1. Introduction

Rolling bearings are key components of rotating machinery [

1]. Monitoring and diagnosing a bearing are significant measurements in ensuring rotation machines run steadily [

2,

3]. In recent decades, researchers studied many methods in condition monitoring and fault diagnosis for mechanical equipment [

4,

5,

6]. These methods include traditional time- and frequency-domain analysis [

7,

8,

9], discrete wavelet transform [

10,

11], fractal dimension (FD) [

12,

13], and empirical mode decomposition (EMD) [

14]. An artificial intelligence (AI) method was also developed to perform mechanical fault diagnosis and running state monitoring, in order to improve the efficiency and effectiveness of fault diagnosis of machines [

15]. However, in all, extraction of the status features for a health condition is one of the most critical steps [

16].

Recently, researchers developed many kinds of feature extraction methods. Immovilli et al. used the Hilbert transformation and envelope analysis to identify the spectrum components and fault information of the fault bearing [

17]. Another way is to use statistical analysis methods to obtain various characteristics of the signal, and these statistical indicators can be used for fault detection and classification [

18]. The time-domain characteristics and frequency-domain characteristics of the vibration signal of bearing were applied to the neural network to establish an automatic motor bearing fault diagnosis system [

19]. The results show that the neural network can be effectively used to diagnose the faults of various motor bearings and provide a new way for motor bearing fault identification. The nonlinear and non-stationary features of vibration signals add difficulty in obtaining feature information from the vibration signals of bearing. To solve this issue, Yang et al. proposed an intelligent fault diagnosis method based on the FD algorithm by using the SVM classifier [

12]. This method, which is based on different dynamic mechanisms, uses fractional dimension algorithm to judge the working condition status of bearing and provides a valid diagnostic method for non-stationary vibrational signals. Sunil Tyagi et al. presented a DWT and SVM hybrid method for fault diagnosis of rolling bearings, which is more effective than the artificial neural network (ANN) classifier. Therefore, SVM has been widely used in bearing fault diagnosis [

20]. Yan et al. proposed an approximate entropy for machine health monitoring [

21]. This method shows that approximate entropy has the advantage of anti-noise ability and anti-wild point traits. Richman et al. proposed the conception of sample entropy (SE) [

22]. This method overcomes low match degree and dependence of the time series length of the approximate entropy. Wang et al. combined SE with EMD for centrifugal pump fault diagnosis [

23]. This combined method has higher recognition rate than single SE. Costa et al. proposed the concept of MSE for improving the drawbacks of SE [

