Removal of Cr(VI) from Wastewater Using Acrylonitrile Grafted Cellulose Extracted from Sugarcane Bagasse

Abstract

:1. Introduction

2. Results and Discussion

2.1. Characterization

2.1.1. Surface Morphology

2.1.2. XRD Analysis

2.1.3. FTIR Analysis

2.2. Effect of Various Parameters on Cr(VI) Removal

Effect of Metal Ion Concentration

2.3. Effect of Adsorbent Mass

2.4. Effect of Time

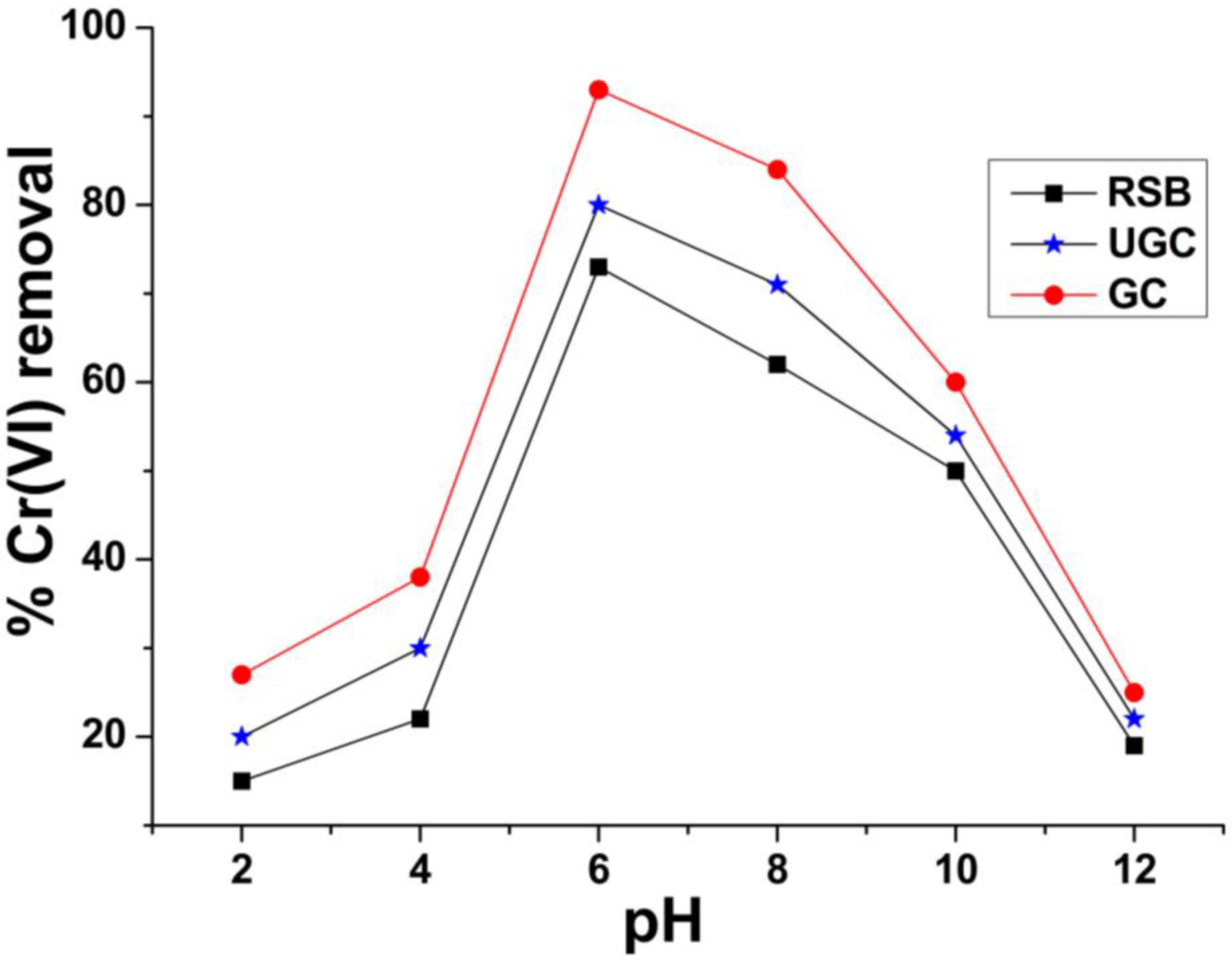

2.5. Effect of pH on the Removal of Cr(VI)

2.6. Isotherm Study

2.6.1. Freundlich Model

2.6.2. Langmuir Isotherm Model

2.7. Adsorption Kinetics

2.7.1. Pseudo First-Order Model

2.7.2. Pseudo Second-Order Model

2.7.3. Intra-Particle Diffusion

2.8. Regeneration and Reuse of Spent Adsorbent (GSB)

3. Material and Methods

3.1. Adsorbent Preparation

3.1.1. Acid Hydrolysis

3.1.2. Alkaline Hydrolysis

3.1.3. Bleaching

3.1.4. Grafting Co-Polymerization

3.2. Characterization

3.3. Adsorption of Cr(VI) on RSB and GSB

3.4. Isotherms Study

3.5. Adsorption Kinetics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Singh, A.; Sharma, A.; Verma, R.K.; Chopade, R.L.; Pandit, P.P.; Nagar, V.; Aseri, V.; Choudhary, S.K.; Awasthi, G.; Awasthi, K.K. Heavy Metal Contamination of Water and Their Toxic Effect on Living Organisms, The Toxicity of Environmental Pollutants; IntechOpen: Rijeka, Croatia, 2022. [Google Scholar]

- Sharma, A.; Grewal, A.S.; Sharma, D.; Srivastav, A.L. Heavy Metal Contamination in Water: Consequences on Human Health and Environment, Metals in Water; Elsevier: Amsterdam, The Netherlands, 2023; pp. 39–52. [Google Scholar]

