Figure 1.

Fourier Transform Infrared (FT-IR) Spectra of DKL products of three levels of Mw (−1), (0), (+1).

Figure 1.

Fourier Transform Infrared (FT-IR) Spectra of DKL products of three levels of Mw (−1), (0), (+1).

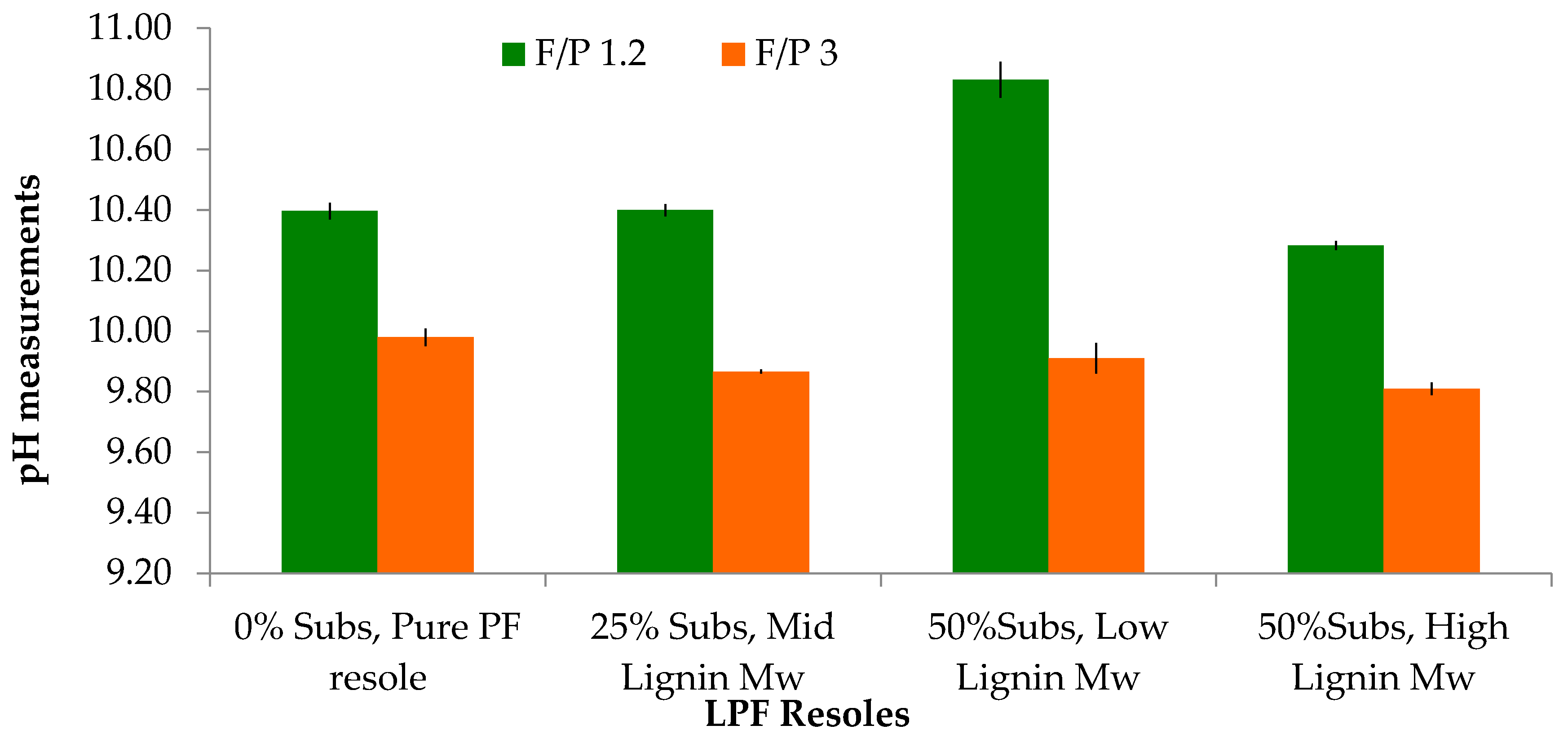

Figure 2.

pH of phenolic resoles with varying F/P ratios for pure PF resoles and BPFs at 25% and 50% phenol substitutions.

Figure 2.

pH of phenolic resoles with varying F/P ratios for pure PF resoles and BPFs at 25% and 50% phenol substitutions.

