A Micro-Scale Investigation on the Behaviors of Asphalt Mixtures under Freeze-Thaw Cycles Using Entropy Theory and a Computerized Tomography Scanning Technique

Abstract

:1. Introduction

2. Material and Methods

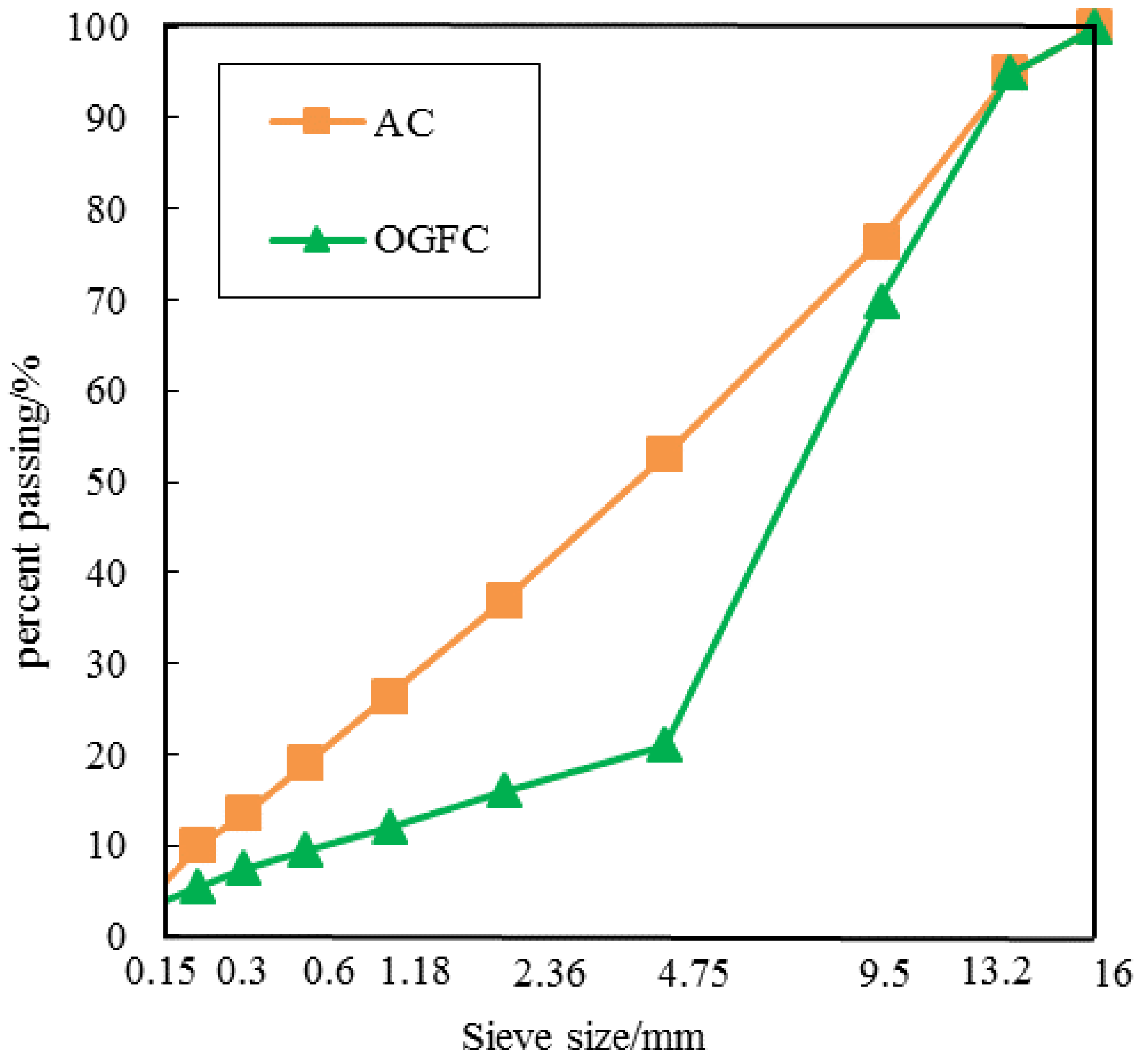

2.1. Asphalt Mixture Preparation and Experimental Condition

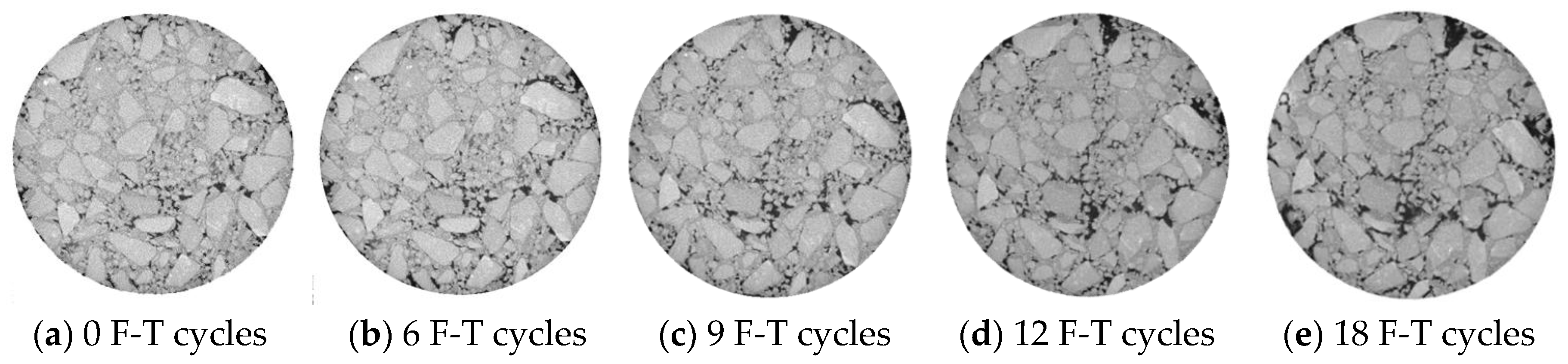

2.2. X-ray Scanning and Internal Structure Extraction

2.3. Information Entropy Analysis from X-ray CT Image

3. Results and Discussion

3.1. Thermodynamic Behaviors of Asphalt Mixtures under F-T Cycles

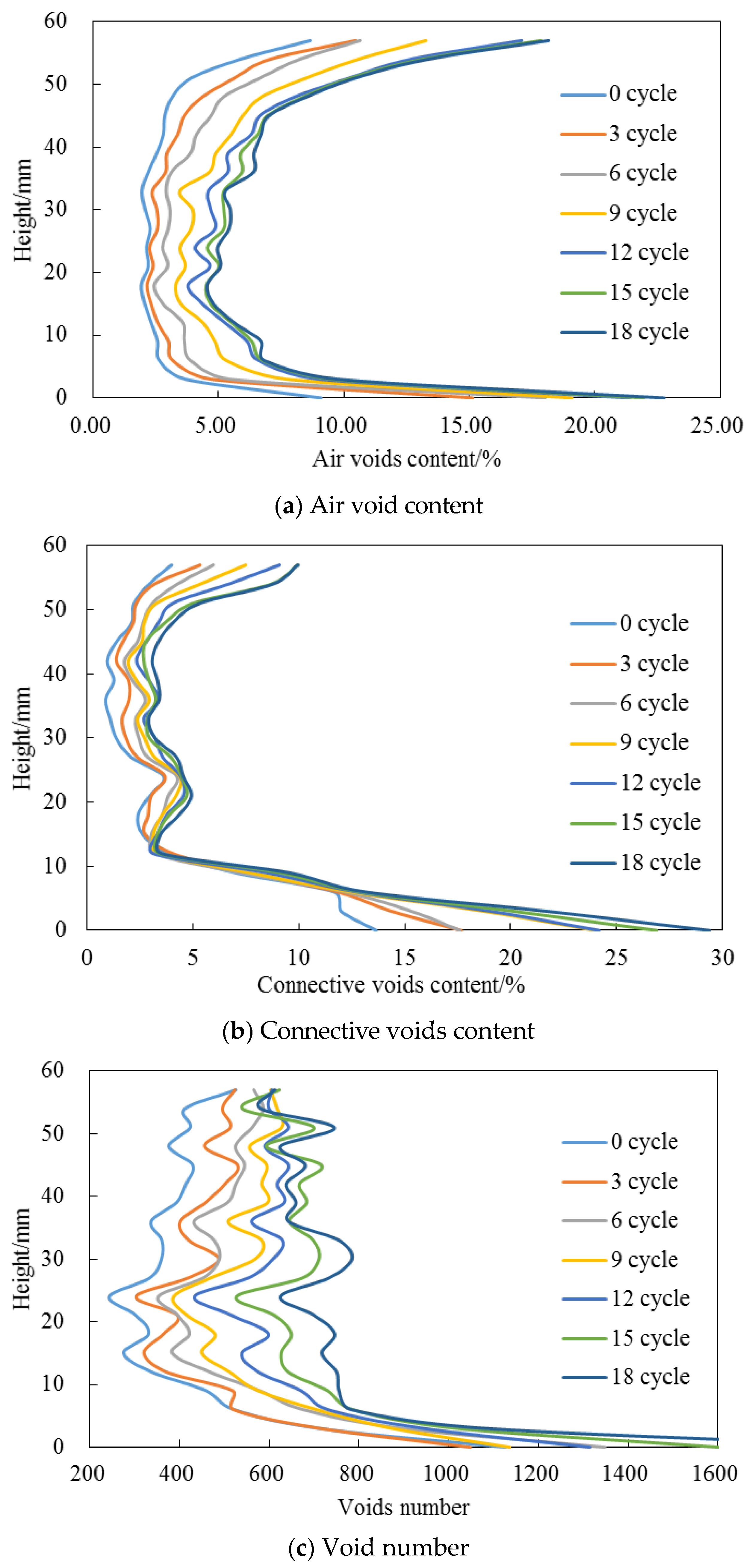

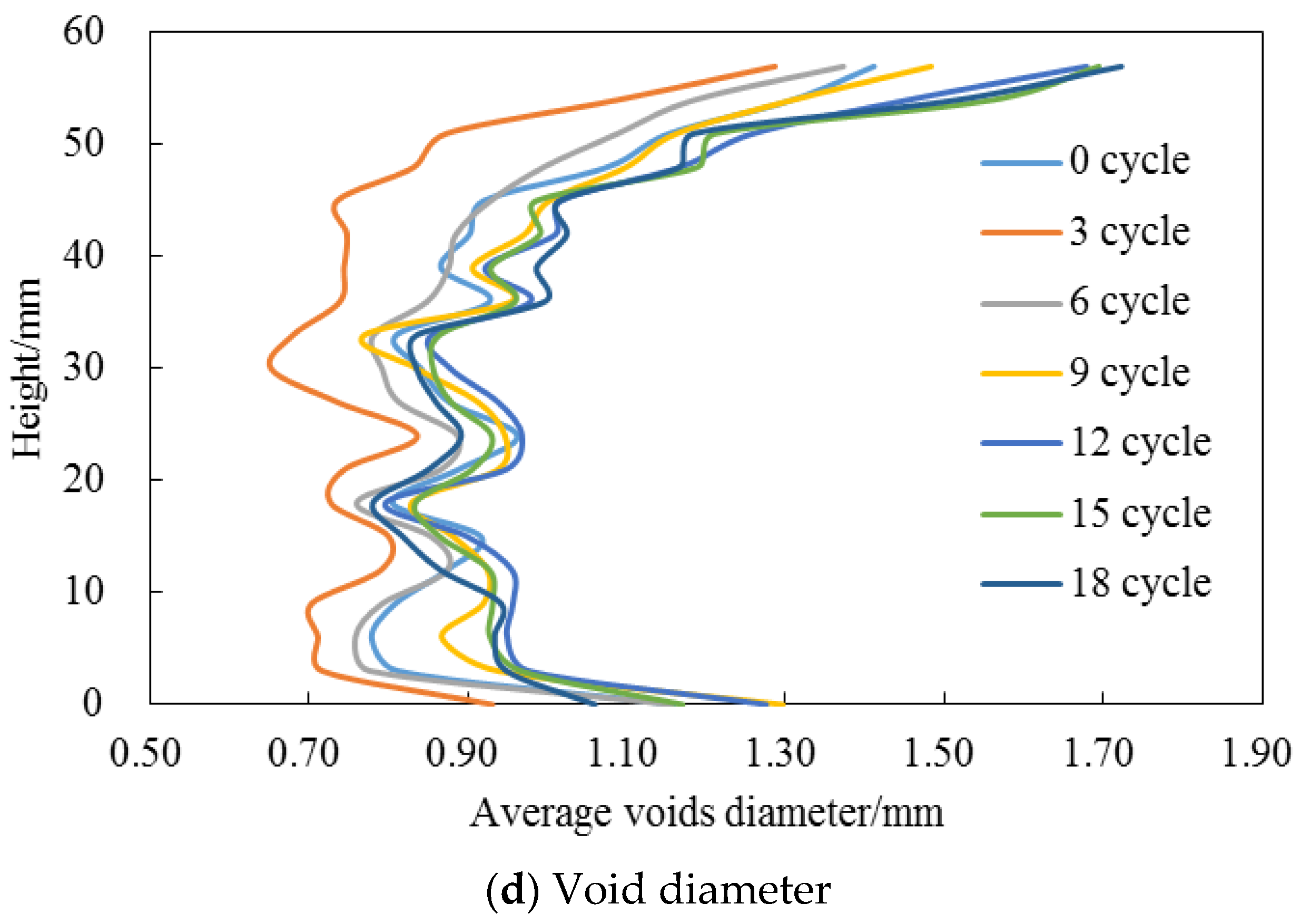