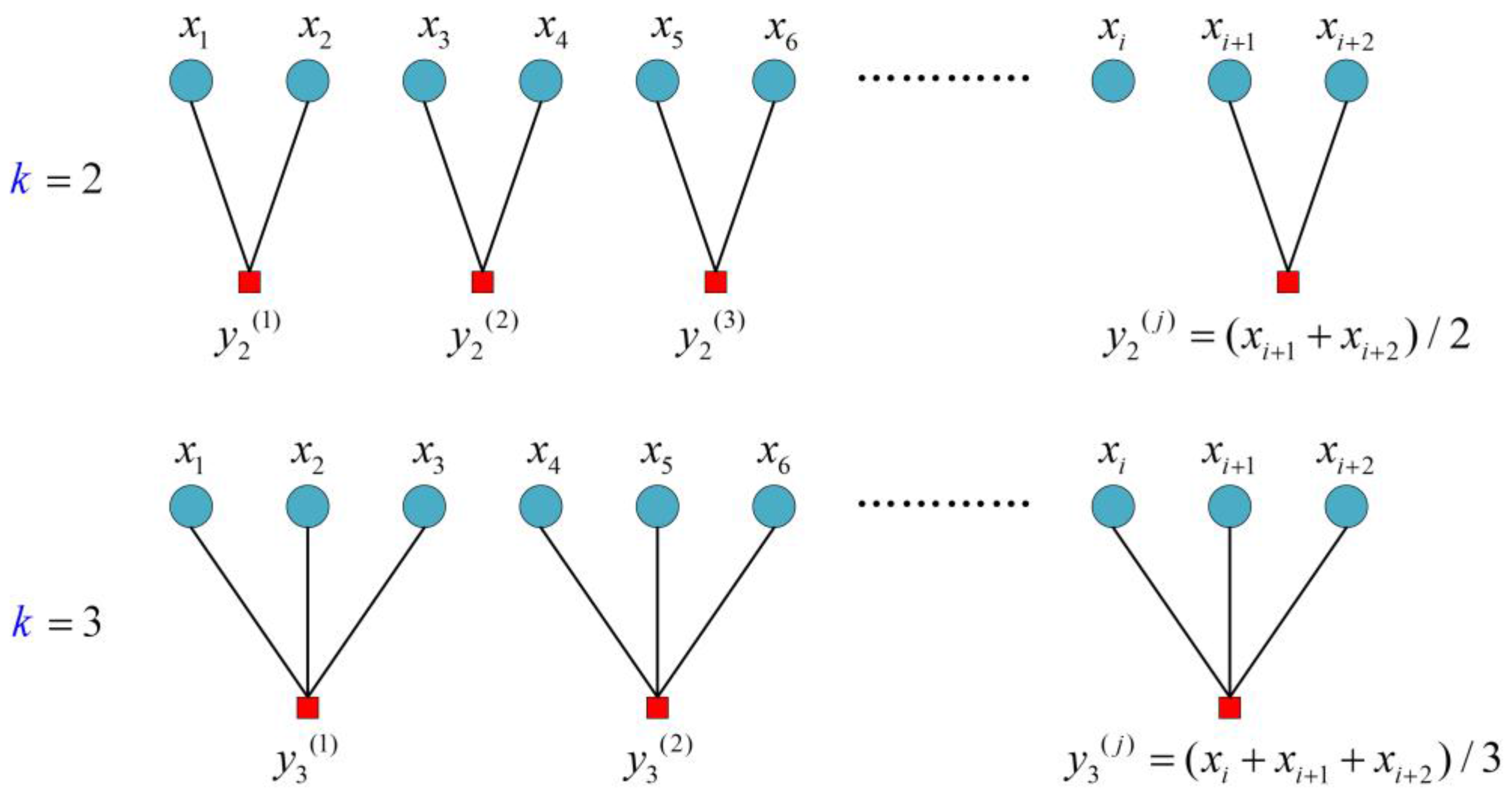

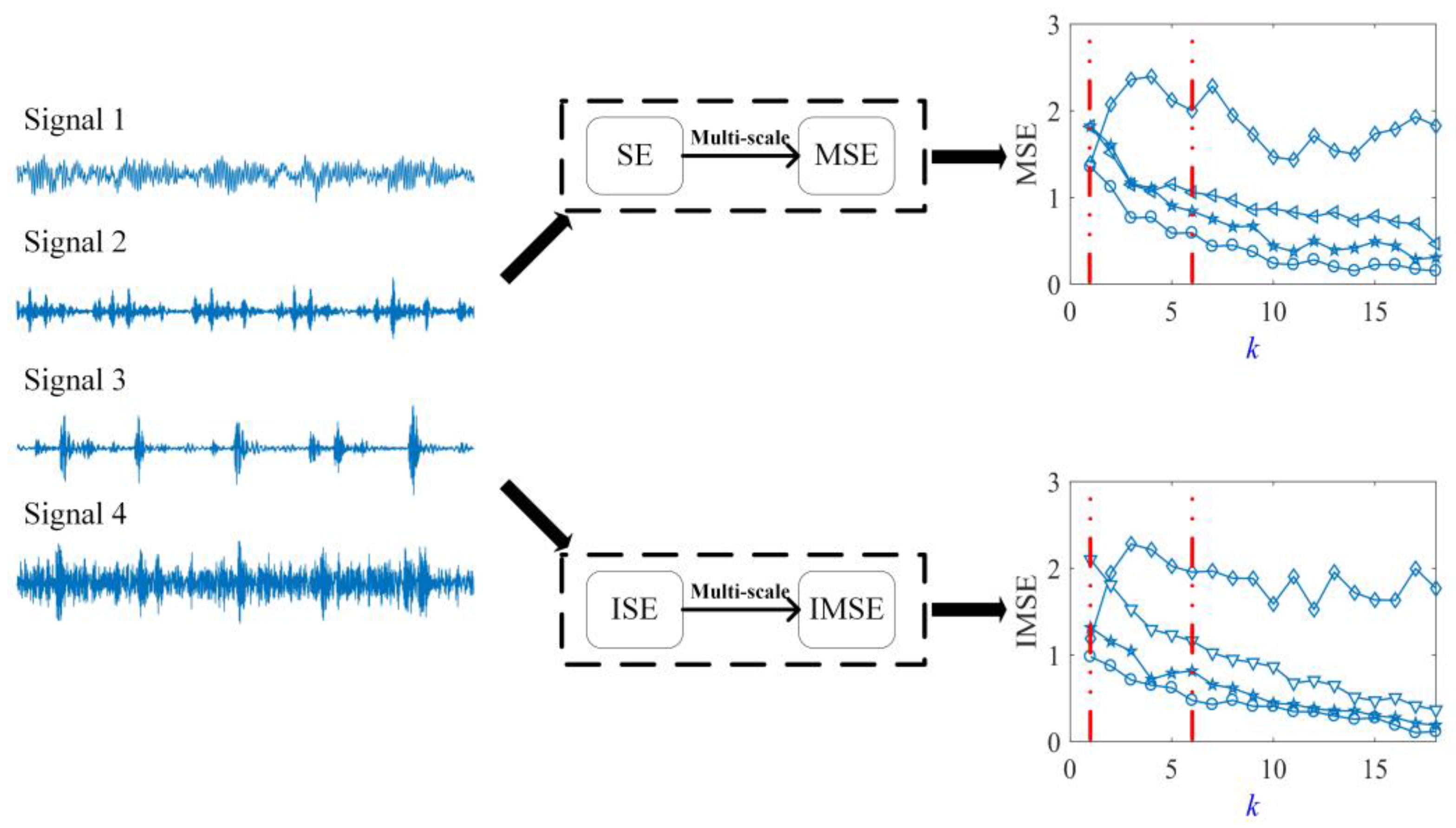

24,

25]. This method is based on SE, applies the coarse granulation into SE, and well measures SE under different scales. The algorithm idea for SE is to find the maximum of the absolute value between the vector distances. However, this method is applied to measure the similarity between vectors, and ignores the second maximum points. To solve this problem, we propose an IMSE method. IMSE fully considers the global information for every distance vector. Experimental results show that IMSE can extract the fault feature information of bearings effectively.

