum oxide nanoparticle-modified asphalt binder and modelling the viscoelastic properties by using artificial neural networks and support vector machines. Adv. Mater. Sci. Eng. 2022, 2022, 9685454. [Google Scholar] [CrossRef]

- Taher, Z.K.; Ismael, M.Q. Moisture susceptibility of hot mix asphalt mixtures modified by nano silica and subjected to aging process. J. Coeng. 2023, 29, 128–143. [Google Scholar] [CrossRef]

- AASHTO M 320; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

- AASHTO T 49; Standard Test Method for Penetration of Bituminous Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- AASHTO T 51; Standard Test Method for Ductility of Asphalt Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- AASHTO T 48; Standard Test Method for Flash and Fire Points by Cleveland Open Cup. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- AASHTO T 53; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- ASTM D7173-20; Standard Practice for Determining the Separation Tendency of Polymer from Polymer Modified Asphalt. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM D2872-22; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM: West Conshohocken, PA, USA, 2020.

- ASHTO TP48; Standard Test Method for Viscosity Determination of Asphalt Binder Using Rotational Viscometer. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- AASHTO T315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

| Ref. | Year | Binder Type | Type of NM | NM Dosage (% by Weight of Asphalt) | Main Conclusions |

|---|---|---|---|---|---|

| US [24] | 2011 | PG 64-16 | NT | 0, 3, 5, 7 | NT did not affect physical properties of virgin binder |

| Malaysia [19] | 2014 | Polymer-modified asphalt (PG-76) | NS | 0, 2, 4 | Scanning electron microscopy (SEM) analysis revealed that NS particles were scattered uniformly throughout asphalt binder, which is better than polymer dispersion |

| China [25] | 2015 | AC 70 | NT | 0, 2 | -Highly effective in improving Ultraviolet (UV) aging resistance through NT surface modification -Enhanced compatibility between asphalt binder and NT by using surface modification |

| Saudi Arabia [26] | 2016 | AC (60-70) | NA | 0, 3, 5, 7 | -NA modification increased asphalt thickness because of rise in viscosity of asphalt binder, which presented better coating of aggregate particles in asphalt mixture -At high temperatures, asphalt binders have great storage stability at 5% NA modification because agglomeration will occur and increase through asphalt binder at 7% NA, which means it is less stable -5% NA sample has highest rutting parameter (G*/sin δ) |

| Turkey [27] | 2017 | PG 64-22 | NS | 0, 0.1, 0.3, 0.5 | -Enhanced anti-cracking performance and rutting resistance for asphalt binder with addition of 0.3% of NS -NS modification improved energy savings |

| Iran [28] | 2017 | AC (60-70) | NA | 0, 0.3, 0.6, 0.9, 1.2 | -Permanent deformation and final strain were decreased for NA-modified stone mastic asphalt |

| Egypt [29] | 2017 | AC (60-70) | NS | 0, 2, 4, 6 | -Addition of NS increased viscosity and softening point (SP) of asphalt binder -No negative effect on temperature susceptibility (TS) for NS-modified asphalt binder -Penetration grade decreased in NS-modified binder compared to base asphalt |

| China [30] | 2018 | AC (60-70) | NS | 0, 0.1, 0.2, 0.3 | -Increased viscosity of binder with increased addition of NS -Increasing NS dosage improves complex modulus of asphalt binder -SEM image analysis revealed that NS activity would decline because agglomerations throughout asphalt matrix caused reduction in bonding force between NS particles and decrease in specific surface area |

| China [31] | 2019 | SBS-modified asphalt | NT | 0, 1, 2, 5, 10 | -Highly effective in improving rutting resistance and aging performance of SBS-modified asphalt with addition of 1% NT -At low temperature, NT had no positive influence on cracking resistance of SBS-modified asphalt because creep rate and creep stiffness are almost identical for all samples |

| Malaysia [32] | 2019 | AC (80/100) | NT | 0, 2, 4, 6, 8, 10 | -Penetration grade is decreased, accompanied by slight increase in SP, which clearly indicates effect of NT on stiffness of modified asphalt binder |

| Iran [33] | 2019 | AC (60-70) | NS | 0, 2, 4, 6 | -As seen in SEM images, NS particles disperse successfully and homogeneously throughout asphalt binder structure -Stiffness and cohesion are decreased for NS-modified binder compared to base asphalt -Decreased TS for binder with addition of NS |

| Turkey [34] | 2020 | AC (50/70) | NT | 0, 2, 4 | -Penetration grade is decreased, accompanied by slight increase in SP, clearly indicating effect of NT on stiffness of modified binder -Higher Penetration Index signifies that NT has positive influence on TS of asphalt binder -Loss of weight of NT-modified asphalt binder decreases slightly after short-term aging process -After NT modification, there is no progress in terms of high temperature for performance grade |

