Analysis and Optimization of Trapezoidal Grooved Microchannel Heat Sink Using Nanofluids in a Micro Solar Cell

Abstract

:1. Introduction

2. Computational Procedure

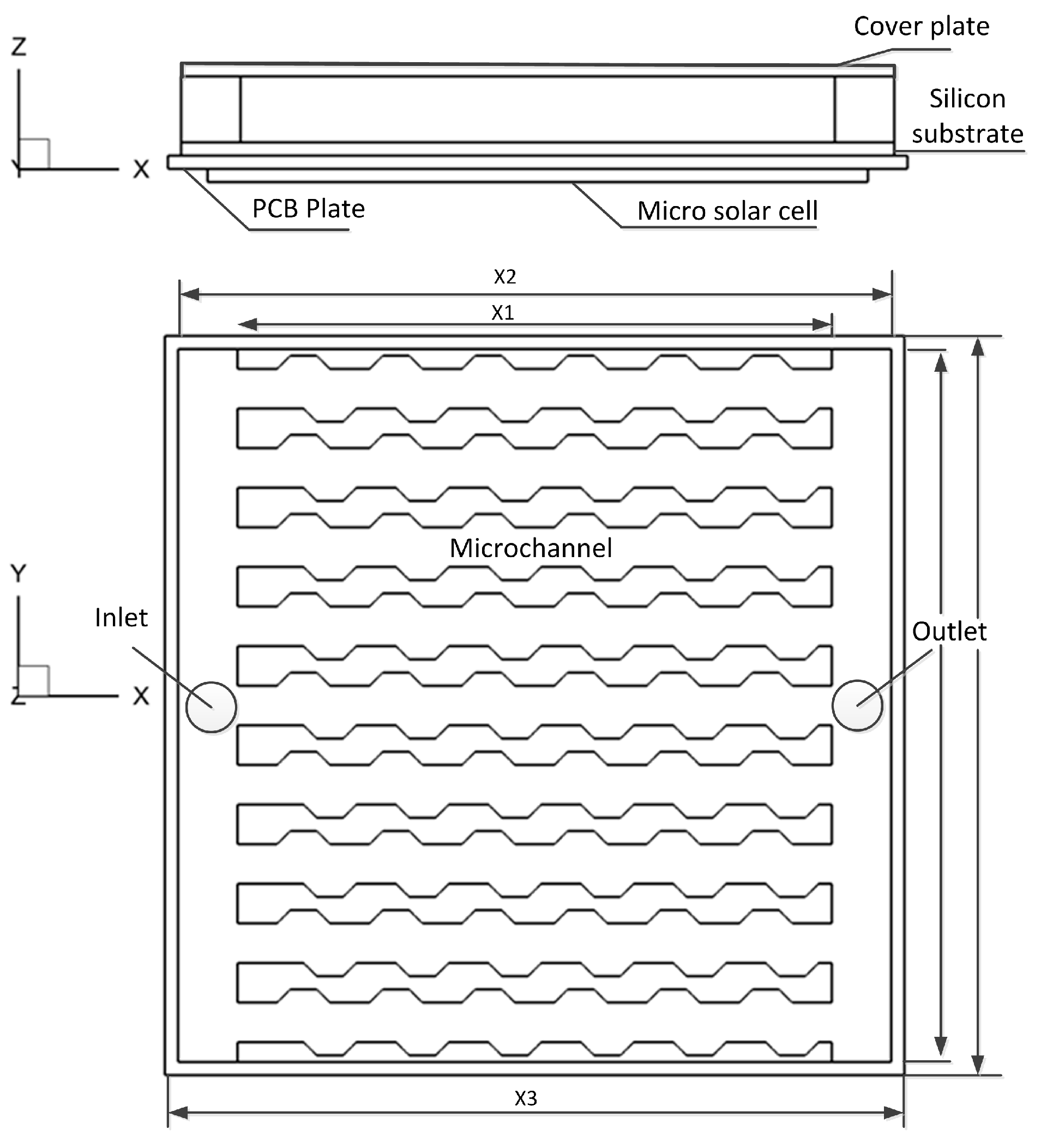

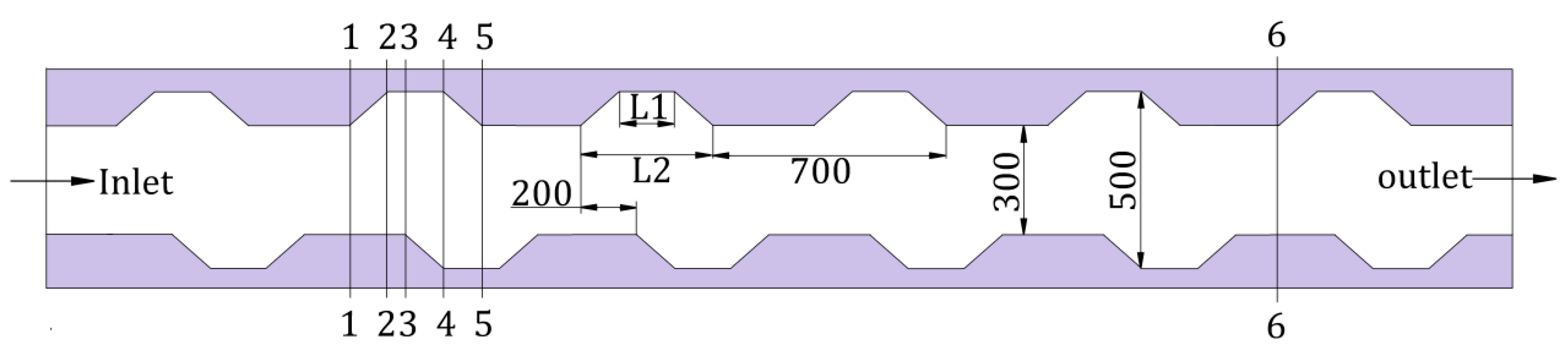

2.1. Geometrical Model

2.2. Numerical Model

2.2.1. Control Equations

2.2.2. Physical Properties of Nanofluids

2.2.3. Performance Evaluation Criterion

2.3. Solving the Numerical Model

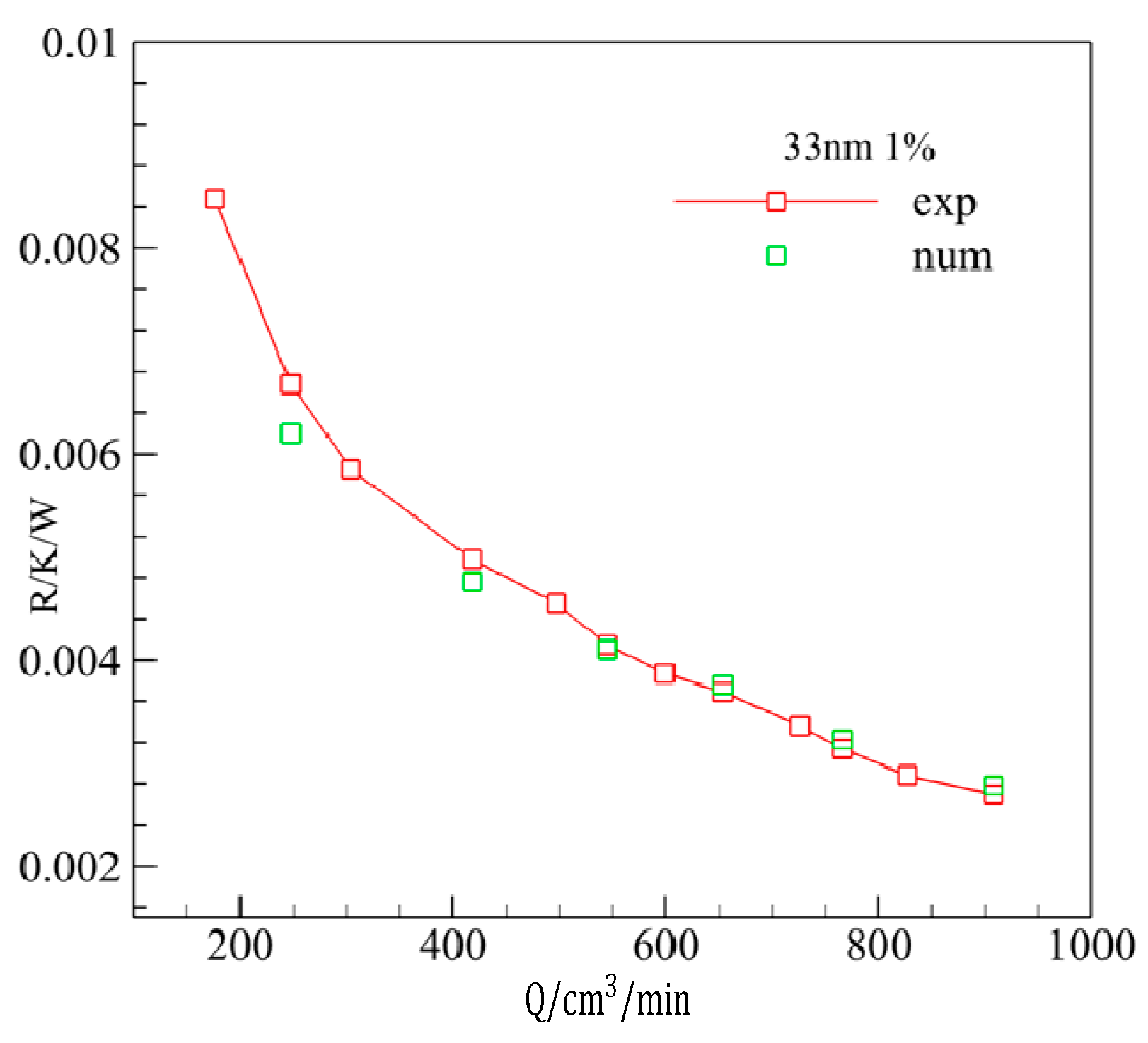

2.4. Model Validity

3. Results and Discussion

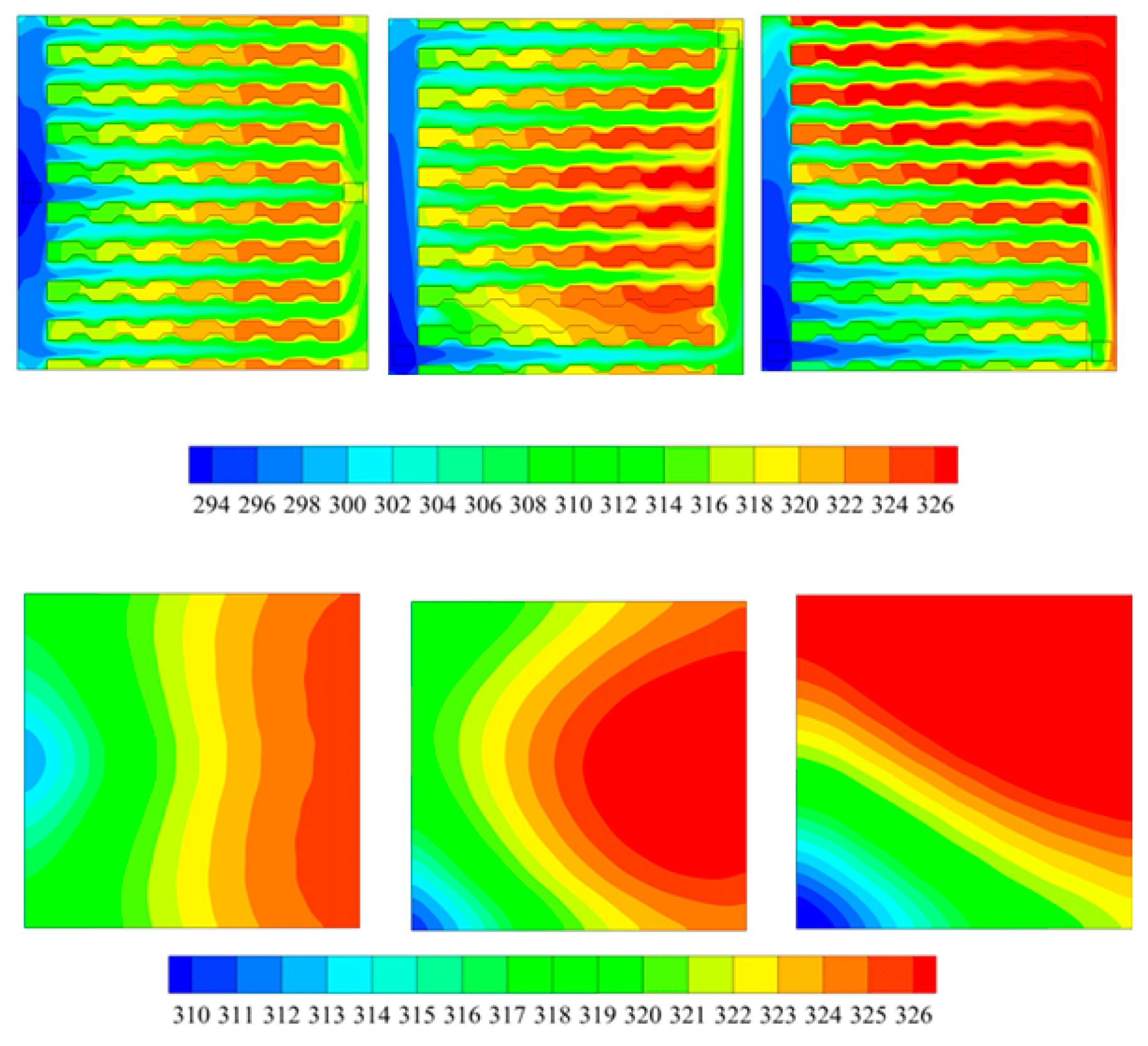

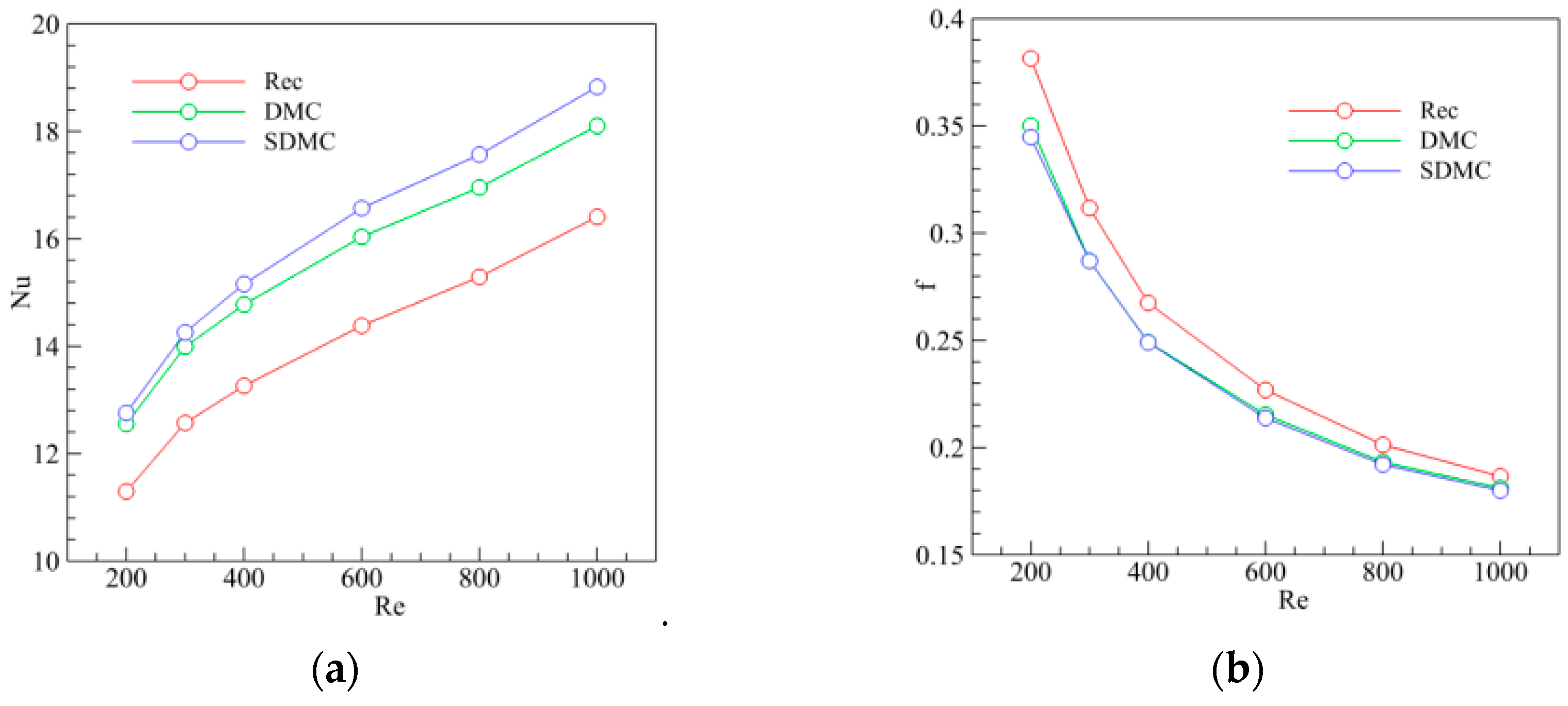

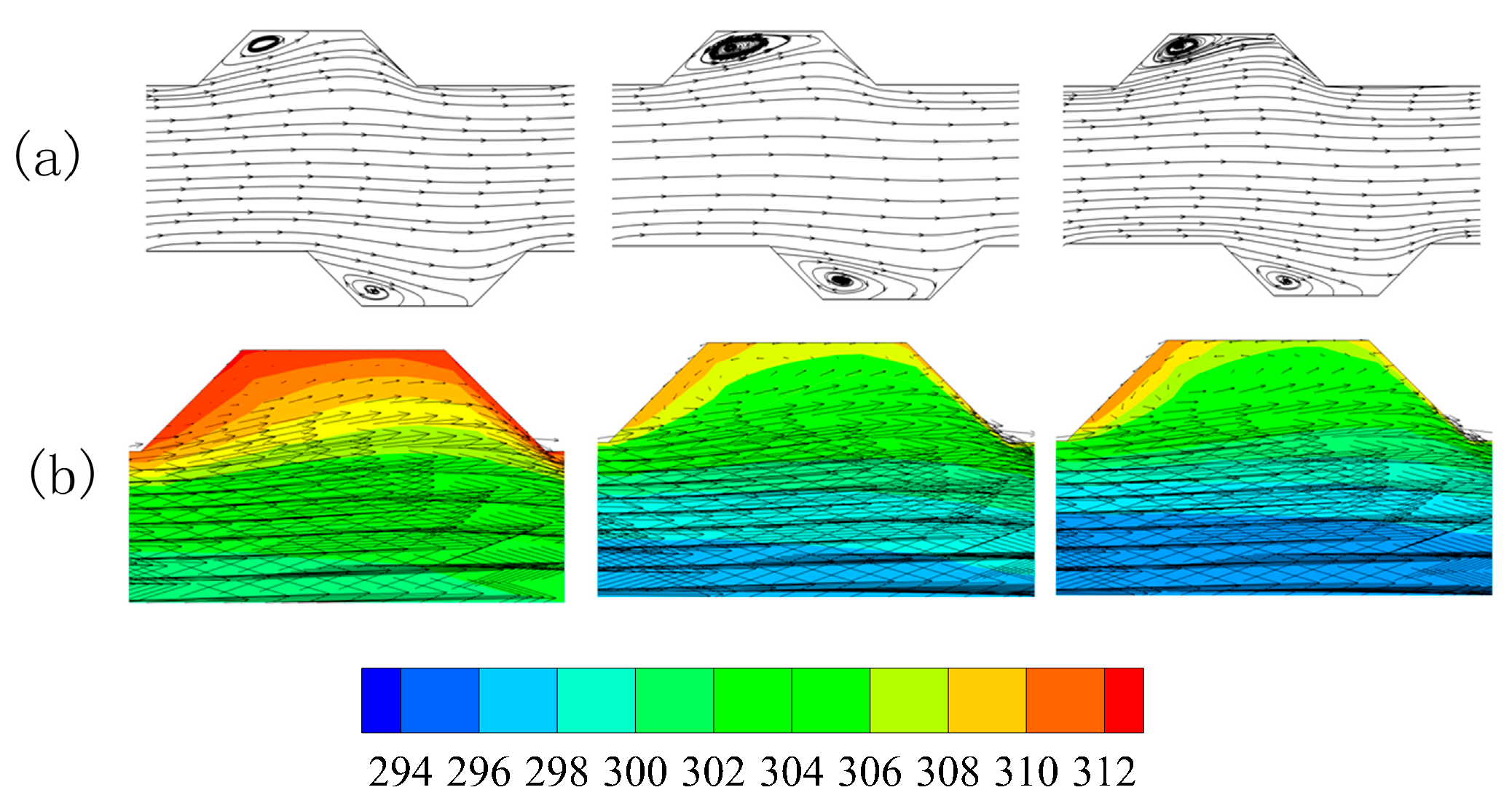

3.1. Effect of the Layout

