Geological Conditions Evaluation of Coalbed Methane of Dacun Block in the Guxu Mining Area, Southern Sichuan Coalfield

Abstract

:1. Introduction

2. Geological Settings

3. Materials and Methods

3.1. Core Data

3.2. Gas Composition Data

3.3. Insitu Reservoir Pressure, Stress, and Permeability Data

4. Results and Discussions

4.1. Chemical Compositions of Coalbed Gas

4.2. Gas Content Characteristics

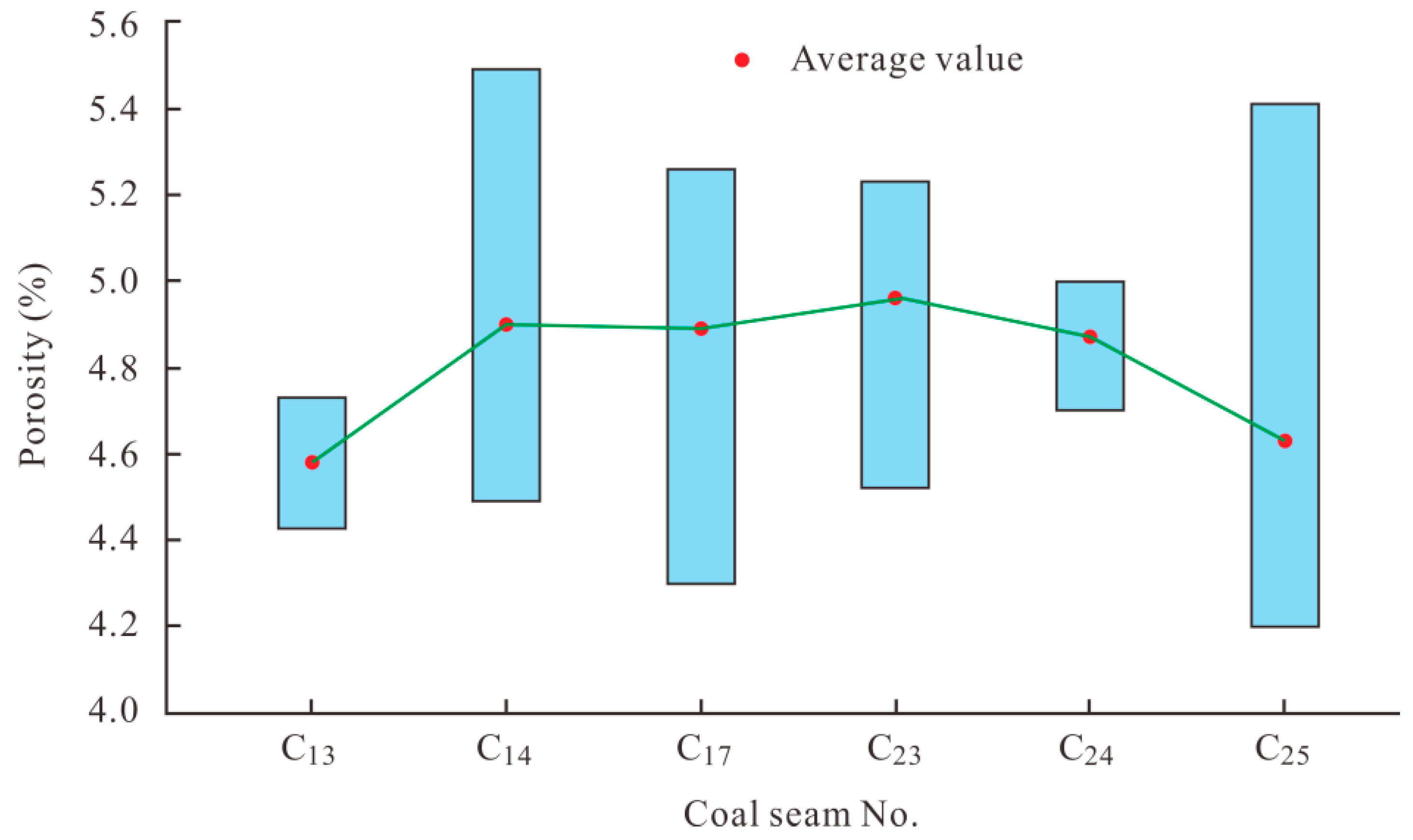

4.3. Porosity Characteristics

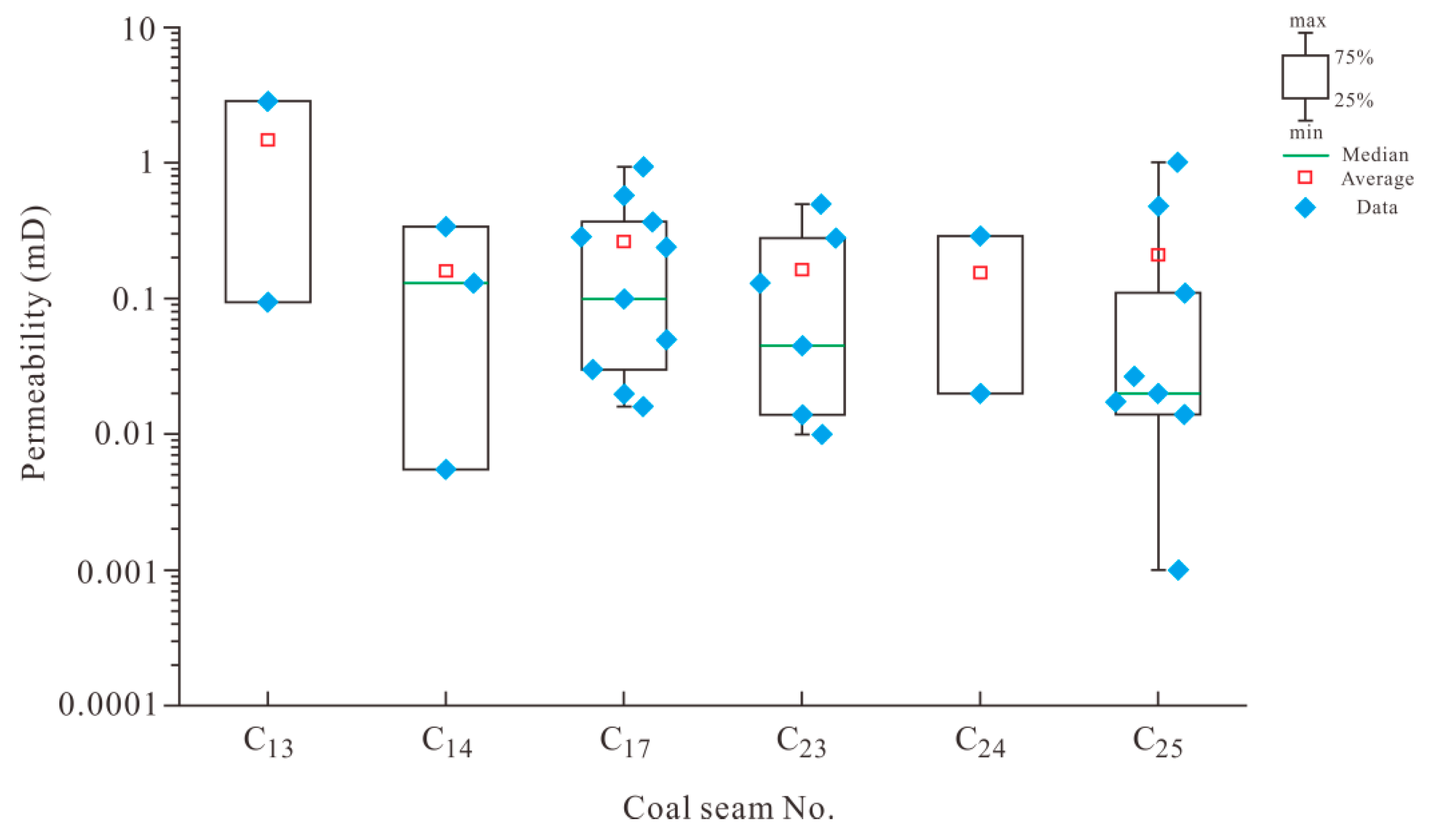

4.4. Permeability Characteristics

4.5. Reservoir Pressure Characteristics

4.6. Adsorption Characteristics

4.7. Gas Saturationcharacteristics

4.8. Critical Desorption Pressure Characteristics

5. Conclusions

- (1)

