1. Introduction

A gas turbine is a type of combustion engine, which usually comprises an upstream compressor, a downstream turbine, and a combustion chamber in between. The design of a high performance gas turbine is a key technology in modern industry due to its significant applications in aircraft, electrical generators, and ships.

Compared to reciprocating engines, gas turbines have the advantages of a higher power-weight ratio, a smaller volume, lower toxic emissions, etc. However, the efficiency of gas turbines is usually lower than that of reciprocating engines. Generally, the efficiency of a gas turbine can be improved by increasing the pressure ratio [

1] and reducing the engine weight [

2]. However, according to the second law of thermodynamics, the efficiency of a gas turbine is ultimately determined by the irreversibility in its flow and temperature field. For example, if a gas turbine has a pressure ratio of 20, its efficiency according to an ideal Brayton cycle is about 60%, whereas the efficiency even for a modern gas turbine is no more than 40%. A gas turbine may be combined with a steam plant to form a “combined cycle” system. In recent years, the efficiency of the gas turbine combined cycle system’s power generation has been increased to 60% [

3]. However, this only increases the system’s overall efficiency, while the efficiency of the gas turbine is not really improved. The key to improving the efficiency of a gas turbine still lies in how to reduce the losses due to irreversibility.

In an ideal gas turbine, the working gases follow the Brayton cycle, which is composed of the procedures of isentropic compression, isobaric (constant pressure) combustion, isentropic expansion, and isobaric heat rejection: see the cycle 0–1–2–3–0 in

Figure 1. The efficiency for the ideal Brayton cycle is:

where

and

are the heat generation and release rates in the processes of isobaric combustion (1–2) and isobaric heat rejection (3–0).

However, irreversibility occurs in a real gas turbine. The T-S diagram for a real Brayton cycle is indicated by 0–1’–2’–3’–0 in

Figure 1, in which only the irreversibility of the compression (0–1’) and expansion (2’–3’) processes are taken into account. The efficiency of the real Brayton cycle is

When the compressor and the turbine are considered to be adiabatic, the entropy will increase in processes 0–1’ and 2’–3’ due to irreversibility, leading to higher entropy at state 3’ than at state 3. As a result, the heat release in process 3’–0 is larger than in the ideal cycle (3–0), i.e., . Thus, the efficiency of a real gas turbine is always lower than that of an ideal one.

The

second-law analysis (SLA) is a very helpful tool for understanding these irreversible processes. In the SLA, irreversibility in both flow and temperature fields are accounted for. However, the SLA was usually used for analyzing a thermal system, while the detailed flow and temperature fields were traditionally studied within the disciplines of fluid mechanics and heat transfer, in which the SLA still has not received much attention. Entropy almost never appears in the text books of fluid dynamics and heat transfer: see [

4,

5] as examples. This concept is ignored perhaps due to the reason that the irreversibility effect is considered to be not important in these two disciplines. However, turbulent flow and heat transfer are typical irreversible processes due to the dissipation in the flow field and irreversibility in the temperature fields. Another possible reason is that it is very difficult to calculate or measure the local entropy generation rate accurately due to model and experimental errors.

Some progress has been made in employing the SLA in flow and heat transfer problems since the 1980s. Bejan [

6,

7] laid the foundation with respect to analyzing and optimizing thermal systems with the SLA approach. Kock and Herwig [

8] extended this concept to a detailed analysis of turbulent flows, and identified four different mechanisms of entropy generation: dissipation in a mean and fluctuating velocity field and heat flux in a mean and fluctuating temperature field. Later, Kock and Herwig [

9] developed equations for computing entropy generation rates for

Reynolds Averaged Navier–Stokes Simulations (RANSs) and implemented them into

computational fluid dynamics (CFD) codes. Jin and Herwig [

10] indicated that model errors in RANS simulations may lead to considerable uncertainties in entropy generation results.

With the development of high performance computers in recent years, people have started to calculate the losses in blade cascades from RANS results. Orhan [

11] investigated the loss mechanism of an axial turbine cascade with the SLA. Denton and Pullan [

12] and Zlatinov et al. [

13] analyzed the local entropy generation rate in turbines with unsteady RANSs. However, Kopriva et al. [

14,

15] found that RANSs have much lower accuracy than large eddy simulations (LESs). Tucker [

16,

17] indicated that it is particularly difficult to predict unsteady separations in turbines with RANSs. As a compromise between the computational cost and the accuracy, Lin et al. [

18] studied the local entropy generation in a turbine cascade passage with a delayed detached eddy simulation (DDES) method. The losses in both flow and temperature fields were visualized according to the numerical results. With the same method, Wang et al. [

19] analyzed the interaction between the corner separation and wakes in a compressor cascade. The detailed coherent structures, local losses information, and turbulence characteristics were identified according to the local entropy generation rate. Despite this progress, more systematic studies are still required for understanding the irreversible processes in gas turbines. In particular, the relationship between local entropy generation and global efficiency should be better understood.

In the present paper, we attempt to investigate several fundamental concepts with respect to the SLA of the irreversible processes in gas turbines. Entropy and exergy transport equations for compressible flows in a rotating frame will be derived in

Section 2. Through the derivation, we will show the relationship between the SLA and the other laws in fluid mechanics. In

Section 3, we will discuss the dimensionless coefficients for assessing irreversible processes in a gas turbine. The concepts of

exergy transformation efficiency and

exergy transformation number will be introduced. CFD modeling for calculating the local entropy generate rate density will be discussed in

Section 4. A test case for applying the developed theories will be provided in

Section 5. The conclusions are given in

Section 6.