3.1.1. Pore Structure Degradation under F-T Cycles

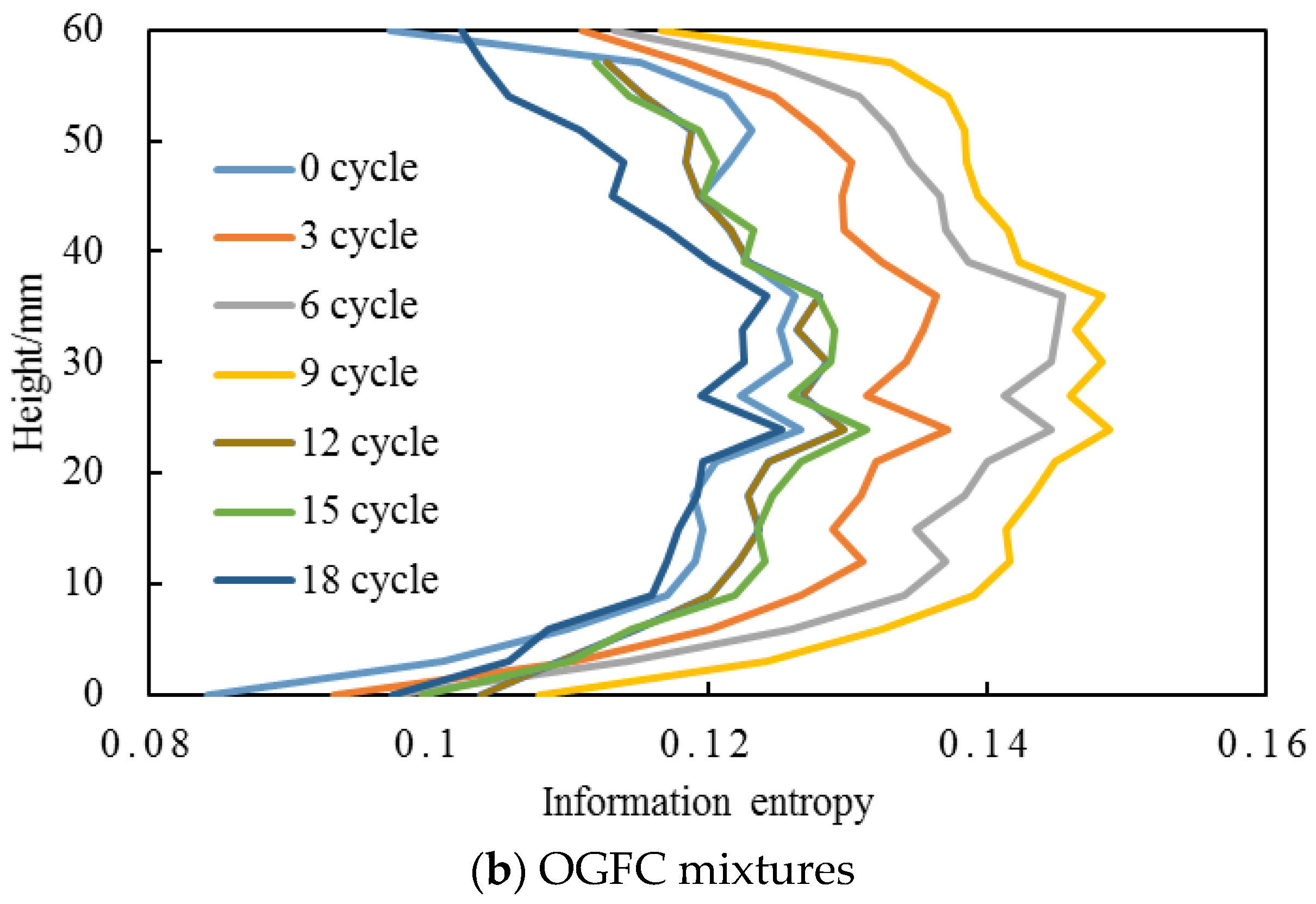

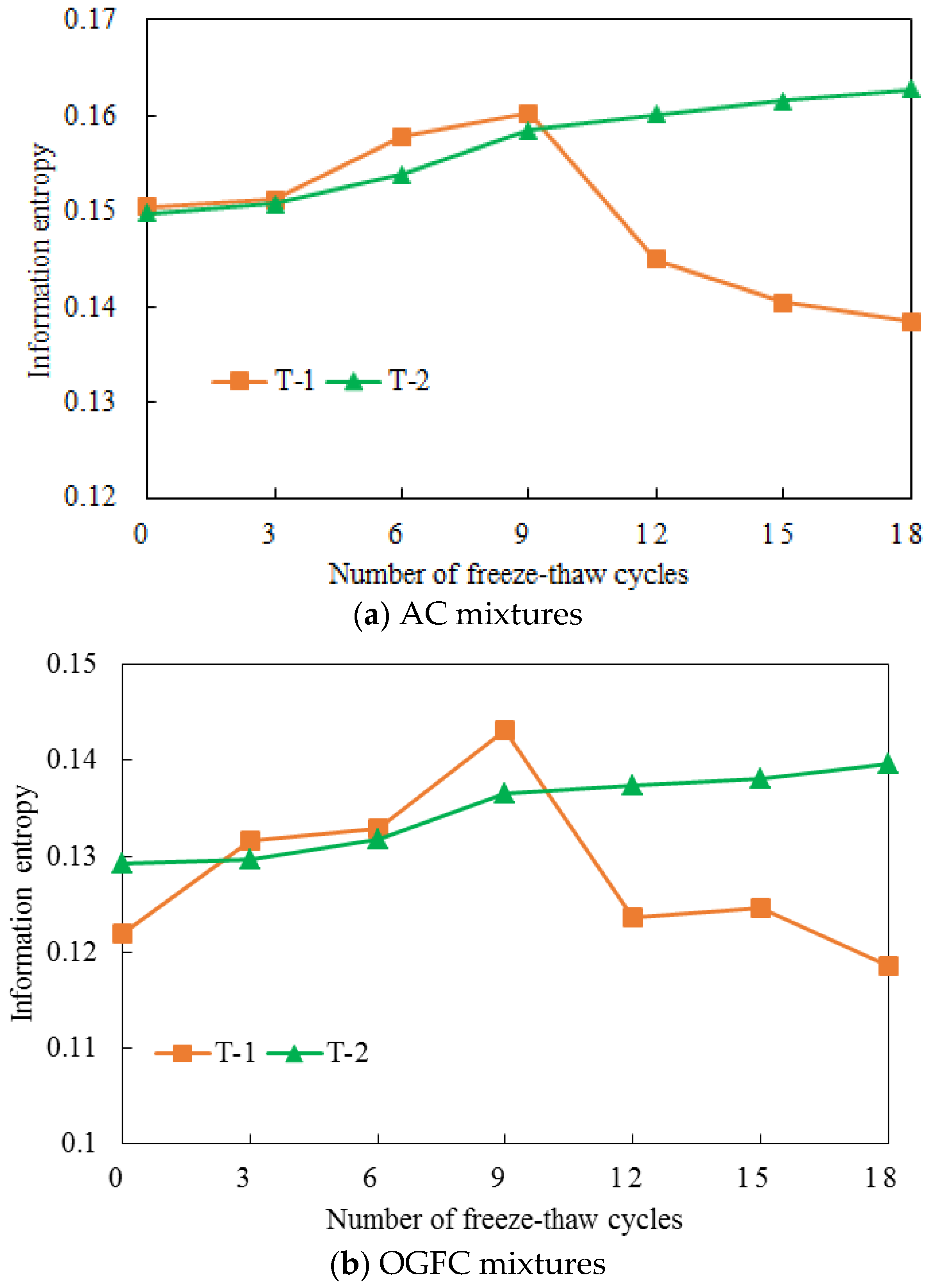

3.1.2. Information Entropy Evolution of Asphalt Mixtures under F-T Cycles

3.2. Effect of Test Conditions on the F-T Damage Propagation in Asphalt Mixtures

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hou, Y.; Sun, W.; Das, P.; Song, X.; Wang, L.; Ge, Z.; Huang, Y. Coupled Navier-Stokes Phase-Field Model to Evaluate the Microscopic Phase Separation in Asphalt Binder under Thermal Loading. J. Mater. Civ. Eng. 2016, 28, 04016100. [Google Scholar] [CrossRef]