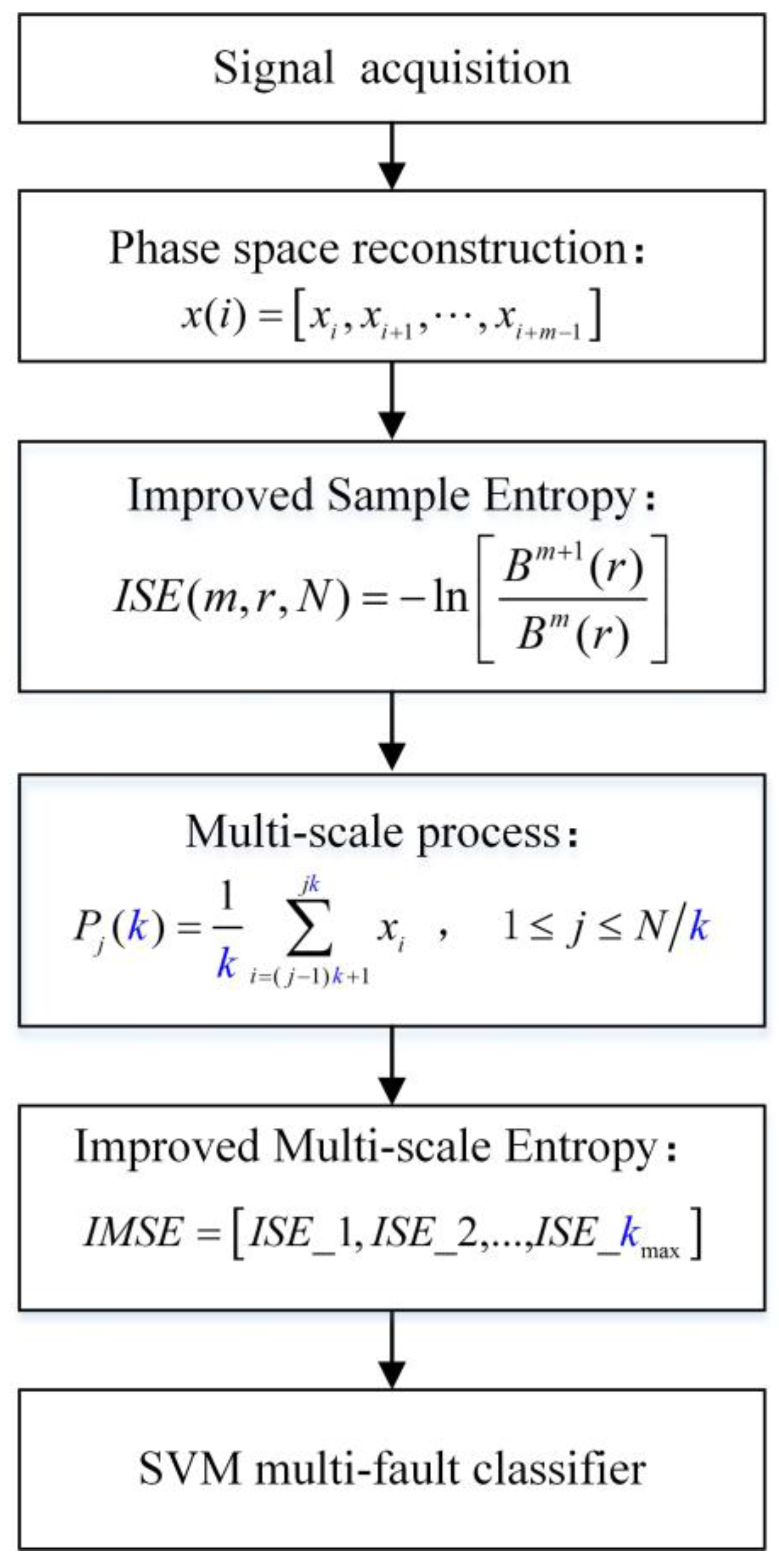

The rest of this paper is arranged as follows. The theoretical background and algorithm steps of IMSE are introduced in

Section 2.

Section 3 gives two experimental cases for bearing fault identification.

Section 4 gives the conclusions.