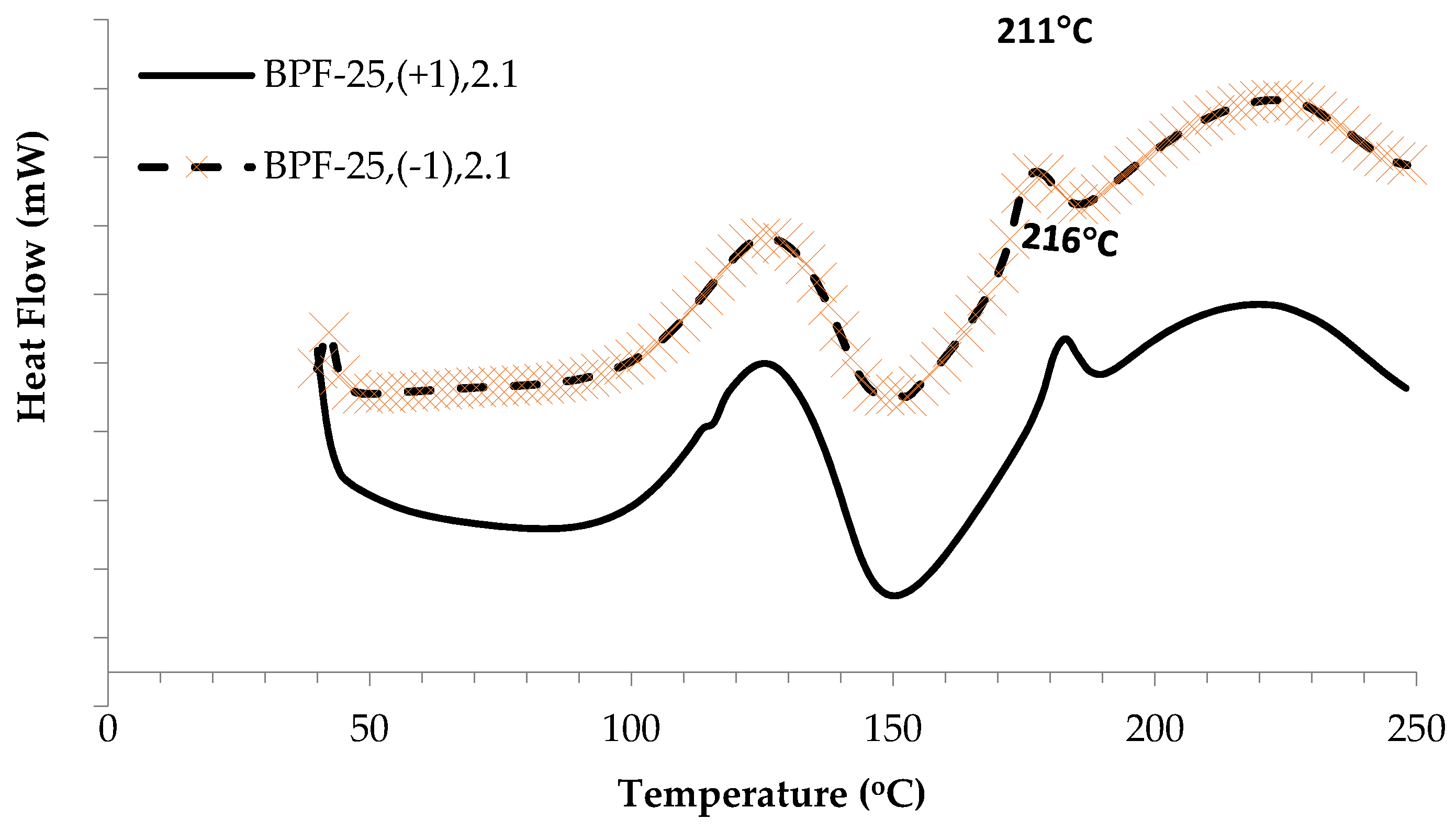

Figure 3.

Effects of lignin molecular weight on curing temperature of the BPF Resins at 25% phenol substitution.

Figure 3.

Effects of lignin molecular weight on curing temperature of the BPF Resins at 25% phenol substitution.

