Energy, Exergy and Economic Evaluation Comparison of Small-Scale Single and Dual Pressure Organic Rankine Cycles Integrated with Low-Grade Heat Sources

Abstract

:1. Introduction

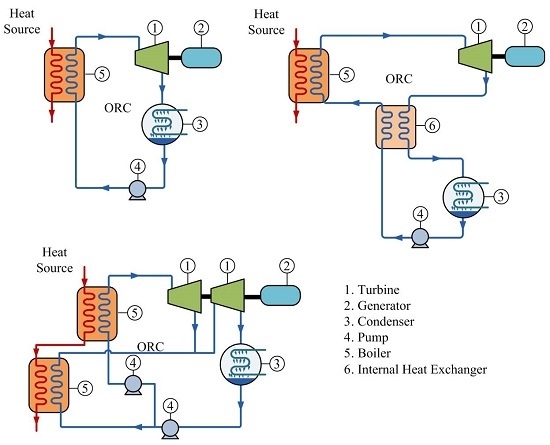

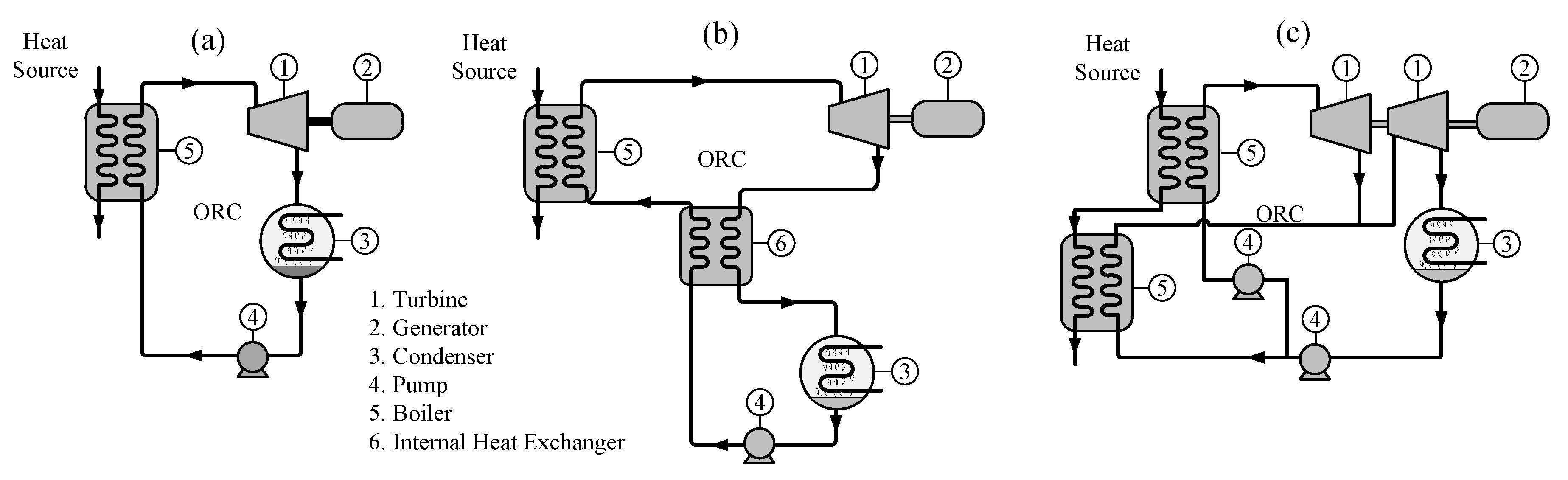

2. Materials and Methods

2.1. Working Fluid Selection

2.2. Simulation Details

2.3. Sizing of Components

2.3.1. Turbine and Pump

2.3.2. Heat Transfer Equipment

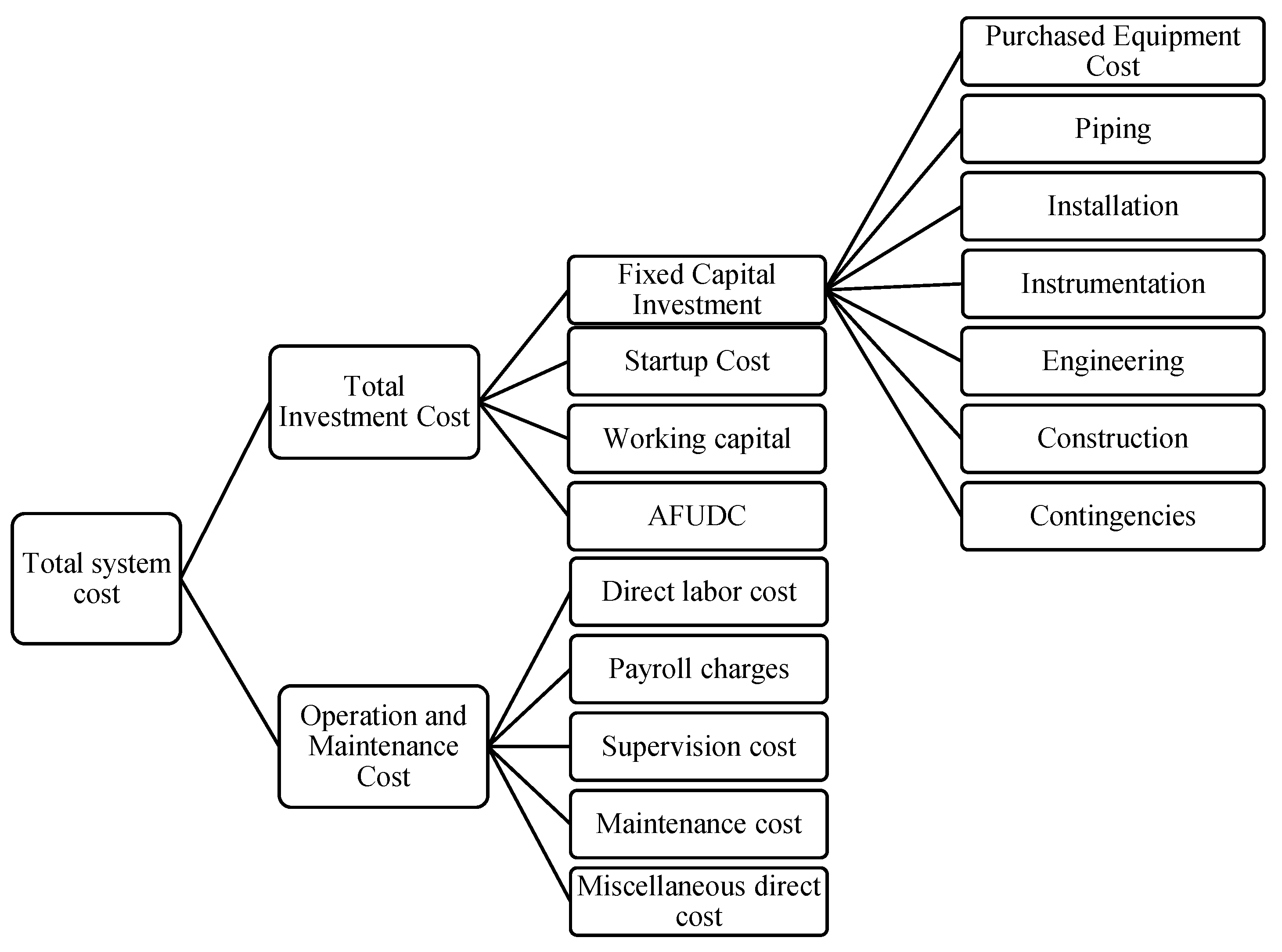

2.4. Cost Structure and Estimation

2.4.1. Total Investment Cost

2.4.2. Operation and Maintenance Costs

2.4.3. Levelized Cost of Electricity and Net Present Value

- The lifetime period is 20 years

- The capacity factor is set to 85%

- Average general inflation rate is 5%

- Average income taxes interest rate is 33%

- Cost of capital or interest rate, 5%

- Straight line depreciation is assumed over the lifetime of the ORC

3. Results and Discussion

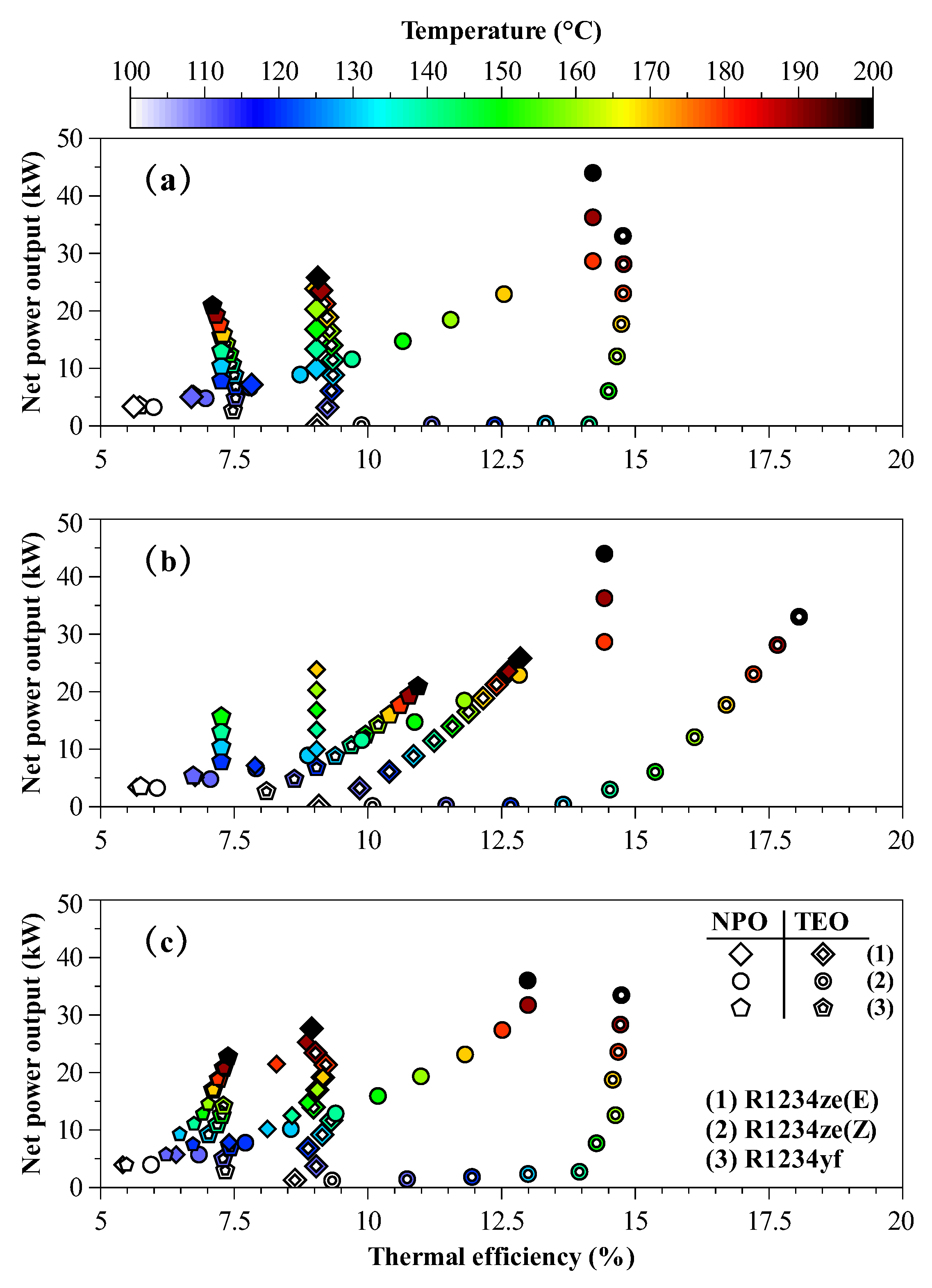

3.1. Power and Thermal Efficiency Optimization

3.1.1. Simple ORC

3.1.2. Regenerative ORC

3.1.3. Dual Pressure ORC

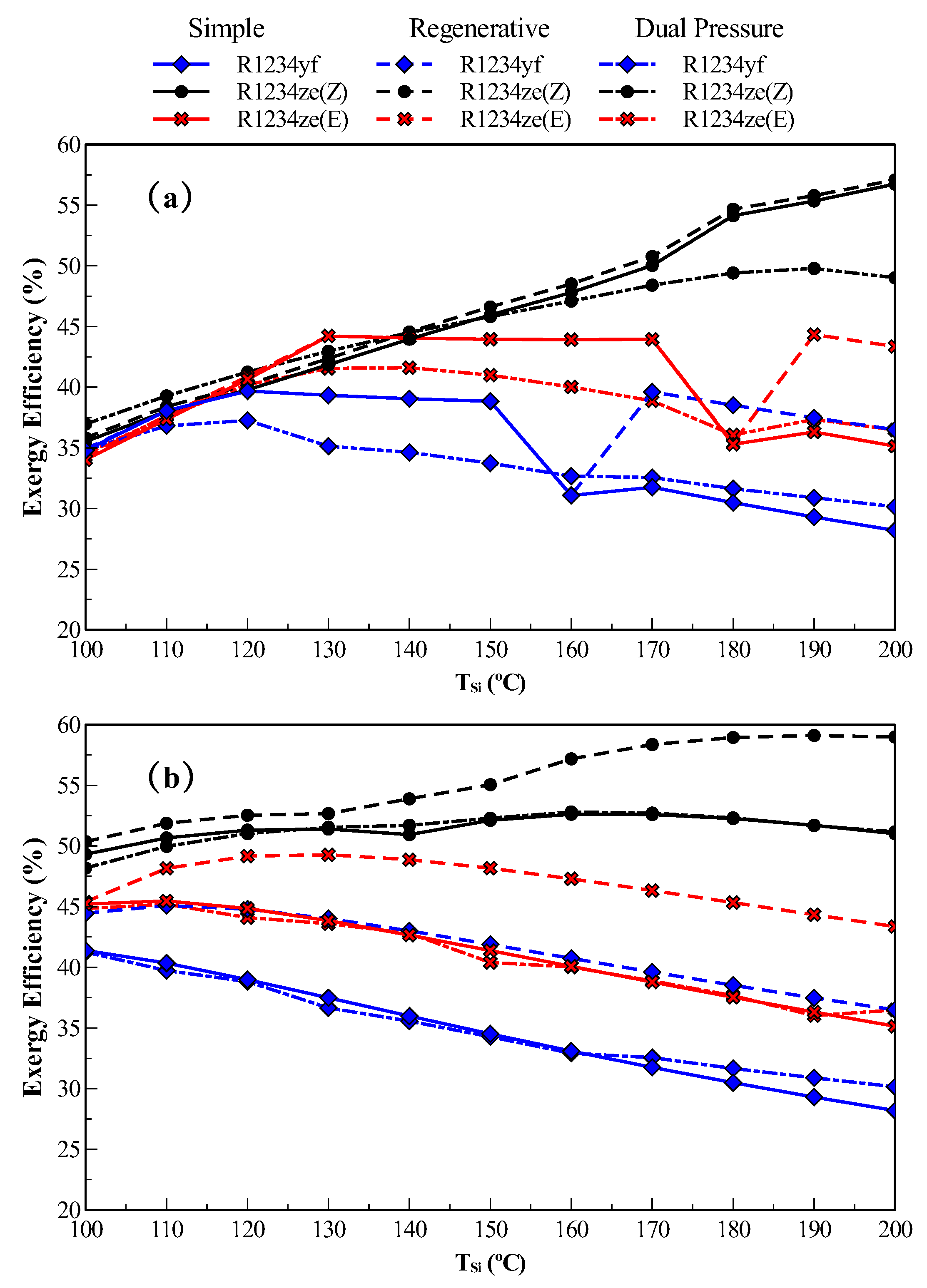

3.2. Exergy Efficiency and Exergy Destruction

3.3. Levelized Cost of Electricity - LCOE

3.4. Specific Investment Cost (SIC)

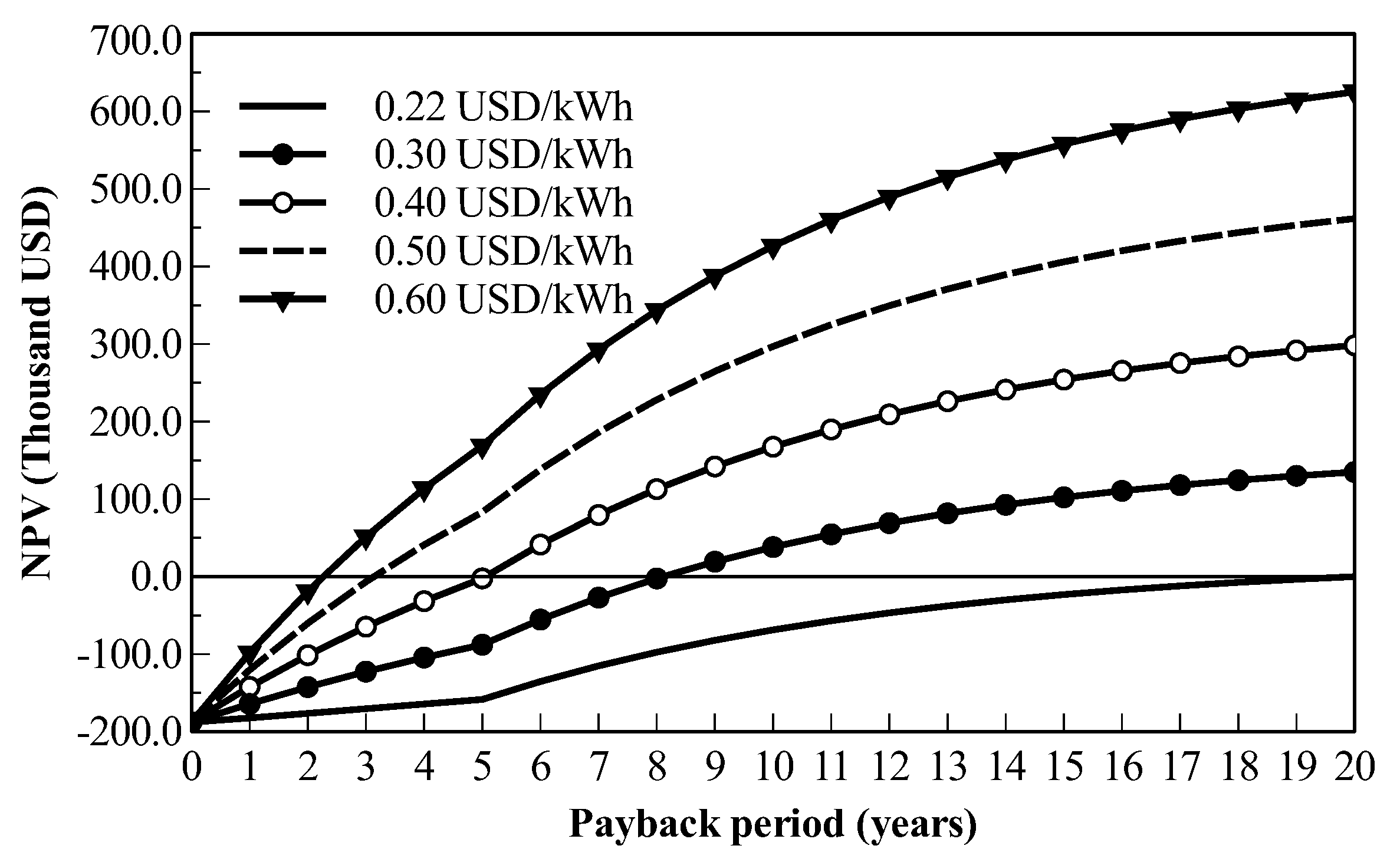

3.5. Net Present Value (NPV)

4. Conclusions