2. The Entropy and Exergy Transport Equations for Compressible Flows in a Rotating Frame

The governing equations for the flows in a cascade passage or the combustion chamber are the compressible Navier–Stokes and energy equations. The equations in a rotating frame were adopted, and thus they can be also used for the flows in rotors. The governing equations [

20,

21] read:

The chemical reaction in the combustion chamber is not considered here for simplicity, while the combustion heat is accounted for by the heat exchange at the boundary walls. The reference frame rotates with the angular velocity of . The value of is zero when a stationary frame is under consideration. The reference frame velocity is , where is the displacement from the axis to the position vector . If is selected as the axis, we have . is the component of the body acceleration rate vector , in which the Coriolis and centrifugal forces are taken into account.

, , , and are the density, frame velocity component, relative velocity component, temperature, and thermal conductivity, respectively. The relative total energy and enthalpy are calculated by and , respectively. is the anisotropic part of the viscous stress tensor, where the strain rate .

Multiplying Equation (4) with

and considering

, the transport equation of the relative kinetic energy

can be derived:

where

. Subtracting Equation (6) from Equation (5), the transport equation of the enthalpy can be obtained, i.e.,

Substituting Equation (7) into the fundamental equation of thermodynamics , the entropy equation can be derived, i.e.,

The irreversibility is due to the last two terms in Equation (8), which are always positive. They are called the entropy generation rate density in the temperature field

and in the flow field

. Their definitions are:

For an open system, the total differential of exergy of a gas is , where is the environmental temperature, is the specific exergy of a gas, and is the total kinetic energy. The transport equation of can be obtained from Equation (4), i.e.,

Substituting Equations (7), (8), and (10) into the total derivative of exergy, the balance equation of exergy can be obtained, i.e.,

Equations (8) and (11) were derived for compressible flows in a rotating frame, but they can also be used for incompressible flows in a non-rotating frame when is a constant and is zero.

Integrating Equations (8) and (11) in a volume under consideration, e.g., a cascade passage or the combustion chamber, the integral forms of the entropy and exergy equations can be obtained. They are:

where

is the overall entropy generation rate in domain

,

is the direction vector of a surface element,

is the exchange of entropy due to heat transfer at the boundary,

is the shaft work when a rotor is accounted for, and

is the increase of exergy due to heat transfer. When the compressor and turbine are assumed to be adiabatic,

is non-zero only in the combustion chamber.

Equation (12) shows that the entropy will always increase or remain constant in an isolated system in which and are zero. The corresponding destruction of exergy according to Equation (13) is . This is accordance with the second law of thermodynamics. The derivation shows that the traditional laws in fluid mechanics and heat transfer are sufficient for satisfying the second law of thermodynamics. It is not necessary to solve the entropy or exergy equations in numerical simulations. The entropy generation rate can be calculated as post processing of the numerical results.

3. Dimensionless Coefficients for Assessing Irreversible Processes

The bulk quantitates , , , and can be calculated by the statistics of the local flow quantities , , , and , respectively. For example, the bulk temperature is calculated by , where is the cross section under consideration. The mass flow rate is . The losses in a certain process step, such as in a cascade passage, can be evaluated with these bulk quantities.

The loss in a cascade passage was traditionally evaluated by the

enthalpy loss coefficient [

22], which is defined by:

where

is the rate of specific enthalpy, and the subscripts “

” and “

” denote the outlet and isentropic process, respectively. The superscript * denotes the stagnation value.

In a real application, instead of Equation (14), it is more convenient to use the

stagnation pressure loss coefficient [

22] instead of

to indicate the loss, i.e.,

where the subscript “

” denotes the inlet. Obviously, the irreversibility due to heat transfer is not taken into account in Equations (14) and (15). However, as shown in

Figure 1, the increase of entropy due to heat transfer will also reduce the efficiency of a gas turbine. The losses in a cascade can be more accurately assessed by the SLA. Denton [

23] suggested the use of an

entropy loss coefficient to indicate the loss of efficiency in a cascade, i.e.,

where

is the entropy generation rate in a cascade under consideration. The losses of exergy due to irreversibility are more accurately assessed by Equation (16) than by Equation (15). However, the contribution of the cascade to the output work is not taken into account by Equation (16). According to Equation (16), the optimized blade cascades should have low loading and work at a small incidence angle, thus the entropy generation can be minimized. This conflicts with some real applications in which higher loading blade cascades which work at higher incidence angles are preferred.

In order to assess the irreversible processes in gas turbines more comprehensively, we adopted and further developed the concepts of

entropic potential and

energy devaluation number, which have been proposed by Herwig and his colleagues [

24,

25,

26] in recent years. According to these studies, the entropic potential is defined by the entropy generation rate by which the entropy of the ambient is increased when the

primary energy rate

becomes part of its internal energy, i.e.,

where

is the environmental temperature. The amount of the

entropic potential rate of

that is consumed by the process step

i under consideration can be determined by the

energy devaluation number, which is defined by

More details can be found in [

24,

25,

26].

In a gas turbine, the

primary energy is the exergy

which is obtained in the combustion chamber in process 1’–2’.

was derived and defined in Equation (13). In order to simplify its calculation, we approximate the local wall temperature

in the combustion chamber with the bulk temperature

in the cross section which is enclosed by the wall surface. Thus, the

primary energy can be calculated by

where

is the exergy obtained in the combustion chamber, and

is the mass flow rate.