- Thanigaivel, S.; Vickram, S.; Dey, N.; Jeyanthi, P.; Subbaiya, R.; Kim, W.; Govarthanan, M.; Karmegam, N. Ecological disturbances and abundance of anthropogenic pollutants in the aquatic ecosystem: Critical review of impact assessment on the aquatic animals. Chemosphere 2023, 313, 137475. [Google Scholar] [CrossRef]

- Elnabi, M.K.A.; Elkaliny, N.E.; Elyazied, M.M.; Azab, S.H.; Elkhalifa, S.A.; Elmasry, S.; Mouhamed, M.S.; Shalamesh, E.M.; Alhorieny, N.A.; Elaty, A.E.A.; et al. Toxicity of heavy metals and recent advances in their removal: A review. Toxics 2023, 11, 580. [Google Scholar] [CrossRef]

- Nivetha, N.; Srivarshine, B.; Sowmya, B.; Rajendiran, M.; Saravanan, P.; Rajeshkannan, R.; Rajasimman, M.; Pham, T.H.T.; Shanmugam, V.; Dragoi, E.-N. A comprehensive review on bio-stimulation and bio-enhancement towards remediation of heavy metals degeneration. Chemosphere 2023, 312, 137099. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, A.G.; Renu, K.; Gopalakrishnan, A.V.; Veeraraghavan, V.P.; Vinayagam, S.; Paz-Montelongo, S.; Dey, A.; Vellingiri, B.; George, A.; Madhyastha, H.; et al. Heavy Metal and Metalloid Contamination in Food and Emerging Technologies for Its Detection. Sustainability 2023, 15, 1195. [Google Scholar] [CrossRef]

- Balali-Mood, M.; Naseri, K.; Tahergorabi, Z.; Khazdair, M.R.; Sadeghi, M. Toxic mechanisms of five heavy metals: Mercury, lead, chromium, cadmium, and arsenic. Front. Pharmacol. 2021, 12, 643972. [Google Scholar] [CrossRef] [PubMed]