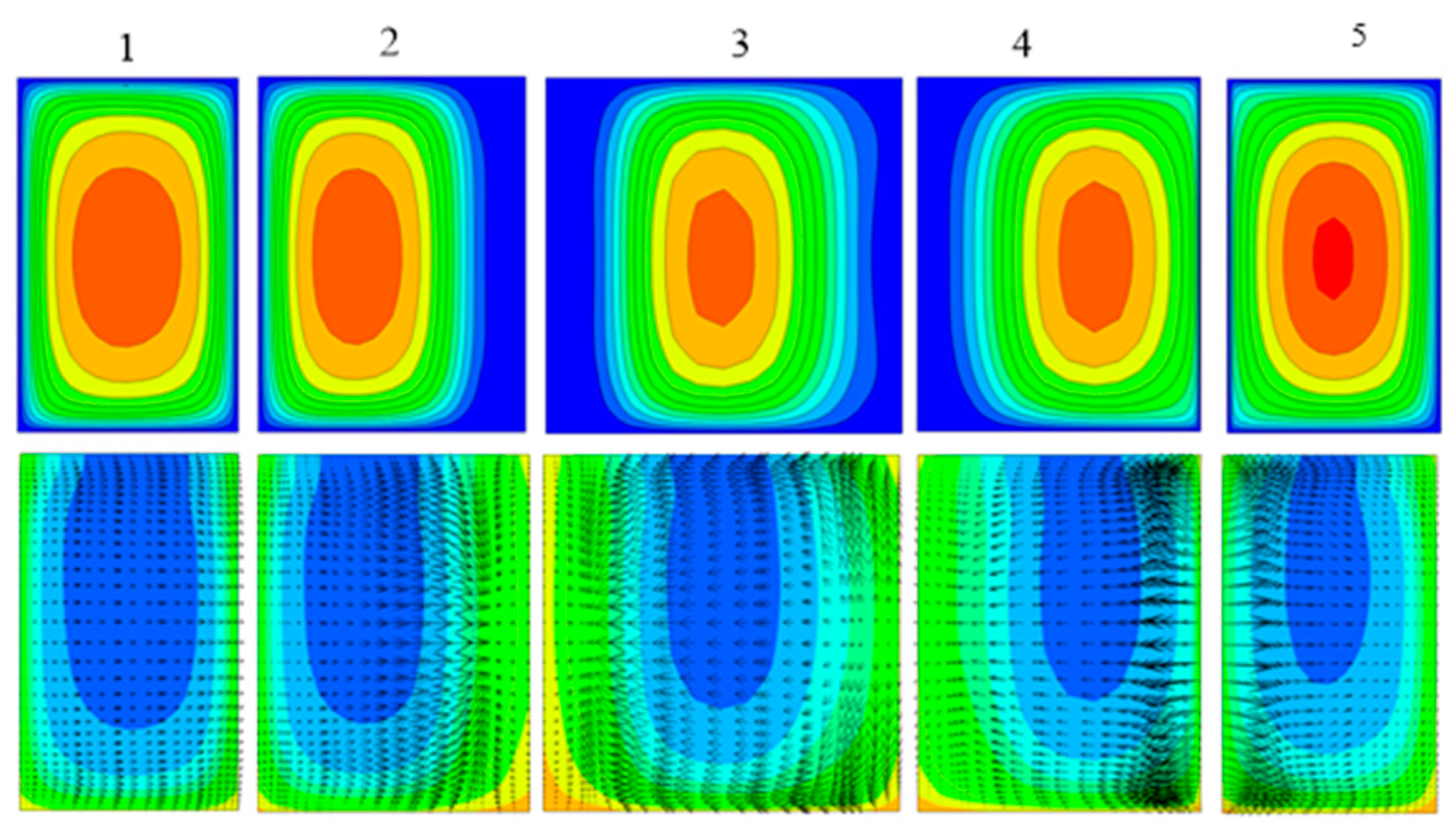

3.2. Effect of Trapezoidal Groove

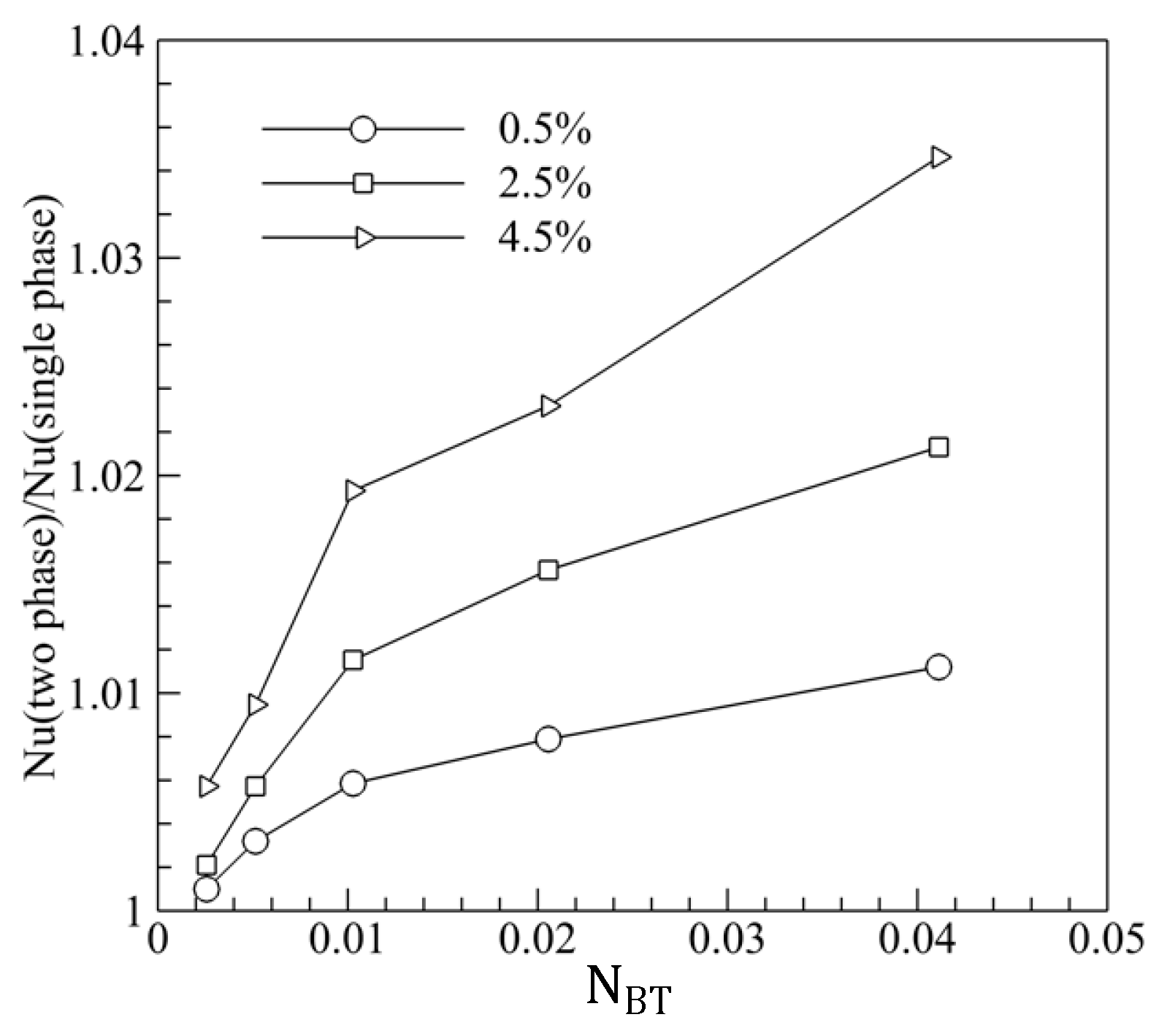

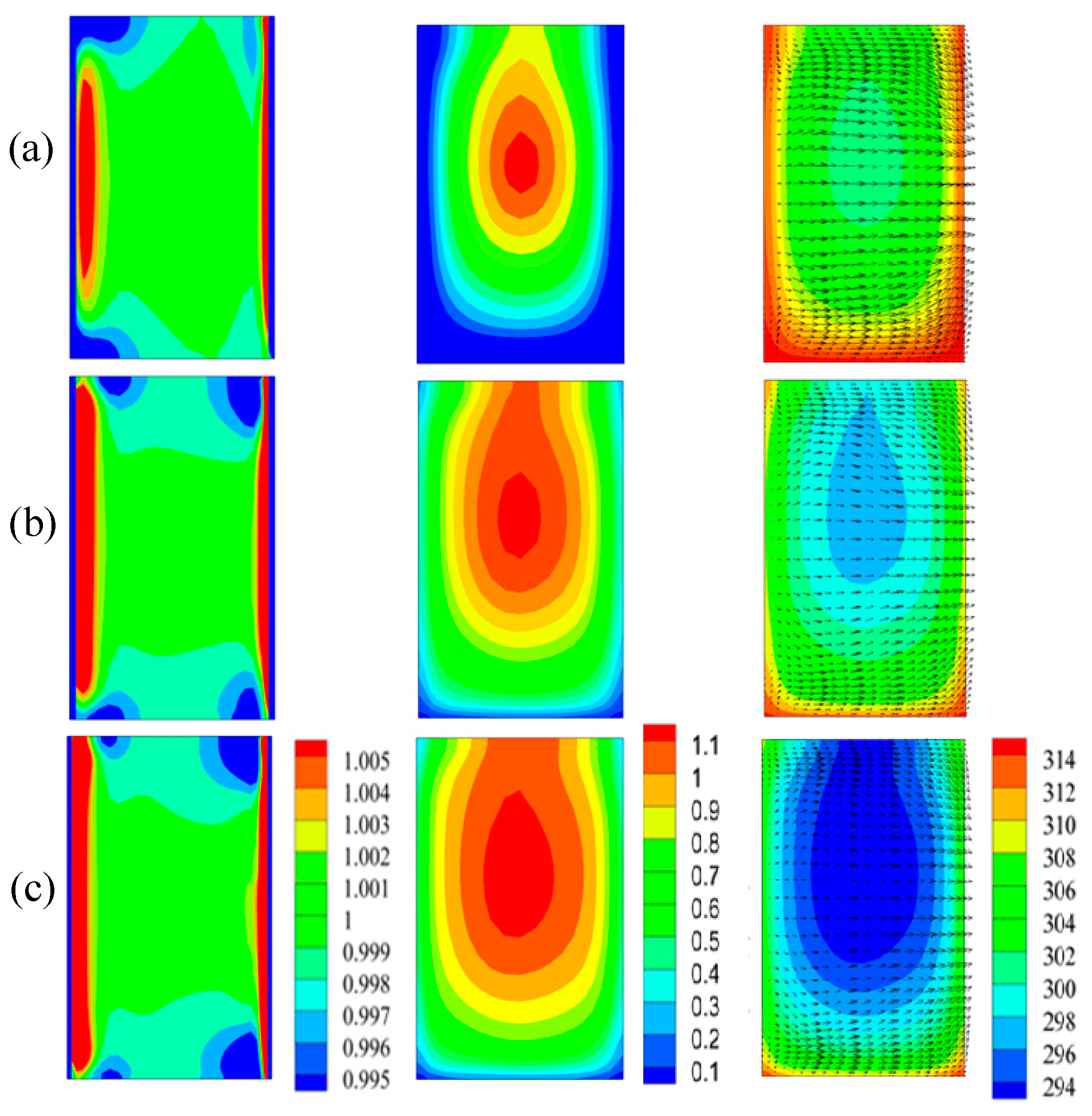

3.3. Discussion on the Relation of Brownian and Thermophoretic Diffusion

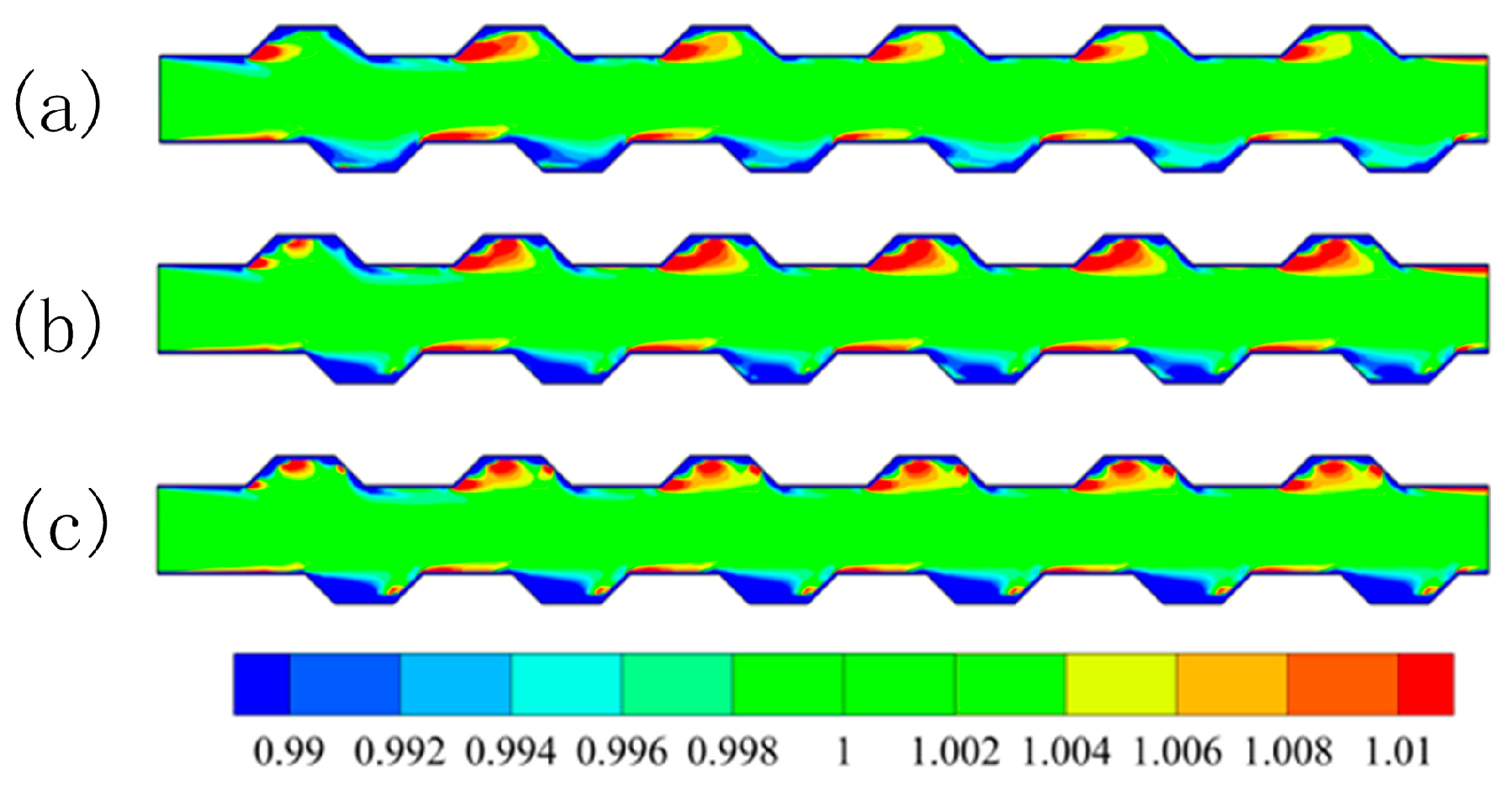

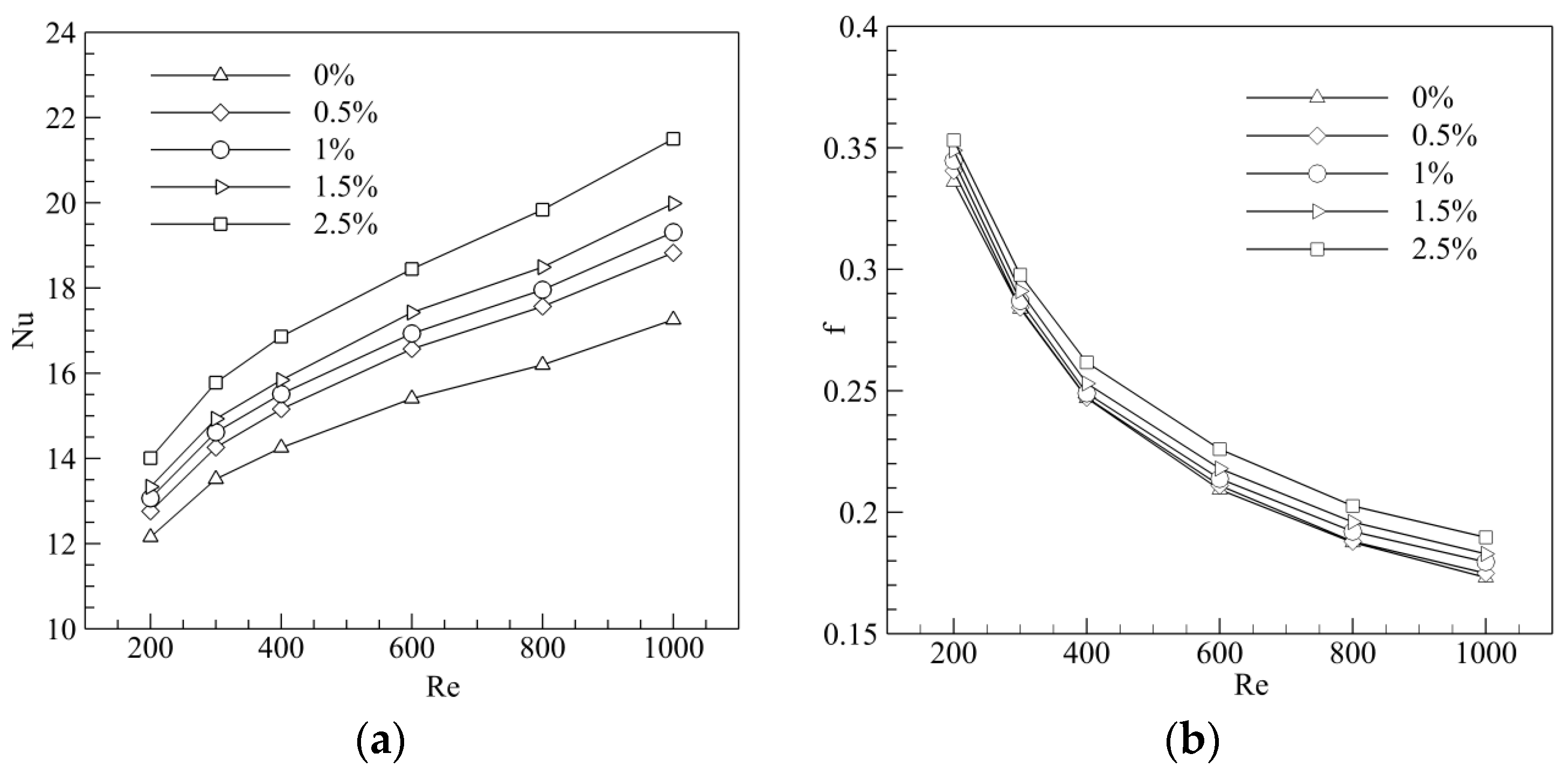

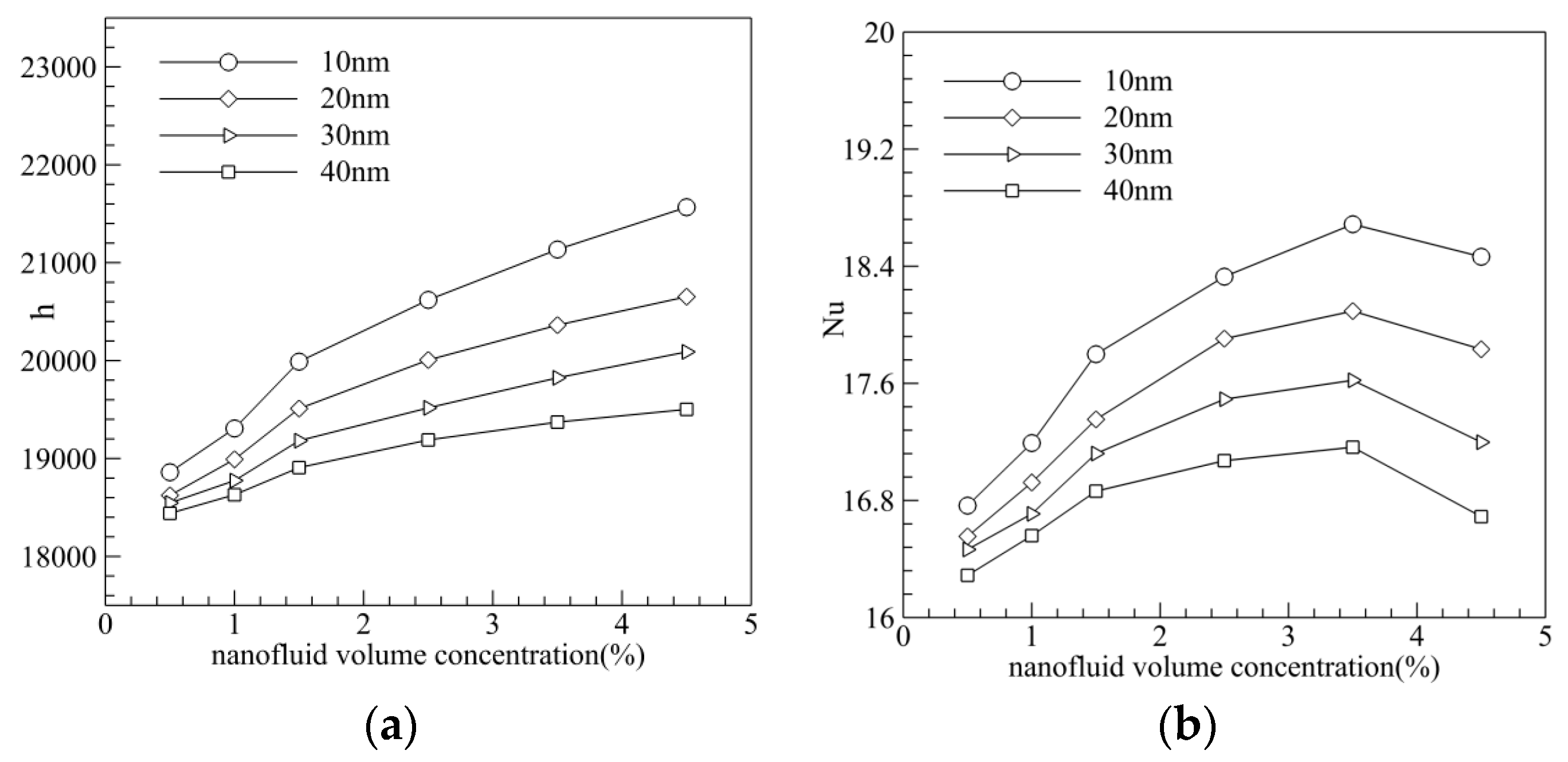

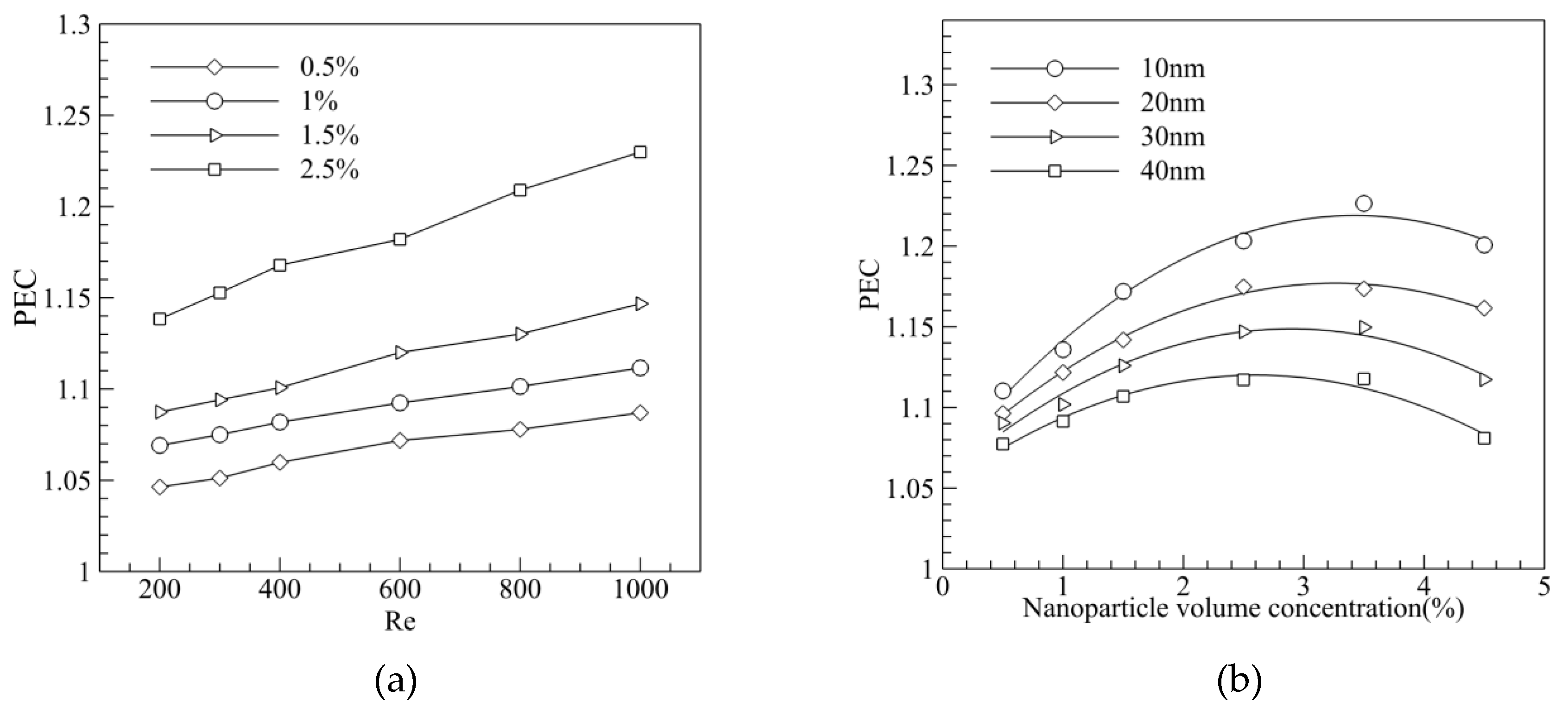

3.4. Impacting Factors on the Thermal Performance of MCHS

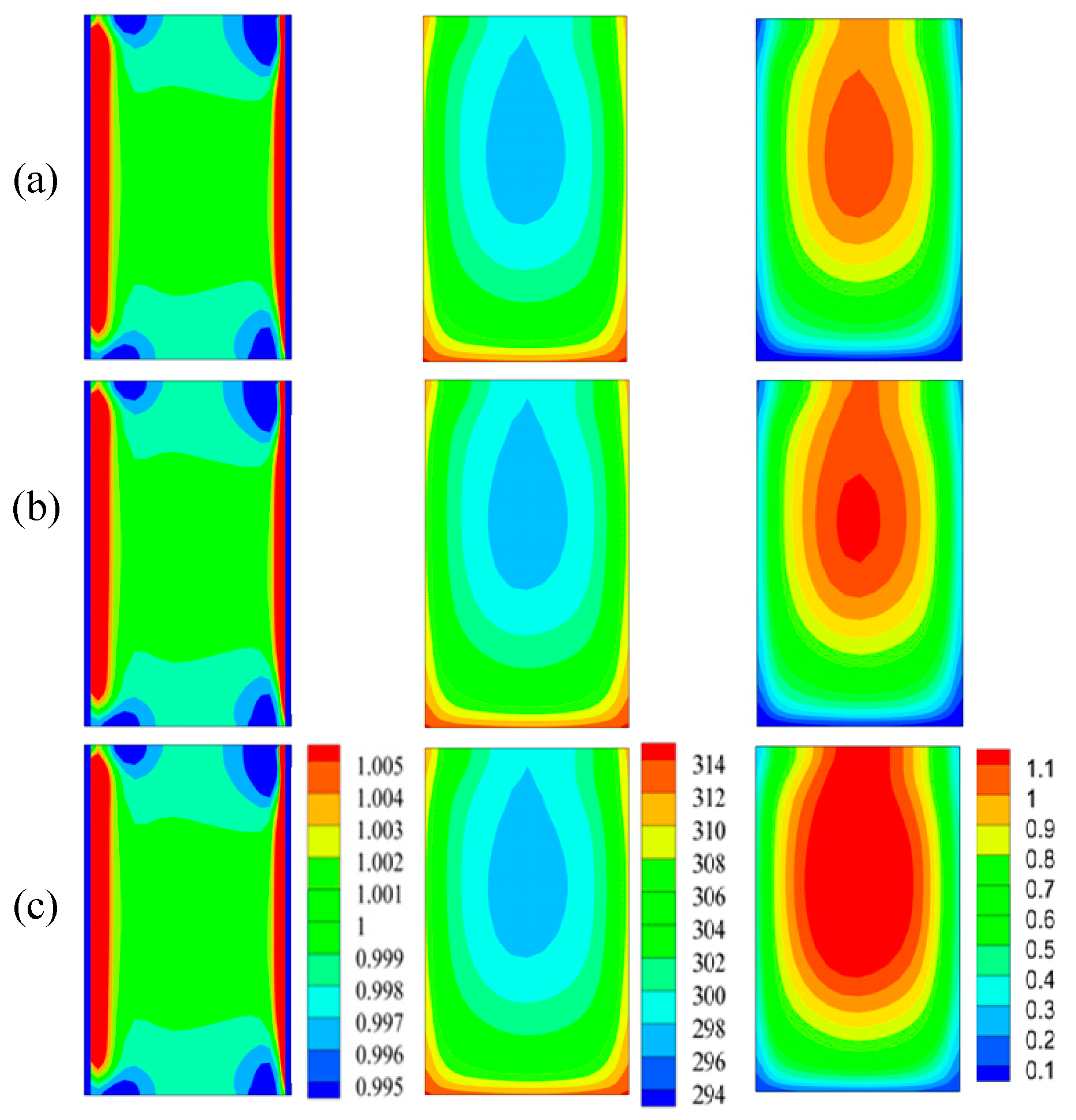

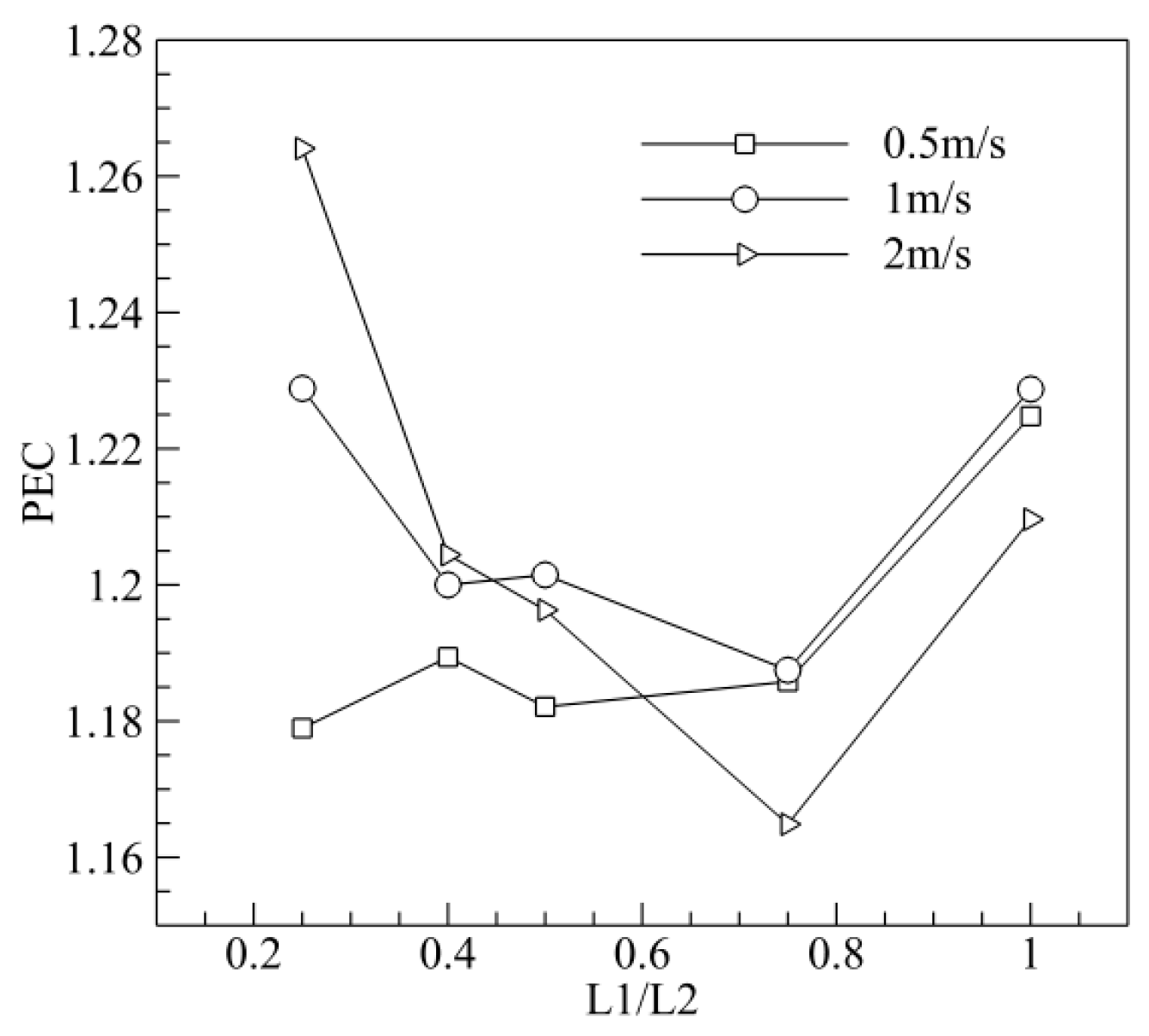

3.5. Optimization of the Structural Parameters

4. Conclusions

- (1)