Time averaging and summing up the integral exergy equations (Equation (13)) of all the processes in a gas turbine and dividing it with

, we have

as the chain of energy devaluation and transportation. In this chain,

is the

energy devaluation number of process

i defined by Equation (18). The exergy obtained in the combustion chamber

is devaluated by

, transformed to shaft work by

, or transported to the environment by

.

occurs in process

(see

Figure 1) due to the release of heat, which is not a real loss of exergy and this part of exergy can be (totally by an ideal process and partly by a real process) regained through a gas turbine combined cycle (GTCC) power generation system. Thus, the exergy transformed by the gas turbine is

. Multiplying Equation (20) with

, we may define the

exergy transformation efficiency of a gas turbine by:

indicates the fraction of the heat which can be transformed to exergy. is higher than defined by Equation (2) by .

is influenced by both the entropy generation rate

in each process step

i and its contribution to

. Thus, we may define the

exergy transformation number of process step

i by:

where

is the contribution of process

i to

. That is to say, although all of the exergy

is obtained in the combustion chamber, the combustion chamber is not the only contributor to

. The compressor upstream also has important effects on

.

When of each process is known, we have as the chain of exergy transformation. In a gas turbine, we use , , and to denote the exergy transformation numbers of turbine cascade i, compressor cascade i, and the combustion chamber.

of turbine cascade i is determined only by the entropy generation rate in it, i.e.,

Compressor cascade

i may have two opposite effects on exergy transformation. On the one hand, similar to a turbine cascade, the exergy is destroyed due to entropy generation. On the other hand, the exergy obtained in the combustion chamber is increased due to the increase of the temperature and the pressure through the compressor cascade. Under this consideration,

is calculated by

where

is the entropy generation rate in compressor cascade

i, and

is the contribution of compressor cascade

i to the exergy obtained in the combustion chamber

.

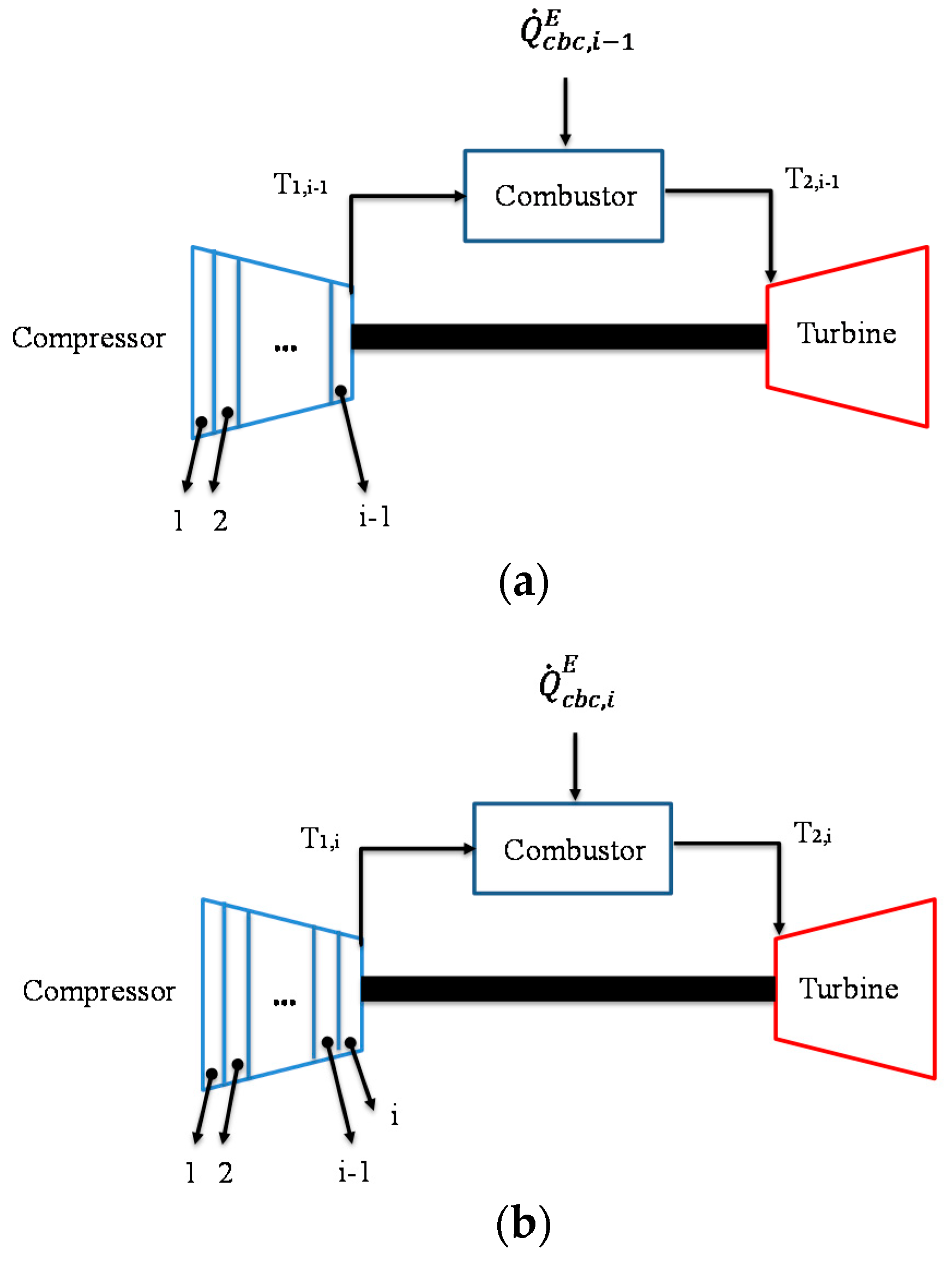

Figure 2 shows the influence of compressor cascade

i on the exergy obtained in the combustion chamber schematically: the static temperature is increased from

to

through compressor cascade

i. The potential exergy that can be obtained in the combustion chamber through a reversible process is increased from

to

.