- Mitra, S.; Chakraborty, A.J.; Tareq, A.M.; Bin Emran, T.; Nainu, F.; Khusro, A.; Idris, A.M.; Khandaker, M.U.; Osman, H.; Alhumaydhi, F.A.; et al. Impact of heavy metals on the environment and human health: Novel therapeutic insights to counter the toxicity. J. King Saud Univ. Sci. 2022, 34, 101865. [Google Scholar] [CrossRef]

- Fu, Z.; Xi, S. The effects of heavy metals on human metabolism. Toxicol. Mech. Methods 2020, 30, 167–176. [Google Scholar] [CrossRef]

- Zaynab, M.; Al-Yahyai, R.; Ameen, A.; Sharif, Y.; Ali, L.; Fatima, M.; Khan, K.A.; Li, S. Health and environmental effects of heavy metals. J. King Saud Univ. Sci. 2022, 34, 101653. [Google Scholar] [CrossRef]

- Hoang, H.-G.; Lin, C.; Tran, H.-T.; Chiang, C.-F.; Bui, X.-T.; Cheruiyot, N.K.; Shern, C.-C.; Lee, C.-W. Heavy metal contamination trends in surface water and sediments of a river in a highly-industrialized region. Environ. Technol. Innov. 2020, 20, 101043. [Google Scholar] [CrossRef]

- Saha, B.; Orvig, C. Biosorbents for hexavalent chromium elimination from industrial and municipal effluents. Coord. Chem. Rev. 2010, 254, 2959–2972. [Google Scholar] [CrossRef]

- Saravanan, A.; Kumar, P.S.; Yashwanthraj, M. Sequestration of toxic Cr(VI) ions from industrial wastewater using waste biomass: A review. Desalination Water Treat. 2017, 68, 245–266. [Google Scholar] [CrossRef]

- Samuel, M.S.; Selvarajan, E.; Chidambaram, R.; Patel, H.; Brindhadevi, K. Clean approach for chromium removal in aqueous environments and role of nanomaterials in bioremediation: Present research and future perspective. Chemosphere 2021, 284, 131368. [Google Scholar] [CrossRef]

- Sharma, P.; Singh, S.P.; Parakh, S.K.; Tong, Y.W. Health hazards of hexavalent chromium (Cr (VI)) and its microbial reduction. Bioengineered 2022, 13, 4923–4938. [Google Scholar] [CrossRef]

- Yang, W.; Lei, G.; Quan, S.; Zhang, L.; Wang, B.; Hu, H.; Li, L.; Ma, H.; Yin, C.; Feng, F. The Removal of Cr (VI) from Aqueous Solutions with Corn Stalk Biochar. Int. J. Environ. Res. Public Health 2022, 19, 14188. [Google Scholar] [CrossRef]

- Thaçi, B.S.; Gashi, S.T. Reverse osmosis removal of heavy metals from wastewater effluents using biowaste materials pretreatment. Pol. J. Environ. Stud. 2018, 28, 337–341. [Google Scholar] [CrossRef]

- Ates, N.; Uzal, N. Removal of heavy metals from aluminum anodic oxidation wastewaters by membrane filtration. Environ. Sci. Pollut. Res. 2018, 25, 22259–22272. [Google Scholar] [CrossRef]

- Bashir, A.; Malik, L.A.; Ahad, S.; Manzoor, T.; Bhat, M.A.; Dar, G.N.; Pandith, A.H. Removal of heavy metal ions from aqueous system by ion-exchange and biosorption methods. Environ. Chem. Lett. 2019, 17, 729–754. [Google Scholar] [CrossRef]

- Zhang, Y.; Duan, X. Chemical precipitation of heavy metals from wastewater by using the synthetical magnesium hydroxy carbonate. Water Sci. Technol. 2020, 81, 1130–1136. [Google Scholar] [CrossRef]