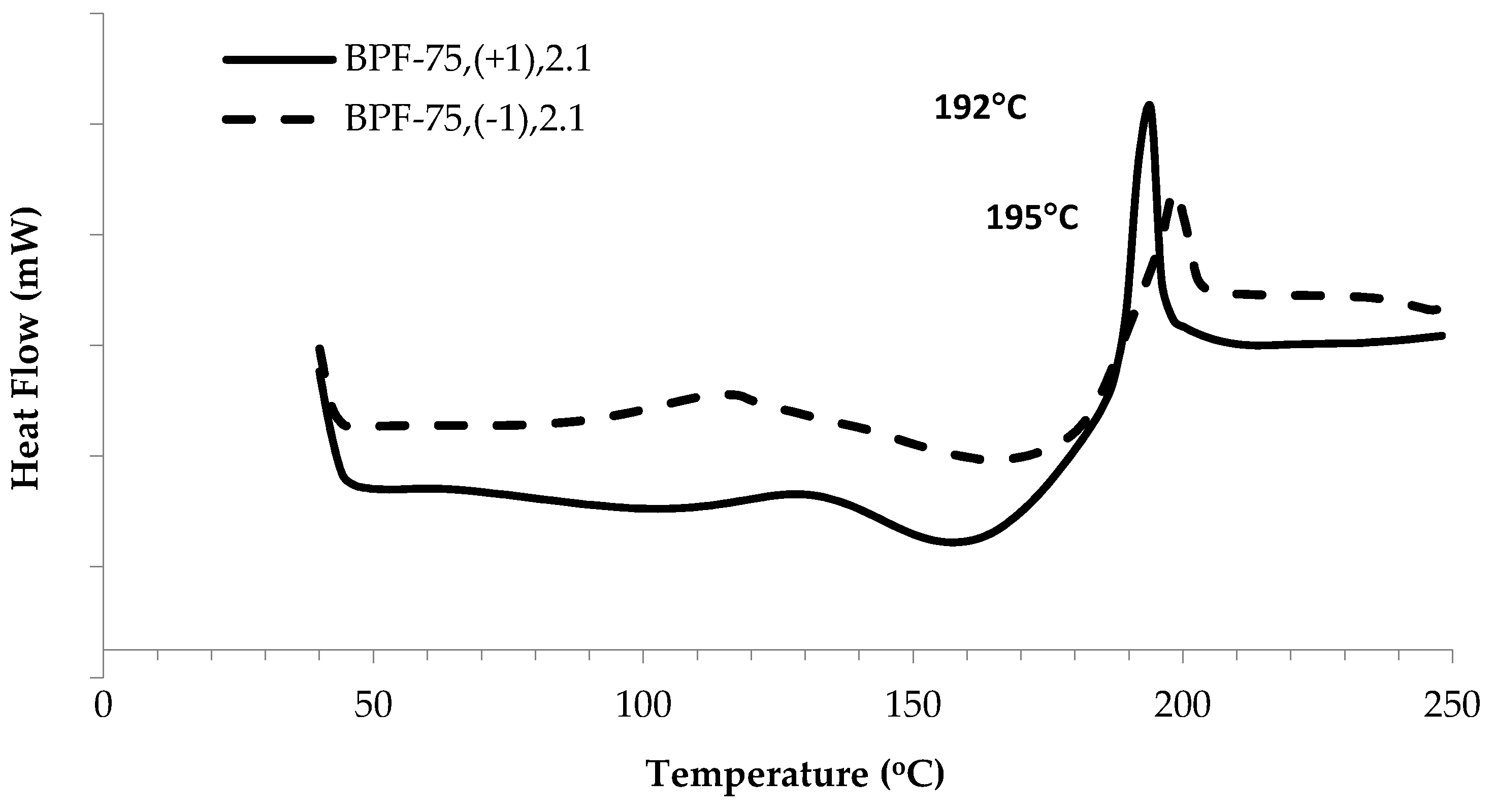

Figure 4.

Effect of lignin molecular weight on curing temperature of BPF resins at 75% phenol substitution.

Figure 4.

Effect of lignin molecular weight on curing temperature of BPF resins at 75% phenol substitution.

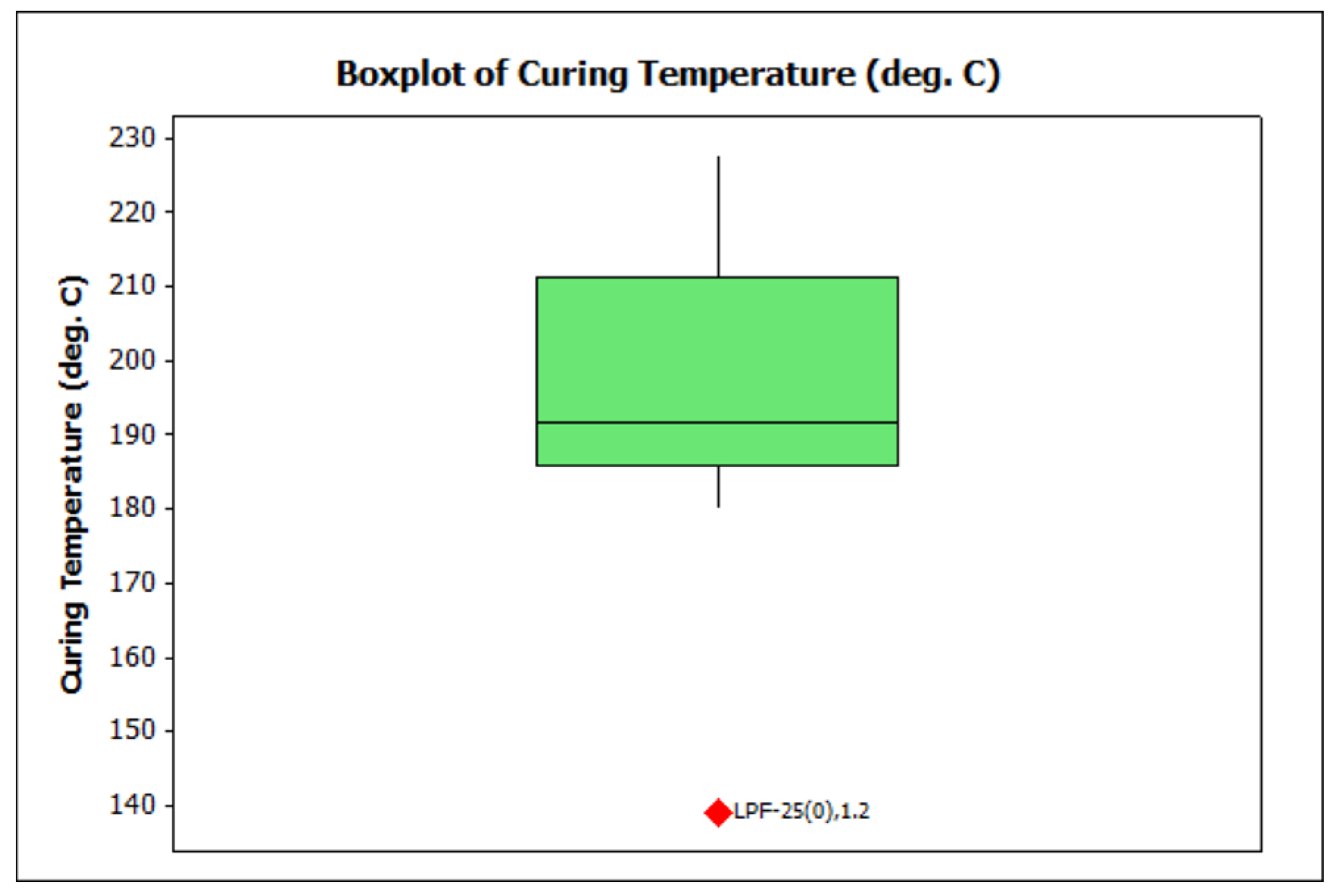

Figure 5.

Box plot of curing temperature (°C).

Figure 5.

Box plot of curing temperature (°C).