and

are the temperature at the exit of the combustion chamber when the temperature at the inlet of the combustion chamber is

and

, respectively. Thus, the contribution of compressor cascade

i to

is calculated by

with

and

being determined according to the first law of thermodynamics, by

When an ideal gas with a constant capacity is taken into account, Equations (25) and (26) can be simplified to

of the combustion chamber is calculated by

where

is the entropy generation rate in the combustion chamber, and

is the increase of exergy in the combustion chamber without the upstream compressor through a reversible process. It is calculated by

where

is the compressor inlet temperature (state 0 is indicated in

Figure 1), and

is temperature at the exit of the combustion chamber when the inlet temperature of the combustion chamber is

. Obviously, we have

.

When the efficiency coefficients of all the processes are known, we have

as a chain of exergy transformation. The

exergy transformation number can be used to assess an isolated process step, since only local flow and temperature fields are needed to calculate its value.

5. A Test Case of Application

As an example for applying the concepts developed in

Section 2,

Section 3 and

Section 4, we analyzed the turbulent flow in an isolated compressor cascade which was taken from the experimental database of [

28] with a RANS method. Through this low cost test case, we will show how to analyze the numerical results with the concepts developed in

Section 2,

Section 3 and

Section 4.

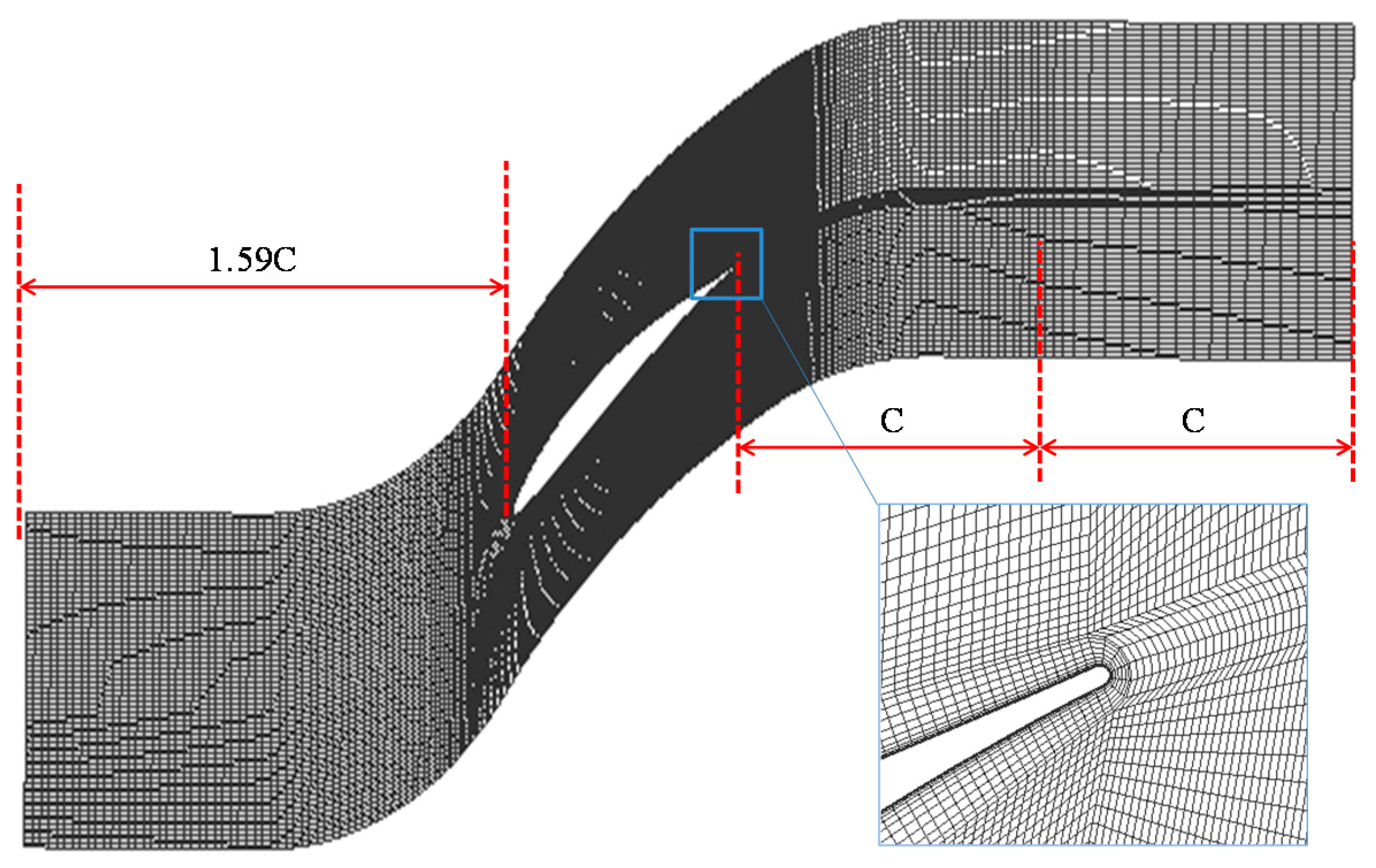

The computational domain is half of the cascade passage. The geometric parameters of the cascade are shown in

Table 1. In order to reduce the boundary effects, the inlet and outlet regions were extended by 1.59

C and 2

C, respectively, where

C is the length of the chord. The velocity profile at the inlet was given according to the experimental data in [

28]. The time and surface averaged inlet velocity

and turbulent intensity are 40 ms

−1 and 0.8%, respectively. The turbulent intensity was calculated by

, where

is the inlet turbulent kinetic energy. The inlet-specific dissipation rate

is

s

−1. Four incidence angles were accounted for in the present study. They are 0°, 2°, 4°, and 7°. Since the flow is at a small velocity (the Mach number is smaller than 0.3), the fluid in the cascade is assumed to be incompressible with the constant density of 1.217 kg m

−3.