- Smara, A.; Delimi, R.; Chainet, E.; Sandeaux, J. Removal of heavy metals from diluted mixtures by a hybrid ion-exchange/electrodialysis process. Sep. Purif. Technol. 2007, 57, 103–110. [Google Scholar] [CrossRef]

- Mungray, A.A.; Kulkarni, S.V.; Mungray, A.K. Removal of heavy metals from wastewater using micellar enhanced ultrafiltration technique: A review. Cent. Eur. J. Chem. 2012, 10, 27–46. [Google Scholar] [CrossRef]

- Tang, X.; Zheng, H.; Teng, H.; Sun, Y.; Guo, J.; Xie, W.; Yang, Q.; Chen, W. Chemical coagulation process for the removal of heavy metals from water: A review. Desalination Water Treat. 2016, 57, 1733–1748. [Google Scholar] [CrossRef]

- Choumane, R.; Peulon, S. Development of an efficient electrochemical process for removing and separating soluble Pb(II) in aqueous solutions in presence of other heavy metals: Studies of key parameters. Chem. Eng. J. 2021, 423, 130161. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, M.; Cheng, Q.; Wang, C.; Li, H.; Han, X.; Fan, Z.; Su, G.; Pan, D.; Li, Z. Research progress of adsorption and removal of heavy metals by chitosan and its derivatives: A review. Chemosphere 2021, 279, 130927. [Google Scholar] [CrossRef]

- Gautam, R.K.; Mudhoo, A.; Lofrano, G.; Chattopadhyaya, M.C. Biomass-derived biosorbents for metal ions sequestration: Adsorbent modification and activation methods and adsorbent regeneration. J. Environ. Chem. Eng. 2014, 2, 239–259. [Google Scholar] [CrossRef]

- Georgaki, M.-N.; Charalambous, M.; Kazakis, N.; Talias, M.A.; Georgakis, C.; Papamitsou, T.; Mytiglaki, C. Chromium in water and carcinogenic human health risk. Environments 2023, 10, 33. [Google Scholar] [CrossRef]

- Bilal, M.; Ihsanullah, I.; Younas, M.; Shah, M.U.H. Recent advances in applications of low-cost adsorbents for the removal of heavy metals from water: A critical review. Sep. Purif. Technol. 2021, 278, 119510. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Sillanpää, M.; Witek-Krowiak, A. Agricultural waste peels as versatile biomass for water purification—A review. Chem. Eng. J. 2015, 270, 244–271. [Google Scholar] [CrossRef]

- Chakraborty, R.; Asthana, A.; Singh, A.K.; Jain, B.; Susan, A.B.H. Adsorption of heavy metal ions by various low-cost adsorbents: A review. Int. J. Environ. Anal. Chem. 2022, 102, 342–379. [Google Scholar] [CrossRef]

- Ali, I.; Asim, M.; Khan, T.A. Low cost adsorbents for the removal of organic pollutants from wastewater. J. Environ. Manag. 2012, 113, 170–183. [Google Scholar] [CrossRef] [PubMed]

- Phuengphai, P.; Singjanusong, T.; Kheangkhun, N.; Wattanakornsiri, A. Removal of copper(II) from aqueous solution using chemically modified fruit peels as efficient low-cost biosorbents. Water Sci. Eng. 2021, 14, 286–294. [Google Scholar] [CrossRef]

- Batagarawa, S.M.; Ajibola, A.K. Comparative evaluation for the adsorption of toxic heavy metals on to millet, corn and rice husks as adsorbents. J. Anal. Pharm. Res. 2019, 8, 119–125. [Google Scholar] [CrossRef]

- Meez, E.; Rahdar, A.; Kyzas, G.Z. Sawdust for the Removal of Heavy Metals from Water: A Review. Molecules 2021, 26, 4318. [Google Scholar] [CrossRef]

