Long-Range Influence of Cr on the Stacking Fault Energy of Cr-Containing Concentrated Solid-Solution Alloys

Abstract

:1. Introduction

2. Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Duval, T.; Hung, U.D.; Yeh, J.W.; Shih, H.C. Microstructure and Electrochemical Properties of High Entropy Alloys-a Comparison with Type-304 Stainless Steel. Corros. Sci. 2005, 47, 2257–2279. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Cantor, B. Multicomponent High-Entropy Cantor Alloys. Prog. Mater. Sci. 2021, 120, 100754. [Google Scholar] [CrossRef]

- Lu, C.; Niu, L.; Chen, N.; Jin, K.; Yang, T.; Xiu, P.; Zhang, Y.; Gao, F.; Bei, H.; Shi, S.; et al. Enhancing Radiation Tolerance by Controlling Defect Mobility and Migration Pathways in Multicomponent Single-Phase Alloys. Nat. Commun. 2016, 7, 13564. [Google Scholar] [CrossRef] [PubMed]

- Granberg, F.; Nordlund, K.; Ullah, M.W.; Jin, K.; Lu, C.; Bei, H.; Wang, L.M.; Djurabekova, F.; Weber, W.J.; Zhang, Y. Mechanism of Radiation Damage Reduction in Equiatomic Multicomponent Single Phase Alloys. Phys. Rev. Lett. 2016, 116, 135504. [Google Scholar] [CrossRef] [PubMed]

- Ullah, M.W.; Aidhy, D.S.; Zhang, Y.; Weber, W.J. Damage Accumulation in Ion-Irradiated Ni-Based Concentrated Solid-Solution Alloys. Acta Mater. 2016, 109, 17–22. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Y.; Miller, J.; Weber, W.J.; Bei, H.; Zhang, Y. Deformation Mechanisms in Single Crystal Ni-Based Concentrated Solid Solution Alloys by Nanoindentation. Mater. Sci. Eng. A 2022, 856, 143685. [Google Scholar] [CrossRef]

- Xiu, P.; Osetsky, Y.N.; Jiang, L.; Velisa, G.; Tong, Y.; Bei, H.; Weber, W.J.; Zhang, Y.; Wang, L. Dislocation Loop Evolution and Radiation Hardening in Nickel-Based Concentrated Solid Solution Alloys. J. Nucl. Mater. 2020, 538, 152247. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.S.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional Damage-Tolerance of a Medium-Entropy Alloy CrCoNi at Cryogenic Temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Mao, M.M.; Wang, J.; Gludovatz, B.; Zhang, Z.; Mao, S.X.; George, E.P.; Yu, Q.; Ritchie, R.O. Nanoscale Origins of the Damage Tolerance of the High-Entropy Alloy CrMnFeCoNi. Nat. Commun. 2015, 6, 2–7. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E.P. Reasons for the Superior Mechanical Properties of Medium-Entropy CrCoNi Compared to High-Entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Zhang, Z.; Sheng, H.; Wang, Z.; Gludovatz, B.; Zhang, Z.; George, E.P.; Yu, Q.; Mao, S.X.; Ritchie, R.O. Dislocation Mechanisms and 3D Twin Architectures Generate Exceptional Strength-Ductility-Toughness Combination in CrCoNi Medium-Entropy Alloy. Nat. Commun. 2017, 8, 14390. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Li, X.; Dong, Z.; Li, W.; Huang, S.; Meng, D.; Lai, X.; Liu, T.; Zhu, S.; Vitos, L. Critical Stress for Twinning Nucleation in CrCoNi-Based Medium and High Entropy Alloys. Acta Mater. 2018, 149, 388–396. [Google Scholar] [CrossRef]