The flow was assumed to be quasi-steady. The following steady Reynolds averaged Navier–Stokes equations were solved during the simulation:

The eddy viscosity

was calculated with the k-ω

Shear-Stress Transport (SST) turbulence model [

29].

An open source CFD software, OpenFoam v16.06+, was used to carry out the simulation. PimpleFoam was selected as the computational solver. This solver is based on a pressure correction method for incompressible flows. The second-order upwind scheme was used for spatial discretization. Body-fitted mesh, which concentrates near the wall, was adopted in the study. The dimensionless mesh spacing

of the first grid point near the wall is ensured to be smaller than 1 to resolve the turbulent boundary layer. The mesh in the region close to the cascade’s trailing edge was refined to capture the corner separation. The mesh in a cross section is shown in

Figure 3. A typical mesh has about 5.8 million grid points. The mesh independence study was performed to ensure the results are mesh resolution independent. More computational details can be found in [

30].

The entropy generation in the temperature field was neglected in the present test case, since it is much smaller than the one in the flow field. The global static temperature at the inlet and outlet were approximated according to the ideal gas law, i.e., . The specific gas constant is 287.1 J kg−1 K−1. Since the density is a constant, the global temperature is proportional to the global static pressure.

The entropy generation rate density in the flow field

was calculated with Equations (31) and (35). When Equation (31) is adopted, the turbulent dissipation rate

must be determined corresponding to the specific turbulent model. For the k-ω SST turbulence model in use,

is calculated by

where

is the constant used in the k-ω SST turbulence model. It is determined empirically according to experimental and DNS data. Reference [

28] suggests its value to be 0.09.