- Xu, H.N.; Zhou, J.; Dong, Q.F.; Tan, Y.Q. Characterization of Moisture Vapor Diffusion in Fine Aggregate Mixtures Using Fickian and non-Fickian Models. Mater. Des. 2017, 124, 108–120. [Google Scholar] [CrossRef]

- Amini, B.; Tehrani, S.S. Simultaneous Effects of Salted Water and Water Flow on Asphalt Concrete Pavement Deterioration under Freeze-Thaw Cycles. Int. J. Pavement Eng. 2014, 15, 383–391. [Google Scholar] [CrossRef]

- Ozgan, E.; Serin, S. Investigation of Certain Engineering Characteristics of Asphalt Concrete Exposed to Freeze-Thaw Cycles. Cold Reg. Sci. Technol. 2013, 85, 131–136. [Google Scholar] [CrossRef]

- Xu, H.N.; Guo, W.; Tan, Y.Q. Internal Structure Evolution of Asphalt Mixtures during Freeze-Thaw Cycles. Mater. Des. 2015, 86, 436–446. [Google Scholar] [CrossRef]

- Feng, D.; Yi, J.; Wang, D.; Chen, L. Impact of Salt and Freeze-Thaw Cycles on Performance of Asphalt Mixtures in Coastal Frozen Region of China. Cold Reg. Sci. Technol. 2010, 62, 34–41. [Google Scholar] [CrossRef]

- Ameri, M.; Kouchaki, S.; Roshani, H. Laboratory Evaluation of the Effect of nano-Arganosilane anti-Stripping Additive on the Moisture Susceptibility of HMA Mixtures under Freeze-Thaw Cycles. Constr. Build. Mater. 2013, 48, 1009–1016. [Google Scholar] [CrossRef]

- Wang, D.W.; Chen, X.H.; Oeser, M.; Stanjek, H.; Steinauer, B. Study of Micro-Texture and Skid Resistance Change of Granite