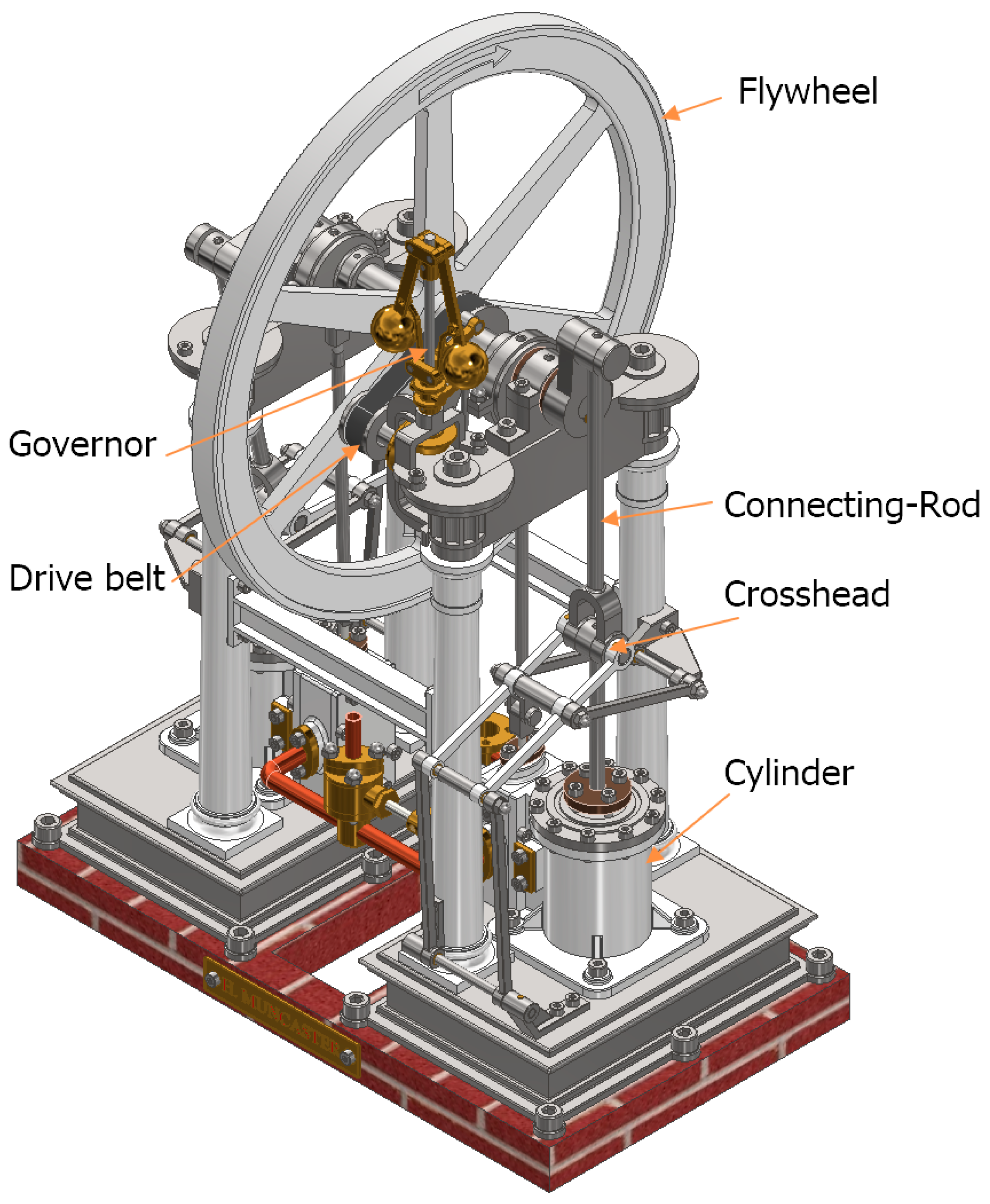

Engineering Drawing Applied to the Study of the Design of a Two-Cylinder Entablature Steam Engine with Parallel Motion Crosshead

Abstract

:1. Introduction

- To carry out a static linear analysis of the invention in order to validate the model and determine whether the invention was well dimensioned and was able to bear the stresses of its operation [21].

- To develop virtual and augmented-reality applications as user interaction techniques that facilitate the understanding of the different elements of the invention and its operation, learning and imparting their specific names and other related information [22].

- To print the model with additive manufacturing techniques in order to physically interact with the model.

- To develop WebGL models for incorporation into thematic websites.