- The macrolithotypes of coals in the Dacun block are dominated by semi-dull coals, followed by semi-bright coals. The organic macerals of coals are dominated by vitrinite, followed by inertinite, and exinite is generally rare. The coals are semi-anthracite to anthracite in coal rank.

- (2)

- CH4 concentration accounts for 33.8–100% (avg. 85.21%) of the total gas component and, overall, takes on an increasing trend as the depth increases. The CH4 weathering zone depth is 310 m. The coal seams, overall, have a high gas content, varying from 0.11 to 35.68 cm3/g (avg. 17.27 cm3/g). The gas content shows a “increase→decrease” trend as the depth increases, and the critical depth is around 700 m.

- (3)

- The coals in the Dacun Block have low porosities (4.20–5.41%) and permeabilities (0.001 mD–2.85 mD). The porosity shows a positive correlation with the Ro,max. The permeabilities present a decreasing trend with the increase in depth. Moreover, a negative relationship exists between the coal permeability and minimum horizontal stress magnitude.

- (4)

- The coal reservoirs in the Dacun Block overall have a low abnormal pressure state. The fluctuation change relationship between the reservoir pressure coefficient and depth indicates that three sets of independent superposed gas-bearing systems possibly exist vertically in the Longtan Formation.

- (5)

- The coals in the Dacun Block have a strong adsorptivity; however, the gas saturation is low. Coals with high gas contents and reservoir pressures usually have high gas saturations. The CBM development in the Dacun Block needs a large depressurization of reservoir pressure due to the low ratio of critical desorption pressure to reservoir pressure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, M.; Yi, X.; Liu, K.; Sun, C.; Kong, Q. How much natural gas does China need: An empirical study from the perspective of energy transition. Energy 2023, 266, 126357. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, X.Q.; Meng, Q.S.; Wang, W.W.; Huang, W. Development status and prospect of gas distributed energy industry. In Annual Report on China’s Petroleum, Gas and New Energy Industry (2022–2023); Springer Nature: Singapore, 2024; pp. 209–227. [Google Scholar]

- Xie, M.H.; Wei, X.N.; Chen, C.L.; Sun, C.W. China’s natural gas production peak and energy return on investment (EROI): From the perspective of energy security. Energy Policy 2022, 164, 112913. [Google Scholar] [CrossRef]

- Karimpouli, S.; Tahmasebi, P.; Ramandi, H.L. A review of experimental and numerical modeling of digital coalbed methane: Imaging, segmentation, fracture modeling and permeability prediction. Int. J. Coal Geol. 2020, 228, 103552. [Google Scholar] [CrossRef]

- Pashin, J.C. Geology of North American coalbed methane reservoirs. In Coal Bed Methane; Elsevier: Amsterdam, The Netherlands, 2020; pp. 35–64. [Google Scholar]

- Ray, S.K.; Khan, A.M.; Mohalik, N.K.; Mishra, D.; Mandal, S.; Pandey, J.K. Review of preventive and constructive measures for coal mine explosions: An Indian perspective. Int. J. Min. Sci. Technol. 2022, 32, 471–485. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, K.; Liu, S.; Ju, Y.; Zhou, H.; Fan, L.; Yang, Y.; Cheng, Y.; Zhang, X.A. synchronous difference in dynamic characteristics of adsorption swelling and mechanical compression of coal: Modeling and experiments. Int. J. Rock Mech. Min. Sci. 2020, 135, 104498. [Google Scholar] [CrossRef]