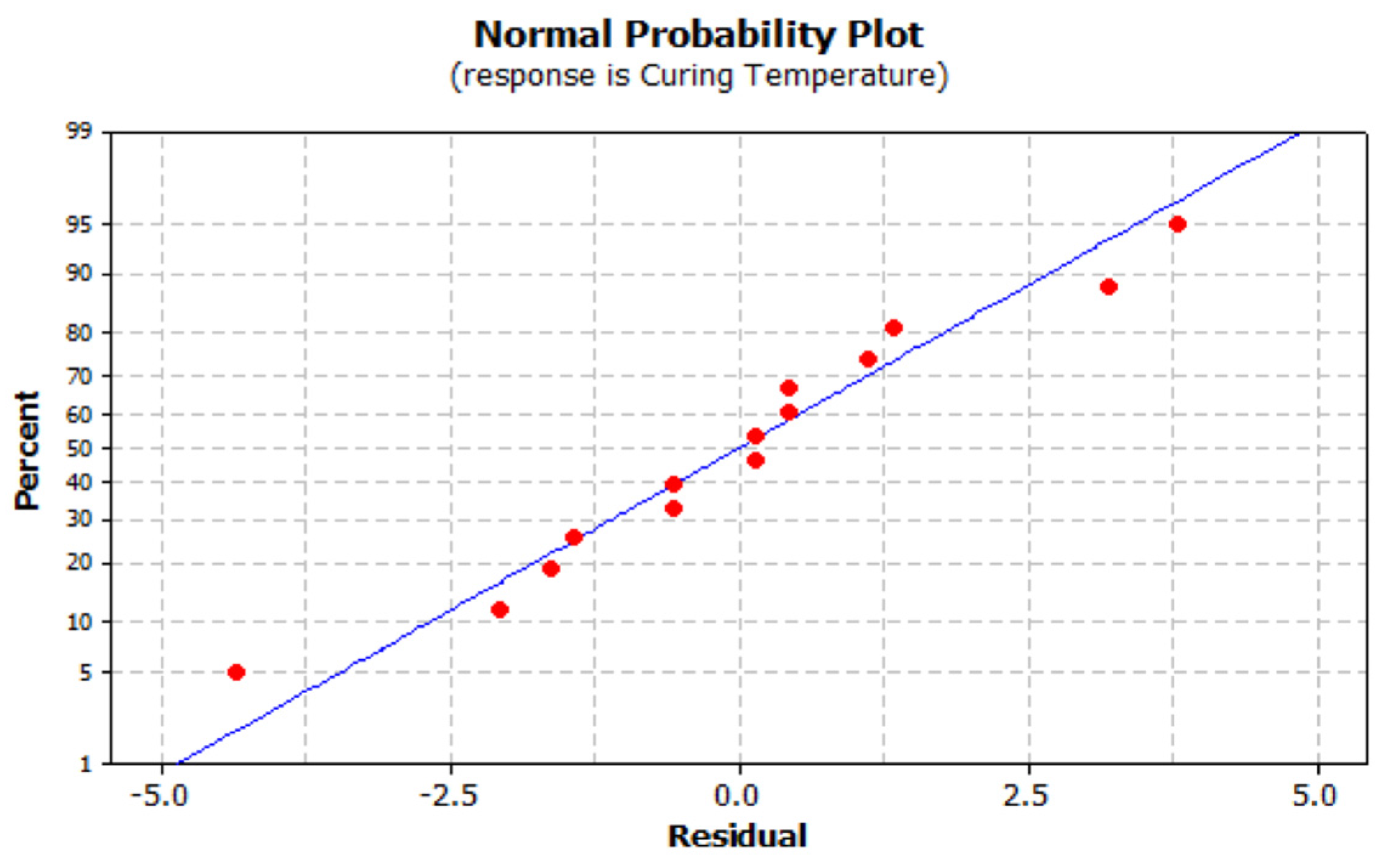

Figure 6.

Normal probability plot for curing temperature (response).

Figure 6.

Normal probability plot for curing temperature (response).

Figure 7.

Residual vs. fitted values of the regression.

Figure 7.

Residual vs. fitted values of the regression.