2. Materials and Methods

3. Results and Discussion

3.1. Steam Intake and Steam Exhaust System

3.2. Crosshead

3.3. Parallel Motion and Crankshaft Rotation Mechanism

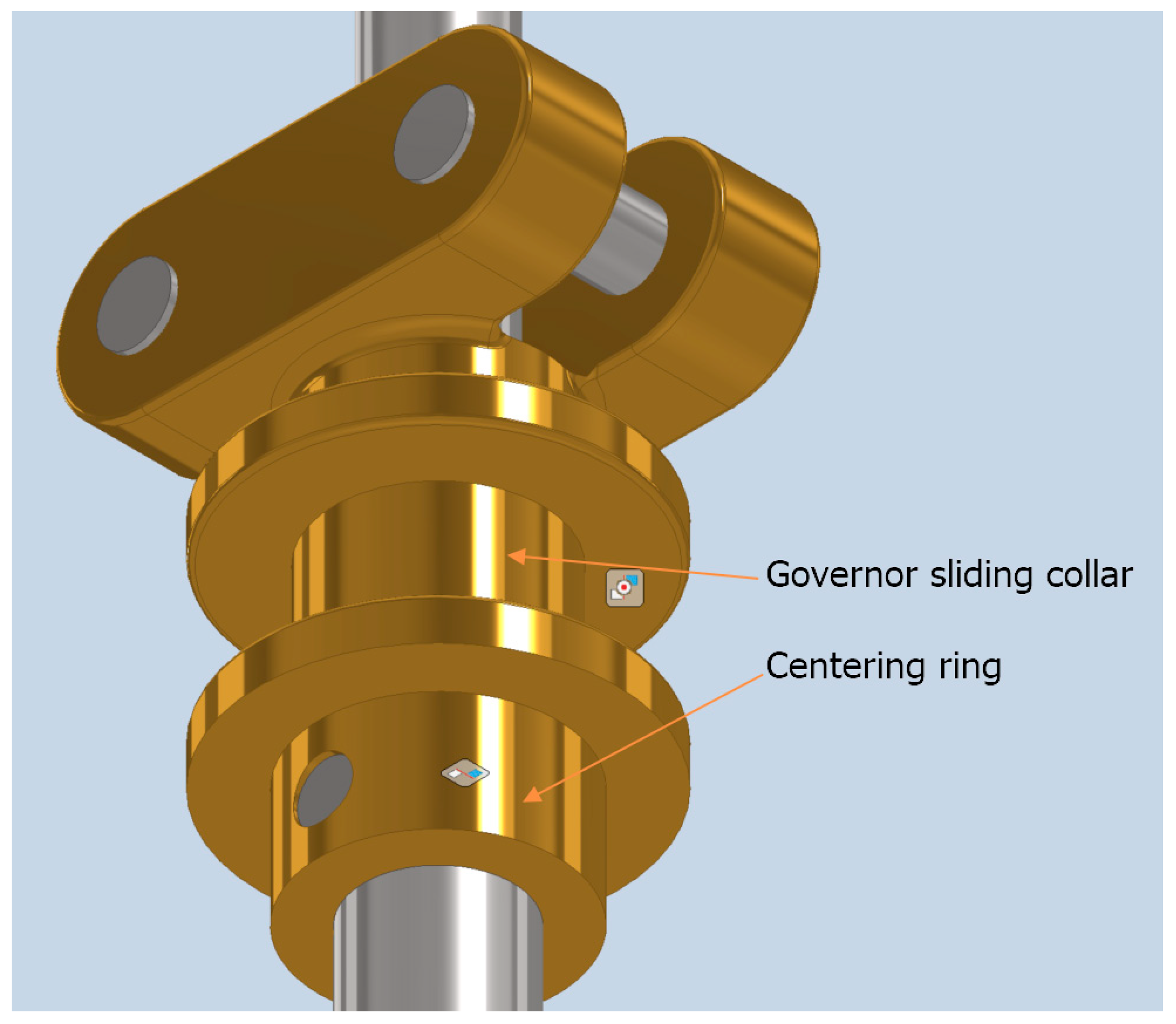

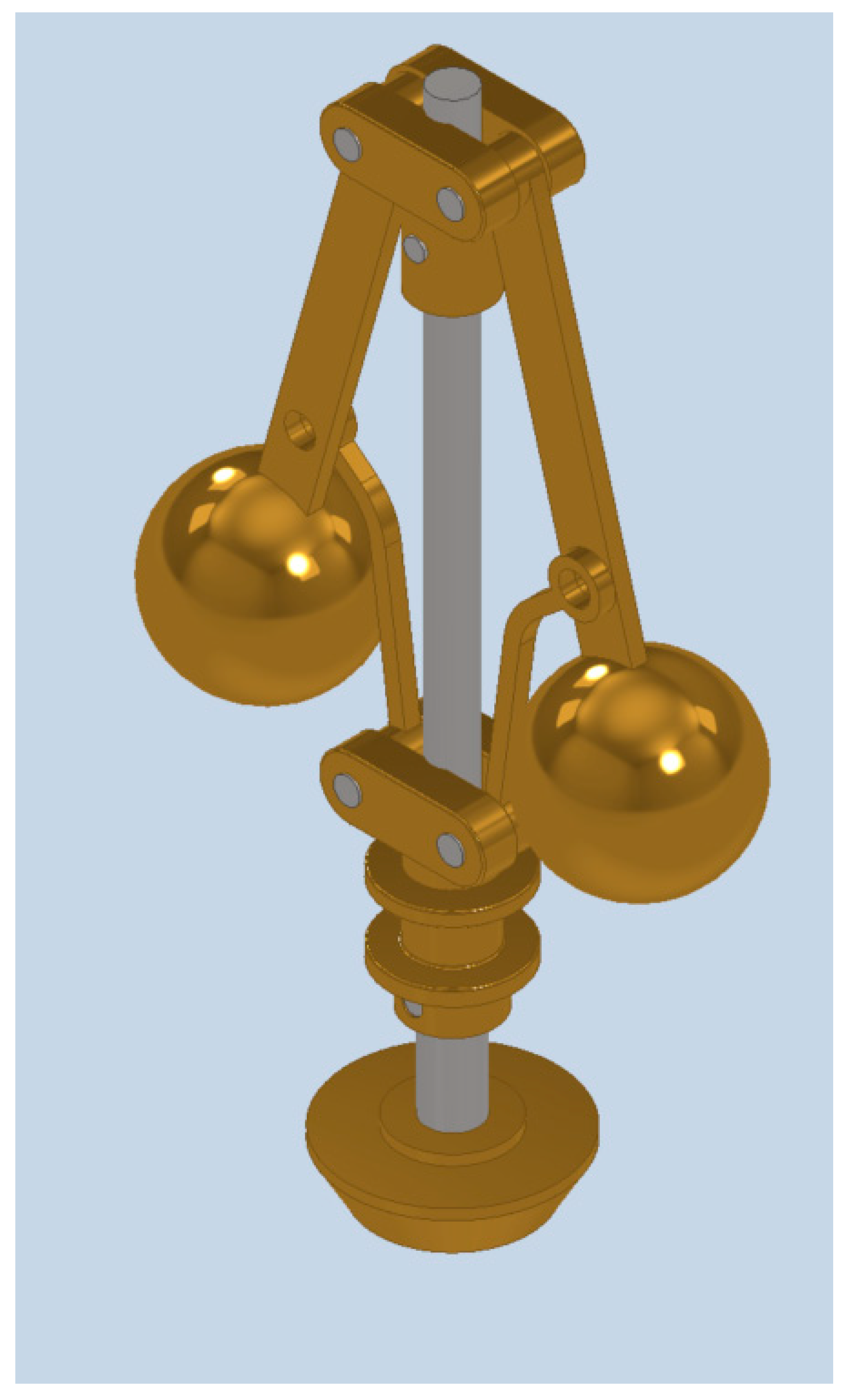

3.4. Speed Control System

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Inkster, I. (Ed.) History of Technology; Bloomsbury Academic: London, UK, 2004; Volume 25. [Google Scholar]

- Jenkins, R. Links in the History of Engineering and Technology from Tudor Times; The Newcomen Society at the Cambridge University Press: Cambridge, UK, 1971. [Google Scholar]

- Russell, B. James Watt: Making the World Anew; Reaktion Books: London, UK, 2014. [Google Scholar]

- Stokes, P.R. Piston steam engine innovation. Proc. Inst. Mech. Eng. Part A—J. Power Energy 1996, 210, 95–98. [Google Scholar] [CrossRef]

- Thoendel, E. Simulation model of the thermodynamic cycle of a three-cylinder double-acting steam engine. Chem. Prod. Process Model. 2008, 3, 21. [Google Scholar] [CrossRef]