- Li, S.; Qin, Y.; Tang, D.; Shen, J.; Wang, J.; Chen, S. A comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.; Shen, Y.; Wang, G. Resources and geology of coalbed methane in China: A review. Int. Geol. Rev. 2018, 60, 777–812. [Google Scholar] [CrossRef]

- Xu, F.; Hou, W.; Xiong, X.; Xu, B.; Wu, P.; Wang, H.; Feng, K.; Yun, J.; Li, S.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Kang, J.Q.; Fu, X.H.; Elsworth, D.; Liang, S. Vertical heterogeneity of permeability and gas content of ultra-high-thickness coalbed methane reservoirs in the southern margin of the Junggar Basin and its influence on gas production. J. Nat. Gas Sci. Eng. 2020, 81, 103455. [Google Scholar] [CrossRef]

- Chen, S.; Tang, D.; Tao, S.; Liu, P.; Mathews, J.P. Implications of the insitu stress distribution for coalbed methane zonation and hydraulic fracturing in multiple seams, western Guizhou, China. J. Pet. Sci. Eng. 2021, 204, 108755. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; Yang, Z.; Li, G.; You, Z. Primary Controlling factors of coalbed methane well productivity and high productive well patterns in Eastern Yunnan and Western Guizhou, China. Nat. Resour. Res. 2023, 32, 2711–2726. [Google Scholar] [CrossRef]

- Yuan, M.; Lyu, S.; Wang, S.; Xu, F.; Yan, X. Macrolithotype controls on natural fracture characteristics of ultra-thick lignite in Erlian Basin, China: Implication for favorable coalbed methane reservoirs. J. Pet. Sci. Eng. 2022, 208, 109598. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Mostaghimi, P.; Armstrong, R.T.; Gerami, A.; Hu, Y.; Jing, Y.; Kamali, F.; Liu, M.; Liu, Z.; Lu, X.; Ramandi, H.L.; et al. Cleat-scale characterisation of coal: An overview. J. Nat. Gas Sci. Eng. 2017, 39, 143–160. [Google Scholar] [CrossRef]

- Cui, Z.; Zhang, Z.; Huang, W.; Liu, L.; Wang, J.; Wei, X.; Shen, J. Pore-fracture structure characteristics of low-medium rank coals from Eastern Surat Basin by FE-SEM and NMR experiments. Nat. Resour. Res. 2024, 33, 743–763. [Google Scholar] [CrossRef]

- Gan, Q.; Xu, J.; Peng, S.; Yan, F.; Wang, R.; Cai, G. Effect of heating on the molecular carbon structure and the evolution of mechanical properties of briquette coal. Energy 2021, 237, 121548. [Google Scholar] [CrossRef]

- Tang, C.; Yao, Q.; Chen, T.; Shan, C.; Li, J. Effects of water content on mechanical failure behaviors of coal samples. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 87. [Google Scholar] [CrossRef]

- Karacan, C.; Okandan, E. Assessment of energetic heterogeneity of coals for gas adsorption and its effect on mixture predictions for coalbed methane studies. Fuel 2000, 79, 1963–1974. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, J.; Hou, Q.; Yu, B.; Li, M.; Niu, Q. Anisotropic characteristics of low-rank coal fractures in the Fukang mining area, China. Fuel 2018, 211, 182–193. [Google Scholar] [CrossRef]

- Scott, A.R. Hydrogeologic factors affecting gas content distribution in coalbeds. Int. J. Coal Geol. 2002, 50, 363–387. [Google Scholar] [CrossRef]

- Guo, C.; Xia, Y.; Ma, D.; Sun, X.; Dai, G.; Shen, J.; Chen, Y.; Lu, L. Geological conditions of coalbed methane accumulation in the Hancheng area, southeastern Ordos Basin, China: Implications for coalbed methane high-yield potential. Energy Explor. Exploit. 2019, 37, 922–944. [Google Scholar] [CrossRef]

- Esen, O.; Özer, S.C.; Soylu, A.; Rend, A.R.; Fişne, A. Geological controls on gas content distribution of coal seams in the Kınık coalfield, Soma Basin, Turkey. Int. J. Coal Geol. 2020, 231, 103602. [Google Scholar] [CrossRef]