3. Application Cases Using IMSE Method

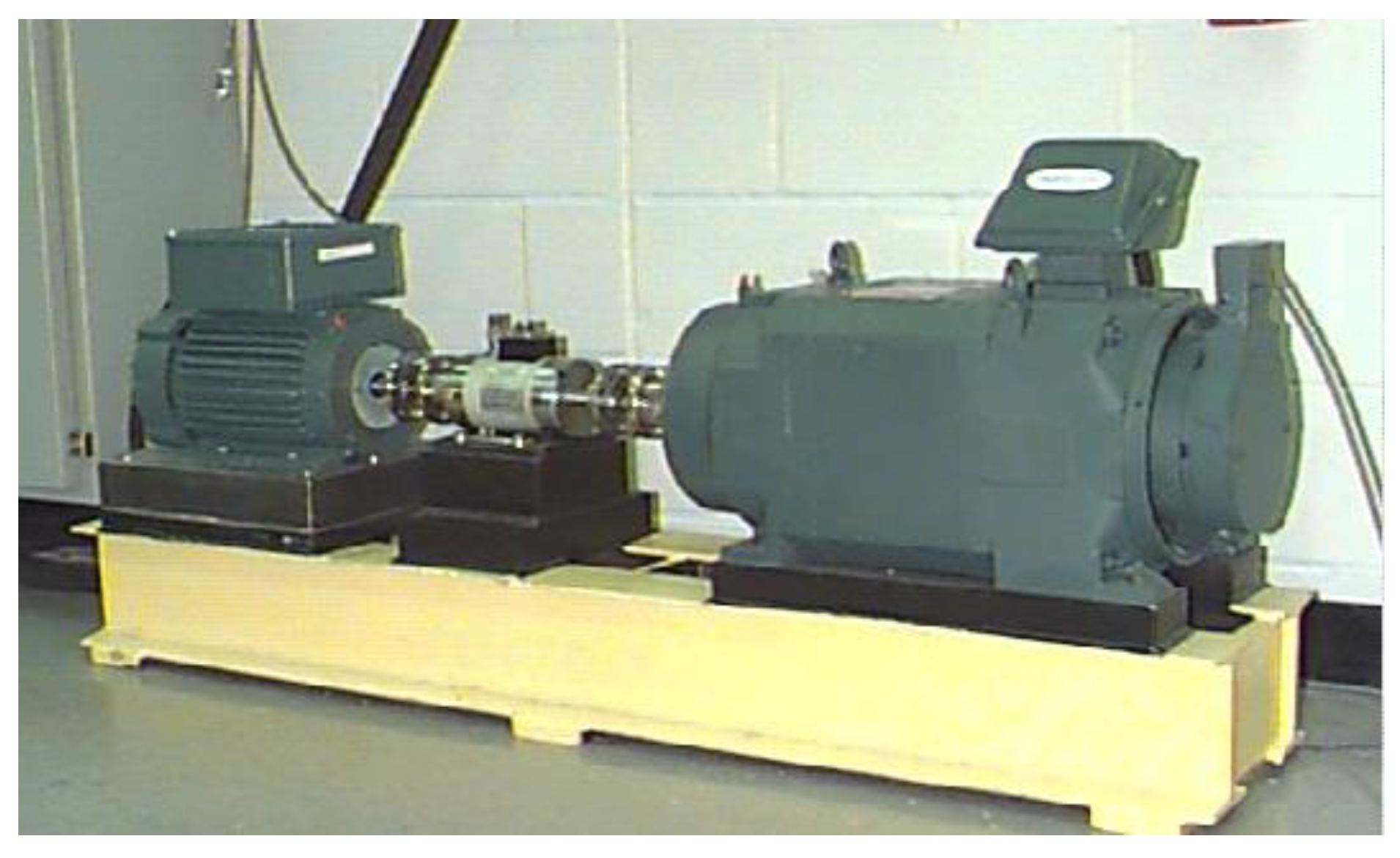

Case I: The acquired vibration signals with different fault types are downloaded freely from the bearing data center of Case Western Reserve University (CWRU) [

38]. Bearing fatigue experiment equipment is shown in

Figure 4.

Table 1 shows the dimensions and parameters of the tested bearing. The tested bearing is a deep groove ball bearing, and the product type is 6205-2RS JEM SKF. The rotating speed of the tested bearing is

nr = 1797 r/min, and the fault diameter is

D = 0.533 mm. The status types of the acquired vibration signals are shown as normal, outer race-way, inner race-way and roller faults. The sampling points are

N = 2048 and sampling frequency is

fs = 12 kHz. Acquired vibration signals in time domain with different status are shown in