- Jin, K.; Lu, C.; Wang, L.M.; Qu, J.; Weber, W.J.; Zhang, Y.; Bei, H. Effects of Compositional Complexity on the Ion-Irradiation Induced Swelling and Hardening in Ni-Containing Equiatomic Alloys. Scr. Mater. 2016, 119, 65–70. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, S.; Weber, W.J.; Nordlund, K.; Granberg, F.; Djurabekova, F. Atomic-Level Heterogeneity and Defect Dynamics in Concentrated Solid-Solution Alloys. Curr. Opin. Solid State Mater. Sci. 2017, 21, 221–237. [Google Scholar] [CrossRef]

- Yamakov, V.; Wolf, D.; Phillpot, S.R.; Mukherjee, A.K.; Gleiter, H. Dislocation Processes in the Deformation of Nanocrystalline Aluminium by Molecular-Dynamics Simulation. Nat. Mater. 2002, 1, 45–48. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Wu, Y.; Lou, H.; Zeng, Z.; Prakapenka, V.B.; Greenberg, E.; Ren, Y.; Yan, J.; Okasinski, J.S.; Liu, X.; et al. Polymorphism in a High-Entropy Alloy. Nat. Commun. 2017, 8, 15687. [Google Scholar] [CrossRef]

- Ding, J.; Yu, Q.; Asta, M.; Ritchie, R.O. Tunable Stacking Fault Energies by Tailoring Local Chemical Order in CrCoNi Medium-Entropy Alloys. Proc. Natl. Acad. Sci. USA 2018, 115, 8919–8924. [Google Scholar] [CrossRef]

- Lin, Q.; Liu, J.; An, X.; Wang, H.; Zhang, Y.; Liao, X. Cryogenic-Deformation-Induced Phase Transformation in an FeCoCrNi High-Entropy Alloy. Mater. Res. Lett. 2018, 6, 236–243. [Google Scholar] [CrossRef]

- Zhao, S.; Stocks, G.M.; Zhang, Y. Stacking Fault Energies of Face-Centered Cubic Concentrated Solid Solution Alloys. Acta Mater. 2017, 134, 334–345. [Google Scholar] [CrossRef]

- Zhao, S.; Osetsky, Y.; Stocks, G.M.; Zhang, Y. Local-Environment Dependence of Stacking Fault Energies in Concentrated Solid-Solution Alloys. Npj Comput. Mater. 2019, 5, 13. [Google Scholar] [CrossRef]

- Niu, C.; LaRosa, C.R.; Miao, J.; Mills, M.J.; Ghazisaeidi, M. Magnetically-Driven Phase Transformation Strengthening in High Entropy Alloys. Nat. Commun. 2018, 9, 1363. [Google Scholar] [CrossRef] [PubMed]

- Smith, T.M.; Hooshmand, M.S.; Esser, B.D.; Otto, F.; Mccomb, D.W.; George, E.P.; Ghazisaeidi, M.; Mills, M.J. Atomic-Scale Characterization and Modeling of 60°dislocations in a High-Entropy Alloy. Acta Mater. 2016, 110, 352–363. [Google Scholar] [CrossRef]

- Zeng, Y.; Cai, X.; Koslowski, M. Effects of the Stacking Fault Energy Fluctuations on the Strengthening of Alloys. Acta Mater. 2019, 164, 1–11. [Google Scholar] [CrossRef]

- Osetsky, Y.N.; Pharr, G.M.; Morris, J.R. Two Modes of Screw Dislocation Glide in Fcc Single-Phase Concentrated Alloys. Acta Mater. 2019, 164, 741–748. [Google Scholar] [CrossRef]

- Zhao, S. Fluctuations in Stacking Fault Energies Improve Irradiation Tolerance of Concentrated Solid-Solution Alloys. J. Nucl. Mater. 2020, 530, 151886. [Google Scholar] [CrossRef]

- Zhang, F.X.; Zhao, S.; Jin, K.; Xue, H.; Velisa, G.; Bei, H.; Huang, R.; Ko, J.Y.P.; Pagan, D.C.; Neuefeind, J.C.; et al. Local Structure and Short-Range Order in a NiCoCr Solid Solution Alloy. Phys. Rev. Lett. 2017, 118, 205501. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, S.; Ding, J.; Chong, Y.; Jia, T.; Ophus, C.; Asta, M.; Ritchie, R.O.; Minor, A.M. Short-Range Order and Its Impact on the CrCoNi Medium-Entropy Alloy. Nature 2020, 581, 283–287. [Google Scholar] [CrossRef] [PubMed]