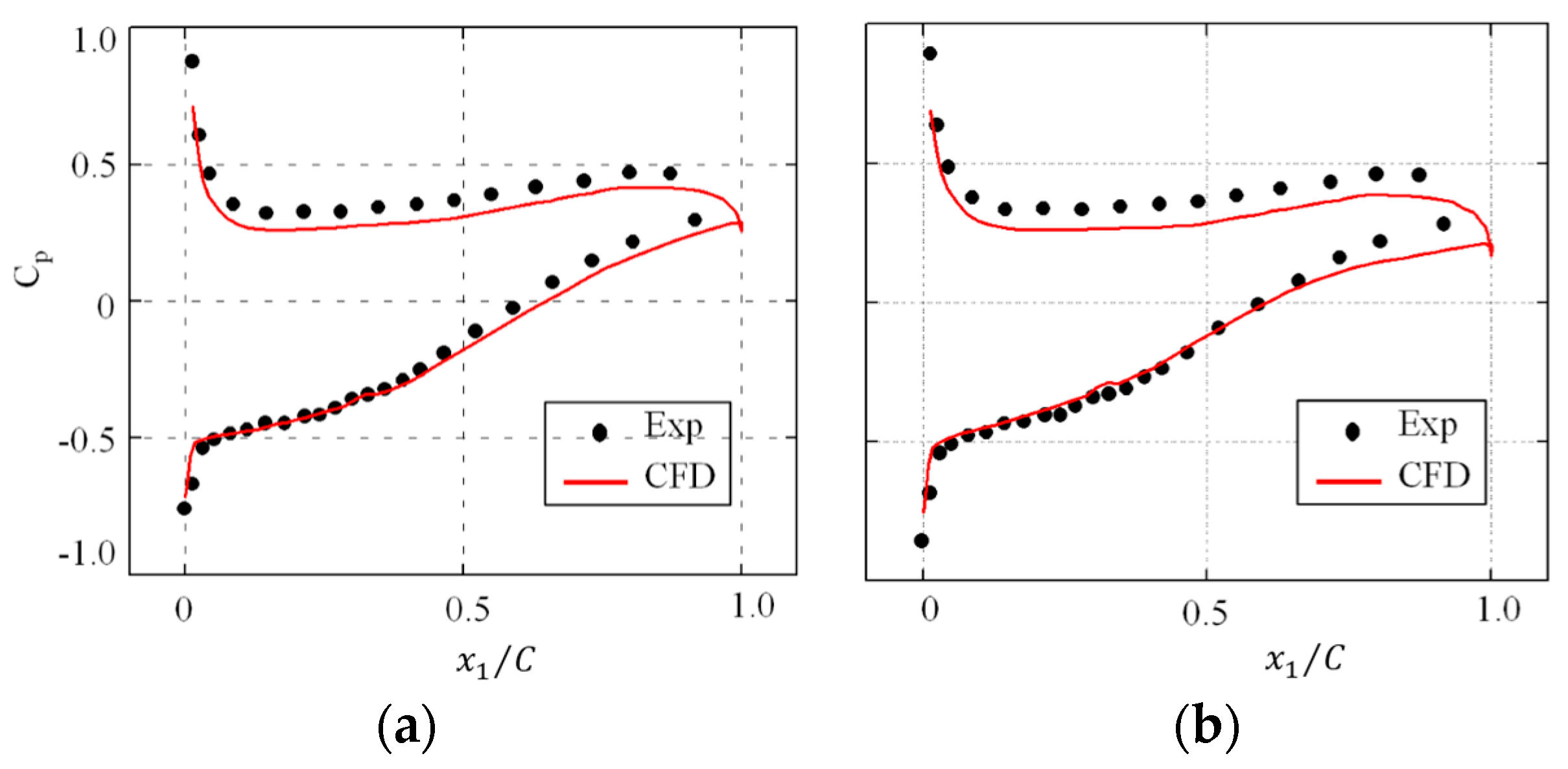

The static pressure coefficient

at two sections (

and 29.7%) are shown in

Figure 4. The gap between the current CFD results and the experimental data in [

28] is due to the model error. The accuracy can be further improved by using more accurate CFD methods, e.g., the large eddy simulation (LES) method. However, the current low cost CFD method is sufficient for the purpose of this study, i.e., demonstrating how to analyze cascade flows with the developed concepts.