| Turkey [35] | 2020 | AC (50/70) | NA | 0, 3, 5, 7 | -5% NA achieved best anti-rutting performance and fatigue cracking of modified asphalt binder due to increase in value of G*/sinδ and decrease in value of G*sinδ, respectively -SEM analysis revealed that some NA particles fully dispersed and other NA particles caused little agglomeration throughout asphalt binder -Based on rotational viscometer test results, mixing and compaction temperatures decreased for NA-modified asphalt binder, which was considered economic advantage -No change in performance grades for NA-modified binder compared to reference binder |

| India [36] | 2020 | AC—viscosity grade 10 (VG-10) | NA | 0, 0.5, 1, 2 | -NA particles have crystalline nature compared to base asphalt because XRD analysis showed that NA has distinct peaks -2% NA achieved best anti-rutting performance of modified asphalt binder due to increase in the value of Superpave rutting parameter, G*/sinδ -Complex modulus increased, and phase angle decreased for NA-modified asphalt binder; this confirmed that adding NA makes binder elastic and stiffer in nature |

| India [37] | 2021 | SBS-modified asphalt | NA | 0, 1, 2, 3, 4, 5 | -Fatigue life and anti-rutting behavior of NA-SBS-modified binder are improved -After adding NA, storage stability and aging resistance of asphalt binder are significantly enhanced |

| Malaysia [38] | 2022 | AC (60-70) | NT | 0, 1, 2, 3, 4, 5 | -NT modification improved mechanical and volumetric properties of stone mastic asphalt -Excellent enhancement in terms of chemical and morphological properties with 3% NT addition |

| Turkey [39] | 2022 | AC (60-70) | NA | 0, 3, 5, 7 | -Penetration grade decreased, accompanied by increase in SP, clearly indicating that NA affects stiffness of modified asphalt binder -Binder viscosity is increased after NA modification -At high temperature, NA-modified asphalt binder has less sensitivity to permanent deformation due to reduction in creep compliance parameter |

| Iraq [40] | 2023 | AC (40-50) | NS | 0, 2, 4, 6 | Microstructural analysis revealed that NS particles disperse homogeneously throughout asphalt binder structure due to good dispersion potential and large specific surface area of NS |

| Current Study | 2024 | AC (40-50) | NT NA NS | 0, 2, 4, 6, 8 | Current study aims to evaluate the following: -Crystalline structure of each NMs using SEM; -Change in asphalt binder consistency of virgin and modified asphalt cements; -Change in storage stability of different modified binders; -Mass loss due to short-term aging of virgin and modified asphalt cements; -Workability of asphalt cement (virgin and modified) by implementing rotational viscosity test at different temperatures (for original and aged asphalt); -Rheological properties of virgin and modified asphalt cements, including rutting and fatigue index by using Dynamic Shear Rheometer (DSR). |

| Property | Standard | Test Result | Specification Limit |

|---|---|---|---|

| Penetration at 25 °C, 100 gm, 5 s. (0.1 mm) | [42] | 49 | (40–50) |

| Ductility at 25 °C, 5 cm/min. (cm) | [43] | 110 | >100 |

| Flashpoint (Cleveland open cup) (°C) | [44] | 311 | Min. 232 |

| Softening point (°C) | [45] | 49.7 | - |

| Specific gravity at 25 °C | [46] | 1.04 | - |

| The residue from thin film oven test | [47] | - | |

| Retained penetration (% of original) | [48] | 58 | |

| Ductility at 25 °C, 5 cm/min (cm) | [49] | 80 | - |

| Asphalt Cement | Properties | Temperature Measured °C | Measured Parameters | Specification Requirements, [41] |

