Analysis of the Influence of Contact Stress on the Fatigue of AD180 High-Carbon Semi-Steel Roll

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

- (a)

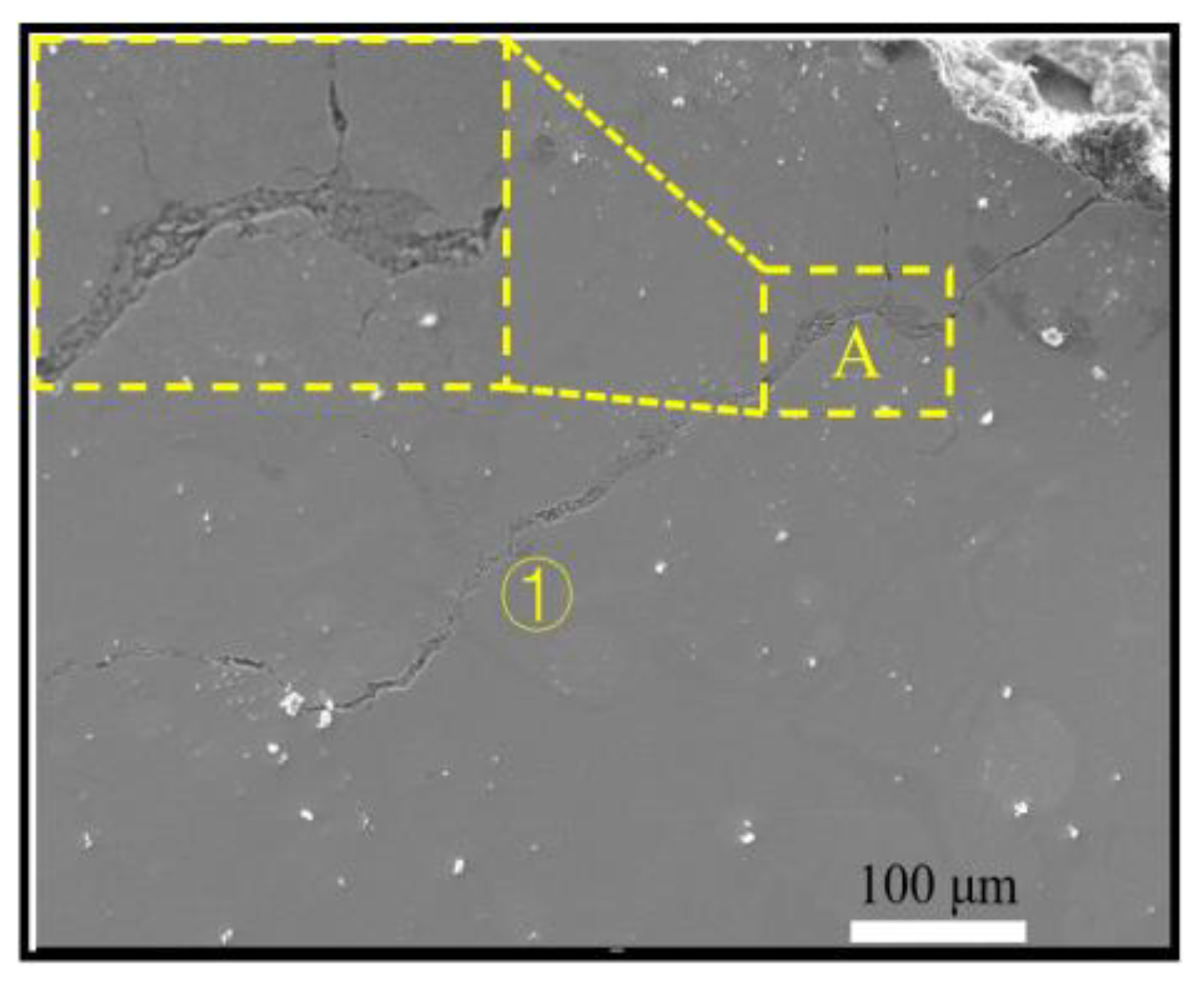

- We observed the damage morphology of the specified test surfaces of fatigue test specimen 1 and test specimen 2 using SEM, and we performed EBSD characterization on test specimen 2.