Slabs during the Polishing with the Aachen Polishing Machine. Wear 2014, 318, 1–11. [Google Scholar] [CrossRef]

- Xu, H.N.; Guo, W.; Tan, Y.Q. Permeability of Asphalt Mixtures Exposed to Freeze-Thaw Cycles. Cold Reg. Sci. Technol. 2016, 123, 99–106. [Google Scholar] [CrossRef]

- Shakiba, M.; Darabi, M.K.; Abu Al-Rub, R.K.; You, T.; Little, D.N.; Masad, E.A. Three-Dimensional Microstructural Modelling of Coupled Moisture-Mechanical Response of Asphalt Concrete. Int. J. Pavement Eng. 2015, 16, 445–466. [Google Scholar] [CrossRef]

- Lamothe, S.; Perraton, D.; Di Benedetto, H. Contraction and Expansion of Partially Saturated Hot Mix Asphalt Samples Exposed to Freeze-Thaw Cycles. Road Mater. Pavement 2015, 16, 277–299. [Google Scholar] [CrossRef]

- Hassan, N.A.; Airey, G.D.; Hainin, M.R. Characterisation of Micro-Structure Damage in Asphalt Mixtures Using Image Analysis. Constr. Build. Mater. 2014, 54, 27–38. [Google Scholar] [CrossRef]

- Taniguchi, S.; Otani, J.; Kumagai, M. A Study on Characteristics Evaluation to Control Quality of Asphalt Mixture Using X-ray CT. Road Mater. Pavement 2014, 15, 892–910. [Google Scholar] [CrossRef]

- Khan, R.; Collop, A.; Airey, G.D.; Khan, A.N. Asphalt Damage Characterization from Cyclic Test and X-ray Computed Tomography. Transport 2013, 166, 203–213. [Google Scholar]