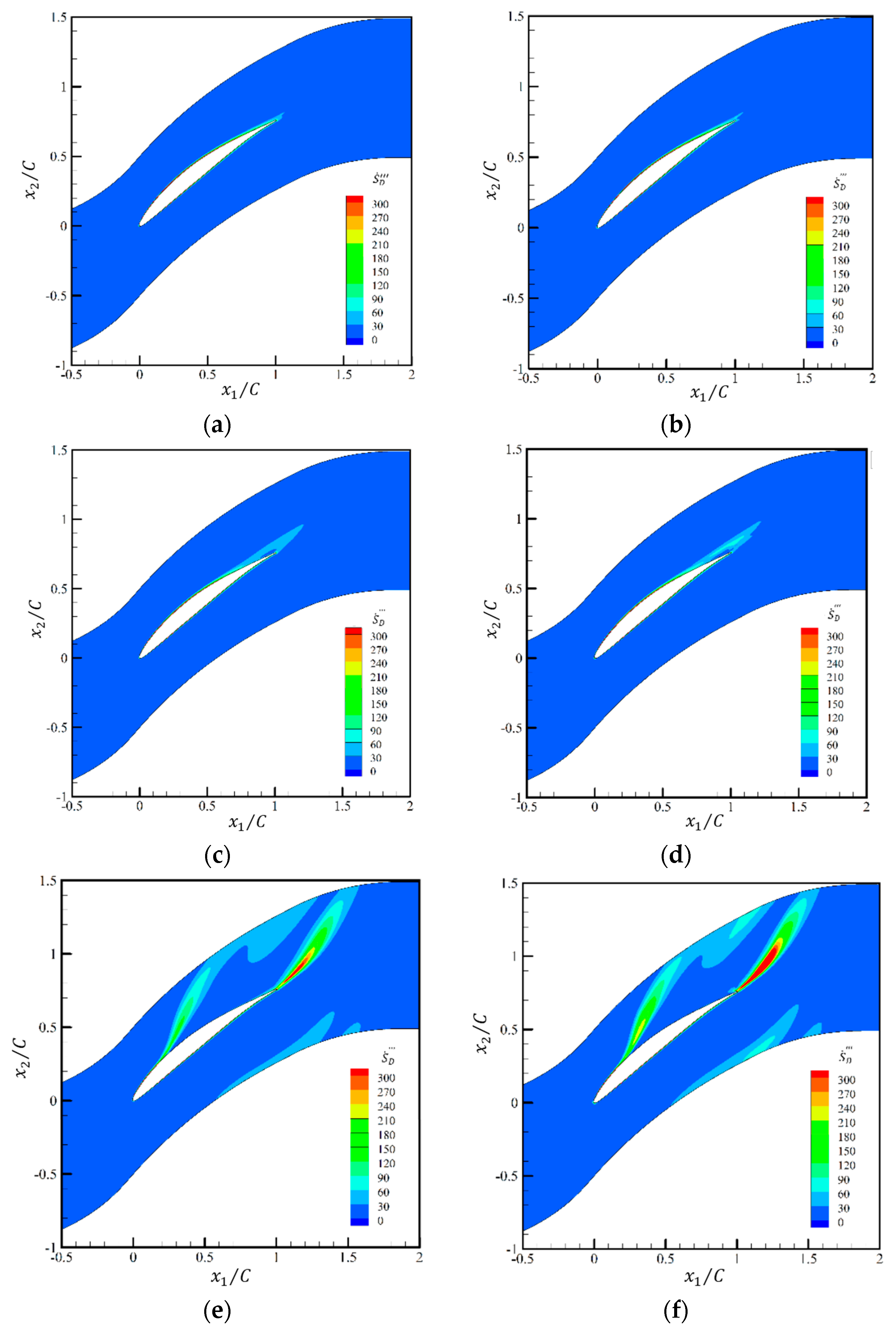

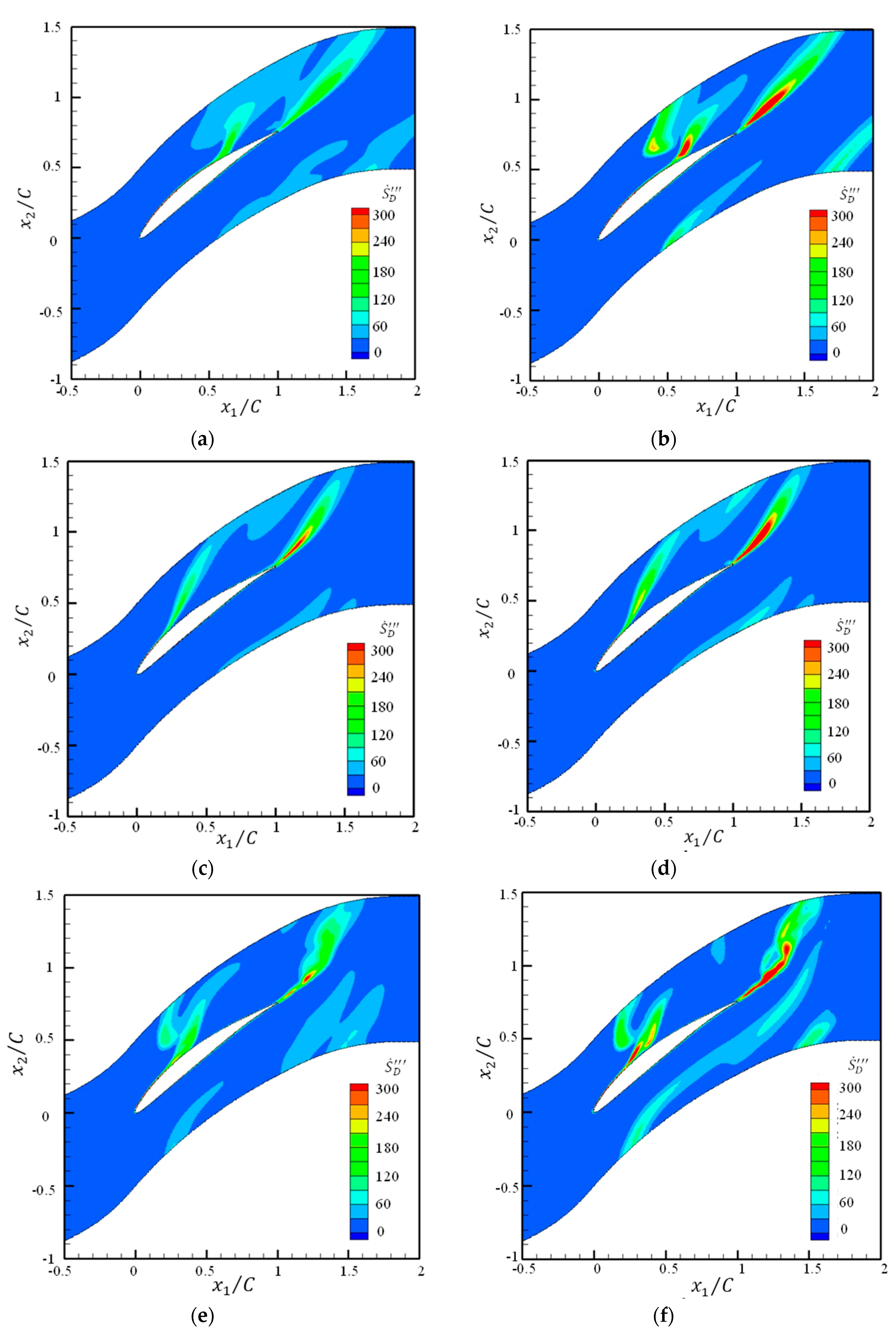

Both model results at the incidence angle of 4° are shown in

Figure 5, which indicates that the two models predict similar patterns of entropy generation.

close to the hub is stronger according to Equation (35) (see

Figure 5f) than Equation (31) (see

Figure 5e), since the turbulence production is stronger than the turbulence dissipation in this region. In other words, not all of the produced turbulence is dissipated locally. Similar phenomena can be found at other incidence angles: see

Figure 6. However, according to our assumption, the turbulence production is in balance with the turbulence dissipation when the domain size is sufficiently large. This assumption was validated by our numerical results: the volume-integrated entropy generation rates by Equations (31) and (35) can be found in

Table 2, which are almost identical. Compared with Equation (31), Equation (35) is more general and is independent of turbulence models.

In the current test case, we are only able to compare the entropy generation rate in the flow field since the energy equation was not solved. More systematic studies, e.g., cascade flows at high Mach numbers, are still required to validate the equivalence between Equation (32) and Equation (36). Besides the entropy generation rates, the other integral quantities for calculating the dimensionless coefficients are also provided in

Table 2.

Fluid properties in the combustion chamber, including the specific combustion heat

, the heat capacity

, and the environmental temperature

, are required to determine the

local exergy transformation number , which is defined by Equation (24). The values of these parameters are shown in

Table 3.

The global coefficients

,

, and

according to the RANS results are shown in

Table 4. Both the

total pressure loss coefficient and the

entropy loss coefficient indicate that losses in the cascade increase with the incidence angle. However, the exergy transformation coefficient

suggests that the optimal incidence angle is

, at which cascade works with the best overall performance: although more losses due to irreversibility occur at

than at

, a larger pressure ratio is obtained through the cascade, which increases the potential exergy obtained in the combustion chamber

.