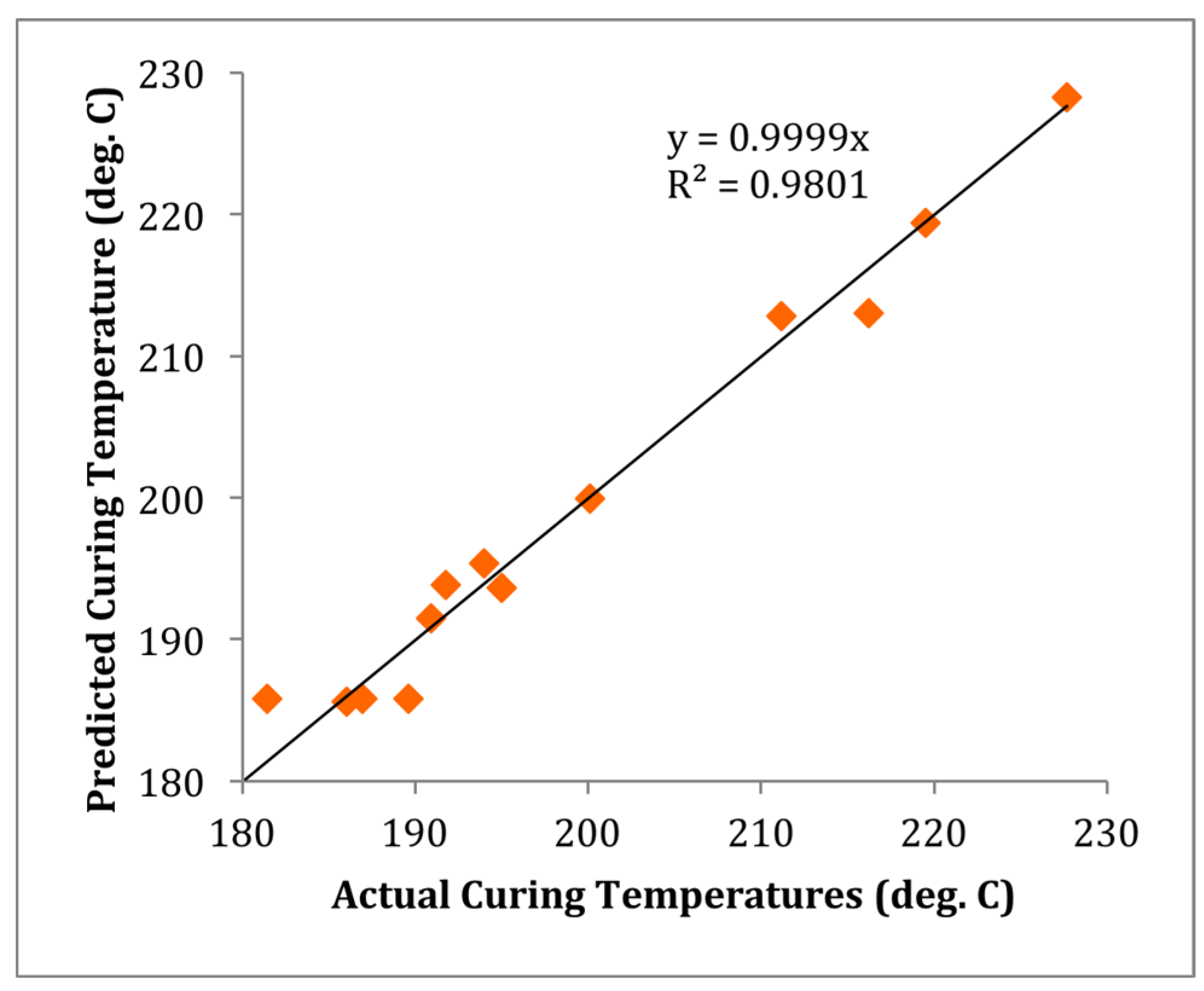

Figure 8.

Predicted vs. actual curing temperatures.

Figure 8.

Predicted vs. actual curing temperatures.

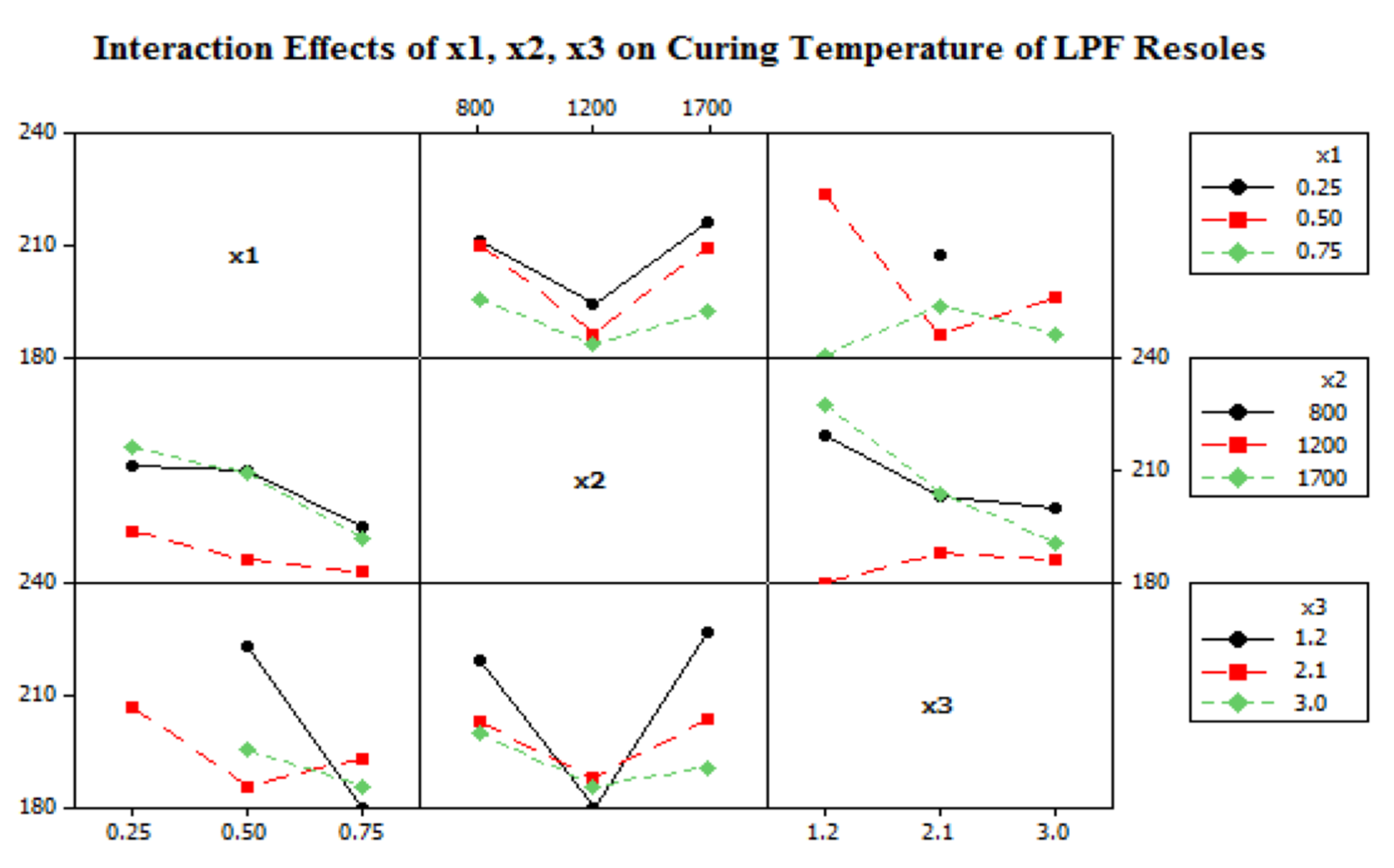

Figure 9.