- Dual pressure ORC is the configuration that achieves the highest net power output at heat source temperatures below 130 °C. Dual pressure ORC is more attractive at heat source temperatures close to 100 °C. Above 130 °C, simple ORC with R1234ze(Z) develops the highest power output.

- From the thermal efficiency optimization, regenerative ORC with R1234ze(Z) is the combination with the maximum thermal efficiency. However, its net power output is rather low compared with R11234yf and R1234ze(E), which develop less thermal efficiency but higher net power output when thermal efficiency is optimized.

- Net power output and thermal efficiency optimization show different trends when they are optimized separately. However, LCOE values show that thermal efficiency optimization is less cost-effective than net power output optimization.

- There are higher exergy destruction and lower exergy efficiency rates when net power is optimized as compared to the case in which thermal efficiency is optimized. The inclusion of the regenerative heat exchanger reduces the exergy destruction and increases the exergy efficiency, but dual pressure ORC is the configuration with the lowest exergy efficiency and the highest exergy destruction, specially at higher temperatures, where the working fluid is superheated.

- According to the economic evaluation, LCOE and SIC values show that the conventional simple ORC is the most cost-effective among the studied cycle configurations when either net power or thermal efficiency is optimized, requiring a selling price of energy of 0.3 USD/kWh to obtain a payback period of 8 years. In addition, the working fluid R1234ze(Z) exhibits great potential for simple ORC when compared to conventional R245fa.