- Coleri, E.; Harvey, J.T.; Yang, K.; Boone, J.M. A Micromechanical Approach to Investigate Asphalt Concrete Rutting Mechanism. Constr. Build. Mater. 2012, 30, 36–49. [Google Scholar] [CrossRef]

- Masad, E.; Jandhyala, V.K.; Dasgupta, N.; Somadevan, N.; Shashidhar, N. Characterization of Air Void Distribution in Asphalt Mixes Using X-ray Computed Tomography. Constr. Build. Mater. 2002, 14, 122–129. [Google Scholar] [CrossRef]

- Shaheen, M.; Al-Mayah, A.; Tighe, S. A Novel Method for Evaluating Hot Mix Asphalt Fatigue Damage: X-ray Computed Tomography. Constr. Build. Mater. 2016, 113, 121–133. [Google Scholar] [CrossRef]

- Kutay, M.E.; Aydilek, A.H.; Masad, E.; Harman, T. Computational and Experimental Evaluation of Hydraulic Conductivity Anisotropy in Hot-Mix Asphalt. Int. J. Pavement Eng. 2007, 8, 29–43. [Google Scholar] [CrossRef]

- Liu, G.H.; Wu, Z.G. New Thought on Dynamic Identification Technology for Damage Detection of RC Structures by Introducing Information Entropy Theory. J. Vib. Shock 2011, 6, 162–171. [Google Scholar]

- Van Siclen, C.D. Information Entropy of Complex Structures. Phys. Rev. E 1997, 56, 5211–5215. [Google Scholar] [CrossRef]

- Bao, T.F.; Peng, B.; Cong, P.J.; Wang, J.L. Analysis of Crack Propagation in Concrete Structures with Structural Information Entropy. Sci. China Technol. Sci. 2010, 53, 1943–1948. [Google Scholar] [CrossRef]

- Su, H.Z.; Hu, J.; Wen, Z.P. Structure Analysis for Concrete Faced Rockfill Dam Based on Information Entropy Theory and Finite Element Method. Int. J. Numer. Anal. Methods 2012, 36, 1041–1055. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, J.; Bai, Y. CT Image Entropy Analysis Technique for the Determination of Damage to Indirect Tensile Test of Asphalt Mixtures. J. Test. Eval. 2011, 39, 780–784. [Google Scholar]

- Judita, G.; Audrius, V.; Vitalijus, A.; Gediminas, G. Methods and criteria for evaluation of asphalt mixture resistance to low temperature cracking. Balt. J. Road Bridge Eng. 2017, 12, 135–144. [Google Scholar]

- Audrius, V.; Viktoras, V.; Aleksandras, J.; Tadas, A.; Boris, F. Peculiarity of low noise pavement design under Lithuanian conditions. Balt. J. Road Bridge Eng. 2014, 9, 155–163. [Google Scholar]

- Lamothe, S.; Sebastlen, P.; Di Benedetto, H. Degradation of Hot Mix Asphalt Samples Subjected to Freeze-Thaw Cycles and Partially Saturated with Water or Brine. Road Mater. Pavement 2017, 18, 849–864. [Google Scholar] [CrossRef]

- Islam, M.R.; Tarefder, R.A. Effect of Large Freeze-Thaw Cycles on Stiffness and Tensile Strength of Asphalt Concrete. J. Cold Reg. Eng. 2016, 30, 06014006. [Google Scholar] [CrossRef]

- Tong, Y.W.; Luo, R.; Lytton, R. Modelling Water Vapor Diffusion in Pavement and its Influence on Fatigue Crack Growth of Fine Aggregate Mixture. Transp. Res. Rec. 2014, 2373, 71–80. [Google Scholar] [CrossRef]

- Kassem, E.; Masad, E.; Lytton, R.; Bulut, R. Measurements of the Moisture Diffusion Coefficient of Asphalt Mixtures and its Relationship to Mixture Composition. Int. J. Pavement Eng. 2009, 10, 389–399. [Google Scholar] [CrossRef]