- (b)

- AztecCrystal software (2.1.2) was used to analyze and process the test data, and the grain map was imported into AztecCrystal software. Then, the grain sizes of the sample under different conditions were calculated from the maximum Frater diameter.

- (c)

- We tested the cross-sectional hardness of the specimen using a Vickers hardness tester.

- (d)

- We captured the morphology of the peeling pits on the contact surface using a contour morphology system and analyzed and processed them using multi-file analysis software

- (e)

- We observed the metallographic structure of specimen 2 after polishing and etching with a 4% “NITAL” using an optical microscope (Leica Microsystems GmbH, Wetzlar, Germany) and analyzed the changes in its structure and crack propagation.

3. Experimental Results and Analysis

3.1. Analysis of Surface Damage of Specimens

3.2. Analysis of Radial Cross-Section Damage of Specimens

4. Discussion

4.1. Influence of Contact Stress on the Damage of Fatigue Specimens

4.2. Influence of Contact Stress on the Surface Structure of Fatigue Specimens

5. Conclusions

- (1)

- The main forms of fatigue damage of an AD180 high-carbon semi-steel roll are peeling, pitting corrosion, and plowing while the surface of the roll also exhibits delamination and plastic deformation characteristics under high contact stress. Among these, peeling causes the most severe damage to the specimen and is the main form of specimen failure.

- (2)

- The surface roughness (axial and tangential) of the rolling contact fatigue specimen and the area and depth of the peeling pits increase with the contact stress.

- (3)

- The crack initiation at the surface edge of the rolling contact fatigue specimen is the main reason for the formation and distribution of peeling pits on both sides of the contact surface. Under low cyclic load, cracks mainly propagate along the pearlite and at the interface between pearlite and cementite. Under high cyclic loads, cracks will also propagate along the cementite.

- (4)

- Repeated cyclic loading can refine the grain size of the specimen, increase the dislocation density, and thus increase the surface hardness. The cross-sectional hardness of the specimen decreases with an increasing depth and gradually stabilizes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ringsberg, J.W.; Bergkvist, A. On propagation of short rolling contact fatigue cracks. Fatigue Fract. Eng. Mater. Struct. 2003, 26, 969–983. [Google Scholar] [CrossRef]

- Gao, B.; Tan, Z.; Liu, Z.; Gao, G.; Zhang, M.; Zhang, G.; Bai, B. Influence of non-uniform microstructure on rolling contact fatigue behavior of high-speed wheel steels. Eng. Fail. Anal. 2019, 100, 485–491. [Google Scholar] [CrossRef]

- Liu, C.-P.; Zhao, X.-J.; Liu, P.-T.; Xu, C.; Ren, R.-M. Influence of slip ratio on worn-surface microstructure and fatigue wear behavior of D2 wheel steel. J. Iron Steel Res. Int. 2018, 25, 1278–1286. [Google Scholar] [CrossRef]

- Xia, Z.; Wu, D.; Zhang, X.; Wang, J.; Han, E.-H. Rolling contact fatigue failure mechanism of bearing steel on different surface roughness levels under heavy load. Int. J. Fatigue 2023, 179, 108042. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, Z.; Tian, Y.; Zhu, J.; Zhang, M.; Zhang, M.; Zhao, H. Temperature-dependent crack induced by microstructure evolution in 20Mn2SiMoCuV bainite wheel steel. Eng. Fail. Anal. 2022, 140, 106593. [Google Scholar] [CrossRef]

- Hanting, D. Failure Analysis for Roll Surfacing; Wuhan University of Technology: Wuhan, China, 2008. [Google Scholar]

- Wang, D.; Mou, Z.; Yang, Z.; Xu, Y.; Xu, H.; Song, X. Fracture failure analysis of high-speed steel composite rolls in hot strip rolling mills. Steel Roll. 2021, 38, 74–79. [Google Scholar]

- Hou, P. Failure analysis of crack on working surface of main roller for wheel. Heavy Cast. Forg. 2020, 6, 47–49. [Google Scholar]

- Chen, X.; Liu, X.; Tao, C.; Li, Z. Study on damage behavior and failure mechanism of rollers. Fail. Anal. Prev. 2018, 13, 60–66. [Google Scholar]

- Zhou, C.; Wu, F.; Zhang, Z.; Zhang, P.; Zhang, L. Fracture failure analysis and research on super-large-diameter roll. Eng. Fail. Anal. 2023, 145, 107043. [Google Scholar] [CrossRef]

- Failure Analysis of Si3N4 rolls for wire hot rolling by numerical simulation of thermal and mechanical stresses. Key Eng. Mater. 2005, 523, 94–101.

