Mathematical Model and Analysis of Novel Bevel Gear with High Load-Capacity Based on the Geometric Elements

Abstract

:1. Introduction

2. Design Principle of Bevel Gear Based on the Geometric Elements

2.1. The Principle of Conjugate Curve

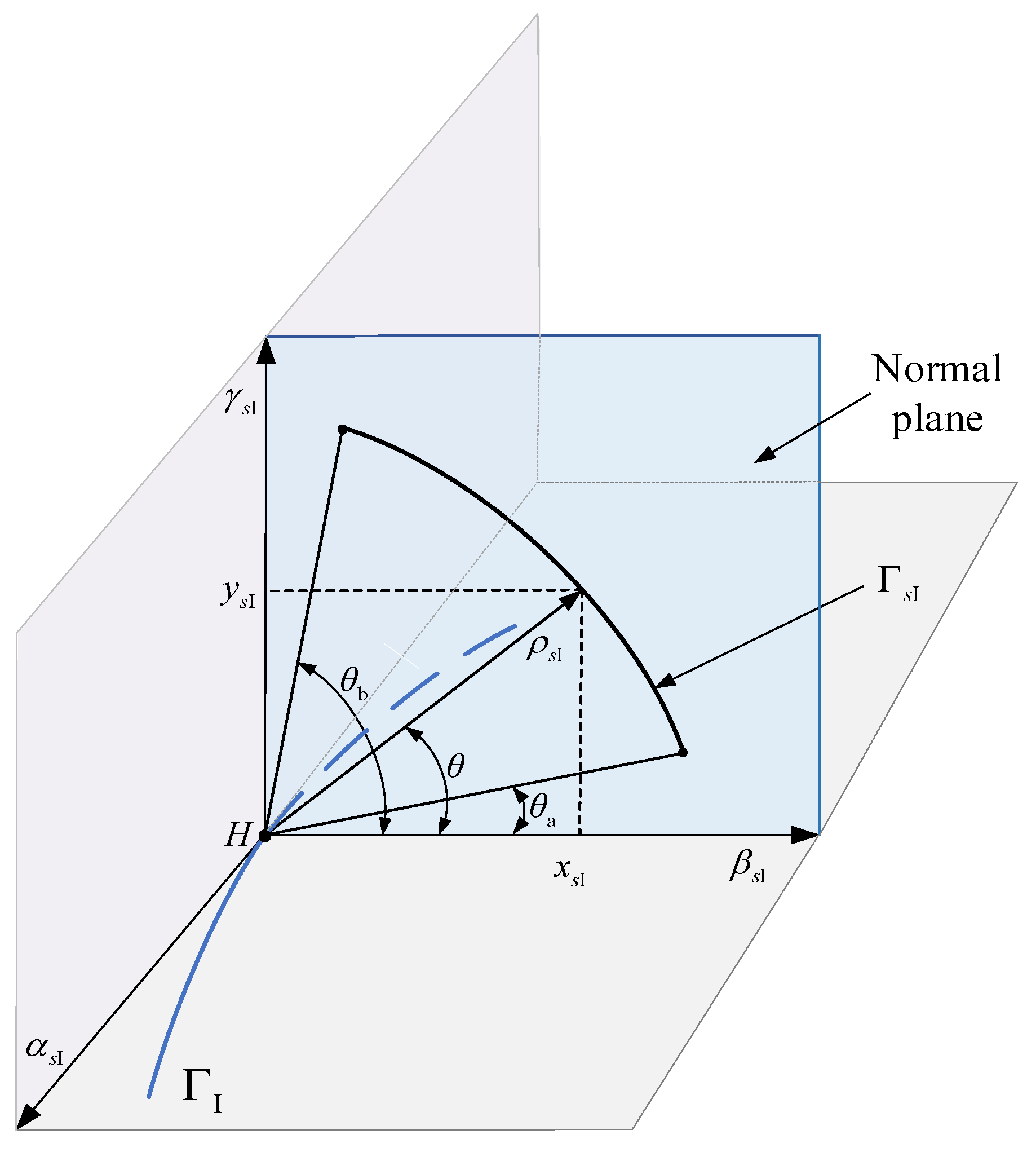

2.2. Applied Coordinate System

2.3. Meshing Equation

2.3.1. Relative Velocity

2.3.2. Meshing Equation

2.4. Conjugate Curve

3. Design Method of Tooth Surfaces with High Load-Capacity

3.1. Principles of Design and Construction

3.2. Design of Tooth Profile with Multi-Point Contact

3.2.1. Tooth Profile Curve of Bevel Gear I

3.2.2. Selection of Contact Points

3.2.3. Construction of Bevel Gear II Tooth Profile Curve

3.3. Construction of Tooth Surface

3.3.1. Construction of Tooth Surface for Bevel Gear I