- Pashin, J.C. Stratigraphy and structure of coalbed methane reservoirs in the United States: An overview. Int. J. Coal Geol. 1998, 35, 209–240. [Google Scholar] [CrossRef]

- Ayers, W.B., Jr. Coalbed gas system, resources, and production and a review of contrasting cases from the San Juan and Powder River basins. AAPG Bull. 2002, 86, 1853–1890. [Google Scholar]

- Chen, Y.; Tang, D.; Xu, H.; Li, Y.; Meng, Y. Structural controls on coalbed methane accumulation and high production models in the eastern margin of Ordos Basin, China. J. Nat. Gas Sci. Eng. 2015, 23, 524–537. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Liu, D.M.; Cai, Y.D.; Pan, Z.J.; Yao, Y.B.; Wang, Y.J. Geological and hydrological controls on the accumulation of coalbed methane within the No.3 coal seam of the southern Qinshui Basin. Int. J. Coal Geol. 2017, 182, 94–111. [Google Scholar] [CrossRef]

- Lv, Y.; Tang, D.; Xu, H.; Luo, H. Production characteristics and the key factors in high-rank coalbed methane fields: A case study on the Fanzhuang Block, Southern Qinshui Basin, China. Int. J. Coal Geol. 2012, 96–97, 93–108. [Google Scholar] [CrossRef]

- Peng, C.; Zou, C.; Zhou, T.; Li, K.; Yang, Y.; Zhang, G.; Wang, W. Factors affecting coalbed methane (CBM) well productivity in the Shizhuangnan block of southern Qinshui basin, North China: Investigation by geophysical log, experiment and production data. Fuel 2017, 191, 427–441. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; Zhuang, X.G.; Li, G.Q.; Liu, D.H. Geological controls on the CBM productivity of No.15 coal seam of Carboniferous–Permian Taiyuan Formation in Southern Qinshui Basin and prediction for CBM high-yield potential regions. Acta Geol. Sin. (Engl. Ed.) 2018, 92, 2310–2332. [Google Scholar]

- Yin, Z.S.; Wei, W.J.; Xiao, J.X. CBM exploration and exploitation status, key issues and proposals in Sichuan Province. Coal Geol. China 2019, 31, 66–69. [Google Scholar]

- Liang, W.L.; Wei, W.J.; Deng, Y.P. Upper Permian coal-bearing stratigraphic framework and coal-accumulation in the Guxu coal mine of the south Sichuan Coalfield. Acta Geol. Sichuan 2013, 33, 287–290. [Google Scholar]

- Chinese Standard SY/T 5336-1996; Method Core Routine Analysis. Industry standard—Oil: Beijing, China, 1996.

- ASTM Standard D3173-11; Test Method for Moisture in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2011. [CrossRef]

- ASTM Standard D3174-11; Annual Book of ASTM Standards. Test Method for Ash in the Analysis Sample of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2011. [CrossRef]

- ISO7404.5-1994; Method for the Petrographic Analysis of Bituminous Coal and Anthracite—Part5: Method of Determining Microscopically the Reflectance of Vitrinite. International Organization for Standardization: Geneva, Switzerland, 1994.

- Chinese Standard GB/T 19560-2004; Experimental Method of High-Pressure Adsorption Isothermal to Coal-Capacity Method. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2004.

- Kissell, F.N.; Mcculloch, C.M.; Elder, C.H. The direct method of determining methane content of coals for ventilation design. In U.S. Bureau of Mines Report of Investigations RI7767; US Department of Interior, Bureau of Mines: Washington, DC, USA, 1981. [Google Scholar]

- Hou, X.; Liu, S.; Zhu, Y.; Yang, Y. Evaluation of gas contents for a multi-seam deep coalbed methane reservoir and their geological controls: Insitu direct method versus indirect method. Fuel 2020, 265, 116917. [Google Scholar] [CrossRef]

- Qin, Y. Progress on geological research of deep coalbed methane in China. Acta Pet. Sin. 2023, 44, 1791–1811. [Google Scholar]

