Advanced Composite Materials and Structures for Aerospace, Automotive and Civil Engineering Applications (Closed)

A topical collection in Materials (ISSN 1996-1944). This collection belongs to the section "Advanced Composites".

Viewed by 83712Editor

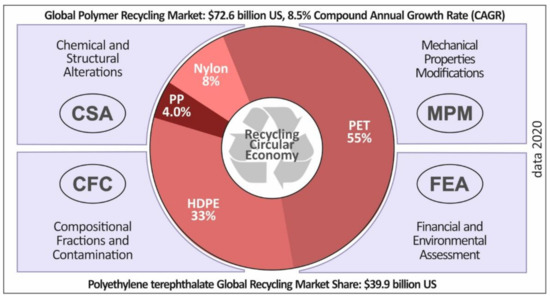

Interests: polymer composites; natural (green) materials; recycling; sustainability and durability aspects in aerospace; energy; automotive; infrastructure and building applications

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

The increasing demand for greener and smarter structures imposes the need for new engineering technologies, digitalization, and materials with multiple abilities disrupting the aerospace, automotive, and infrastructure industry in various ways. New materials, processing methods, characterization, and modelling tools are continuously developed with a view to reduce structural weight, minimize environmental impact, reduce energy consuption and provide advanced solutions aiming at safe and maintenance-free structures. These advanced smart materials exploit enabling technologies for new functionalities, without compromising structural integrity.

This Special Issue is dedicated to studying radically new composite material formulations, special treatments, recyclability, intelligent features, engineering phenomena, and new manufacturing concepts bringing new composite material trends in the aerospace, automotive, and civil engineering areas. New material trends are paving the way towards the next generation of composite materials for structural and non-structural applications. Researchers from the academic and industrial sphere are invited to publish results of their research and latest achievements in this field.

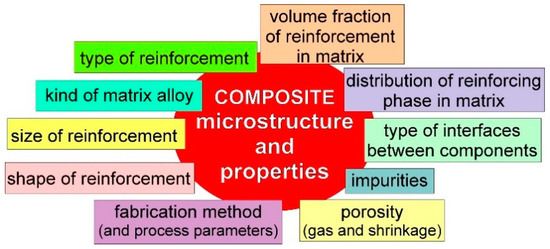

Research works that focus on progressive materials and technologies, new characterization techniques to study the relationship between microstructure and structural properties, and also physical and numerical simulation studies are especially encouraged.

Prof. Dr. Sotirios A. Grammatikos

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- polymers

- composites

- sustainability

- multifunctionality

- self-sensing

- energy storage

- energy harvesting

- recycling

- fibre coatings

- modelling