- Zhao, X.; Chen, Q.; Liu, Y.; Qiu, X.; Meli, E.; Rindi, A. Effects of slip ratio and contact stress on rolling contact fatigue of defected rail materials. Eng. Fail. Anal. 2021, 131, 105817. [Google Scholar] [CrossRef]

- Zhang, S.-Y.; Spiryagin, M.; Lin, Q.; Ding, H.-H.; Wu, Q.; Guo, J.; Liu, Q.-Y.; Wang, W.-J. Study on wear and rolling contact fatigue behaviours of defective rail under different slip ratio and contact stress conditions. Tribol. Int. 2022, 169, 107491. [Google Scholar] [CrossRef]

- Kang, J.-J.; Xu, B.-S.; Wang, H.-D.; Wang, C.-B. Influence of contact stress on rolling contact fatigue of composite ceramic coatings plasma sprayed on a steel roller. Tribol. Int. 2014, 73, 47–56. [Google Scholar] [CrossRef]

- Zhang, J. Formation and prevention of crack and slag inclusion defects in high carbon alloy semi-steel roll Ring. Foundry Equip. Technol. 2017, 6, 71–75. [Google Scholar]

- Wang, G.J.; Bai, S.N.; Ma, X.L. Analysis and solution of outer circle mottle problem of semi-steel roller ring. China Foundry Mach. Technol. 2022, 57, 64–67. [Google Scholar]

- Nannan, S.; Yikun, L.; Yunlong, B.; Xiuhong, K.; Lijun, X.; Dianzhong, L. Computer simulation of core filling process of cast high speed steel roll. China Foundry 2009, 6, 314–318. [Google Scholar]

- Zhang, W.; Guo, J.; Liu, Q. An investigationof rails rolling contact fatigue. Lubr. Eng. 2005, 6, 195–199. [Google Scholar]

- She, L. Study on Rolling Contact Fatigue Properties of Bainite Bearing Steels; Yanshan University: Qinhuangdao, China, 2015. [Google Scholar]

- Zhu, W. Study on Wear Mapping and Wear Transition Mechanism of CL60 Wheel Material; Southwest Jiaotong University: Chengdu, China, 2018. [Google Scholar]

- Wang, B.; Zhang, Y.; Zuo, H.; Wang, H. Study on the influence of compressive stress on the compressive shear crack propagation. Chin. J. Theor. Appl. 2019, 51, 845–851. [Google Scholar]

- Ekberg, A.; Marais, J. Effects of imperfections on fatigue initiation in railway wheels. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2000, 214, 45–54. [Google Scholar] [CrossRef]

- Cao, G.; Guo, H.; Yang, J.; Bai, S.; Wang, B.; Wang, Y. Research on graphite alloy steel roll ring for H-beam. Tianjin Metall. 2020, 6, 52–54. [Google Scholar]

- Wang, W.; Guo, J.; Liu, Q. Study on adhesion characteristics of wheels/rails under different Conditions. J. Mech. Eng. 2012, 48, 100–104. [Google Scholar] [CrossRef]

- Qiu, L.N.; Li, S.X.; Jiang, G.H.; Yu, F.; Ru, S.Y. Fatigue analysis of carbide-free bainite high carbon steel under rolling contact fatigue. J. Ningbo Univ. 2021, 34, 55–60. [Google Scholar]

- Wang, X.Y.; Huang, C.Z.; Zou, B.; Liu, G.L.; Zhu, H.T.; Wang, J. Experimental study of surface integrity and fatigue life in the face milling of inconel 718. Front. Mech. Eng. 2017, 13, 243–250. [Google Scholar] [CrossRef]

- Bian, Y.; Liang, A.; Zhang, Z.; Chen, Z. Mechanism analysis of overloading contact test. J. Tongji Univ. 2017, 45, 1009–1015. [Google Scholar]