3.3.2. Construction of Tooth Surface for Bevel Gear II

4. Gear Tooth Characteristics Analysis

4.1. Continuity Conditions of Tooth Surface

4.2. Non-Interference Condition of Tooth Surface

5. Analysis of Load-Bearing Characteristics

5.1. Bevel Gear Pair Parameters

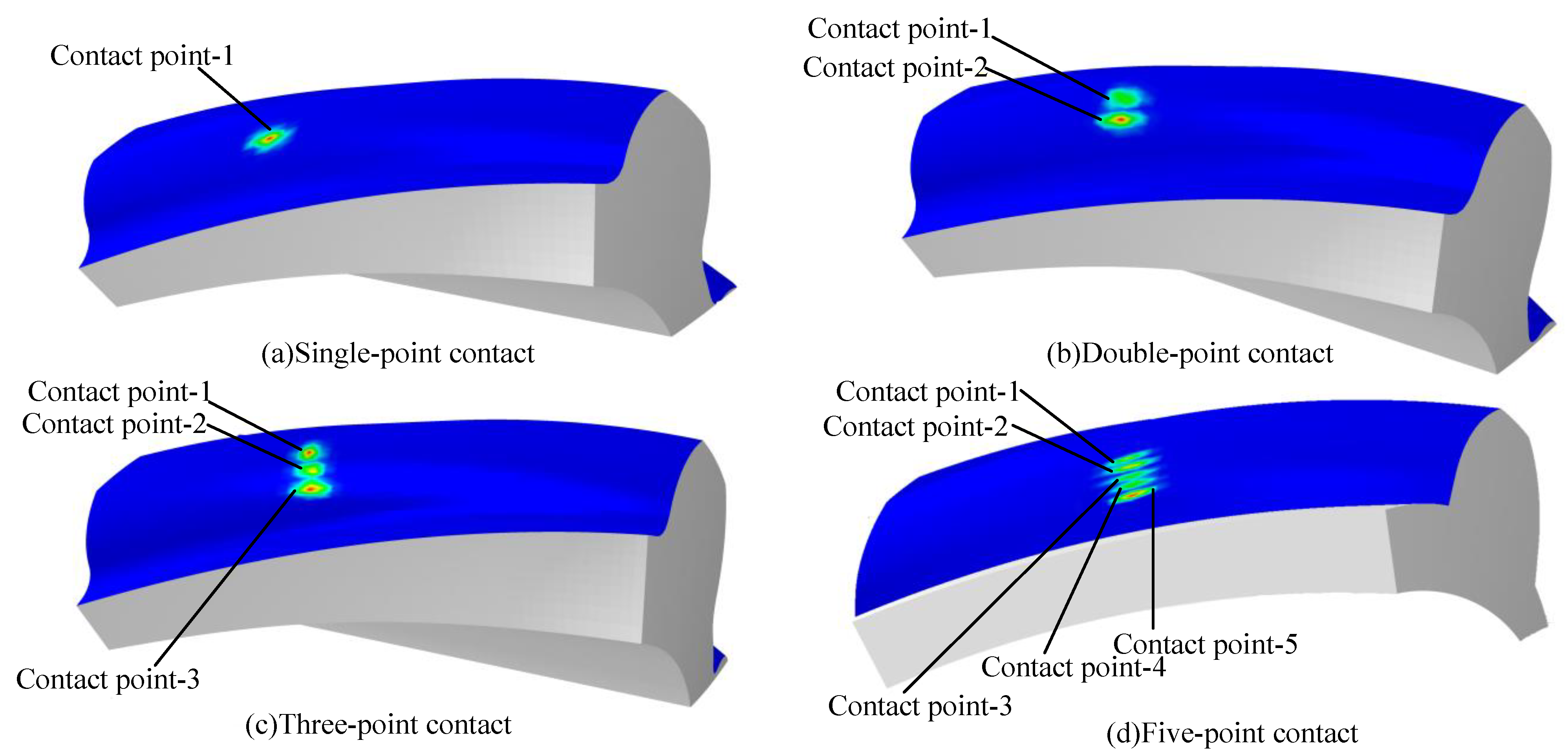

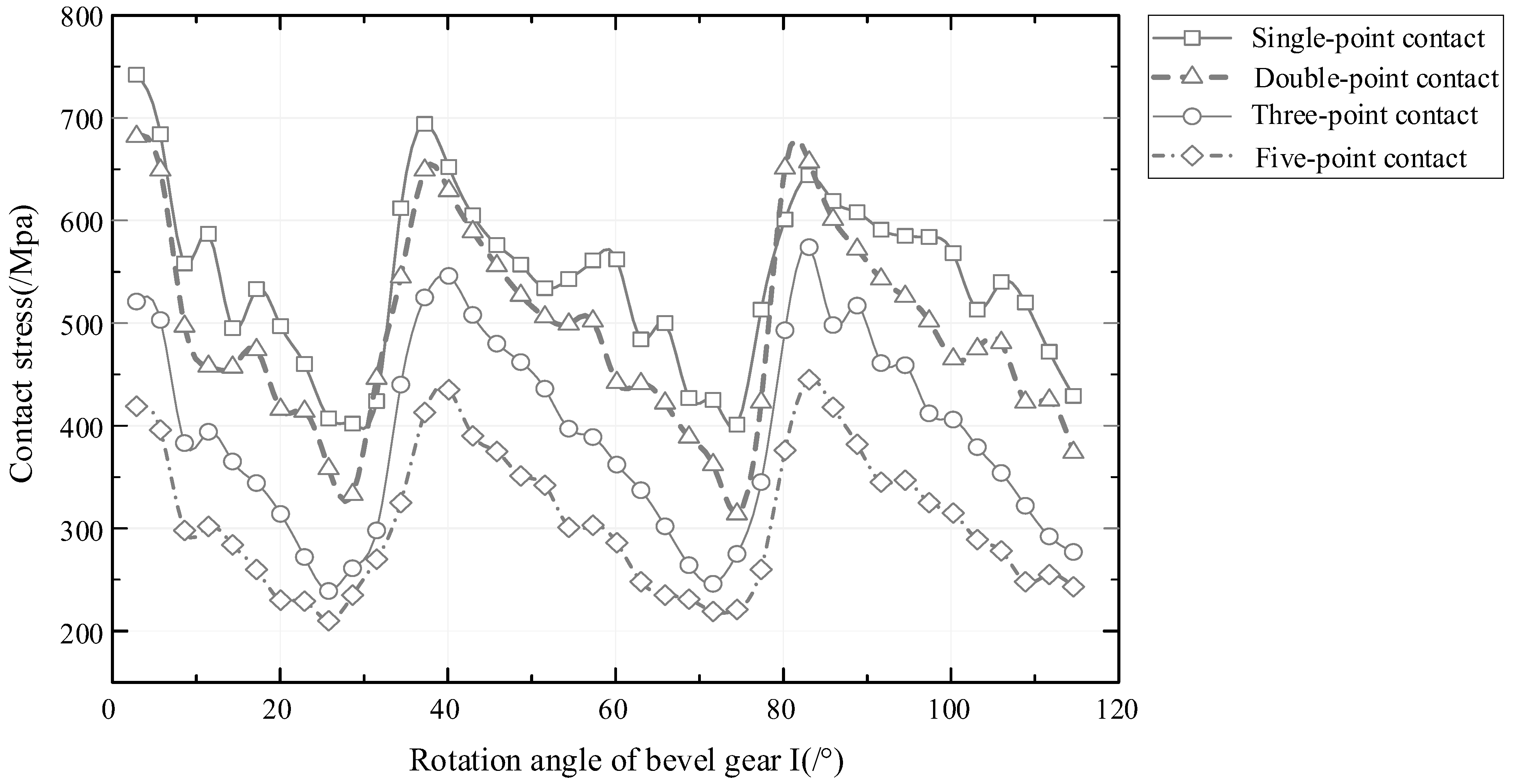

5.2. Influence of Meshing Points on Contact Stress

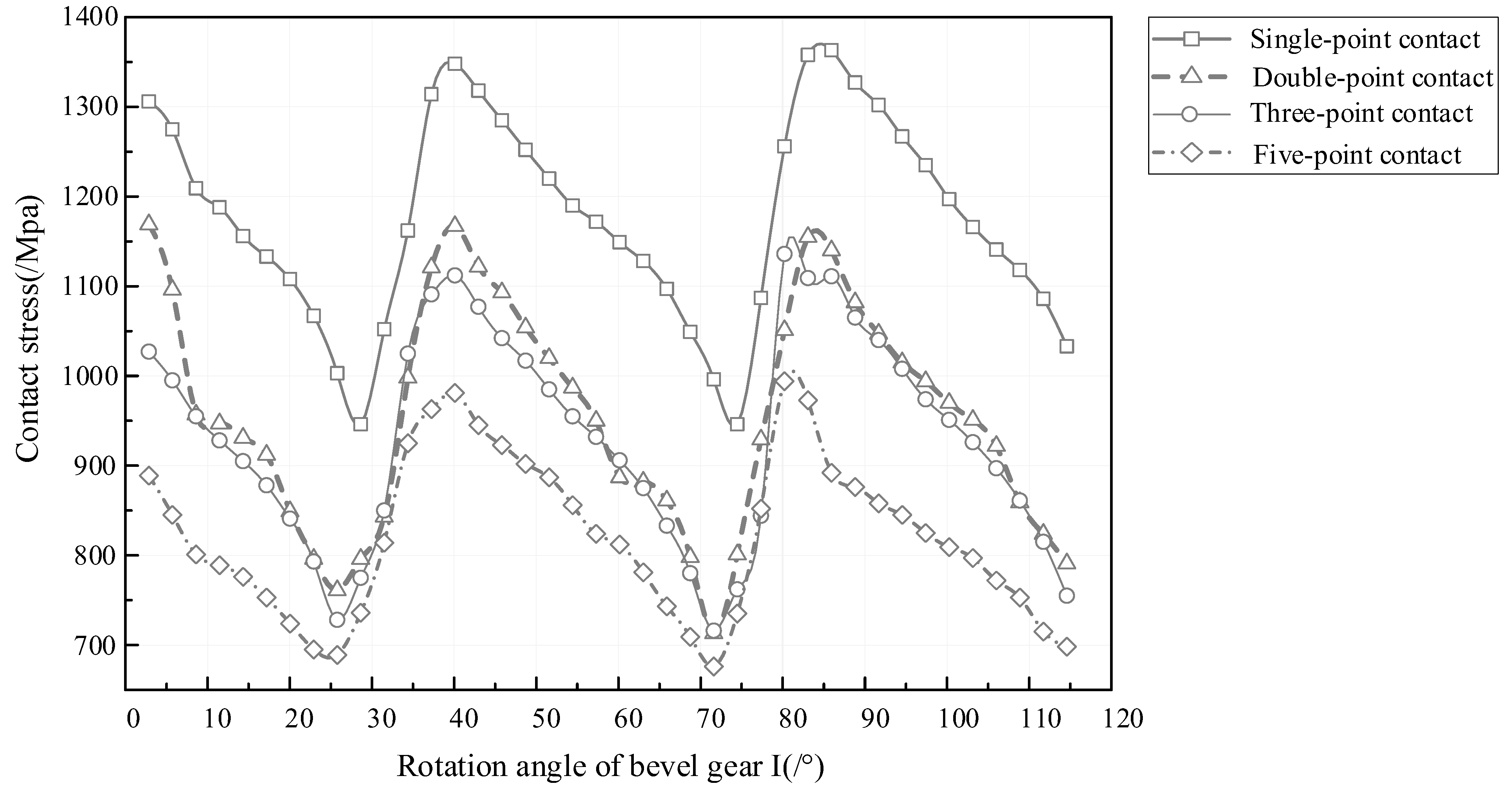

5.3. Influence of Distance between Contact Points on Contact Stress

6. Conclusions

- (1)

- The design method of bevel gear with high load-capacity is put forward, the proposed novel gear enables multi-point contact in the tooth height direction, and full-tooth-width contact along the tooth width direction.

- (2)