- Iwuozor, K.O.; Oyekunle, I.P.; Oladunjoye, I.O.; Ibitogbe, E.M.; Olorunfemi, T.S. A review on the mitigation of heavy metals from aqueous solution using sugarcane bagasse. Sugar Tech 2021, 24, 1167–1185. [Google Scholar] [CrossRef]

- Shahrokhi-Shahraki, R.; Benally, C.; El-Din, M.G.; Park, J. High efficiency removal of heavy metals using tire-derived activated carbon vs commercial activated carbon: Insights into the adsorption mechanisms. Chemosphere 2021, 264, 128455. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Wang, T.; Wang, J.; Zhang, Y.; Pan, W.-P. A novel modified method for the efficient removal of Pb and Cd from wastewater by biochar: Enhanced the ion exchange and precipitation capacity. Sci. Total. Environ. 2021, 754, 142150. [Google Scholar] [CrossRef] [PubMed]

- Maharana, M.; Manna, M.; Sardar, M.; Sen, S. Heavy Metal Removal by Low-Cost Adsorbents. In Green Adsorbents to Remove Metals, Dyes and Boron from Polluted Water; Springer: Berlin/Heidelberg, Germany, 2021; pp. 245–272. [Google Scholar]

- Shi, S.-C.; Liu, G.-T. Cellulose nanocrystal extraction from rice straw using a chlorine-free bleaching process. Cellulose 2021, 28, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Saeed, K. Phenol removal from aqueous medium using chemically modified banana peels as low-cost adsorbent. Desalination Water Treat. 2016, 57, 11242–11254. [Google Scholar] [CrossRef]

- Sudhaik, A.; Raizada, P.; Ahamad, T.; Alshehri, S.M.; Nguyen, V.-H.; Van Le, Q.; Thakur, S.; Thakur, V.K.; Selvasembian, R.; Singh, P. Recent advances in cellulose supported photocatalysis for pollutant mitigation: A review. Int. J. Biol. Macromol. 2022, 226, 1284–1308. [Google Scholar] [CrossRef] [PubMed]

- Ortega, F.; Versino, F.; López, O.V.; García, M.A. Biobased composites from agro-industrial wastes and by-products. Emergent Mater. 2022, 5, 873–921. [Google Scholar] [CrossRef]

- Etale, A.; Onyianta, A.J.; Turner, S.R.; Eichhorn, S.J. Cellulose: A review of water interactions, applications in composites, and water treatment. Chem. Rev. 2023, 123, 2016–2048. [Google Scholar] [CrossRef]

- Kaur, J.; Sengupta, P.; Mukhopadhyay, S. Critical review of bioadsorption on modified cellulose and removal of divalent heavy metals (Cd, Pb, and Cu). Ind. Eng. Chem. Res. 2022, 61, 1921–1954. [Google Scholar] [CrossRef]

- Rahman, L.; Fui, C.J.; Ting, T.X.; Sarjadi, M.S.; Arshad, S.E.; Musta, B. Polymer ligands derived from jute fiber for heavy metal removal from electroplating wastewater. Polymers 2020, 12, 2521. [Google Scholar] [CrossRef]

- Daochalermwong, A.; Chanka, N.; Songsrirote, K.; Dittanet, P.; Niamnuy, C.; Seubsai, A. Removal of heavy metal ions using modified celluloses prepared from pineapple leaf fiber. ACS Omega 2020, 5, 5285–5296. [Google Scholar] [CrossRef] [PubMed]

- Ali, A. Removal of Mn(II) from water using chemically modified banana peels as efficient adsorbent. Environ. Nanotechnol. Monit. Manag. 2017, 7, 57–63. [Google Scholar] [CrossRef]

- Hasani, N.; Selimi, T.; Mele, A.; Thaçi, V.; Halili, J.; Berisha, A.; Sadiku, M. Theoretical, equilibrium, kinetics and thermodynamic investigations of methylene blue adsorption onto lignite coal. Molecules 2022, 27, 1856. [Google Scholar] [CrossRef]

