Synthesis of PLA-b-PEG Multiblock Copolymers for Stealth Drug Carrier Preparation

Abstract

:Introduction

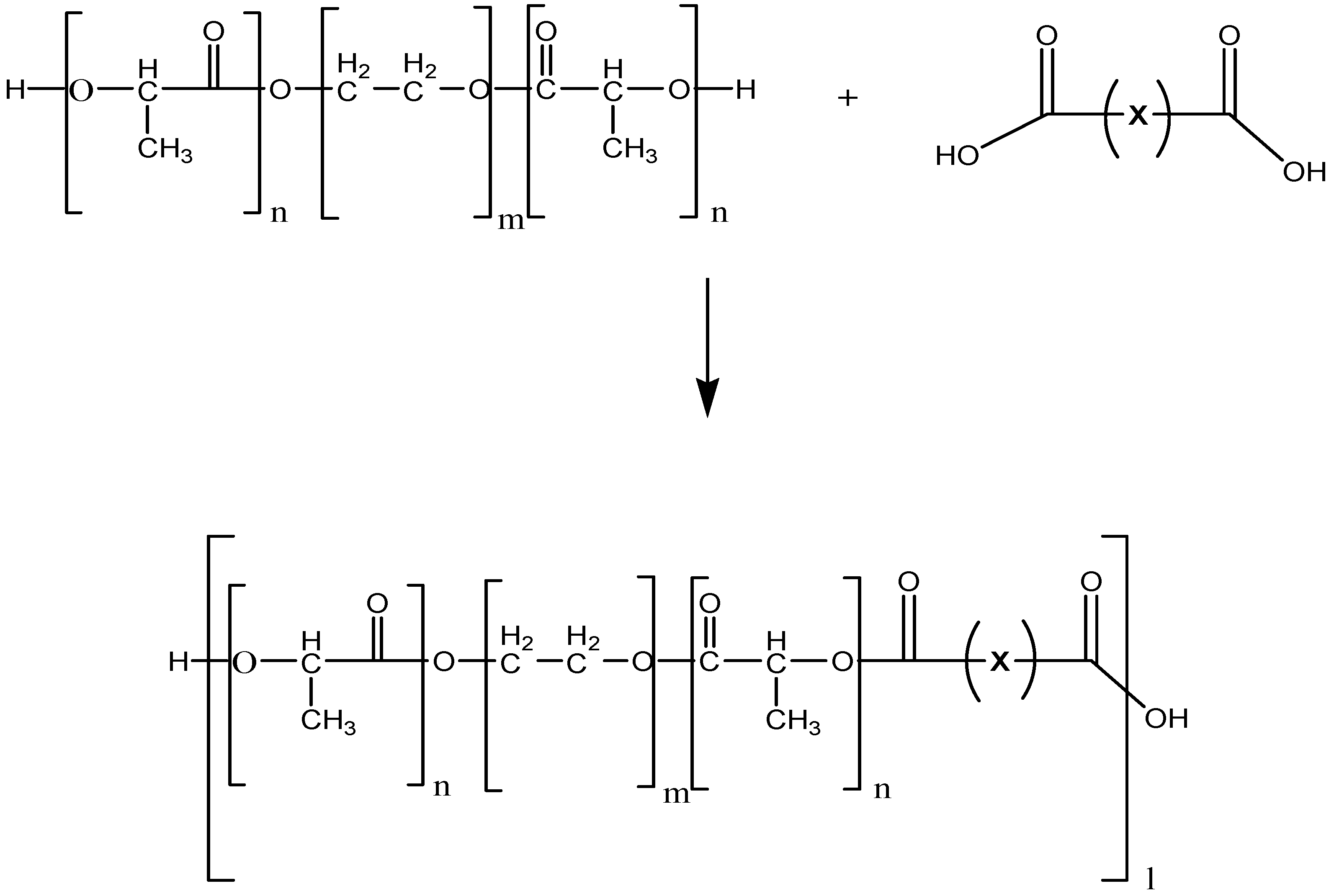

Results and Discussion

| Sample | MWNMR | MN | MW | MW/MN | PEG % |

|---|---|---|---|---|---|

| 1a | 955.84 | 926.29 | 1695.8 | 1.83 | 9.5 |

| 1b | 1710.0 | 900.84 | 1285.34 | 1.43 | 5.56 |

| 1c | 2289.68 | 2835.22 | 3595.42 | 1.27 | 9.12 |

| 1d | 3769.6 | 3863 | 4485 | 1.16 | 2.17 |

| 1e | 15488 | 13466 | 20623 | 1.53 | 0.51 |

| Sample | MN (g/mol) | MW (g/mol) | MW/MN |

|---|---|---|---|

| 2a | 1983.87 | 2670.60 | 1.35 |

| 2b | 3646.71 | 8537.77 | 2.34 |

| 2c | 6607.95 | 12040.6 | 1.82 |

| 3a | 4246 | 5132 | 1.21 |

| 4a | 18815 | 31309 | 1.66 |

| Polymer | Contact angle ( t = 0s ) | Contact angle ( t = 420s ) |

|---|---|---|

| PLA | 73.7 | 49.3 |

| Multiblock 2a (PEG 200) | 59.6 | 38.6 |

| Multiblock 2b (PEG 400) | 19.2 | 2.0 |

| Multiblock 2c (PEG 1450) | 17.6 | 0.6 |

| NS composition (multiblock:PLA) | Size (nm) ± sd | ζ (mV) ± sd |

|---|---|---|

| 40:60 | 785.0 ± 169.8 | -1.68± 0.45 |

| 50:50 | 336.1 ± 92.5 | -1.28± 0.75 |

| 60:40 | 513.1 ± 107.9 | -0.64± 0.60 |

| 70:30 | 717.3 ± 141.4 | +0.64± 0.75 |

| 80:20 | 536.3 ± 42.4 | +0.94± 0.45 |

| 90:10 | 560.6 ± 72.5 | +1.10± 0.55 |

Conclusions

Experimental

General

References

- Rosen, H.B.; Chang, J.; Wnek, G.E.; Linhardt, R.J.; Langer, R. Bioerodible polyanhydrides for drug delivery. Biomaterials 1983, 4, 131–133. [Google Scholar] [CrossRef]

- Peppas, N.A.; Sahlin, J.J. Hydrogels as Mucoadhesive and Bioadhesive materials: a review. Biomaterials 1996, 17, 1553–1561. [Google Scholar]

- Ogawa, Y. Injectable microcapsules prepared with biodegradable poly(alpha-hydroxy) acids for prolonged release of drugs. J. Biomat. Sci. Polym. E. 1997, 8, 391–409. [Google Scholar]

- Jain, R.A. The manufacturing techniques of various drug loaded biodegradable poly(lactide-co-glycolide) (PLGA) devices. Biomaterials 2000, 21, 2475–90. [Google Scholar]

- Fournier, E.; Passirani, C.; Montero-Menei, C.; N. Benoit, J. P. Biocompatibility of implantable synthetic polymeric drug carriers: focus on brain biocompatibility. Biomaterials 2003, 24, 3311–3331. [Google Scholar]

- Piskin, E.; Kaitian, X.; Denkbas, E.B.; Kucukyavuz, Z. Novel PDLLA/PEG copolymer micelles as drug carrier. J. Biomat. Sci. Polym. Ed. 1995, 7, 359–373. [Google Scholar]

- Celikkaya, E.; Denkbas, E.B.; Piskin, E. Rifampicin Carrying Poly (D,L-Lactide)/Poly (Ethylene Glycol) Microspheres: Loading and Release. Artif. Organs 1996, 20, 743–751. [Google Scholar]