- The mathematical model of novel bevel gear is established, and then the analysis of gear tooth characteristics is conducted, conditions for tooth surface continuity and non-interference are also deduced.

- (3)

- The load-bearing characteristics are analyzed, revealing that increasing the number of contact points can reduce the contact stress. For the bevel gear pair with five-point contact, the contact stress is 41.37% lower than that of a bevel gear pair with single-point contact under the torque of 100 Nm.

- (4)

- When the number of contact points is the same, increasing the distance between the contact points can also reduce the contact stress.

- (5)

- For the bevel gear pairs with multi-point contact based on the geometric elements, it requires higher tooth surface accuracy and still face challenges in manufacturing, which need to be further addressed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Klingelnberg, J. (Ed.) Fields of Application for Bevel Gears. In Bevel Gear: Fundamentals and Applications; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–10. [Google Scholar]

- Zhou, C.J.; Li, Z.D.; Hu, B.; Zhan, H.F.; Han, X. Analytical solution to bending and contact strength of spiral bevel gears in consideration of friction. Int. J. Mech. Sci. 2017, 128, 475–485. [Google Scholar] [CrossRef]

- Jedlinski, L.; Jonak, J. A disassembly-free method for evaluation of spiral bevel gear assembly. Mech. Syst. Signal Process. 2017, 88, 399–412. [Google Scholar] [CrossRef]

- Ding, H.; Tang, J.Y.; Zhong, J.; Zhou, Z.Y. A hybrid modification approach of machine-tool setting considering high tooth contact performance in spiral bevel and hypoid gears. J. Manuf. Syst. 2016, 41, 228–238. [Google Scholar] [CrossRef]

- Yavuz, S.D.; Saribay, Z.B.; Cigeroglu, E. Nonlinear time-varying dynamic analysis of a spiral bevel geared system. Nonlinear Dyn. 2018, 92, 1901–1919. [Google Scholar] [CrossRef]

- Kong, X.; Ding, H.; Huang, R.; Tang, J.Y. Adaptive data-driven modeling, prediction and optimal control for loaded transmission error of helicopter zero spiral bevel gear transmission system. Mech. Mach. Theory 2021, 165, 104417. [Google Scholar] [CrossRef]

- Li, H.N.; Tang, J.Y.; Chen, S.Y.; Rong, K.B.; Ding, H.; Lu, R. Loaded contact pressure distribution prediction for spiral bevel gear. Int. J. Mech. Sci. 2023, 242, 108027. [Google Scholar] [CrossRef]