- The solar cell with I-type MCHS has the most homogeneous temperature distribution on the surface compared to that with Z-type or C-type MCHS.

- (2)

- Higher heat transfer capability can be produced by a heterogeneous two-phase model than by a single-phase model. The thermal performance increases with NBT. The reason for this is that larger NBT can induce much more microconvection to enhance heat transfer by Brownian motion when the particle size is smaller. The volume fraction has no relation to NBT.

- (3)

- Thermal performance at an equal pump power as an index of heat transfer enhancement will increase with an increase in the Reynolds number and volume fraction. There is an optimum volume fraction to every particle size. A smaller optimum volume fraction corresponds to smaller particle size.

- (4)

- The heat transfer performance is the worst when the parameter of the trapezoidal groove L1/L2 is 0.75, and it should be avoided in the MCHS design.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Böer, K.W. Cadmium sulfide enhances solar cell efficiency. Energy Convers. Manag. 2011, 52, 426–430. [Google Scholar] [CrossRef]

- Han, X.; Wang, Y.; Zhu, L. The performance and long-term stability of silicon concentrator solar cells immersed in dielectric liquids. Energy Convers. Manag. 2013, 66, 189–198. [Google Scholar] [CrossRef]

- Sathe, T.M.; Dhoble, A.S. A review on recent advancements in photovoltaic thermal techniques. Renew. Sustain. Energy Rev. 2017, 76, 645–672. [Google Scholar] [CrossRef]

- Barrau, J.; Rosell, J.; Chemisana, D.; Tadrist, L.; Ibáñez, M. Effect of a hybrid jet impingement/micro-channel cooling device on the performance of densely packed PV cells under high concentration. Sol. Energy 2011, 85, 2655–2665. [Google Scholar] [CrossRef]

- Do, K.H.; Kim, T.H.; Han, Y.S.; Choi, B.I.; Kim, M.B. General correlation of a natural convective heat sink with plate-fins for high concentrating photovoltaic module cooling. Sol. Energy 2012, 86, 2725–2734. [Google Scholar] [CrossRef]