- Wang, W.J.; Guo, J.; Liu, Q.Y. Effect of contact stress on rolling frition and wear behaviour of wheel-rail material. Tribology 2011, 31, 352–366. [Google Scholar]

- Jones, A.B. Metallographic Observations of Ball Bearing Fatigue Phenomenon; American Society for Testing and Materials: Philadelphia, PA, USA, 1947; pp. 35–52. [Google Scholar]

- Masoud, M.; Mahdieh, S.; Gregor, M. Combined thermal desorption spectroscopy, hydrogen visualiza-tion, HRTEM and EBSD investigation of a Ni–Fe–Cr alloy: The role of hydrogen trapping behavior in hydrogen-assisted fracture. Mater. Sci. Eng. A 2022, 848, 143428. [Google Scholar]

- Apparao, K.C.; Bannaravuri, P.K.; Pulisheru, K.S.; Francis, E.D.; Sunny, K.A.; Rao, G.B.; Birru, A.K. Effect of novel grain refiner and Ni alloying additions on microstructure and mechanical properties of Al-Si9.8-Cu3.4 HPDC castings–optimization using Multi Criteria Decision making approach. Mater. Sci.-Pol. 2022, 40, 9–24. [Google Scholar] [CrossRef]

- Fan, W.; Bai, Y.; Zuo, G.; Hao, H. Enhanced grain refinement and mechanical properties of AZ91 alloy by a novel Al-5.1 V-2.3B refiner containing VB2 and VB particles. Addit. Manufactuing 2023, 225, 111474. [Google Scholar] [CrossRef]

- Niu, T.; Wang, X.; Wu, X. Effect of shot peening process on surface properties and wear behavior of 4Cr5Mo2V steel. Heat Treat. Met. 2023, 48, 153–159. [Google Scholar]

| Elements | C | Si | Mn | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|---|

| Actual chemical composition content | 2.2 | 0.5 | 0.9 | <0.035 | <0.03 | 1.7 | 1.4 | 0.5 |

| Contact Stress [MPa] | Depth Data of Each Group [μm] | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | Average Depth | |

| 1300 | 305 | 311 | 247 | 327 | 396 | 207 | 298.83 |

| 1400 | 339 | 280 | 357 | 460 | 246 | 236 | 319.67 |

| 1500 | 545 | 404 | 420 | 362 | 233 | 363 | 387.83 |

| Contact Stress [MPa] | 1 | 2 | 3 | 4 | 5 | 6 | Average Value [μm] | |

|---|---|---|---|---|---|---|---|---|

| Tangential roughness | 1300 | 3.215 | 3.427 | 3.620 | 4.210 | 3.746 | 3.998 | 3.703 |

| 1400 | 4.785 | 4.875 | 4.595 | 4.120 | 4.280 | 4.657 | 4.552 | |

| 1500 | 5.513 | 4.810 | 5.029 | 4.941 | 5.755 | 4.577 | 5.104 | |

| Axial roughness | 1300 | 5.537 | 4.525 | 4.508 | 4.753 | 4.741 | 4.596 | 4.777 |

| 1400 | 5.952 | 6.600 | 5.130 | 4.286 | 4.706 | 5.546 | 5.370 | |

| 1500 | 5.997 | 5.530 | 6.685 | 6.876 | 8.058 | 6.519 | 6.611 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liu, L.; Cheng, Q.; Hou, H.; Zhang, Z.; Ren, Z. Analysis of the Influence of Contact Stress on the Fatigue of AD180 High-Carbon Semi-Steel Roll. Metals 2024, 14, 548. https://doi.org/10.3390/met14050548

Liu Y, Liu L, Cheng Q, Hou H, Zhang Z, Ren Z. Analysis of the Influence of Contact Stress on the Fatigue of AD180 High-Carbon Semi-Steel Roll. Metals. 2024; 14(5):548. https://doi.org/10.3390/met14050548

Chicago/Turabian StyleLiu, Yaxing, Lixin Liu, Qian Cheng, Haipeng Hou, Zehua Zhang, and Zhongkai Ren. 2024. "Analysis of the Influence of Contact Stress on the Fatigue of AD180 High-Carbon Semi-Steel Roll" Metals 14, no. 5: 548. https://doi.org/10.3390/met14050548