Interaction effects on curing temperature of BPF resoles.

Figure 9.

Interaction effects on curing temperature of BPF resoles.

Figure 10.

Surface plots for effects of lignin Mw and F/P on curing temperature of BPF resoles at substitution of phenol with lignin at (a) 0.25; (b) 0.50; (c) 0.75.

Figure 10.

Surface plots for effects of lignin Mw and F/P on curing temperature of BPF resoles at substitution of phenol with lignin at (a) 0.25; (b) 0.50; (c) 0.75.

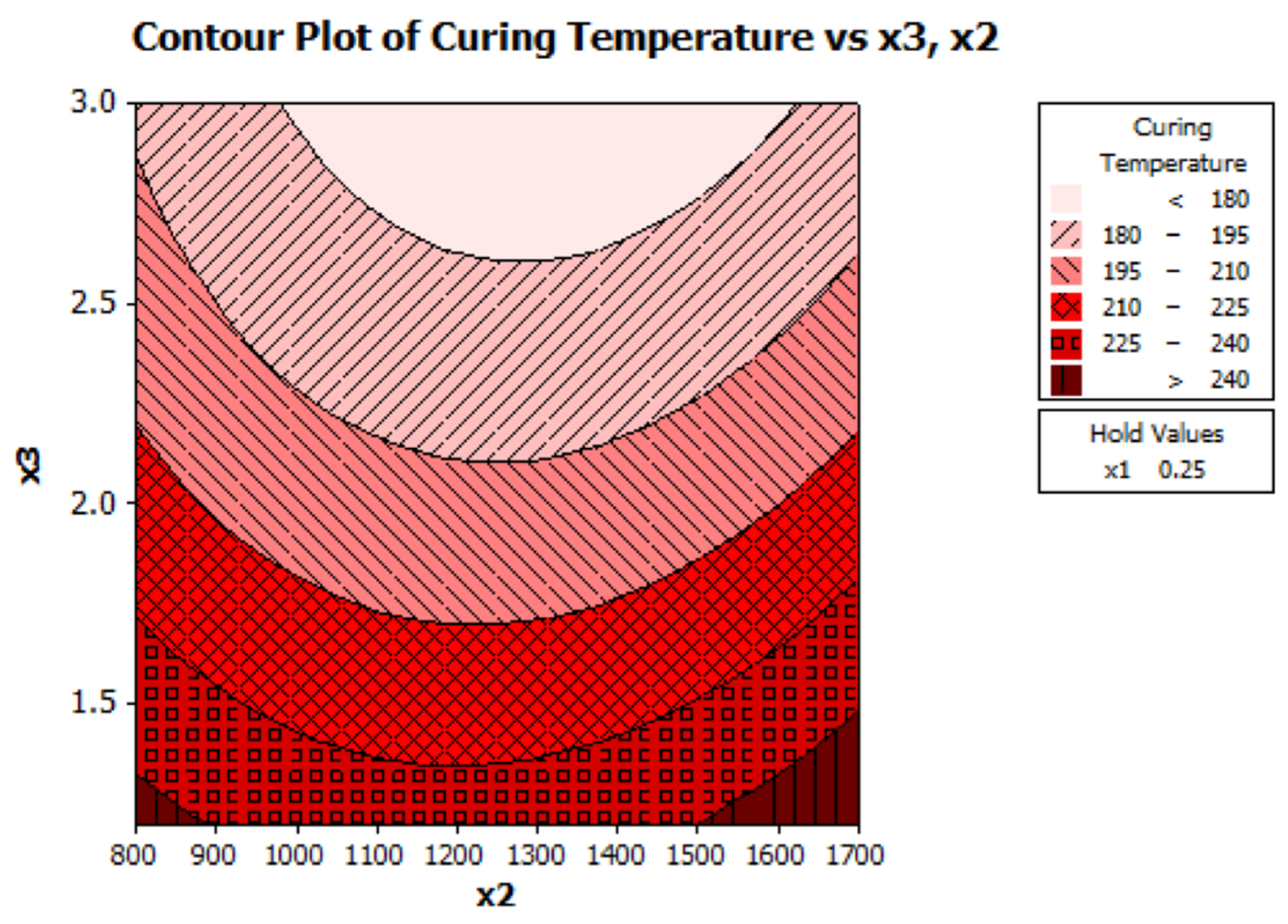

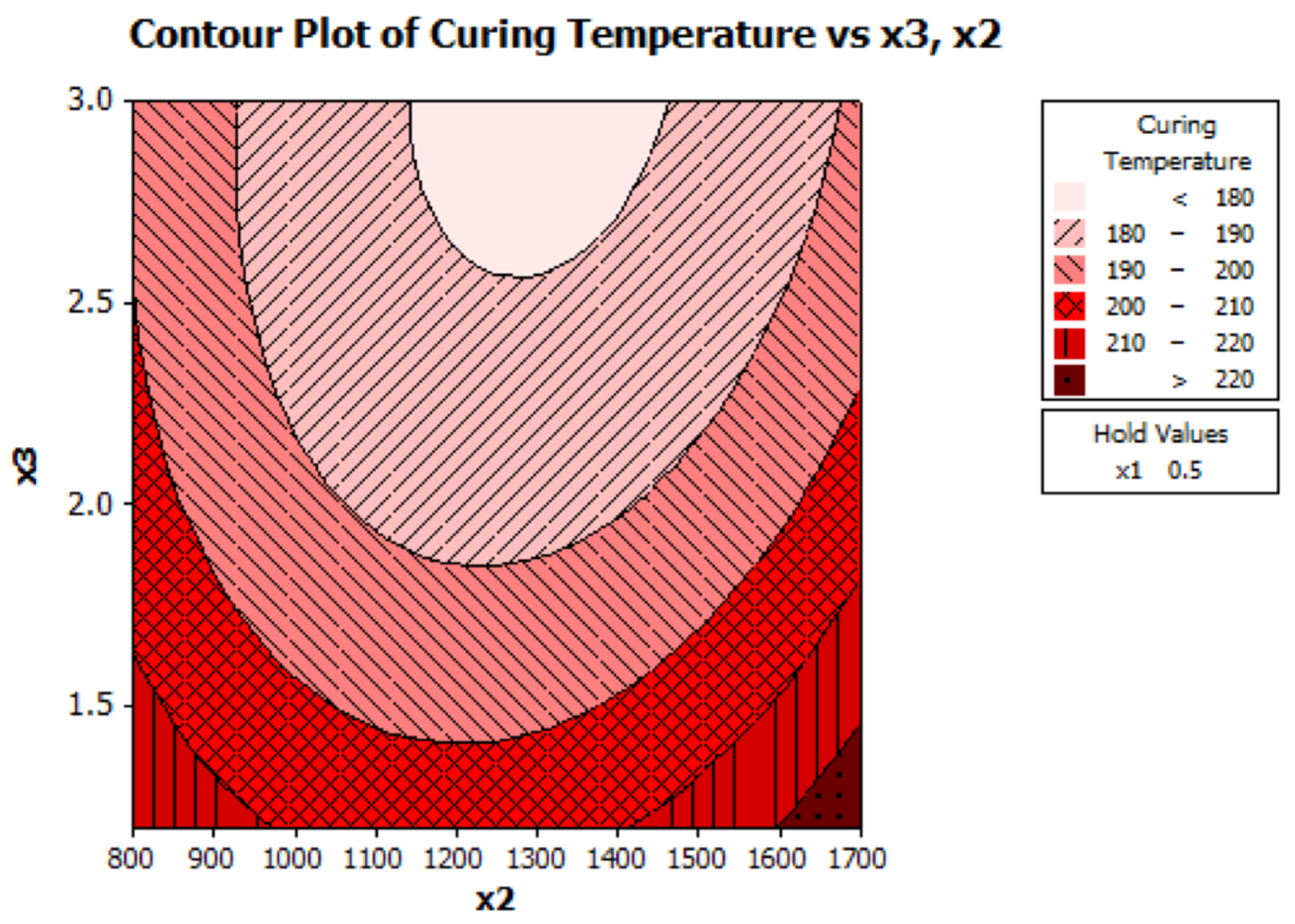

Figure 11.

Contour plot for lignin Mw (X2) and F/P (X3) on curing temperatures of BPF resoles at 25% substitution of phenol with lignin.

Figure 11.

Contour plot for lignin Mw (X2) and F/P (X3) on curing temperatures of BPF resoles at 25% substitution of phenol with lignin.