- Moharram, K.A.; Abd-Elhady, M.S.; Kandil, H.A.; El-Sherif, H. Enhancing the performance of photovoltaic panels by water cooling. Ain Shams Eng. J. 2013, 4, 869–877. [Google Scholar] [CrossRef]

- Modjinou, M.; Ji, J.; Li, J.; Yuan, W.; Zhou, F. A numerical and experimental study of micro-channel heat pipe solar photovoltaics thermal system. Appl. Energy 2017, 206, 708–722. [Google Scholar] [CrossRef]

- Rahimi, M.; Karimi, E.; Asadi, M.; Valeh-e-Sheyda, P. Heat transfer augmentation in a hybrid microchannel solar cell. Int. Commun. Heat Mass Transf. 2013, 43, 131–137. [Google Scholar] [CrossRef]

- Radwan, A.; Ahmed, M. The influence of microchannel heat sink configurations on the performance of low concentrator photovoltaic systems. Appl. Energy 2017, 206, 594–611. [Google Scholar] [CrossRef]

- Rahimi, M.; Asadi, M.; Karami, N.; Karimi, E. A comparative study on using single and multi header microchannels in a hybrid PV cell cooling. Energy Convers. Manag. 2015, 101, 1–8. [Google Scholar] [CrossRef]

- Radwan, A.; Ookawara, S.; Ahmed, M. Analysis and simulation of concentrating photovoltaic systems with a microchannel heat sink. Sol. Energy 2016, 136, 35–48. [Google Scholar] [CrossRef]

- Sidik, N.A.C.; Muhamad, M.N.A.W.; Japar, W.M.A.A.; Rasid, Z.A. An overview of passive techniques for heat transfer augmentation in microchannel heat sink. Int. Commun. Heat Mass Transf. 2017, 88, 74–83. [Google Scholar] [CrossRef]