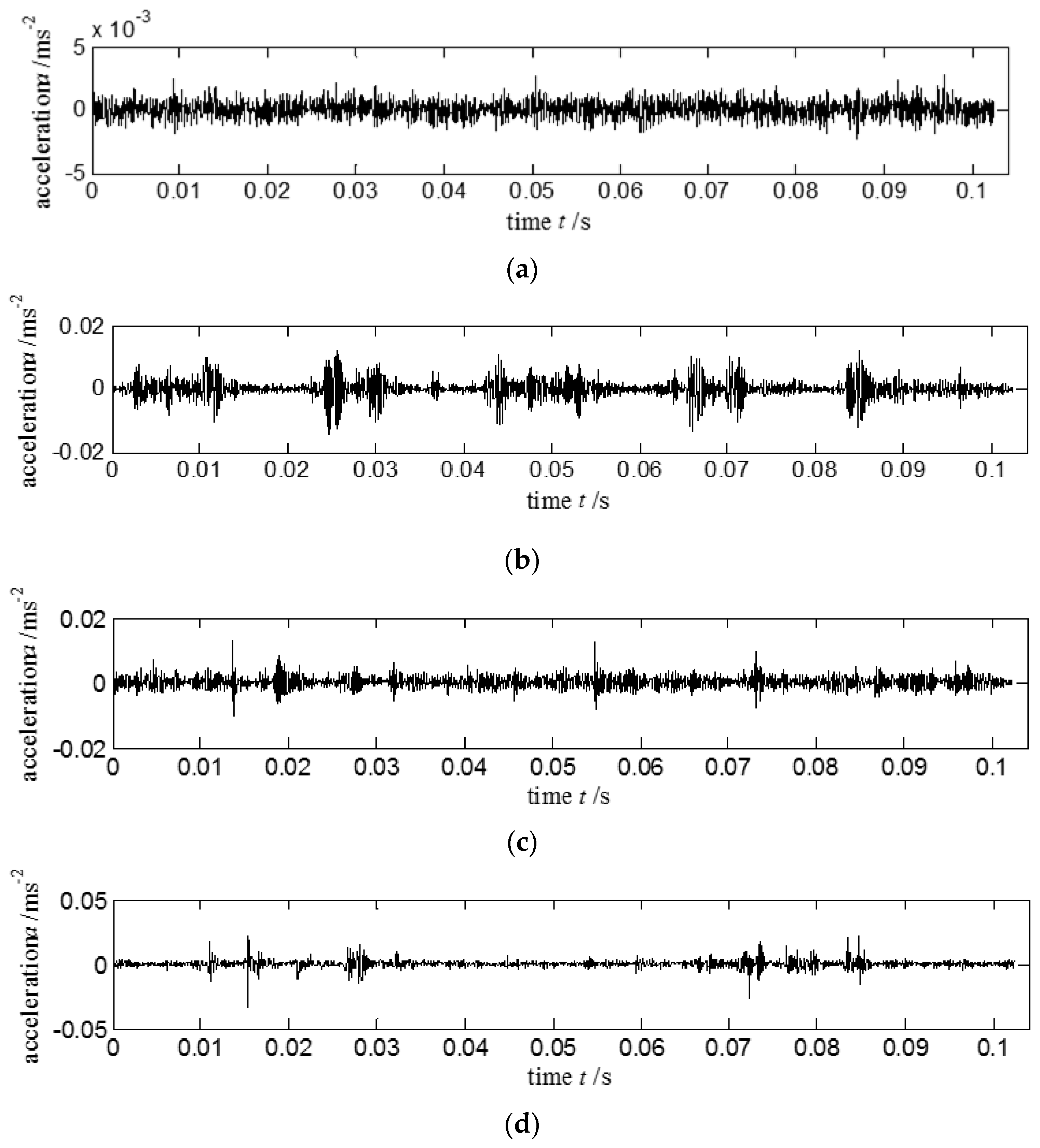

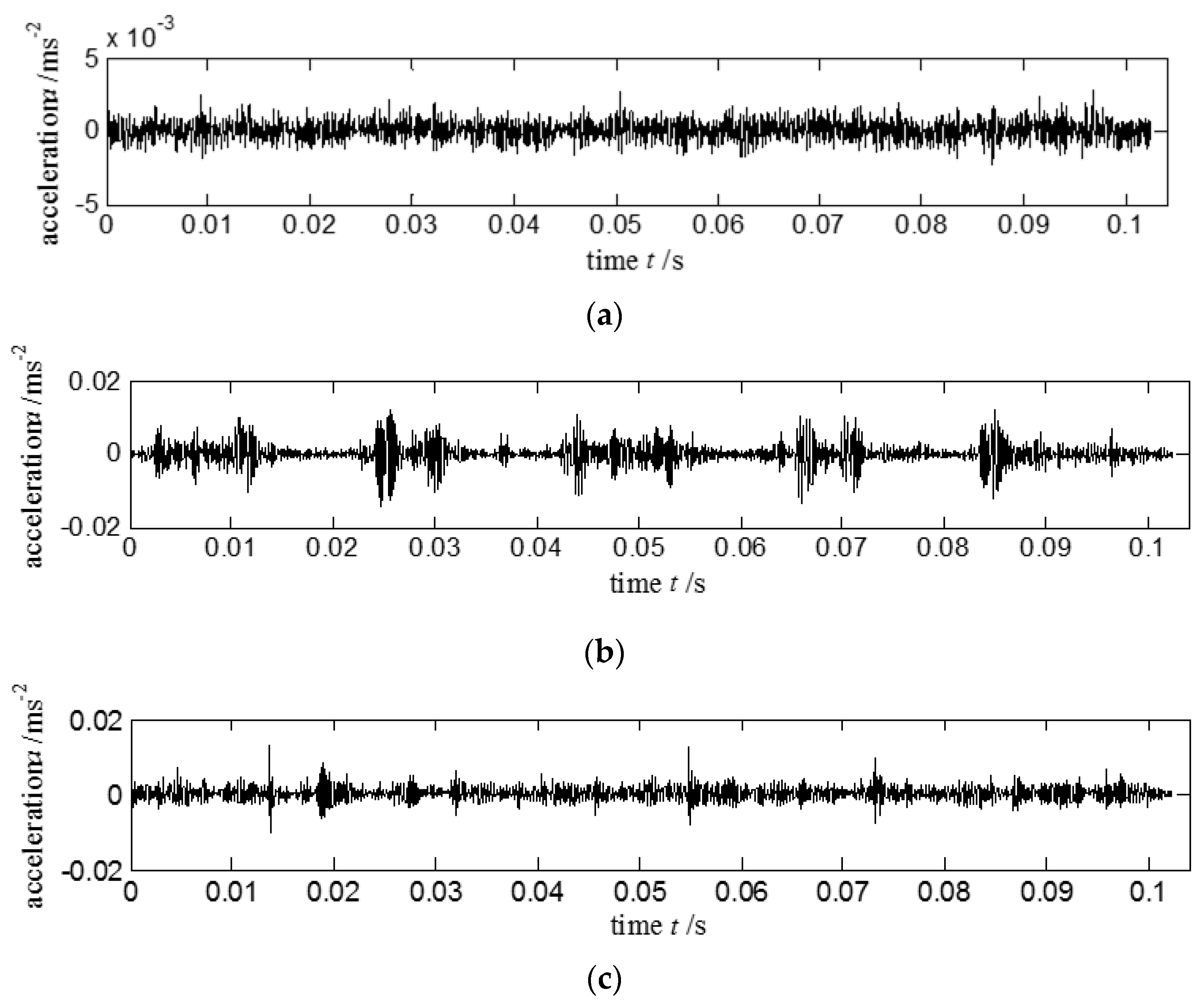

Figure 5.

Figure 5a displays the vibration signal of bearing on normal condition.

Figure 5b–d show the vibration signals of the bearing with inner race-way, outer race-way, and roller faults, respectively. The feature information of

Figure 5b–d are difficult to observe. However, these figures indicate that the impact components obviously existed given several local defects occurring in the bearings.

MSE and IMSE of four bearing status are calculated. We selected 20 training and 30 testing samples, and different scale factors are trained as different eigenvalues. Therefore, the fault recognition rate under different eigenvalues is calculated. The calculation results are shown in

Table 2.

Table 2 shows that when the numbers of eigenvalues 4 and 7 are selected as the sensitive fault features, the recognition rates of MSE and IMSE have the same value. When the numbers of eigenvalues are changed to 5, 6, 10, 15, and 18, the fault recognition rate of IMSE is higher than that of the MSE. The reason is the possible existence of correlation and redundancy between the features of MSE and IMSE. Overall,

Table 2 shows that IMSE has higher recognition rate than the MSE. When more eigenvalues are selected, more time is consumed. Therefore, the number of eigenvalues

k is chosen as 5.