- Tuomisto, F.; Makkonen, I.; Heikinheimo, J.; Granberg, F.; Djurabekova, F.; Nordlund, K.; Velisa, G.; Bei, H.; Xue, H.; Weber, W.J.; et al. Segregation of Ni at Early Stages of Radiation Damage in NiCoFeCr Solid Solution Alloys. Acta Mater. 2020, 196, 44–51. [Google Scholar] [CrossRef]

- Lu, C.; Yang, T.; Jin, K.; Gao, N.; Xiu, P.; Zhang, Y.; Gao, F.; Bei, H.; Weber, W.J.; Sun, K.; et al. Radiation-Induced Segregation on Defect Clusters in Single-Phase Concentrated Solid-Solution Alloys. Acta Mater. 2017, 127, 98–107. [Google Scholar] [CrossRef]

- He, M.R.; Wang, S.; Shi, S.; Jin, K.; Bei, H.; Yasuda, K.; Matsumura, S.; Higashida, K.; Robertson, I.M. Mechanisms of Radiation-Induced Segregation in CrFeCoNi-Based Single-Phase Concentrated Solid Solution Alloys. Acta Mater. 2017, 126, 182–193. [Google Scholar] [CrossRef]

- Koizumi, Y.; Nukaya, T.; Suzuki, S.; Kurosu, S.; Li, Y.; Matsumoto, H.; Sato, K.; Tanaka, Y.; Chiba, A. Suzuki Segregation in Co-Ni-Based Superalloy at 973 K: An Experimental and Computational Study by Phase-Field Simulation. Acta Mater. 2012, 60, 2901–2915. [Google Scholar] [CrossRef]

- Zhao, S.; Egami, T.; Stocks, G.M.; Zhang, Y. Effect of d Electrons on Defect Properties in Equiatomic NiCoCr and NiCoFeCr Concentrated Solid Solution Alloys. Phys. Rev. Mater. 2018, 2, 013602. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficiency of Ab-Initio Total Energy Calculations for Metals and Semiconductors Using a Plane-Wave Basis Set. Comput. Mater. Sci. 1996, 6, 15–50. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef]

- Blöchl, P.E. Projector Augmented-Wave Method. Phys. Rev. B 1994, 50, 17953–17979. [Google Scholar] [CrossRef]

- Methfessel, M.; Paxton, A.T. High-Precision Sampling for Brillouin-Zone Integration in Metals. Phys. Rev. B 1989, 40, 3616–3621. [Google Scholar] [CrossRef]

- Cowley, J.M. Short-Range Order and Long-Range Order Parameters. Phys. Rev. 1965, 138, A1384. [Google Scholar] [CrossRef]

- Cowley, J.M. An Approximate Theory of Order in Alloys. Phys. Rev. 1950, 77, 669–675. [Google Scholar] [CrossRef]

- Van de Walle, A.; Asta, M.; Ceder, G. The Alloy Theoretic Automated Toolkit: A User Guide. Calphad Comput. Coupling Phase Diagr. Thermochem. 2002, 26, 539–553. [Google Scholar] [CrossRef]

- Vítek, V. Intrinsic Stacking Faults in Body-Centred Cubic Crystals. Philos. Mag. 1968, 18, 773–786. [Google Scholar] [CrossRef]

- Siegel, D.J. Generalized Stacking Fault Energies, Ductilities, and Twinnabilities of Ni and Selected Ni Alloys. Appl. Phys. Lett. 2005, 87, 121901. [Google Scholar] [CrossRef]