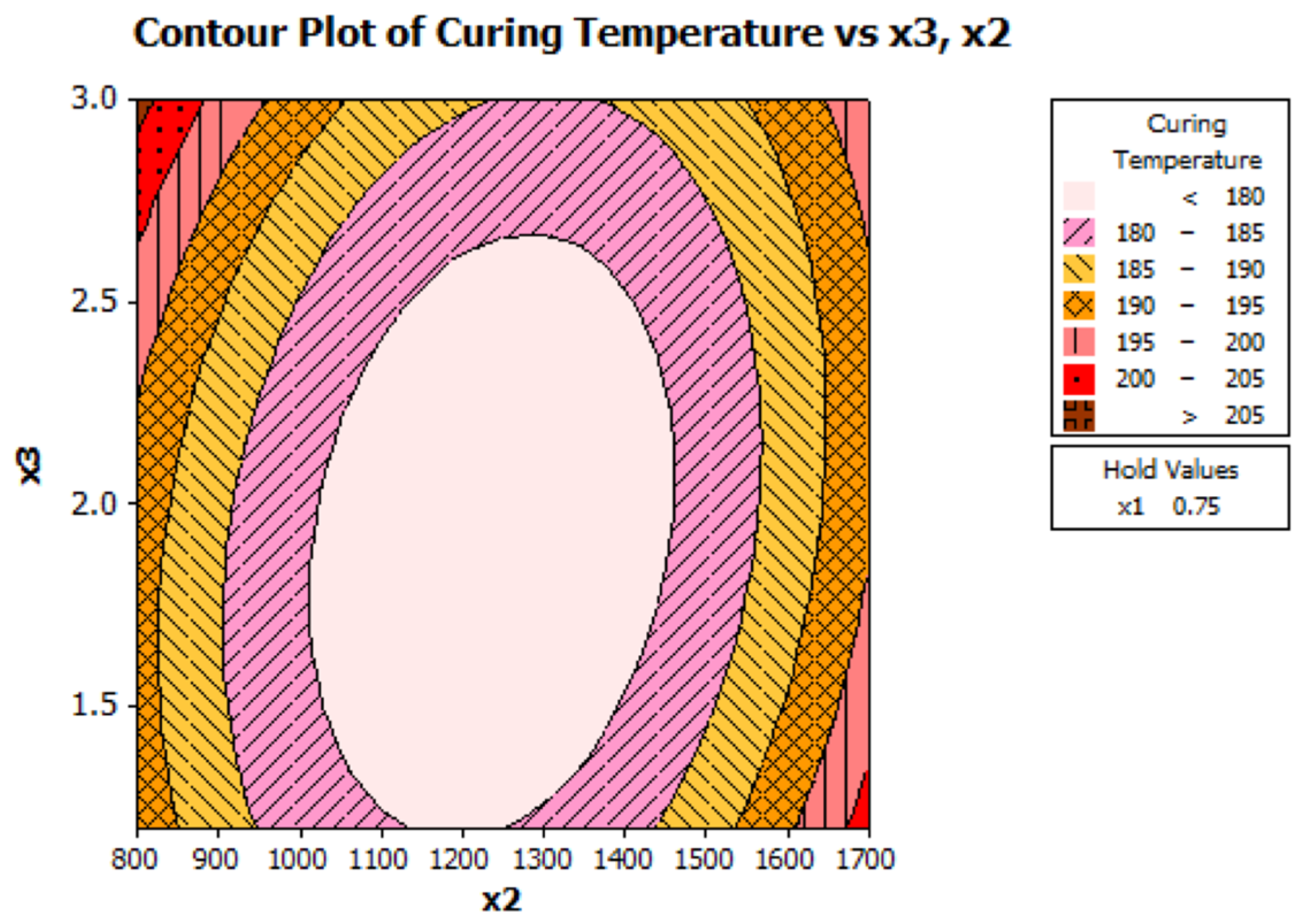

Figure 12.

Contour plot for lignin Mw (X2) and F/P (X3) on curing temperatures of BPF resoles at 50% substitution of phenol with lignin.

Figure 12.

Contour plot for lignin Mw (X2) and F/P (X3) on curing temperatures of BPF resoles at 50% substitution of phenol with lignin.

Figure 13.

Contour plot for lignin Mw (X2) and F/P (X3) on curing temperatures of BPF resoles at 75% substitution of phenol with lignin.