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| Inlet Heat Source Temperature (°C) | |

| Outlet Heat Source Temperature (°C) | |

| A | Heat transfer area (m) |

| Q | Heat (kW) |

| U | Overall heat transfer coefficient |

| Mean logarithmic temperature difference, K | |

| h | heat transfer coefficient |

| Thermal resistance of the wall | |

| Nusselt number | |

| Hydraulic Diameter, m | |

| k | Thermal conductivity |

| q | Heat flux, |

| G | Mass flux, |

| Bubble departure diameter, m | |

| Specific latent heat of vaporization, | |

| x | Vapor quality |

| Subscripts | |

| Single phase | |

| Cold source | |

| Heat source | |

| m | Liquid-vapor mixture |

| v | Vapor phase |

| Equivalent | |

| Two phase | |

| l | Liquid phase |

| Greek symbols | |

| Thermal diffusivity () | |

| Density () | |

| Dinamic viscosity () | |

References

- Cruz Virosa, I.; Filgueiras Sainz de Rozas, M.L.; Sorinas Gonzáles, L.; Cabello Eras, J.J.; Fernández Pérez, L. Gestión comparada del riesgo en el control de la contaminación atmosférica de Generadores de Vapor. Ingeniería Energética 2016, 37, 195–206. (In Spanish) [Google Scholar]