- Yatsuzuka, S.; Niiyama, Y.; Fukuda, K.; Muramatsu, K.; Shikazono, N. Experimental and numerical evaluation of liquid-piston steam engine. Energy 2015, 87, 1–9. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Z.J.; Zhou, J.H.; Liu, J.Z.; Wang, Z.H.; Cen, K.F. Micro Newcomen steam engine using two-phase working fluid. Energy 2011, 36, 917–921. [Google Scholar] [CrossRef]

- Muncaster, H. Model Stationary Engines—Their Design and Construction; TEE Publishing Ltd.: Oxford, UK, 1912. [Google Scholar]

- Ceccarelli, M.; Koetsier, T. Burmester and Allievi: A theory and its application for mechanism design at the end of 19th century. J. Mech. Des. 2008, 130, 072301. [Google Scholar] [CrossRef]

- Fang, Y.; Ceccarelli, M. Peculiarities of evolution of machine technology and its industrialization in Italy during 19th century. Adv. Hist. Stud. 2015, 4, 338–355. [Google Scholar] [CrossRef]

- Fang, Y.; Ceccarelli, M. Findings on Italian historical developments of machine technology in 19th century towards industrial revolution. In The 11th IFToMM International Symposium on Science of Mechanisms and Machines; Springer International Publishing: Cham, Switzerland, 2013; pp. 493–501. [Google Scholar] [CrossRef]

- Ceccarelli, M.; Cocconcelli, M. Plans for a Course on the History of Mechanisms and Machine Science. In Trends in Educational Activity in the Field of Mechanism and Machine Theory; Springer Nature: Cham, Switzerland, 2022; pp. 135–144. [Google Scholar] [CrossRef]

- Cocconcelli, M.; Ceccarelli, M. Italian teaching with models from mechanism catalogues in 19th century. In Explorations in the History and Heritage of Machines and Mechanisms; Springer Nature: Cham, Switzerland, 2024; pp. 18–30. [Google Scholar] [CrossRef]

- Ceccarelli, M.; Cocconcelli, M. Italian historical developments of teaching and museum valorization of mechanism models. Machines 2022, 10, 628. [Google Scholar] [CrossRef]

- Jensen, C.H.; Branoff, T.J. Interpreting Engineering Drawings, 8th ed.; Delmar Cengage Learning: Independence, KY, USA, 2015. [Google Scholar]

- Chang, K.H. Design Theory and Methods Using CAD/CAE; Academic Press: London, UK, 2014. [Google Scholar]

- Westbury, E.T. The Muncaster steam-engine models: Entablature or table engines. Model Eng. 1957, 116, 700–702. [Google Scholar]

- Two-Cylinder Entablature Steam Engine with Parallel Motion Crosshead. Available online: https://modelengineeringwebsite.com/Muncaster_2-cyl_entablature.html (accessed on 13 April 2024).

- Principles of Seville on Virtual Archaeology. Available online: https://icomos.es/wp-content/uploads/2020/06/Seville-Principles-IN-ES-FR.pdf (accessed on 13 April 2024).

- London Charter. Available online: https://londoncharter.org (accessed on 13 April 2024).

- Rojas-Sola, J.I.; Gutiérrez-Antúnez, J.F. Analysis of the design of Henry Muncaster’ two-cylinder compound vertical steam engine with speed control. Appl. Sci. 2023, 13, 9150. [Google Scholar] [CrossRef]

- Rojas-Sola, J.I.; Aguilera-García, A. Virtual and augmented reality: Applications for the learning of technical historical heritage. Comput. Appl. Eng. Educ. 2018, 13, 1725–1733. [Google Scholar] [CrossRef]

- Shih, R.H.; Jumper, L. Parametric Modeling with Autodesk Inventor 2024; SDC Publications: Mission, KS, USA, 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas-Sola, J.I.; Barranco-Molina, J.C. Engineering Drawing Applied to the Study of the Design of a Two-Cylinder Entablature Steam Engine with Parallel Motion Crosshead. Symmetry 2024, 16, 578. https://doi.org/10.3390/sym16050578

Rojas-Sola JI, Barranco-Molina JC. Engineering Drawing Applied to the Study of the Design of a Two-Cylinder Entablature Steam Engine with Parallel Motion Crosshead. Symmetry. 2024; 16(5):578. https://doi.org/10.3390/sym16050578

Chicago/Turabian StyleRojas-Sola, José Ignacio, and Juan Carlos Barranco-Molina. 2024. "Engineering Drawing Applied to the Study of the Design of a Two-Cylinder Entablature Steam Engine with Parallel Motion Crosshead" Symmetry 16, no. 5: 578. https://doi.org/10.3390/sym16050578