- Edebali, S. Advanced Sorption Process Applications; Intech Open: London, UK, 2019. [Google Scholar]

- Pérez, B.F.; Espina, J.A.; González, M.d.L.F. Adsorption of Heavy Metals Ions from Mining Metallurgical Tailings Leachate Using a Shell-Based Adsorbent: Characterization, Kinetics and Isotherm Studies. Materials 2022, 15, 5315. [Google Scholar] [CrossRef]

- Ali, A.; Saeed, K.; Mabood, F. Removal of chromium (VI) from aqueous medium using chemically modified banana peels as efficient low-cost adsorbent. Alex. Eng. J. 2016, 55, 2933–2942. [Google Scholar] [CrossRef]

- Ezeonuegbu, B.A.; Machido, D.A.; Whong, C.M.; Japhet, W.S.; Alexiou, A.; Elazab, S.T.; Qusty, N.; Yaro, C.A.; Batiha, G.E.-S. Agricultural waste of sugarcane bagasse as efficient adsorbent for lead and nickel removal from untreated wastewater: Biosorption, equilibrium isotherms, kinetics and desorption studies. Biotechnol. Rep. 2021, 30, e00614. [Google Scholar] [CrossRef] [PubMed]

- Gusmão, K.A.G.; Gurgel, L.V.A.; Melo, T.M.S.; Carvalho, C.d.F.; Gil, L.F. Adsorption studies of etherdiamine onto modified sugarcane bagasses in aqueous solution. J. Environ. Manag. 2014, 133, 332–342. [Google Scholar] [CrossRef]

- Al-Mokhalelati, K.; Al-Bakri, I.; Wattar, N.A.S.A. Adsorption of methylene blue onto sugarcane bagasse-based adsorbent materials. J. Phys. Org. Chem. 2021, 34, e4193. [Google Scholar] [CrossRef]

- Jiang, W.; Xing, Y.; Zhang, L.; Guo, X.; Lu, Y.; Yang, M.; Wang, J.; Wei, G. Polyethylenimine-modified sugarcane bagasse cellulose as an effective adsorbent for removing Cu(II) from aqueous solution. J. Appl. Polym. Sci. 2021, 138, 49830. [Google Scholar] [CrossRef]

- Yan, L.; Dong, F.-X.; Lin, X.; Zhou, X.-H.; Kong, L.-J.; Chu, W.; Diao, Z.-H. Insights into the removal of Cr (VI) by a biochar–iron composite from aqueous solution: Reactivity, kinetics and mechanism. Environ. Technol. Innov. 2021, 24, 102057. [Google Scholar] [CrossRef]

- Tsegay, M.; Gebretinsae, H.; Nuru, Z. Structural and optical properties of green synthesized Cr2O3 nanoparticles. Mater. Today Proc. 2021, 36, 587–590. [Google Scholar] [CrossRef]

- Xia, Y.; Li, Y.; Xu, Y. Adsorption of Pb (II) and Cr (VI) from aqueous solution by synthetic allophane suspension: Isotherm, kinetics, and mechanisms. Toxics 2022, 10, 291. [Google Scholar] [CrossRef] [PubMed]

- Silva, B.A.N.A.; Figueiredo, H.; Neves, I.C.; Tavares, T. The role of pH on Cr (VI) reduction and removal by Arthrobacter viscosus. Int. J. Chem. Biol. Eng. 2009, 2, 100–103. [Google Scholar]

- Abin-Bazaine, A.; Trujillo, A.C.; Olmos-Marquez, M. Adsorption isotherms: Enlightenment of the phenomenon of adsorption. Wastewater Treat. 2022, 1–15. [Google Scholar] [CrossRef]

- Bazaine, A.; Trujillo, A.; Marquez, M. Adsorption Isotherms: Enlightenment of the Phenomenon of Adsorption, Wastewater Treatment; IntechOpen: Rijeka, Croatia, 2022; Volume 2. [Google Scholar]