- Eras, J.J.C.; Gutiérrez, A.S.; Lorenzo, D.G.; Martínez, J.B.C.; Hens, L.; Vandecasteele, C. Bridging universities and industry through cleaner production activities. Experiences from the Cleaner Production Center at the University of Cienfuegos, Cuba. J. Clean. Prod. 2015, 108, 873–882. [Google Scholar] [CrossRef]

- Fontalvo, A.; Pinzon, H.; Duarte, J.; Bula, A.; Quiroga, A.G.; Padilla, R.V. Exergy analysis of a combined power and cooling cycle. Appl. Therm. Eng. 2013, 60, 164–171. [Google Scholar] [CrossRef]

- Loni, R.; Kasaeian, A.; Mahian, O.; Sahin, A.Z.; Wongwises, S. Exergy analysis of a solar organic Rankine cycle with square prismatic cavity receiver. Int. J. Exergy 2017, 22, 103–124. [Google Scholar] [CrossRef]

- Demirkaya, G.; Padilla, R.V.; Fontalvo, A.; Lake, M.; Lim, Y.Y. Thermal and Exergetic Analysis of the Goswami Cycle Integrated with Mid-Grade Heat Sources. Entropy 2017, 19, 416. [Google Scholar] [CrossRef]

- Golzari, S.; Kasaeian, A.; Daviran, S.; Mahian, O.; Wongwises, S.; Sahin, A.Z. Second law analysis of an automotive air conditioning system using HFO-1234yf, an environmentally friendly refrigerant. Int. J. Refrig. 2017, 73, 134–143. [Google Scholar] [CrossRef]

- Mahian, O.; Kianifar, A.; Heris, S.Z.; Wen, D.; Sahin, A.Z.; Wongwises, S. Nanofluids effects on the evaporation rate in a solar still equipped with a heat exchanger. Nano Energy 2017, 36, 134–155. [Google Scholar] [CrossRef]

- Ormat Technologies Global Projects. Available online: http://www.ormat.com/global-project (accessed on 1 February 2017).