- Ma, L.; Zhao, X.; Sun, H.; Wu, Q.; Liu, W. Experimental Study of Single Phase Flow in a Closed-Loop Cooling stem with Integrated Mini-Channel Heat Sink. Entropy 2016, 18, 128–134. [Google Scholar] [CrossRef]

- Radwan, A.; Ahmed, M.; Ookawara, S. Performance enhancement of concentrated photovoltaic systems using a microchannel heat sink with nanofluids. Energy Convers. Manag. 2016, 119, 289–303. [Google Scholar] [CrossRef]

- Yang, Y.T.; Tsai, K.T.; Wang, Y.H.; Lin, S.H. Numerical study of microchannel heat sink performance using nanofluids. Int. Commun. Heat Mass Transf. 2014, 57, 27–35. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, J.; Lei, J.; Liu, B. Effectiveness of nanofluid on improving the performance of microchannel heat sink. Appl. Therm. Eng. 2016, 101, 402–412. [Google Scholar] [CrossRef]

- Karami, N.; Rahimi, M. Heat transfer enhancement in a hybrid microchannel-photovoltaic cell using Boehmite nanofluid. Int. Commun. Heat Mass Transf. 2014, 55, 45–52. [Google Scholar] [CrossRef]

- Osman, K.S.; Syed, M.Z. Efficient energy utilization through proper design of microchannel heat exchanger manifolds: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 74, 969–1002. [Google Scholar]

- Gunnasegaran, P.; Mohammed, H.; Shuaib, N.; Saidur, R. The effect of geometrical parameters on heat transfer characteristics of microchannelsheat sink with different shapes. Int. Commun. Heat Mass Transf. 2010, 37, 1078–1086. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Ahmed, M.I. Optimum thermal design of triangular, trapezoidal and rectangular grooved microchannel heat sinks. Int. Commun. Heat Mass Transf. 2015, 66, 47–57. [Google Scholar] [CrossRef]

- Lee, Y.J.; Singh, P.K.; Lee, P.S. Fluid flow and heat transfer investigations on enhanced microchannel heat sink using oblique fins with parametric study. Int. J. Heat Mass Transf. 2015, 81, 325–336. [Google Scholar] [CrossRef]

- Li, Q.; Xuan, Y.M. A preliminary study of the intensified thermal conductivity mechanism of nanofluid. J. Eng. Therm. Energy Power 2002, 17, 568–571. [Google Scholar]

- Xuan, Y.; Li, Q.; Hu, W. Aggregation structure and thermal conductivity of nanofluids. AIChE J. 2003, 49, 1038–1043. [Google Scholar] [CrossRef]

- Yu, W.; Choi, S.U.S. The role of interfacial layers in the enhanced thermal conductivity of nanofluids: A renovated Maxwell model. J. Nanopart. Res. 2003, 5, 167–171. [Google Scholar] [CrossRef]

- Prasher, R.; Phelan, P.E.; Bhattacharya, P. Effect of aggregation kinetics on the thermal conductivity of nanoscale colloidal solutions (nanofluids). Nano Lett. 2006, 6, 1529–1534. [Google Scholar] [CrossRef] [PubMed]

- Xiao, B.; Chen, H.; Xiao, S.; Cai, J. Research on Relative Permeability of Nanofibers with Capillary Pressure Effect by Means of Fractal-Monte Carlo Technique. J. Nanosci. Nanotechnol. 2017, 17, 6811–6817. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, W.; Fan, J.; Chen, H.; Hu, X.; Zhao, D.; Zhang, X.; Ren, W. Optimization of the fractal-like architecture of porous fibrous materials related to permeability, diffusivity and thermal conductivity. Fractals 2017, 25, 1750030. [Google Scholar] [CrossRef]

- Kalteh, M.; Abbassi, A.; Saffar-Avval, M.; Harting, J. Eulerian–Eulerian two-phase numerical simulation of nanofluid laminar forced convection in a microchannel. Int. J. Heat Fluid Flow 2011, 32, 107–116. [Google Scholar] [CrossRef]

- Mirzaei, M.; Saffar-Avval, M.; Naderan, H. Heat transfer investigation of laminar developing flow of nanofluids in a microchannel based on Eulerian-Lagrangian approach. Can. J. Chem. Eng. 2014, 92, 1139–1149. [Google Scholar] [CrossRef]

- Buongiorno, J. Convective transport in nanofluids. Heat Transf. 2006, 128, 240–250. [Google Scholar] [CrossRef]

- Alvariño, P.F.; Jabardo, J.M.S.; Arce, A.; Galdo, M.L. A numerical investigation of laminar flow of a water/alumina nanofluid. Int. J. Heat Mass Transf. 2013, 59, 423–432. [Google Scholar] [CrossRef]

- Ryzhkov, I.I.; Minakov, A.V. The effect of nanoparticle diffusion and thermophoresis on convective heat transfer of nanofluid in a circular tube. Int. J. Heat Mass Transf. 2014, 77, 956–969. [Google Scholar] [CrossRef]

- Kuppusamy, N.R.; Mohammed, H.A.; Lim, C.W. Numerical investigation of trapezoidal grooved microchannel heatsink using nanofluids. Thermochim. Acta 2013, 573, 39–56. [Google Scholar] [CrossRef]

- Qu, W.; Mudawar, I. Experimental and numerical study of pressure drop and heat transfer in a single-phase microchannel heat sink. Int. J. Heat Mass Transf. 2002, 45, 2549–2565. [Google Scholar] [CrossRef]

- Alshemmeri, T. Engineering Fluid Mechanics. Appl. Mech. Rev. 1985, 85, 87–88. [Google Scholar]

- Brinkman, H.C. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 1952, 20, 571–581. [Google Scholar] [CrossRef]

- Einstein, A. An Investigation on the Theory of Brownian Movement. James Joyce Q. 1956, 35, 155–158. [Google Scholar]

- Chon, C.H.; Kihm, K.D.; Lee, S.P.; Choi, S.U. Empirical correlation finding the role of temperature and particle size for nanofluid (Al2O3), thermal conductivity enhancement. Appl. Phys. Lett. 2005, 87, 153107. [Google Scholar] [CrossRef]

- Karwa, R.; Sharma, C.; Karwa, N. Performance Evaluation Criterion at Equal Pumping Power for Enhanced Performance Heat Transfer Surfaces. J. Sol. Energy 2013, 2013, 370823. [Google Scholar] [CrossRef]

- Hu, Y.J.; Wang, F.; Yan, S.Y. Heat characteristic analysis of solar battery under non-uniform heat flux. Renew. Energy Resour. 2017, 35, 668–674. [Google Scholar]

- Ho, C.J.; Wei, L.C. An Experimental investigation of forced convective cooling performance of a microchannel heat sink with Al2O3 water nanofluid. Appl. Therm. Eng. 2010, 30, 96–103. [Google Scholar] [CrossRef]

- Stephen, W.; Julio, M.O. Foundations of chaotic mixing. Philos. Trans. R. Soc. Lond. A 2004, 362, 937–970. [Google Scholar]

- Lee, J.; Mudawar, I. Assessment of the effectiveness of nanofluids for single-phase and two-phase heat transfer in micro-channels. Int. J. Heat Mass Transf. 2007, 50, 452–463. [Google Scholar] [CrossRef]

| Thermal Conductivity (W/m·K) | Density (kg/m3) | Specific Heat (J/kg·K) | |

|---|---|---|---|

| photovoltaic modules | 59 | 5320 | 310 |

| PCB plate | 107 | 2610 | 904 |

| ρ/kg/m3 | k/W/m·K | cp/J/kg·K | |

|---|---|---|---|

| Water | 988.2 | 0.6 | 4182 |

| Al2O3 | 3970 | 42 | 880 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Wang, W.; Wang, J.; Zhu, Z. Analysis and Optimization of Trapezoidal Grooved Microchannel Heat Sink Using Nanofluids in a Micro Solar Cell. Entropy 2018, 20, 9. https://doi.org/10.3390/e20010009

Wang R, Wang W, Wang J, Zhu Z. Analysis and Optimization of Trapezoidal Grooved Microchannel Heat Sink Using Nanofluids in a Micro Solar Cell. Entropy. 2018; 20(1):9. https://doi.org/10.3390/e20010009

Chicago/Turabian StyleWang, Ruijin, Wen Wang, Jiawei Wang, and Zefei Zhu. 2018. "Analysis and Optimization of Trapezoidal Grooved Microchannel Heat Sink Using Nanofluids in a Micro Solar Cell" Entropy 20, no. 1: 9. https://doi.org/10.3390/e20010009