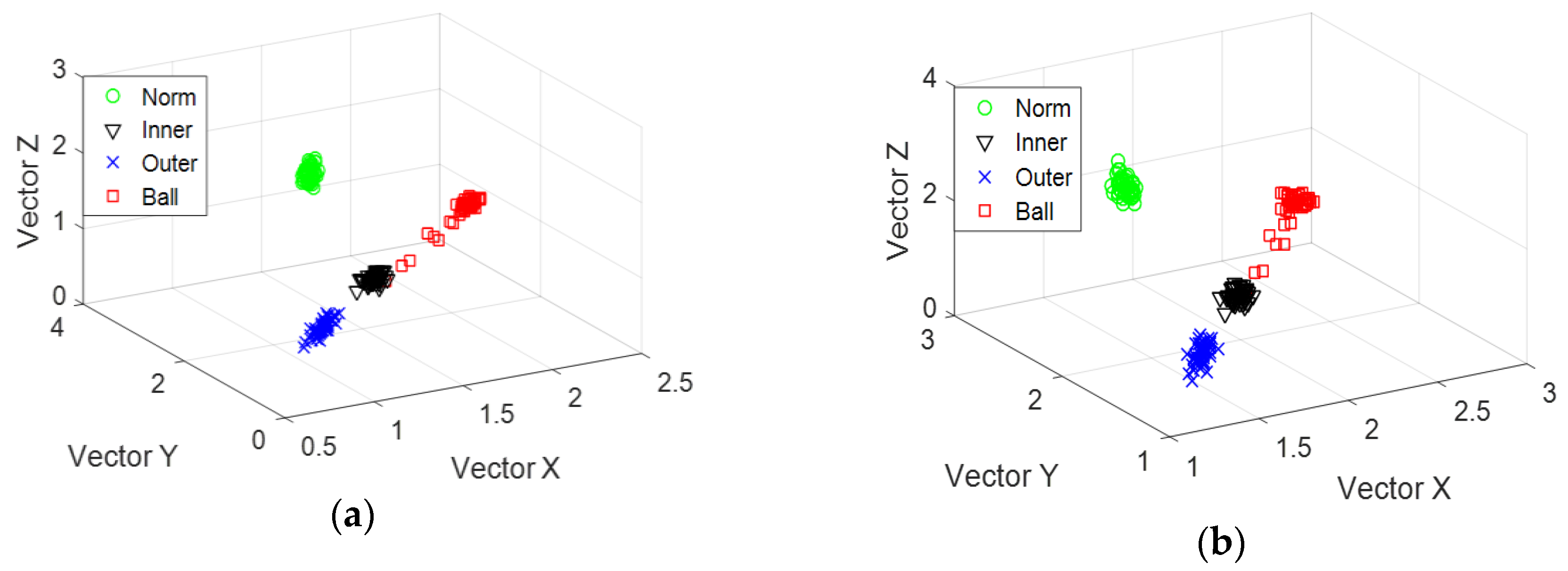

Different status information is calculated using MSE and IMSE methods. For each state, we considered 50 data sets and eigenvalue

k = 5. Thus, the data dimension is 200 × 5. We took the first 200 × 3 data matrix as an eigenvector matrix. Classification results are shown in

Figure 6a,b.

Figure 6a shows an overlap between the roller and inner race-way faults. However, the overlapping phenomenon does not occur under different bearing statuses, as illustrated in

Figure 6b. This result implies that different bearing statuses could be easily classified by using the IMSE feature.