- Quoilin, S.; Van Den Broek, M.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef]

- Turbodenl Products for Combined Heat and Power (CHP). Available online: http://www.turboden.eu/en/products/products-chp.php (accessed on 1 February 2017).

- Turboden Solar Thermal Power Applications. Available online: http://www.turboden.eu/en/public/downloads/11-COM.P-6-rev.10%20-%20SOLAR%20ENGLISH.pdf (accessed on 1 February 2017).

- White, M.; Sayma, A.I. Improving the economy-of-scale of small organic rankine cycle systems through appropriate working fluid selection. Appl. Energy 2016, 183, 1227–1239. [Google Scholar] [CrossRef]

- Baral, S.; Kim, D.; Yun, E.; Kim, K.C. Experimental and thermoeconomic analysis of small-scale solar organic Rankine cycle (SORC) system. Entropy 2015, 17, 2039–2061. [Google Scholar] [CrossRef]

- Peris, B.; Navarro-Esbri, J.; Moles, F.; Mota-Babiloni, A. Experimental study of an ORC (organic Rankine cycle) for low grade waste heat recovery in a ceramic industry. Energy 2015, 85, 534–542. [Google Scholar] [CrossRef]

- Li, J.; Pei, G.; Li, Y.; Ji, J. Evaluation of external heat loss from a small-scale expander used in organic Rankine cycle. Appl. Therm. Eng. 2011, 31, 2694–2701. [Google Scholar] [CrossRef]

- Lemort, V.; Quoilin, S.; Cuevas, C.; Lebrun, J. Testing and modeling a scroll expander integrated into an Organic Rankine Cycle. Appl. Therm. Eng. 2009, 29, 3094–3102. [Google Scholar] [CrossRef]

- Gao, P.; Jiang, L.; Wang, L.; Wang, R.; Song, F. Simulation and experiments on an ORC system with different scroll expanders based on energy and exergy analysis. Appl. Therm. Eng. 2015, 75, 880–888. [Google Scholar] [CrossRef]

- Wang, E.; Zhang, H.; Fan, B.; Ouyang, M.; Zhao, Y.; Mu, Q. Study of working fluid selection of organic Rankine cycle (ORC) for engine waste heat recovery. Energy 2011, 36, 3406–3418. [Google Scholar] [CrossRef]

- Leibowitz, H.; Smith, I.; Stosic, N. Cost effective small scale ORC systems for power recovery from low grade heat sources. In Proceedings of the ASME 2006 International Mechanical Engineering Congress and Exposition, Chicago, IL, USA, 5–10 November 2006; pp. 521–527. [Google Scholar]

- Ziviani, D.; Bell, I.; van den Broek, M.; De Paepe, M. Comprehensive Model of a Single-screw Expander for ORC-Systems. In Proceedings of the International Compressor Engineering Conference, Ghent, Belgium, 14–17 July 2014. [Google Scholar]

- Yamamoto, T.; Furuhata, T.; Arai, N.; Mori, K. Design and testing of the organic Rankine cycle. Energy 2001, 26, 239–251. [Google Scholar] [CrossRef]

- Kang, S.H. Design and experimental study of ORC (organic Rankine cycle) and radial turbine using R245fa working fluid. Energy 2012, 41, 514–524. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Maraschiello, F. Thermo-fluid dynamics preliminary design of turbo-expanders for ORC cycles. Appl. Energy 2012, 97, 601–608. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Maraschiello, F. Design and performance prediction of radial ORC turboexpanders. Appl. Energy 2015, 138, 517–532. [Google Scholar] [CrossRef]

- Manente, G.; Lazzaretto, A.; Bonamico, E. Design guidelines for the choice between single and dual pressure layouts in organic Rankine cycle (ORC) systems. Energy 2017, 123, 413–431. [Google Scholar] [CrossRef]

- Abadi, G.B.; Yun, E.; Kim, K.C. Experimental study of a 1 kw organic Rankine cycle with a zeotropic mixture of R245fa/R134a. Energy 2015, 93, 2363–2373. [Google Scholar] [CrossRef]

- Li, T.; Zhang, Z.; Lu, J.; Yang, J.; Hu, Y. Two-stage evaporation strategy to improve system performance for organic Rankine cycle. Appl. Energy 2015, 150, 323–334. [Google Scholar] [CrossRef]

- Lecompte, S.; Huisseune, H.; van den Broek, M.; Vanslambrouck, B.; De Paepe, M. Review of organic Rankine cycle (ORC) architectures for waste heat recovery. Renew. Sustain. Energy Rev. 2015, 47, 448–461. [Google Scholar] [CrossRef]

- Abadi, G.B.; Kim, K.C. Investigation of organic Rankine cycles with zeotropic mixtures as a working fluid: Advantages and issues. Renew. Sustain. Energy Rev. 2017, 73, 1000–1013. [Google Scholar] [CrossRef]

- Rahbar, K.; Mahmoud, S.; Al-Dadah, R.K.; Moazami, N.; Mirhadizadeh, S.A. Review of organic Rankine cycle for small-scale applications. Energy Convers. Manag. 2017, 134, 135–155. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 9.1.; Technical Report; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013. [Google Scholar]

- European Union. Directive 2006/40/EC of the European Parliament and of the Council of 17 May 2006 relating to emissions from air-conditioning systems in motor vehicles and Amending Council Directive 70/156/EEC. Off. J. Eur. Union 2006, 1, 12–18. [Google Scholar]

- Maizza, V.; Maizza, A. Working fluids in non-steady flows for waste energy recovery systems. Appl. Therm. Eng. 1996, 16, 579–590. [Google Scholar] [CrossRef]