- Guo, Z.; Cao, Y.; Zhang, Z.; Dong, S. Geological controls on the gas content and permeability of coal reservoirs in the Daning Block, Southern Qinshui Basin. ACS Omega 2022, 7, 17063–17074. [Google Scholar] [CrossRef]

- Rodrigues, C.; de Sousa, M.L. The measurement of coal porosity with different gases. Int. J. Coal Geol. 2002, 48, 245–251. [Google Scholar] [CrossRef]

- Mares, T.E.; Radliński, A.P.; Moore, T.A.; Cookson, D.; Thiyagarajan, P.; Ilavsky, J.; Klepp, J. Assessing the potential for CO2 adsorption in a subbituminous coal, Huntly Coalfield, New Zealand, using small angle scattering techniques. Int. J. Coal Geol. 2009, 77, 54–68. [Google Scholar] [CrossRef]

- Chen, D.; Shi, J.-Q.; Durucan, S.; Korre, A. Gas and water relative permeability in different coals: Model match and new insights. Int. J. Coal Geol. 2014, 122, 37–49. [Google Scholar] [CrossRef]

- Liu, H.H.; Sang, S.X.; Wang, G.G.X.; Li, Y.M.; Li, M.X.; Liu, S.Q. Evaluation of the synergetic gas-enrichment and higher-permeability regions for coalbed methane recovery with a fuzzy model. Energy 2012, 39, 426–439. [Google Scholar] [CrossRef]

- Burra, A.; Esterle, J.S.; Golding, S.D. Horizontal stress anisotropy and effective stress as regulator of coal seam gas zonation in the Sydney Basin, Australia. Int. J. Coal Geol. 2014, 132, 103–116. [Google Scholar] [CrossRef]

- Mukherjee, S.; Rajabi, M.; Esterle, J.; Copley, J. Subsurface fractures, in-situ stress and permeability variations in the Walloon Coal Measures, eastern Surat Basin, Queensland, Australia. Int. J. Coal Geol. 2020, 222, 103449. [Google Scholar] [CrossRef]

- Chen, S.; Tao, S.; Tang, D. Insitu coal permeability and favorable development methods for coalbed methane (CBM) extraction in China: From real data. Int. J. Coal Geol. 2024, 284, 104472. [Google Scholar] [CrossRef]

- Wu, C.; Qin, Y.; Zhou, L. Effective migration system of coalbed methane reservoirs in the southern Qinshui Basin. Sci. China Earth Sci. 2014, 57, 2978–2984. [Google Scholar] [CrossRef]

- Fu, X.H.; Qin, Y.; Wei, C.T. Coalbed Methane Geology; China University of Mining and Technology Press: Xuzhou, China, 2007. [Google Scholar]

- Qin, Y.; Shen, J.; Shen, Y.L.; Li, G.; Fan, B.H.; Yao, H.P. Geological causes and inspirations for high production of coal measure gas in Surat Basin. Acta Pet. Sin. 2019, 40, 1147–1157. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Zhang, Z.; Wu, Y.; Long, Z.; Lai, X. Geological Conditions Evaluation of Coalbed Methane of Dacun Block in the Guxu Mining Area, Southern Sichuan Coalfield. Appl. Sci. 2024, 14, 3937. https://doi.org/10.3390/app14093937

Zhu X, Zhang Z, Wu Y, Long Z, Lai X. Geological Conditions Evaluation of Coalbed Methane of Dacun Block in the Guxu Mining Area, Southern Sichuan Coalfield. Applied Sciences. 2024; 14(9):3937. https://doi.org/10.3390/app14093937

Chicago/Turabian StyleZhu, Xushuang, Zheng Zhang, Yonggui Wu, Zhengjiang Long, and Xiaodong Lai. 2024. "Geological Conditions Evaluation of Coalbed Methane of Dacun Block in the Guxu Mining Area, Southern Sichuan Coalfield" Applied Sciences 14, no. 9: 3937. https://doi.org/10.3390/app14093937