- Mu, Y.M.; He, X.M. Design and dynamic performance analysis of high-contact-ratio spiral bevel gear based on the higher-order tooth surface modification. Mech. Mach. Theory 2021, 161, 104312. [Google Scholar] [CrossRef]

- Song, B.Y.; Chen, J.; Zhou, Z.Y.; Rong, K.B.; Zhao, J.Y.; Ding, H. Sensitive misalignment oriented loaded contact pressure regulation model for spiral bevel gears. Mech. Mach. Theory 2023, 188, 105410. [Google Scholar] [CrossRef]

- Vivet, M.; Tamarozzi, T.; Desmet, W.; Mundo, D. On the modelling of gear alignment errors in the tooth contact analysis of spiral bevel gears. Mech. Mach. Theory 2021, 155, 104065. [Google Scholar] [CrossRef]

- Pigé, A.; Velex, P.; Lanquetin, R.; Cutuli, P. A model for the quasi-static and dynamic simulations of bevel gears. Mech. Mach. Theory 2022, 175, 104971. [Google Scholar]

- Batsch, M. Mathematical model and tooth contact analysis of convexo-concave helical bevel Novikov gear mesh. Mech. Mach. Theory 2020, 149, 103842. [Google Scholar] [CrossRef]

- Han, Q.K.; Chu, F.L. Nonlinear dynamic model for skidding behavior of angular contact ball bearings. J. Sound Vib. 2015, 354, 219–235. [Google Scholar] [CrossRef]

- Chen, R.; Zhao, B.; He, T.; Tu, L.Y.; Xie, Z.L.; Zhong, N.; Zou, D.Q. Study on coupling transient mixed lubrication and time-varying wear of main bearing in actual operation of low-speed diesel engine. Tribol. Int. 2024, 191, 109159. [Google Scholar] [CrossRef]

- Shi, J.H.; Zhao, B.; Tu, L.Y.; Xin, Q.; Xie, Z.L.; Zhong, N.; Lu, X.Q. Transient lubrication analysis of journal-thrust coupled bearing considering time-varying loads and thermal-pressure coupled effect. Tribol. Int. 2024, 194, 109502. [Google Scholar] [CrossRef]

- Litvin, F.L.; Tsung, W.J.; Coy, J.J.; Heine, C. Method for generation of spiral bevel gears with conjugate gear tooth surfaces. J. Mech. Transm. Autom. Des. Trans. Asme 1987, 109, 163–170. [Google Scholar] [CrossRef]

- Litvin, F.L.; Wang, A.G.; Handschuh, R.F. Computerized design and analysis of face-milled, uniform tooth height spiral bevel gear drives. J. Mech. Des. 1996, 118, 573–579. [Google Scholar] [CrossRef]

- Litvin, F.L.; Fuentes, A.; Fan, Q.; Handschuh, R.F. Computerized design, simulation of meshing, and contact and stress analysis of face-milled formate generated spiral bevel gears. Mech. Mach. Theory 2002, 37, 441–459. [Google Scholar] [CrossRef]

- Litvin, F.L.; Fuentes, A.; Hayasaka, K. Design, manufacture, stress analysis, and experimental tests of low-noise high endurance spiral bevel gears. Mech. Mach. Theory 2006, 41, 83–118. [Google Scholar] [CrossRef]

- Chen, B.K.; Liang, D.; Li, Z.Y. A study on geometry design of spiral bevel gears based on conjugate curves. Int. J. Precis. Eng. Manuf. 2014, 15, 477–482. [Google Scholar] [CrossRef]

- Peng, S.; Chen, B.K.; Liang, D.; Zhang, L.; Qin, S. Mathematical model and tooth contact analysis of an internal helical gear pair with selectable contact path. Int. J. Precis. Eng. Manuf. 2018, 19, 837–848. [Google Scholar] [CrossRef]