- Tchanche, B.F. Low Grade Heat Conversion into Power Using Small Scale Organic Rankine Cycles. Ph.D. Thesis, Agricultural University of Athens, Athens, Greece, 2011. [Google Scholar]

- Moran, M.J.; Shapiro, H.N. Fundamentals of Engineering Thermodynamics, 5th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Shah, R.K.; Sekulic, D.P. Fundamentals of Heat Exchanger Design; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Turizo-Santos, J.; Barros-Ballesteros, O.; Fontalvo-Lascano, A.; Vasquez-Padilla, R.; Bula-Silvera, A. Experimental characterization of thermal hydraulic performance of louvered brazed plate fin heat exchangers. Rev. Fac. Ing. Univ. Antioquia 2015, 74, 108–116. [Google Scholar]

- Sinnott, R.K. Chemical Engineering Design: SI Edition; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Huang, J.; Sheer, T.J.; Bailey-McEwan, M. Heat transfer and pressure drop in plate heat exchanger refrigerant evaporators. Int. J. Refrig. 2012, 35, 325–335. [Google Scholar] [CrossRef]

- Yan, Y.Y.; Lio, H.C.; Lin, T.F. Condensation heat transfer and pressure drop of refrigerant R-134a in a plate heat exchanger. Int. J. Heat Mass Transf. 1999, 42, 993–1006. [Google Scholar] [CrossRef]

- Bejan, A.; Tsatsaronis, G. Thermal Design and Optimization; John Wiley & Sons: Hoboken, NJ, USA, 1996. [Google Scholar]

- Infinity Turbine Waste Heat to Power. Available online: http://www.infinityturbine.com/ (accessed on 1 February 2017).

- Standard Xchange, Xylem Brazepak—Stainless Steel/copper Brazed Plate. Available online: http://www.standard-xchange.com/ (accessed on 1 February 2017).

- Lukawski, M. Design and Optimization of Standardized Organic Rankine Cycle Power Plant for European Conditions. Master’s Thesis, School for Renewable Energy Science, Akureyri, Iceland, December 2010. [Google Scholar]

- Perry, R.H.; Green, D.W. Perry’s Chemical Engineers’ Handbook; McGraw-Hill: New York, NY, USA, 2008. [Google Scholar]

- Loni, R.; Kasaeian, A.B.; Mahian, O.; Sahin, A.Z. Thermodynamic analysis of an organic rankine cycle using a tubular solar cavity receiver. Energy Convers. Manag. 2016, 127, 494–503. [Google Scholar] [CrossRef]

- Galindo, J.; Climent, H.; Dolz, V.; Royo-Pascual, L. Multi-objective optimization of a bottoming Organic Rankine Cycle (ORC) of gasoline engine using swash-plate expander. Energy Convers. Manag. 2016, 126, 1054–1065. [Google Scholar] [CrossRef]

- Quoilin, S.; Declaye, S.; Tchanche, B.; Lemort, V. Thermo-economic optimization of waste heat recovery Organic Rankine Cycles. Appl. Therm. Eng. 2011, 31, 2885–2893. [Google Scholar] [CrossRef]

- Electric Power Monthly. Available online: https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_5_6_a (accessed on 25 August 2017).

- Technology Roadmap: Solar Photovoltaic Energy, 2014 edition. Available online: https://www.iea.org/publications/freepublications/publication/TechnologyRoadmapSolarPhotovoltaicEnergy_2014edition.pdf (accessed on 25 August 2017).

- Padilla, R.V.; Fontalvo, A.; Demirkaya, G.; Martinez, A.; Quiroga, A.G. Exergy analysis of parabolic trough solar receiver. Appl. Therm. Eng. 2014, 67, 579–586. [Google Scholar] [CrossRef]

- Renewable Power Generation Costs in 2014. Available online: https://www.irena.org/DocumentDownloads/Publications/IRENA_RE_Power_Costs_2014_report.pdf (accessed on 25 August 2017).

| Parameter | Units | Value |

|---|---|---|

| Heat source temperature | °C | 100–200 |

| Pinch Point Temperature Difference | °C | 10 |

| Turbine isoentropic efficiency | °C | 85 |

| Pump isoentropic efficiency | °C | 85 |

| Condensation temperature | °C | 40 |

| Heat source fluid or Heat transfer fluid (HTF) | - | Therminol 55 |

| Heat source mass flow rate | kg/s | 1.0 |

| Component | Parameter | Units | (USD) | n | Reference | |

|---|---|---|---|---|---|---|

| Turbine | Power | kW | 0.1 | 500 | 0.73 | [42] |

| Heat exchangers | Area | m | 0.12 | 304 | 0.69 | [43] |

| Pump | Power | kW | 0.3 | 1000 | 0.45 | [34] |

| Parameter | Percentage | Base for Percentage Calculation | Reference |

|---|---|---|---|

| Piping | 9% | Purchased Equipment Cost | [44] |

| Installation of equipment | 20% | Purchased Equipment Cost | [41] |

| Instrumentation and controls | 5% | Purchased Equipment Cost | [44] |

| Electrical equipment | 4% | Purchased Equipment Cost | [44] |

| Civil and structural work | 5% | Purchased Equipment Cost | [44] |

| Engineering and supervision | 30% | Purchased Equipment Cost | [41] |

| Construction | 10% | Direct costs | [41] |

| Contingencies | 15% | Fixed Capital Investment | [41] |

| Startup cost | 1% | Fixed Capital Investment | [44] |

| Working capital | 3% | Purchased Equipment Cost | [44] |

| AFUDC | 15% | Fixed Capital Investment | [41] |

| Parameter | Percentage | Base |

|---|---|---|

| Payroll charges | 35% | Direct labor and supervision costs |

| Supervision costs | 15% | Direct labor cost |

| Maintenance costs | 6% | Fixed Capital Investment |

| Operating supplies | 5–7% | Direct labor cost |

| Laundry | 10–15% | Direct labor cost |

| Laboratory | 10–15% | Direct labor cost |

| Thermal Efficiency Simple ORC (%) | Thermal Efficiency Dual Pressure ORC (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Heat source temperature (°C) | NPO | TEO | UN | CON | NPO | TEO | UN | CON |