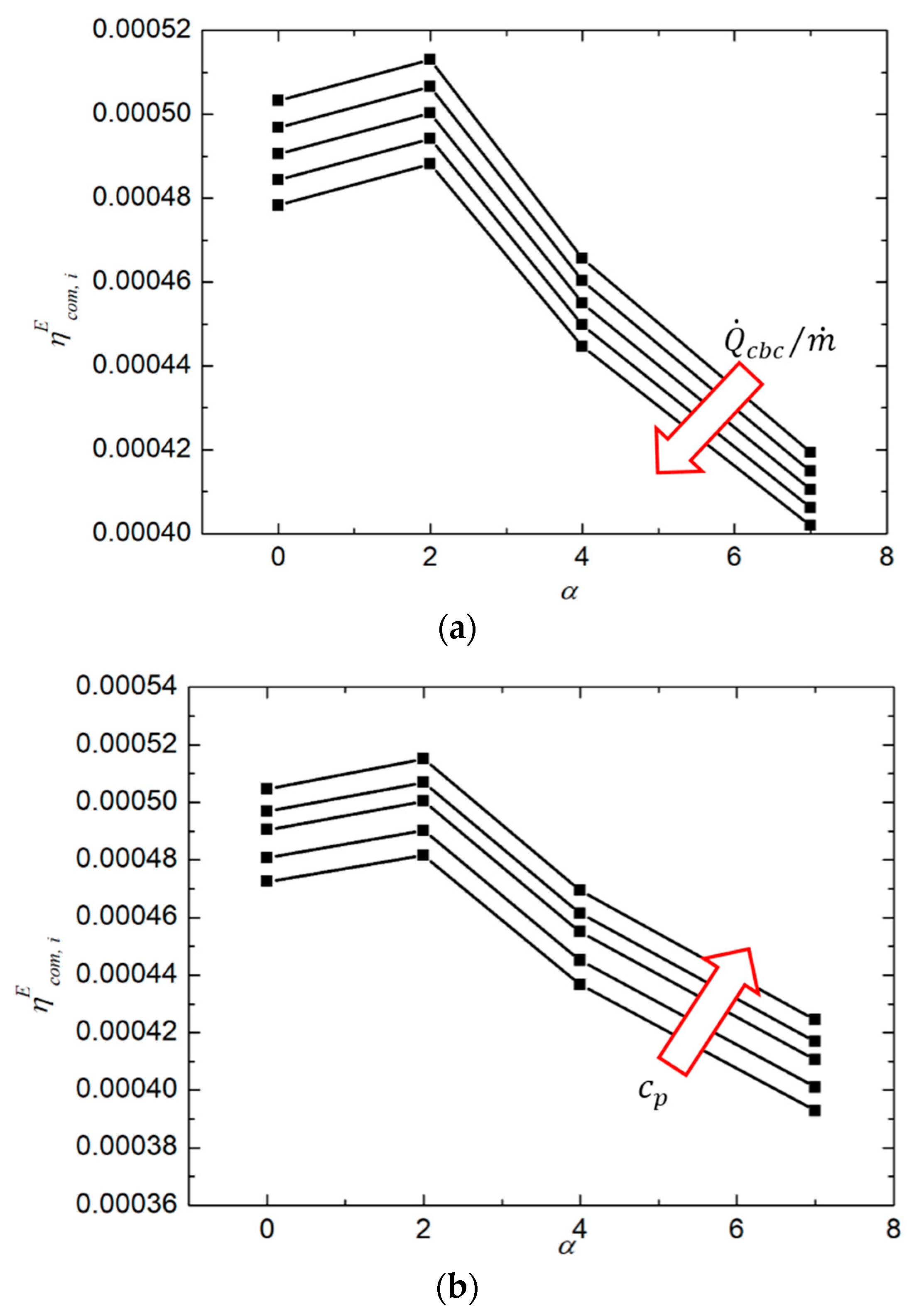

The exergy transformation number

is linearly related with the environmental temperature

, thus

does not influence the optimal results.

Figure 7 shows the influence of the other reference parameters

and

on

:

decreases with

and increases with

. However, the optimal results are not influenced by

and

when they are only mildly changed.

6. Conclusions

Several fundamental aspects with respect to the SLA of the turbulent flows in gas turbines were discussed in this study.

Entropy and exergy equations (Equations (8) and (11)) for compressible/incompressible flows in a rotating/non-rotating frame were derived. The derivation shows that the Navier–Stokes equations and the energy equation are sufficient to satisfy the second law of thermodynamics, thus it is not necessary to solve the entropy and exergy equations to evaluate their quantities. The entropy and exergy can be determined by the post processing of CFD simulations. However, the entropy and exergy equations and their budgets are helpful tools for analyzing the irreversible processes in gas turbines.

The exergy transformation efficiency of a gas turbine as well as the exergy transformation number of a single process step were proposed in this study. in a turbine cascade, a compressor cascade, or the combustion chamber are suggested to be calculated by Equations (23), (24), or (28). The value of indicates the overall effects of an irreversible process, including its destruction of exergy and its contribution to the potential exergy obtained in the combustion chamber. can be used to assess the performance of an isolated process in a gas turbine, since only local flow and temperature fields are required to calculate its value.

The methods for calculating the local entropy generation rate densities were discussed. It was suggested to use turbulence production rates (Equations (35) and (36)) instead of the turbulence dissipation rates (Equations (31) and (32)) to calculate the local entropy generation rate densities. The assumption behind this approximation is that the turbulence production rate is in balance with the turbulence dissipation rate when the domain is sufficiently large. An advantage of Equations (35) and (36) is that they are independent from the choices of turbulence models. However, more systematic studies, e.g., LESs of cascade flows at high Mach numbers, are still required to further validate these equations.

A test case with respect to a compressor cascade has been employed for applying the concepts developed in the study. The numerical results show that the entropy generation rates calculated by Equations (35) and (31) are almost identical. The exergy transformation number suggests an optimal incidence angle at which the compressor cascade works with the best overall performance.