- Ronneberger, B.; Kao, W. J.; Anderson, J. M.; Kissel, T. In vivo biocompatibility study of aba triblock copolymers consisting of poly(l-lactic-co-glycolic acid) a blocks attached to central poly(oxyethylene) b blocks. J. Biomed. Mat. Res. 1996, 30, 31–40. [Google Scholar]

- Zhang, X.C.; Jackson, J. K.; Wong, W.; Min, W. X.; Cruz, T.; Hunter, W. L.; Burt, H. M. Development of biodegradable polymeric paste formulations for taxol - an in vitro and in vivo study. Int. J. Pharm. 1996, 137, 199–208. [Google Scholar]

- Zhu, K.J.; Xiangzhou, L.; Shilin, Y. Preparation, Charcterisation, and Properties of Polylactide (PLA)-Poly(ethylene Glycol) (PEG) Copolymers: A potential Drug Carrier. J. Appl. Polym. Sci. 1990, 39, 1–9. [Google Scholar]

- Youxin, L.; Kissel, T. Synthesis and properties of biodegradable ABA triblock copolymers consisting of poly (L-lactic acid) or poly (L-lactic-co-glycolic acid) A-blocks attached to central poly (oxyethylene) B-block. J. Control. Rel. 1993, 27, 247–257. [Google Scholar]

- Ferruti, P.; Penco, M.; D'Addato, P.; Ranucci, E.; Deghenghi, R. Synthesis and properties of novel block copolymers containing poly(lactic-glycolic acid) and poly(ethyleneglycol) segments. Biomaterials 1995, 16, 1423–1428. [Google Scholar]

- Cohn, D.; Younes, H. Biodegradable PEO/PLA block copolymers. J. Biomed. Mat. Res. 1988, 22, 993–1009. [Google Scholar]

- Muller, R.H. Colloidal carriers for controlled drug delivery and targeting: modification, characterization, and in vivo distribution, CRC Press Inc.: Boca Raton, Florida, 1991; 45–46.

- Panoyan, A.; Quesnel, R.; Hildgen, P. Injectable nanospheres from a novel multiblock copolymer: cytocompatibility, degradation and in vitro release studies. J. Microencapsul. 2003, 20, 745–58. [Google Scholar]

© 2005 by MDPI (http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.

Share and Cite

Quesnel, R.; Hildgen, P. Synthesis of PLA-b-PEG Multiblock Copolymers for Stealth Drug Carrier Preparation. Molecules 2005, 10, 98-104. https://doi.org/10.3390/10010098

Quesnel R, Hildgen P. Synthesis of PLA-b-PEG Multiblock Copolymers for Stealth Drug Carrier Preparation. Molecules. 2005; 10(1):98-104. https://doi.org/10.3390/10010098

Chicago/Turabian StyleQuesnel, R., and P. Hildgen. 2005. "Synthesis of PLA-b-PEG Multiblock Copolymers for Stealth Drug Carrier Preparation" Molecules 10, no. 1: 98-104. https://doi.org/10.3390/10010098