| R1234yf | ||||||||

| 100 | 5.7 | 7.5 | 5.4 | 6.0 | 5.5 | 7.3 | 5.5 | 6.6 |

| R1234ze(E) | ||||||||

| 100 | 5.6 | 9.0 | 5.5 | 6.0 | 5.4 | 8.6 | 5.6 | 6.8 |

| 150 | 9.0 | 9.3 | 9.8 | 10.5 | 8.9 | 9.0 | 9.9 | 10.4 |

| R1234ze(Z) | ||||||||

| 100 | 6.0 | 9.9 | 5.8 | 5.9 | 5.9 | 9.3 | 5.8 | 7.1 |

| 150 | 10.6 | 14.5 | 10.3 | 10.3 | 10.2 | 14.3 | 10.5 | 10.9 |

| R1234yf | R1234ze(Z) | R1234ze(E) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Heat Source Temperature (°C) | Net Power (kW) | Thermal Efficiency (%) | Cycle | Net Power (kW) | Thermal Efficiency (%) | Cycle | Net Power (kW) | Thermal Efficiency (%) | Cycle |

| Net Power Optimized | |||||||||

| 100 | 4.0 | 5.5 | DP | 4.0 | 5.9 | DP | 4.0 | 5.4 | DP |

| 110 | 5.7 | 6.2 | DP | 5.7 | 6.8 | DP | 5.7 | 6.4 | DP |

| 120 | 7.8 | 7.3 | R | 7.8 | 7.7 | DP | 7.8 | 7.4 | DP |

| 130 | 10.4 | 7.3 | R | 10.2 | 8.6 | DP | 10.2 | 8.1 | DP |

| 140 | 13.0 | 7.3 | R | 12.9 | 9.4 | DP | 13.4 | 9.0 | R |

| 150 | 15.7 | 7.3 | R | 15.9 | 10.2 | DP | 16.8 | 9.0 | R |

| 160 | 14.5 | 7.0 | DP | 19.3 | 11.0 | DP | 20.3 | 9.0 | R |

| 170 | 17.0 | 7.1 | DP | 23.1 | 11.8 | DP | 23.8 | 9.0 | R |

| 180 | 18.8 | 7.2 | DP | 28.7 | 14.4 | R | 21.6 | 7.6 | R |

| 190 | 20.8 | 7.3 | DP | 36.3 | 14.4 | R | 25.3 | 8.8 | DP |

| 200 | 22.7 | 7.4 | DP | 44.0 | 14.4 | R | 27.7 | 8.9 | DP |

| Thermal Efficiency Optimized | |||||||||

| 100 | 2.6 | 8.1 | R | 0.1 | 10.1 | R | 0.1 | 9.1 | R |

| 110 | 4.8 | 8.6 | R | 0.2 | 11.5 | R | 3.2 | 9.8 | R |

| 120 | 6.8 | 9.0 | R | 0.1 | 12.7 | R | 6.1 | 10.4 | R |

| 130 | 8.8 | 9.4 | R | 0.4 | 13.7 | R | 8.8 | 10.9 | R |

| 140 | 10.6 | 9.7 | R | 3.0 | 14.5 | R | 11.5 | 11.2 | R |

| 150 | 12.5 | 10.0 | R | 6.1 | 15.4 | R | 14.0 | 11.6 | R |

| 160 | 14.2 | 10.2 | R | 12.1 | 16.1 | R | 16.5 | 11.9 | R |

| 170 | 15.9 | 10.4 | R | 17.7 | 16.7 | R | 18.9 | 12.2 | R |

| 180 | 17.6 | 10.6 | R | 23.0 | 17.2 | R | 21.2 | 12.4 | R |

| 190 | 19.3 | 10.8 | R | 28.1 | 17.7 | R | 23.5 | 12.6 | R |

| 200 | 20.9 | 10.9 | R | 33.0 | 18.1 | R | 25.8 | 12.8 | R |

| R1234yf | R1234ze(E) | R1234ze(Z) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Heat Source Temperature (°C) | S | R | DP | S | R | DP | S | R | DP |