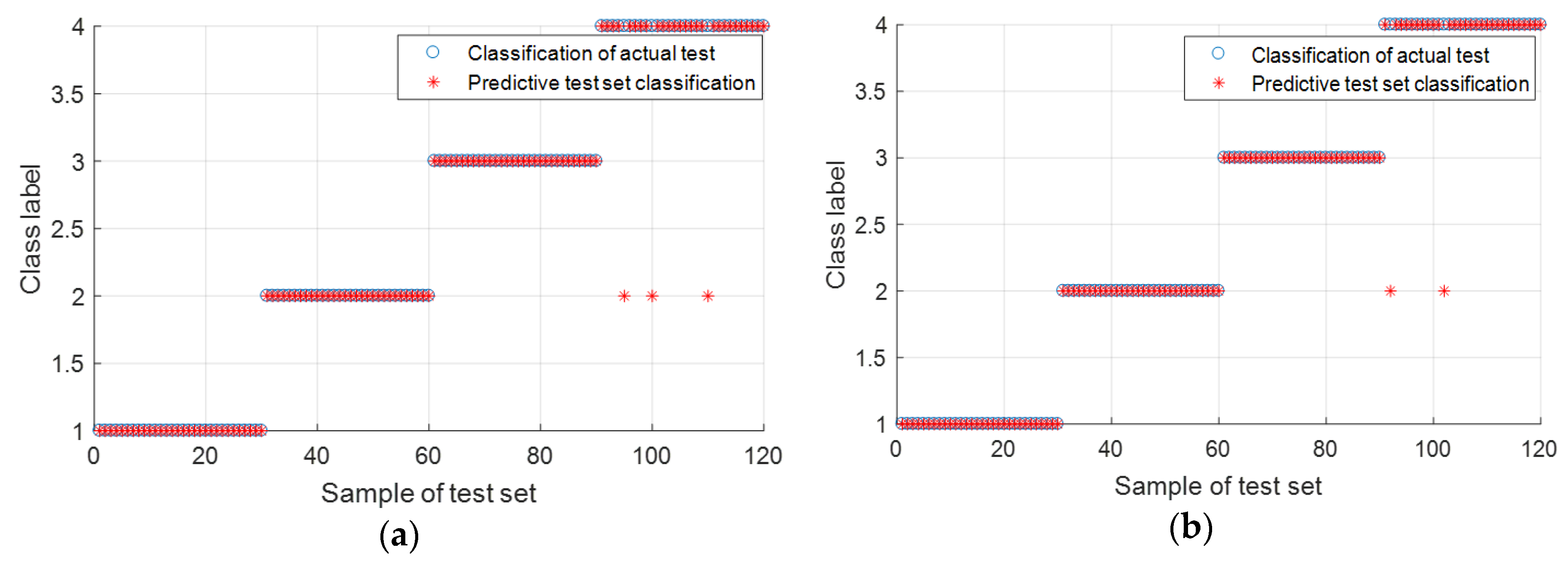

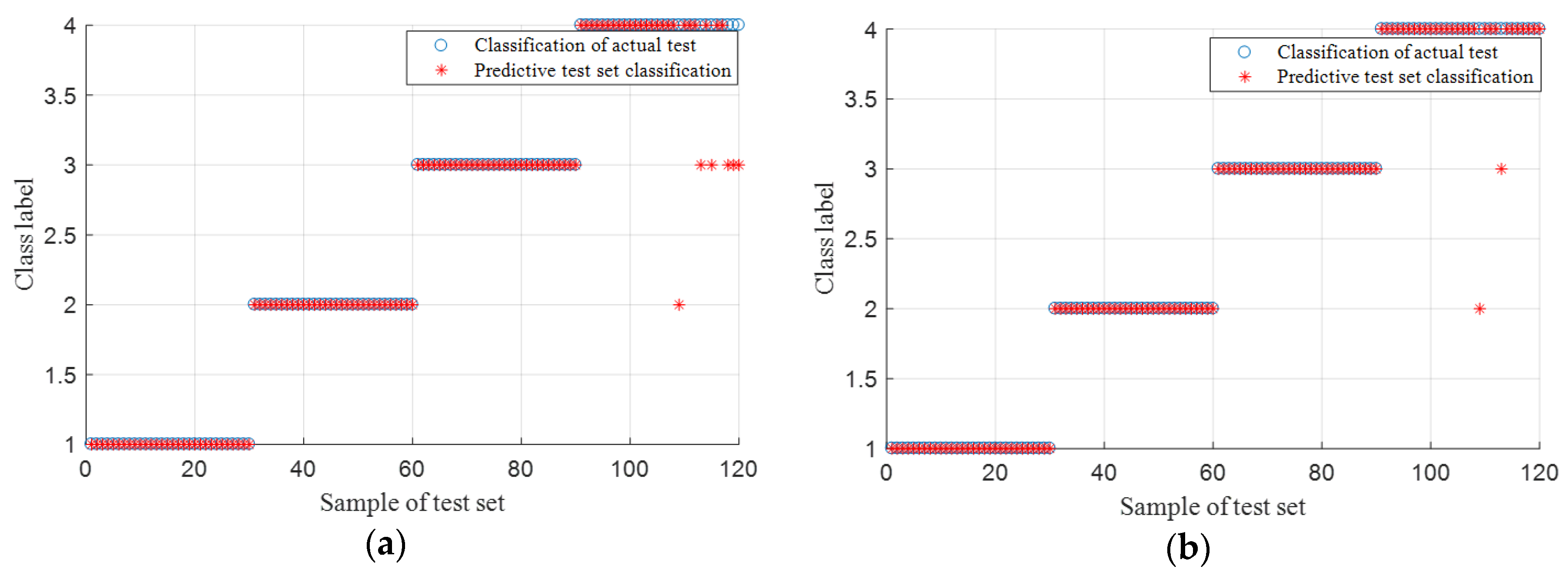

To be more intuitive in describing the superiority of IMSE, four state data are randomly selected, which included training and testing sets. Then, we calculated MSE and IMSE features. Eigenvector is inputted into the SVM system. Fault classification comparison results are shown in

Figure 7a,b. These two figures show that the classification result processed by IMSE is slightly better than MSE.

Finally, different training samples are used as testing data to illustrate the influence of the number of training samples on identification results. The fault recognition rates of using different methods under different training samples are shown in

Table 3.

Table 3 indicates that when the training sample is selected as 20 and 30, the recognition rates processed by IMSE are slightly higher than those of SE and MSE. When the training samples are greater than 15, with the increase of training samples, identification rates of SE, MSE, and IMSE are gradually increased, and overall recognition rates of IMSE are slightly higher than those of the other methods.

In order to verify the anti-noise ability of MSE and IMSE, we applied these two methods on vibration signals with Gaussian white noise. The signal to noise ratio (SNR) of these added Gaussian white noises are 5, 10, 15 and 20 dB, respectively. These processed results using MSE and IMSE algorithms are shown in

Table 4. From the definition of SNR, the larger the SNR, the smaller the noise mixed in the signal. It can be seen from

Table 4 that the fault recognition rate of IMSE algorithm is slightly higher than that of MSE algorithm.