- Bag, P.; Su, Y.C.; Kuo, Y.K.; Lai, Y.C.; Wu, S.K. Physical Properties of Face-Centered Cubic Structured High-Entropy Alloys: Effects of NiCo, NiFe, and NiCoFe Alloying with Mn, Cr, and Pd. Phys. Rev. Mater. 2021, 5, 29–31. [Google Scholar] [CrossRef]

- Bleskov, I.; Hickel, T.; Neugebauer, J.; Ruban, A. Impact of Local Magnetism on Stacking Fault Energies: A First-Principles Investigation for Fcc Iron. Phys. Rev. B 2016, 93, 214115. [Google Scholar] [CrossRef]

- Ogata, S.; Li, J.; Yip, S. Ideal Pure Shear Strength of Aluminum and Copper. Science 2002, 298, 807–811. [Google Scholar] [CrossRef]

- Shang, S.L.; Wang, W.Y.; Zhou, B.C.; Wang, Y.; Darling, K.A.; Kecskes, L.J.; Mathaudhu, S.N.; Liu, Z.K. Generalized Stacking Fault Energy, Ideal Strength and Twinnability of Dilute Mg-Based Alloys: A First-Principles Study of Shear Deformation. Acta Mater. 2014, 67, 168–180. [Google Scholar] [CrossRef]

- Shang, S.L.; Zacherl, C.L.; Fang, H.Z.; Wang, Y.; Du, Y.; Liu, Z.K. Effects of Alloying Element and Temperature on the Stacking Fault Energies of Dilute Ni-Base Superalloys. J. Phys. Condens. Matter 2012, 24, 505403. [Google Scholar] [CrossRef]

- Xin, H.; Vojvodic, A.; Voss, J.; Nørskov, J.K.; Abild-Pedersen, F. Effects of d -Band Shape on the Surface Reactivity of Transition-Metal Alloys. Phys. Rev. B—Condens. Matter Mater. Phys. 2014, 89, 115114. [Google Scholar] [CrossRef]

- Li, H.; Draxl, C.; Wurster, S.; Pippan, R.; Romaner, L. Impact of d -Band Filling on the Dislocation Properties of Bcc Transition Metals: The Case of Tantalum-Tungsten Alloys Investigated by Density-Functional Theory. Phys. Rev. B 2017, 95, 094114. [Google Scholar] [CrossRef]