| Net Power Optimized | |||||||||

| 100 | 0.80 | 1.11 | 0.92 | 0.78 | 1.11 | 0.84 | 0.80 | 1.09 | 0.90 |

| 110 | 0.62 | 0.64 | 0.74 | 0.60 | 0.81 | 0.67 | 0.62 | 0.80 | 0.72 |

| 120 | 0.51 | 0.52 | 0.64 | 0.49 | 0.64 | 0.56 | 0.51 | 0.62 | 0.60 |

| 130 | 0.46 | 0.47 | 0.58 | 0.42 | 0.52 | 0.49 | 0.42 | 0.51 | 0.52 |

| 140 | 0.43 | 0.44 | 0.53 | 0.36 | 0.43 | 0.43 | 0.38 | 0.43 | 0.47 |

| 150 | 0.49 | 0.50 | 0.49 | 0.32 | 0.37 | 0.39 | 0.35 | 0.39 | 0.43 |

| 160 | 0.50 | 0.54 | 0.46 | 0.29 | 0.33 | 0.35 | 0.34 | 0.36 | 0.40 |

| 170 | 0.39 | 0.38 | 0.44 | 0.26 | 0.29 | 0.32 | 0.44 | 0.46 | 0.38 |

| 180 | 0.37 | 0.36 | 0.42 | 0.24 | 0.26 | 0.30 | 0.43 | 0.43 | 0.36 |

| 190 | 0.36 | 0.34 | 0.40 | 0.22 | 0.24 | 0.28 | 0.30 | 0.30 | 0.35 |

| 200 | 0.35 | 0.32 | 0.38 | 0.22 | 0.23 | 0.27 | 0.29 | 0.28 | 0.33 |

| Thermal Efficiency Optimized | |||||||||

| 100 | 0.96 | 1.45 | 1.02 | 9.78 | 63.74 | 1.64 | 8.80 | 47.16 | 1.61 |

| 110 | 0.68 | 0.88 | 0.76 | 6.52 | 35.54 | 1.41 | 0.81 | 1.21 | 0.84 |

| 120 | 0.57 | 0.68 | 0.64 | 9.38 | 66.72 | 1.17 | 0.56 | 0.71 | 0.61 |

| 130 | 0.51 | 0.57 | 0.57 | 3.72 | 15.75 | 0.99 | 0.47 | 0.55 | 0.53 |

| 140 | 0.46 | 0.50 | 0.53 | 5.14 | 1.36 | 0.90 | 0.42 | 0.47 | 0.47 |

| 150 | 0.43 | 0.45 | 0.49 | 0.51 | 0.72 | 0.50 | 0.38 | 0.41 | 0.44 |

| 160 | 0.41 | 0.41 | 0.46 | 0.36 | 0.43 | 0.40 | 0.35 | 0.37 | 0.40 |

| 170 | 0.39 | 0.38 | 0.44 | 0.30 | 0.34 | 0.34 | 0.33 | 0.34 | 0.38 |

| 180 | 0.37 | 0.36 | 0.42 | 0.27 | 0.30 | 0.31 | 0.32 | 0.32 | 0.36 |

| 190 | 0.36 | 0.34 | 0.40 | 0.25 | 0.27 | 0.29 | 0.30 | 0.30 | 0.35 |

| 200 | 0.35 | 0.32 | 0.38 | 0.23 | 0.25 | 0.27 | 0.29 | 0.28 | 0.33 |

| R1234yf | R1234ze(E) | R1234ze(Z) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Heat Source Temperature (°C) | S | R | DP | S | R | DP | S | R | DP |

| Net Power Optimized | |||||||||

| 100 | 6.0 | 8.3 | 6.9 | 5.8 | 8.3 | 6.2 | 5.9 | 8.2 | 6.7 |

| 110 | 4.7 | 4.8 | 5.6 | 4.5 | 6.1 | 5.0 | 4.6 | 6.0 | 5.4 |

| 120 | 3.8 | 3.9 | 4.8 | 3.7 | 4.8 | 4.2 | 3.8 | 4.7 | 4.5 |

| 130 | 3.4 | 3.5 | 4.3 | 3.1 | 3.9 | 3.7 | 3.2 | 3.8 | 3.9 |

| 140 | 3.2 | 3.3 | 4.0 | 2.7 | 3.2 | 3.2 | 2.8 | 3.2 | 3.5 |

| 150 | 3.7 | 3.8 | 3.7 | 2.4 | 2.8 | 2.9 | 2.6 | 2.9 | 3.3 |

| 160 | 3.8 | 4.0 | 3.5 | 2.2 | 2.5 | 2.7 | 2.5 | 2.7 | 3.0 |

| 170 | 2.9 | 2.8 | 3.3 | 2.0 | 2.2 | 2.5 | 3.3 | 3.5 | 2.9 |

| 180 | 2.8 | 2.7 | 3.1 | 1.8 | 2.0 | 2.3 | 3.2 | 3.3 | 2.7 |

| 190 | 2.7 | 2.5 | 3.0 | 1.7 | 1.8 | 2.1 | 2.3 | 2.3 | 2.6 |

| 200 | 2.6 | 2.4 | 2.9 | 1.6 | 1.7 | 2.0 | 2.2 | 2.1 | 2.5 |

| Thermal Efficiency Optimized | |||||||||

| 100 | 7.1 | 10.8 | 7.6 | 70.3 | 481.5 | 12.1 | 63.4 | 355.6 | 11.9 |

| 110 | 5.1 | 6.6 | 5.7 | 47.0 | 268.1 | 10.4 | 6.0 | 9.1 | 6.2 |

| 120 | 4.3 | 5.1 | 4.8 | 67.4 | 504.4 | 8.6 | 4.2 | 5.4 | 4.6 |

| 130 | 3.8 | 4.3 | 4.3 | 26.9 | 118.5 | 7.3 | 3.5 | 4.1 | 4.0 |

| 140 | 3.5 | 3.8 | 4.0 | 37.1 | 10.2 | 6.7 | 3.1 | 3.5 | 3.5 |

| 150 | 3.3 | 3.4 | 3.7 | 3.8 | 5.4 | 3.8 | 2.9 | 3.1 | 3.3 |

| 160 | 3.1 | 3.1 | 3.5 | 2.7 | 3.2 | 3.0 | 2.7 | 2.8 | 3.0 |

| 170 | 2.9 | 2.8 | 3.3 | 2.3 | 2.6 | 2.5 | 2.5 | 2.6 | 2.9 |

| 180 | 2.8 | 2.7 | 3.1 | 2.0 | 2.2 | 2.3 | 2.4 | 2.4 | 2.7 |

| 190 | 2.7 | 2.5 | 3.0 | 1.9 | 2.0 | 2.2 | 2.3 | 2.3 | 2.6 |

| 200 | 2.6 | 2.4 | 2.9 | 1.8 | 1.9 | 2.0 | 2.2 | 2.1 | 2.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fontalvo, A.; Solano, J.; Pedraza, C.; Bula, A.; Gonzalez Quiroga, A.; Vasquez Padilla, R. Energy, Exergy and Economic Evaluation Comparison of Small-Scale Single and Dual Pressure Organic Rankine Cycles Integrated with Low-Grade Heat Sources. Entropy 2017, 19, 476. https://doi.org/10.3390/e19100476

Fontalvo A, Solano J, Pedraza C, Bula A, Gonzalez Quiroga A, Vasquez Padilla R. Energy, Exergy and Economic Evaluation Comparison of Small-Scale Single and Dual Pressure Organic Rankine Cycles Integrated with Low-Grade Heat Sources. Entropy. 2017; 19(10):476. https://doi.org/10.3390/e19100476

Chicago/Turabian StyleFontalvo, Armando, Jose Solano, Cristian Pedraza, Antonio Bula, Arturo Gonzalez Quiroga, and Ricardo Vasquez Padilla. 2017. "Energy, Exergy and Economic Evaluation Comparison of Small-Scale Single and Dual Pressure Organic Rankine Cycles Integrated with Low-Grade Heat Sources" Entropy 19, no. 10: 476. https://doi.org/10.3390/e19100476