- Apeagyei, A.K.; Grenfell, J.R.A.; Airey, G.D. Evaluation of Moisture Sorption and Diffusion Characteristics of Asphalt Mastics Using Manual and Automated Gravimetric Sorption Techniques. J. Mater. Civ. Eng. 2014, 26, 04014045. [Google Scholar] [CrossRef]

| Index | Test Values | Requirement |

|---|---|---|

| Penetration 25 °C, 5 s, 100 g, (0.1 mm) | 86.2 | 80~100 |

| Softening point/(T/°C) | 46.2 | >45 |

| Ductility/(cm) | >100 | >100 |

| Index | Sieve Size/mm | Requirement | |||

|---|---|---|---|---|---|

| 13.2 | 9.5 | 4.75 | 2.36 | ||

| Bulk specific gravity | 2.892 | 2.752 | 2.627 | 2.730 | ≥2.5 |

| Crushed stone value/% | 15.3 | 15 | 14.9 | 15.0 | ≤28 |

| Weared stone value/% | 13.2 | 13.1 | 15.4 | 16.0 | ≤30 |

| Adhesion level | 5 | 5 | 5 | 5 | ≥4 |

| Index | Sieve Size/mm | ||||

|---|---|---|---|---|---|

| 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| Apparent specific gravity | 2.789 | 2.772 | 2.766 | 2.778 | 2.752 |

| Angularity/s | 41 | ||||

| F-T Test Details | Mixture Type | Initial Air Void Content/% | |||

|---|---|---|---|---|---|

| Test Procedure | Step 1 | Step 2 | Step 3 | ||

| T-1 | Water conditioned by vacuum saturation using a residual pressure of 98 kPa for 15 min | Freezing in the air at −18 °C for 16 h | Thawing in the water at 20 °C for 12 h | AC | 3.5 |

| OGFC | 21.1 | ||||

| T-2 | Air conditioned by RH of 90% at 20 °C for 15 days before the first F-T test. | Thawing in the air with RH of 90 ± 1% at 20 °C for 12 h | AC | 3.8 | |

| OGFC | 23.7 | ||||

| Pore Structure Characteristics | Number of F-T Cycles | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | 15 | 18 | |

| Air void content (%) | 2.8 | 3.3 | 4.0 | 5.0 | 5.8 | 6.2 | 6.4 |

| Void number | 358 | 430 | 474 | 527 | 587 | 658 | 704 |

| Average void diameter (mm) | 0.95 | 0.79 | 0.91 | 0.97 | 0.99 | 0.97 | 0.95 |

| Connective void content (%) | 1.4 | 1.8 | 2.2 | 2.8 | 3.7 | 3.9 | 4.1 |

| Pore Structure Characteristics | Number of F-T cycles | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | 15 | 18 | |

| Air void content (%) | 21.0 | 21.5 | 21.8 | 22.7 | 23.7 | 24.2 | 24.4 |

| Void number | 196 | 238 | 309 | 382 | 405 | 418 | 425 |

| Average void diameter (mm) | 2.52 | 2.33 | 2.09 | 1.97 | 1.97 | 2.05 | 2.07 |

| Connective void content (%) | 20.6 | 20.8 | 21.0 | 21.4 | 21.7 | 21.9 | 22.2 |

| Mixture Type | Number of Freeze-Thaw Cycles | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 3 | 6 | 9 | 12 | 15 | 18 | |

| AC | 0.1504 | 0.1511 | 0.1577 | 0.1602 | 0.1449 | 0.1404 | 0.1384 |

| OGFC | 0.1220 | 0.1316 | 0.1329 | 0.1432 | 0.1236 | 0.1246 | 0.1186 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Li, H.; Tan, Y.; Wang, L.; Hou, Y. A Micro-Scale Investigation on the Behaviors of Asphalt Mixtures under Freeze-Thaw Cycles Using Entropy Theory and a Computerized Tomography Scanning Technique. Entropy 2018, 20, 68. https://doi.org/10.3390/e20020068

Xu H, Li H, Tan Y, Wang L, Hou Y. A Micro-Scale Investigation on the Behaviors of Asphalt Mixtures under Freeze-Thaw Cycles Using Entropy Theory and a Computerized Tomography Scanning Technique. Entropy. 2018; 20(2):68. https://doi.org/10.3390/e20020068

Chicago/Turabian StyleXu, Huining, Hengzhen Li, Yiqiu Tan, Linbing Wang, and Yue Hou. 2018. "A Micro-Scale Investigation on the Behaviors of Asphalt Mixtures under Freeze-Thaw Cycles Using Entropy Theory and a Computerized Tomography Scanning Technique" Entropy 20, no. 2: 68. https://doi.org/10.3390/e20020068