|---|---|---|---|---|

| Original | Flash point (°C) | - | 311 | 230 °C, min |

| Viscosity at 135 °C (Pa·s) | - | 719.7 | 3000 m Pa·s, max | |

| DSR, G/sinδ at 10 rad/s (kPa) | 58 | 3.4515 | 1.00 kPa, min | |

| 64 | 1.6623 | |||

| 70 | 0.8425 | |||

| RTFO Aged | Mass loss (%) | - | 0.266 | 1%, max |

| DSR, G/sinδ at 10 rad/s (kPa) | 58 | 6.8651 | 2.2 kPa, min | |

| 64 | 3.4578 | |||

| 70 | 1.7241 | |||

| PAV Aged | DSR, G.sinδ at 10 rad/s (kPa) | 28 | 3485 | 5000 kPa, max |

| 25 | 5068 | |||

| BBR, creep stiffness (MPa) | −6 | 183 | 300 MPa, max | |

| Slope m-value | −6 | 0.368 | 0.3, min |

| Properties | Nanomaterial | ||

|---|---|---|---|

| NT | NA | NS | |

| Chemical formula | TiO2 | Al2O3 | SiO2 |

| Molecule wt. (g/mol) | 85.42 | 101.96 | 60.08 |

| Appearance | White Powder | White Powder | White Powder |

| Average particle size (nm) | 20–30 | 10–20 | 25–35 |

| Purity (%) | 99.9 | 99.9 | 99.8 |

| Specific surface area (m2/gm) | 120–160 | 120–160 | 190–250 |

| Meting point (°C) | 1860 | 2030 | 1730 |

| Bulk Density (g/mL) | 0.51 | 0.2 | 0.08 |

| Ph | 5.5–6.5 | 8.5–9.5 | 5–6.5 |

| Nanomaterial | 0% | 2% | 4% | 6% | 8% |

|---|---|---|---|---|---|

| NT | −1.33 | −1.30 | −1.34 | −1.22 | −0.96 |

| NA | −1.33 | −1.32 | −1.22 | −0.95 | −0.85 |

| NS | −1.33 | −1.12 | −1.03 | −1.10 | −1.04 |

| Temperature | RV Values (mPa·s) | |||||

|---|---|---|---|---|---|---|

| NT | NA | NS | ||||

| Original | After TFOT | Original | After TFOT | Original | After TFOT | |

| 115 °C | 2730.12 | 3634.92 | 2937.5 | 3742.9 | 3554.46 | 4742.9 |

| 135 °C | 863.3 | 1157.78 | 936.56 | 1215.32 | 1150.1 | 1498.1 |

| 155 °C | 285.04 | 380.48 | 315.82 | 406.06 | 397.24 | 520.18 |

| Test | Parameter | NT Content, % | ||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | ||

| Penetration, 1/10 mm | X1(0) | 49 | 48 | 45 | 42 | 40 |

| X1* | 0.000 | 0.111 | 0.444 | 0.778 | 1.000 | |

| Softening point, °C | X2(0) | 49.7 | 50 | 50.4 | 51.5 | 53.1 |

| X2* | 0.000 | 0.088 | 0.206 | 0.529 | 1.000 | |

| PI | X3(0) | −1.33 | −1.3 | −1.34 | −1.22 | −0.96 |

| X3* | 0.026 | 0.105 | 0.300 | 0.316 | 1.000 | |

| Mass loss, % | X4(0) | 0.266 | 0.234 | 0.226 | 0.238 | 0.259 |

| X4* | 0.000 | 0.808 | 1.000 | 0.695 | 0.169 | |

| Storage stability, °C | X5(0) | 0.4 | 0.8 | 1.3 | 1.7 | 2 |

| X5* | 1.000 | 0.750 | 0.438 | 0.188 | 0.000 | |

| RV at 135 °C, mPa·s | X6(0) | 719.7 | 793.1 | 904.4 | 916.8 | 982.5 |

| X6* | 0.000 | 0.279 | 0.703 | 0.750 | 1.000 | |

| Temp (°C) at rutting index = 1 kPa | X7(0) | 68.85 | 69.92 | 69.93 | 74.61 | 79.47 |

| X7* | 0.000 | 0.101 | 0.102 | 0.542 | 1.000 | |

| Temp (°C) at rutting index = 2.2 kPa | X8(0) | 68.35 | 69.06 | 70.68 | 74.71 | 76.08 |

| X8* | 0.000 | 0.092 | 0.301 | 0.823 | 1.000 | |

| Temp (°C) at fatigue index = 5000 kPa | X9(0) | 25.13 | 25.48 | 25.72 | 26.31 | 26.89 |

| X9* | 1.000 | 0.801 | 0.665 | 0.330 | 0.000 | |

| Overall Desirability (OD) | 0.000 | 0.222 | 0.382 | 0.498 | 0.000 | |

| Test | Parameter | NA Content, % | ||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | ||