- An, L.Q.; Zhang, L.H.; Qin, S.L.; Lan, G.; Chen, B.K. Mathematical design and computerized analysis of spiral bevel gears based on geometric elements. Mech. Mach. Theory 2021, 156, 104131. [Google Scholar] [CrossRef]

- Tan, R.L.; Zhang, W.Q.; Guo, X.D.; Chen, B.K.; Shu, R.Z. An analytical framework of the kinematic geometry for general point-contact gears from contact path. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 6363–6382. [Google Scholar] [CrossRef]

- Tan, R.L.; Chen, B.K.; Xiang, D.; Liang, D. A study on the design and performance of epicycloid bevels of pure-rolling contact. ASME J. Mech. 2018, 140, 043301. [Google Scholar] [CrossRef]

- Liang, D.; Li, M.; Jiang, P.; Meng, S. Optimization design and analysis of internal gear transmission with double contact points. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 5788–5798. [Google Scholar] [CrossRef]

- Liang, D.; Meng, S.; Gao, Y. Design principle and meshing analysis of internal gear drive with three contact points. Adv. Mech. Eng. 2022, 14, 16878132221081576. [Google Scholar] [CrossRef]

- Li, J.; Song, L.; Liu, C. The cubic trigonometric automatic interpolation spline. IEEE/CAA J. Autom. Sin. 2018, 5, 1136–1141. [Google Scholar] [CrossRef]

- Luo, Z.X. C1, C2-smooth interpolants on curved sides element. Comput. Math. Appl. 1998, 35, 125–130. [Google Scholar] [CrossRef]

- Phung, V.M.; Nguyen, V.M.; Phan, T.H. Hermite interpolation on algebraic curves in C2. Indag. Math. 2019, 30, 874–890. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Wu, X.Q.; Chen, F.L. C~3 continuous shape-preserving piecewise quadratic triangular Bézier interpolation curves. J. Hunan Univ. Technol. 2012, 25, 25–29. [Google Scholar]

- Chen, S.Y.; Zhang, A.Q.; Wei, J.; Lim, T.C. Nonlinear excitation and mesh characteristics model for spiral bevel gears. Int. J. Mech. Sci. 2023, 257, 108541. [Google Scholar] [CrossRef]

- Tan, R.; Chen, B.K.; Peng, C.Y. General mathematical model of spiral bevel gears of continuous pure-rolling contact. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 2810–2826. [Google Scholar] [CrossRef]

| Parameter | Bevel Gear I | Bevel Gear II |

|---|---|---|

| Number of teeth | 8 | 24 |

| Module | 6.75 mm | |

| Pitch cone angle | 18.435 deg. | 71.565 deg. |

| Spiral angle | 35 deg. | |

| Hand of spiral | Left hand | Right hand |

| Shaft angle | 90 deg. | |

| Face width | 30 mm | |

| Outer cone distance | 83.48 mm | 250.45 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Zhang, L.; Tian, C.; Miao, J.; An, L.; Shi, J.; Chen, B. Mathematical Model and Analysis of Novel Bevel Gear with High Load-Capacity Based on the Geometric Elements. Mathematics 2024, 12, 1373. https://doi.org/10.3390/math12091373

Wang D, Zhang L, Tian C, Miao J, An L, Shi J, Chen B. Mathematical Model and Analysis of Novel Bevel Gear with High Load-Capacity Based on the Geometric Elements. Mathematics. 2024; 12(9):1373. https://doi.org/10.3390/math12091373

Chicago/Turabian StyleWang, Dongyu, Luhe Zhang, Chao Tian, Jiacheng Miao, Laiqiang An, Jia Shi, and Bingkui Chen. 2024. "Mathematical Model and Analysis of Novel Bevel Gear with High Load-Capacity Based on the Geometric Elements" Mathematics 12, no. 9: 1373. https://doi.org/10.3390/math12091373