- Khamwichit, A.; Dechapanya, W.; Dechapanya, W. Adsorption kinetics and isotherms of binary metal ion aqueous solution using untreated venus shell. Heliyon 2022, 8, e09610. [Google Scholar] [CrossRef]

- Ali, A.; Alharthi, S.; Al-Shaalan, N.H.; Naz, A.; Fan, H.-J.S. Efficient Removal of Hexavalent Chromium (Cr(VI)) from Wastewater Using Amide-Modified Biochar. Molecules 2023, 28, 5146. [Google Scholar] [CrossRef]

- Long, W.; Chen, Z.; Chen, X.; Zhong, Z. Investigation of the Adsorption Process of Chromium (VI) Ions from Petrochemical Wastewater Using Nanomagnetic Carbon Materials. Nanomaterials 2022, 12, 3815. [Google Scholar] [CrossRef] [PubMed]

- Pholosi, A.; Naidoo, E.B.; Ofomaja, A.E. Intraparticle diffusion of Cr(VI) through biomass and magnetite coated biomass: A comparative kinetic and diffusion study. S. Afr. J. Chem. Eng. 2020, 32, 39–55. [Google Scholar] [CrossRef]

| Adsorbent | Freundlich Model | Langmuir Model | ||||

|---|---|---|---|---|---|---|

| 1/n | KF (mg/g) | R2 | qmax (mg/g) | K (L/mg) | R2 | |

| RSB | 42.45 | 2.8210 | 0.97 | 125.95 | 4.5808 | 0.91 |

| UGC | 63.30 | 4.7237 | 0.97 | 202.37 | 4.1733 | 0.89 |

| GC | 124.36 | 9.7863 | 0.98 | 267.93 | 3.9563 | 0.84 |

| Concentration (ppm) | First-Order | Second-Order | IPD Model | |||||

|---|---|---|---|---|---|---|---|---|

| qe (mgg−1) | K1 | R2 | qe (mgg−1) | K2 | R2 | R2 | Ki (mgg−1min−1) | |

| 100 | 188 | 0.644 | 0.938 | 176 | 0.0137 | 0.94 | 0.9713 | 2.0828 |

| 200 | 368 | 0.66 | 0.978 | 336 | 0.0242 | 0.95 | 0.9005 | 2.4641 |

| 300 | 546 | 0.637 | 0.936 | 480 | 0.0451 | 0.97 | 0.9281 | 3.2259 |

| 400 | 720 | 0.681 | 0.989 | 592 | 0.0550 | 0.99 | 0.9172 | 4.0492 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, I.; Ali, A.; Naz, A.; Baig, Z.T.; Shah, W.; Rahman, Z.U.; Shah, T.A.; Attia, K.A.; Mohammed, A.A.; Hafez, Y.M. Removal of Cr(VI) from Wastewater Using Acrylonitrile Grafted Cellulose Extracted from Sugarcane Bagasse. Molecules 2024, 29, 2207. https://doi.org/10.3390/molecules29102207

Khan I, Ali A, Naz A, Baig ZT, Shah W, Rahman ZU, Shah TA, Attia KA, Mohammed AA, Hafez YM. Removal of Cr(VI) from Wastewater Using Acrylonitrile Grafted Cellulose Extracted from Sugarcane Bagasse. Molecules. 2024; 29(10):2207. https://doi.org/10.3390/molecules29102207

Chicago/Turabian StyleKhan, Idrees, Ashraf Ali, Alia Naz, Zenab Tariq Baig, Wisal Shah, Zia Ur Rahman, Tawaf Ali Shah, Kotb A. Attia, Arif Ahmed Mohammed, and Yaser M. Hafez. 2024. "Removal of Cr(VI) from Wastewater Using Acrylonitrile Grafted Cellulose Extracted from Sugarcane Bagasse" Molecules 29, no. 10: 2207. https://doi.org/10.3390/molecules29102207