| Penetration, 1/10 mm | X1(0) | 49 | 47 | 44 | 41 | 36 |

| X1* | 0.000 | 0.154 | 0.385 | 0.615 | 1.000 | |

| Softening point, °C | X2(0) | 49.7 | 50.1 | 51.1 | 52.9 | 54.6 |

| X2* | 0.000 | 0.082 | 0.286 | 0.653 | 1.000 | |

| PI | X3(0) | −1.33 | −1.32 | −1.22 | −0.95 | −0.85 |

| X3* | 0.000 | 0.021 | 0.229 | 0.792 | 1.000 | |

| Mass loss, % | X4(0) | 0.266 | 0.245 | 0.275 | 0.303 | 0.414 |

| X4* | 0.876 | 1.000 | 0.822 | 0.657 | 0.000 | |

| Storage stability, °C | X5(0) | 0.4 | 0.6 | 0.9 | 1.3 | 1.6 |

| X5* | 1.000 | 0.833 | 0.583 | 0.250 | 0.000 | |

| RV at 135 °C, mPa·s | X6(0) | 719.7 | 845.2 | 965.9 | 1063 | 1089 |

| X6* | 1.000 | 0.660 | 0.333 | 0.070 | 0.000 | |

| Temp (°C) at rutting index = 1 kPa | X7(0) | 68.85 | 69.97 | 70.91 | 75.36 | 80.42 |

| X7* | 0.000 | 0.097 | 0.178 | 0.563 | 1.000 | |

| Temp (°C) at rutting index = 2.2 kPa | X8(0) | 68.35 | 69.75 | 71.36 | 76.14 | 78.57 |

| X8* | 0.000 | 0.137 | 0.295 | 0.762 | 1.000 | |

| Temp (°C) at fatigue index = 5000 kPa | X9(0) | 25.13 | 24.88 | 25.02 | 25.08 | 25.53 |

| X9* | 0.615 | 1.000 | 0.785 | 0.692 | 0.000 | |

| Overall Desirability (OD) | 0.000 | 0.231 | 0.380 | 0.469 | 0.000 | |

| Test | Parameter | NS Content, % | ||||

|---|---|---|---|---|---|---|

| 0 | 2 | 4 | 6 | 8 | ||

| Penetration, 1/10 mm | X1(0) | 49 | 47 | 43 | 37 | 29 |

| X1* | 0.000 | 0.100 | 0.300 | 0.600 | 1.000 | |

| Softening point, °C | X2(0) | 49.7 | 50.9 | 52.1 | 53.2 | 55.7 |

| X2* | 0.000 | 0.200 | 0.400 | 0.583 | 1.000 | |

| PI | X3(0) | −1.33 | −1.12 | −1.03 | −1.1 | −1.04 |

| X3* | 0.000 | 0.700 | 1.000 | 0.767 | 0.967 | |

| Mass loss, % | X4(0) | 0.266 | 0.282 | 0.321 | 0.432 | 0.558 |

| X4* | 1.000 | 0.945 | 0.812 | 0.432 | 0.000 | |

| Storage stability, °C | X5(0) | 0.4 | 0.6 | 0.7 | 0.9 | 1.3 |

| X5* | 1.000 | 0.778 | 0.667 | 0.444 | 0.000 | |

| RV at 135 °C, mPa·s | X6(0) | 719.7 | 804.9 | 1129.3 | 1325.8 | 1770.8 |

| X6* | 1.000 | 0.919 | 0.610 | 0.423 | 0.000 | |

| Temp (°C) at rutting index = 1 kPa | X7(0) | 68.85 | 71.53 | 77.56 | 79.72 | 81 |

| X7* | 0.000 | 0.221 | 0.717 | 0.895 | 1.000 | |

| Temp (°C) at rutting index = 2.2 kPa | X8(0) | 68.35 | 70.71 | 74.61 | 77.3 | 80.87 |

| X8* | 0.000 | 0.188 | 0.500 | 0.715 | 1.000 | |

| Temp (°C) at fatigue index = 5000 kPa | X9(0) | 25.13 | 26.12 | 27.56 | 28.67 | 30.6 |

| X9* | 1.000 | 0.819 | 0.556 | 0.353 | 0.000 | |

| Overall Desirability (OD) | 0.000 | 0.409 | 0.584 | 0.554 | 0.000 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albayati, A.H.; Latief, R.H.; Al-Mosawe, H.; Wang, Y. Nano-Additives in Asphalt Binder: Bridging the Gap between Traditional Materials and Modern Requirements. Appl. Sci. 2024, 14, 3998. https://doi.org/10.3390/app14103998

Albayati AH, Latief RH, Al-Mosawe H, Wang Y. Nano-Additives in Asphalt Binder: Bridging the Gap between Traditional Materials and Modern Requirements. Applied Sciences. 2024; 14(10):3998. https://doi.org/10.3390/app14103998

Chicago/Turabian StyleAlbayati, Amjad H., Roaa H. Latief, Hasan Al-Mosawe, and Yu Wang. 2024. "Nano-Additives in Asphalt Binder: Bridging the Gap between Traditional Materials and Modern Requirements" Applied Sciences 14, no. 10: 3998. https://doi.org/10.3390/app14103998