| Lattice Parameter (Å) | SFE (mJ/m2) | ||

|---|---|---|---|

| This Work | Reference | This Work | |

| Ni | 3.517 | 3.522 [43] | 130 |

| NiFe | 3.574 | 3.583 [44] | 0–200 |

| NiCoCr | 3.527 | 3.529 [21] | −200–60 |

| Perfect Structure | SF Structure | Difference | ||||

|---|---|---|---|---|---|---|

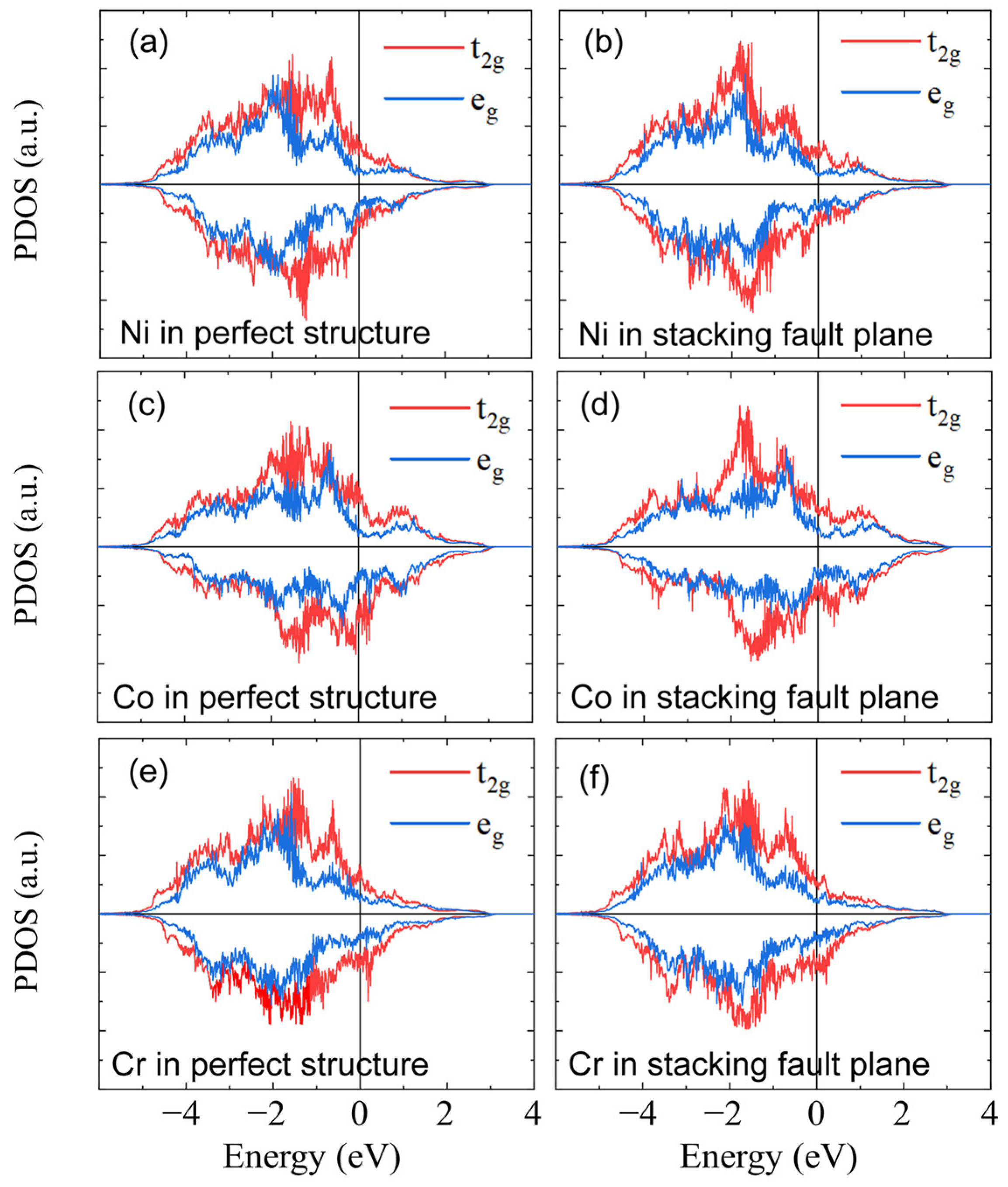

| t2g | eg | t2g | eg | Δ(t2g) | Δ(eg) | |

| Ni | 5.03 | 3.28 | 5.02 | 3.29 | −0.01 | 0.01 |

| Co | 4.41 | 2.92 | 4.38 | 2.93 | −0.03 | 0.01 |

| Cr | 2.47 | 1.69 | 2.53 | 1.66 | 0.06 | −0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Liu, Q.; Zhao, S.; Xia, S.; Wang, Y.; Wang, C. Long-Range Influence of Cr on the Stacking Fault Energy of Cr-Containing Concentrated Solid-Solution Alloys. Metals 2024, 14, 560. https://doi.org/10.3390/met14050560

Xiao H, Liu Q, Zhao S, Xia S, Wang Y, Wang C. Long-Range Influence of Cr on the Stacking Fault Energy of Cr-Containing Concentrated Solid-Solution Alloys. Metals. 2024; 14(5):560. https://doi.org/10.3390/met14050560

Chicago/Turabian StyleXiao, Hao, Qingyuan Liu, Shijun Zhao, Songqin Xia, Yugang Wang, and Chenxu Wang. 2024. "Long-Range Influence of Cr on the Stacking Fault Energy of Cr-Containing Concentrated Solid-Solution Alloys" Metals 14, no. 5: 560. https://doi.org/10.3390/met14050560