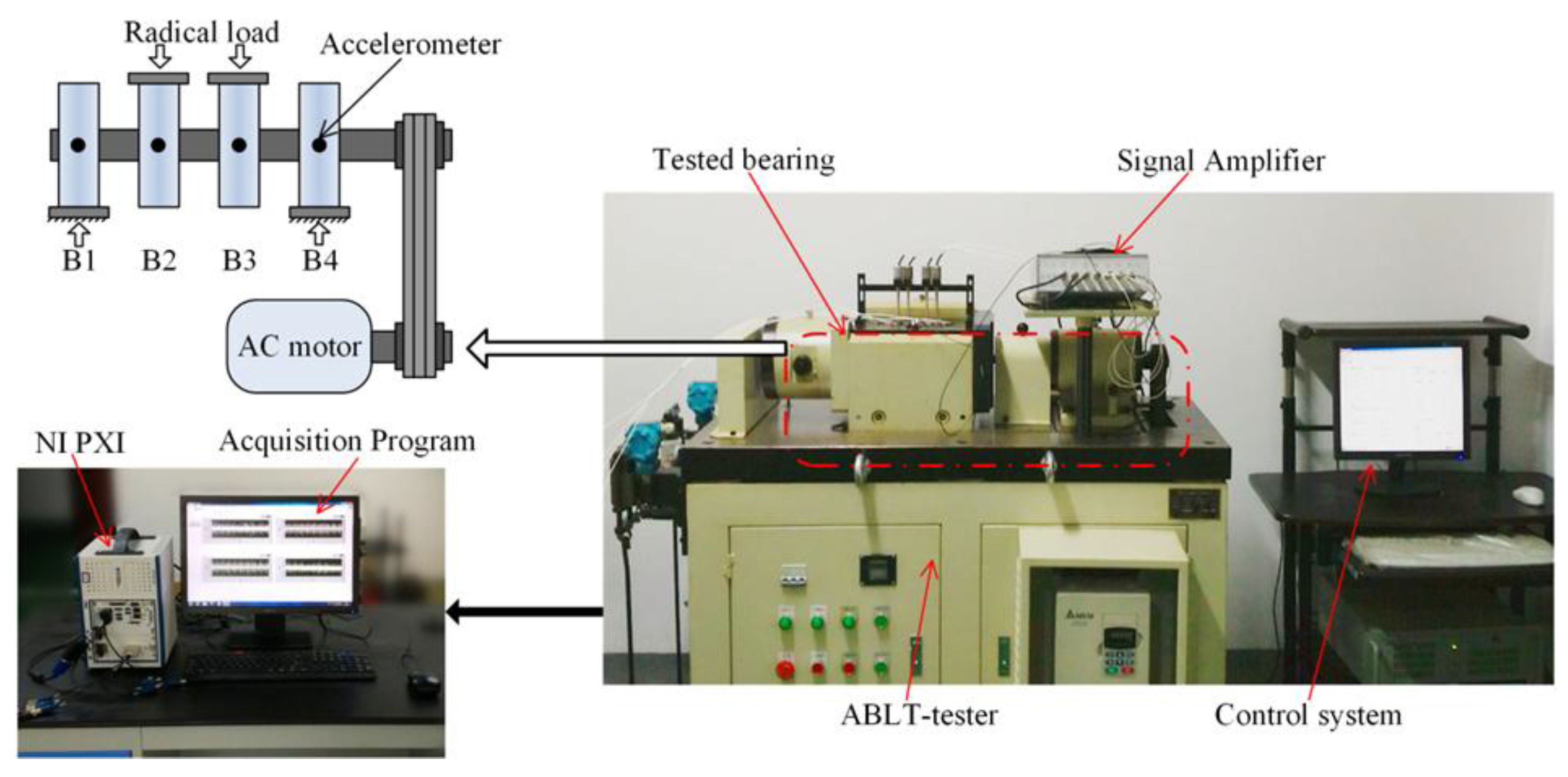

Case II: This experiment combined LabVIEW with other data acquisition devices for acquiring vibration signals. Experimental test platform is shown in

Figure 8. Detailed facilities included ABLT test platform, signal enhancement equipment, monitoring system, four tested bearings, and NI PXI acquisition system. Production type of the tested bearing is HRB6305. The tested bearing is embedded into the bearing sleeve. A three-phase electric motor provides the power. The bell is connected to the motor through the pulley. Radial load of the loading system

P = 20 kN is loaded into the tested bearing. The rotating rated speed of the electric motor

nr = 3000 r/min, the rated current

Ie = 6.3 A, and the sampling frequency

fs = 20 kHz. Tested bearing with different fault types is presented in

Figure 9. Acquired vibration signals in time domain with different status are given in

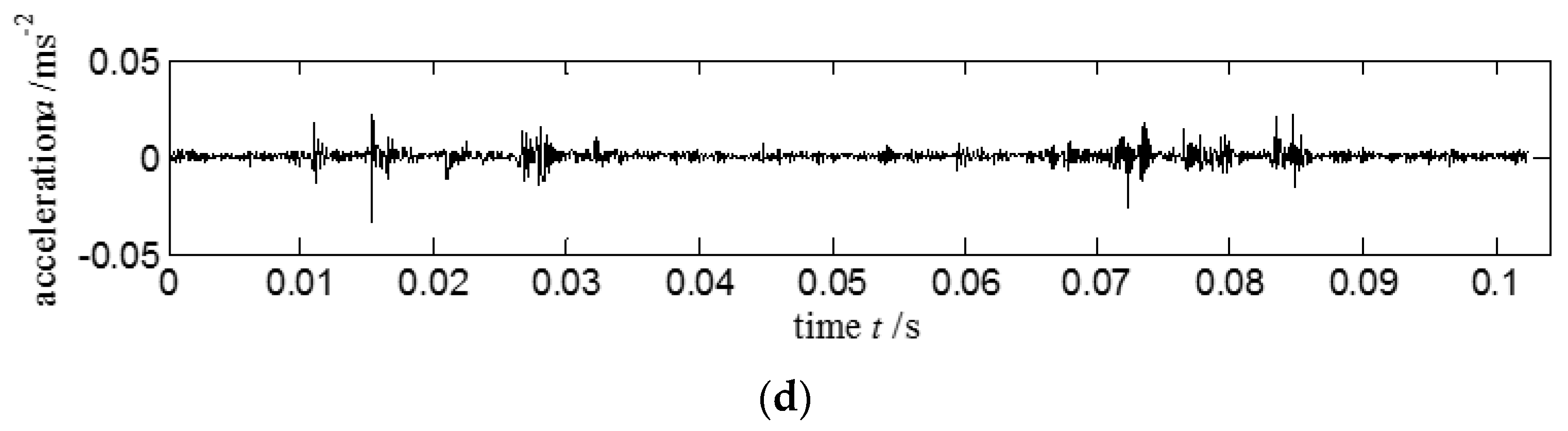

Figure 10.

Figure 10a–d show the vibration signals of the bearing with normal, inner race-way fault, outer race-way fault and roller fault, respectively.

In this part, MSE and IMSE are applied to evaluate the recognition rate quantitatively. From

Table 5, when

k = 6, the recognition rate processed by IMSE is higher than the MSE. Fault recognition results using these two features are shown in

Figure 11.

Figure 11a shows the classification result using MSE.

Figure 11b shows the classification result using IMSE. The two subfigures indicate that the obtained fault identifiability handled with IMSE is slightly better than that of the MSE. The experimental results showed that the fault recognition using IMSE is better than the MSE.

Classification results are illustrated in

Figure 12a,b, respectively.

Figure 12a shows that five test samples with roller fault are wrongly classified into the outer race-way fault, and one test sample is wrongly classified into the inner race-way fault.

Figure 12b indicates that only two test samples with roller fault are wrongly classified into the outer and inner race-way faults. Experimental results of this case show the improvement in fault identification using IMSE compared with MSE.

Table 6 shows the quantitative analysis results. Here, different recognition rates using different classification methods are shown under different training samples numbers. Under different training samples numbers, identification rates processed by IMSE are higher than the other methods. The higher the fault recognition rate, the more accurate the detection of the bearing faults.