Figure 13.

Contour plot for lignin Mw (X2) and F/P (X3) on curing temperatures of BPF resoles at 75% substitution of phenol with lignin.

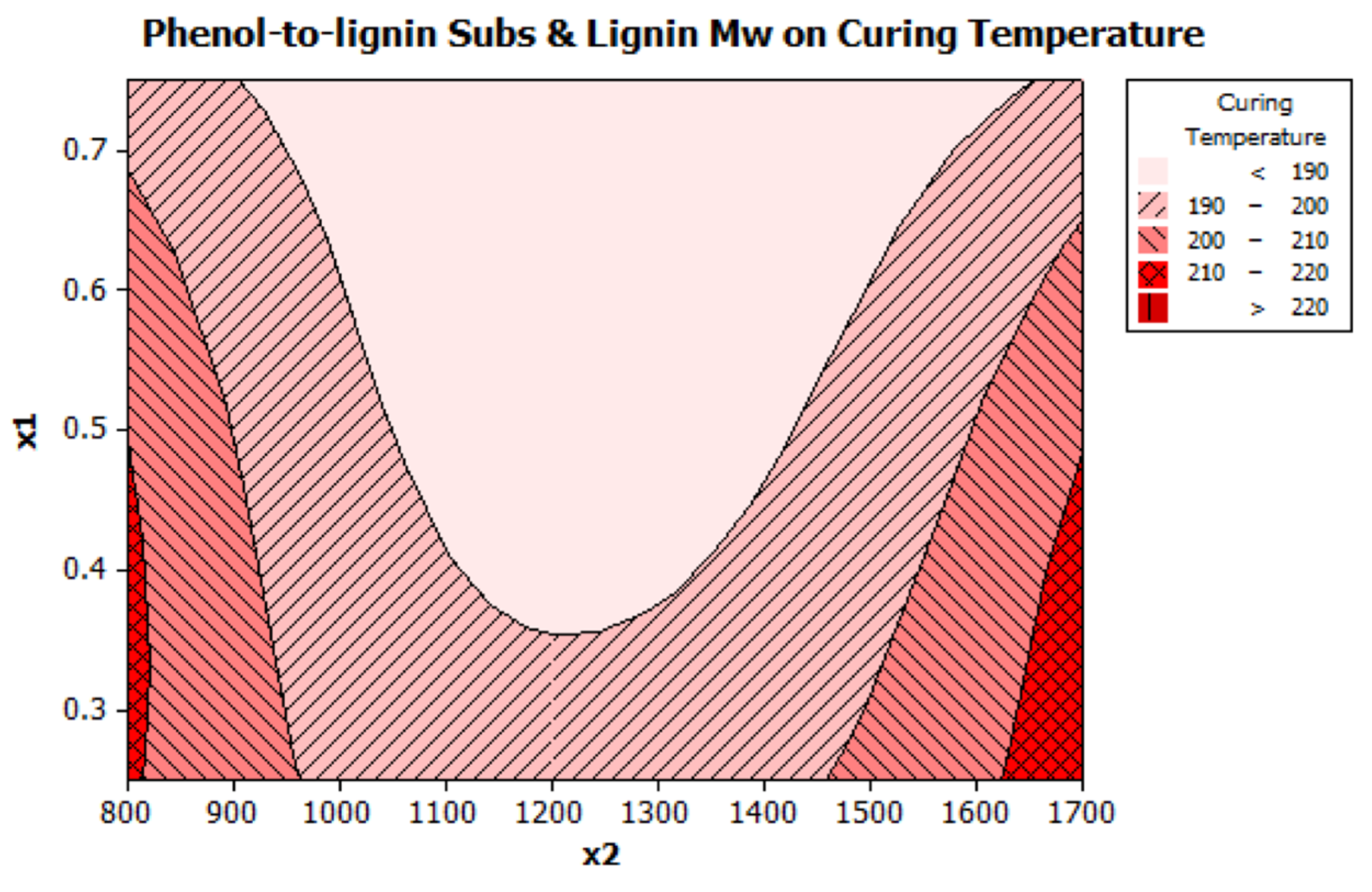

Figure 14.

Contour plot for substitution of phenol with lignin (X1) Mw on curing temperatures of BPF resoles.

Figure 14.

Contour plot for substitution of phenol with lignin (X1) Mw on curing temperatures of BPF resoles.

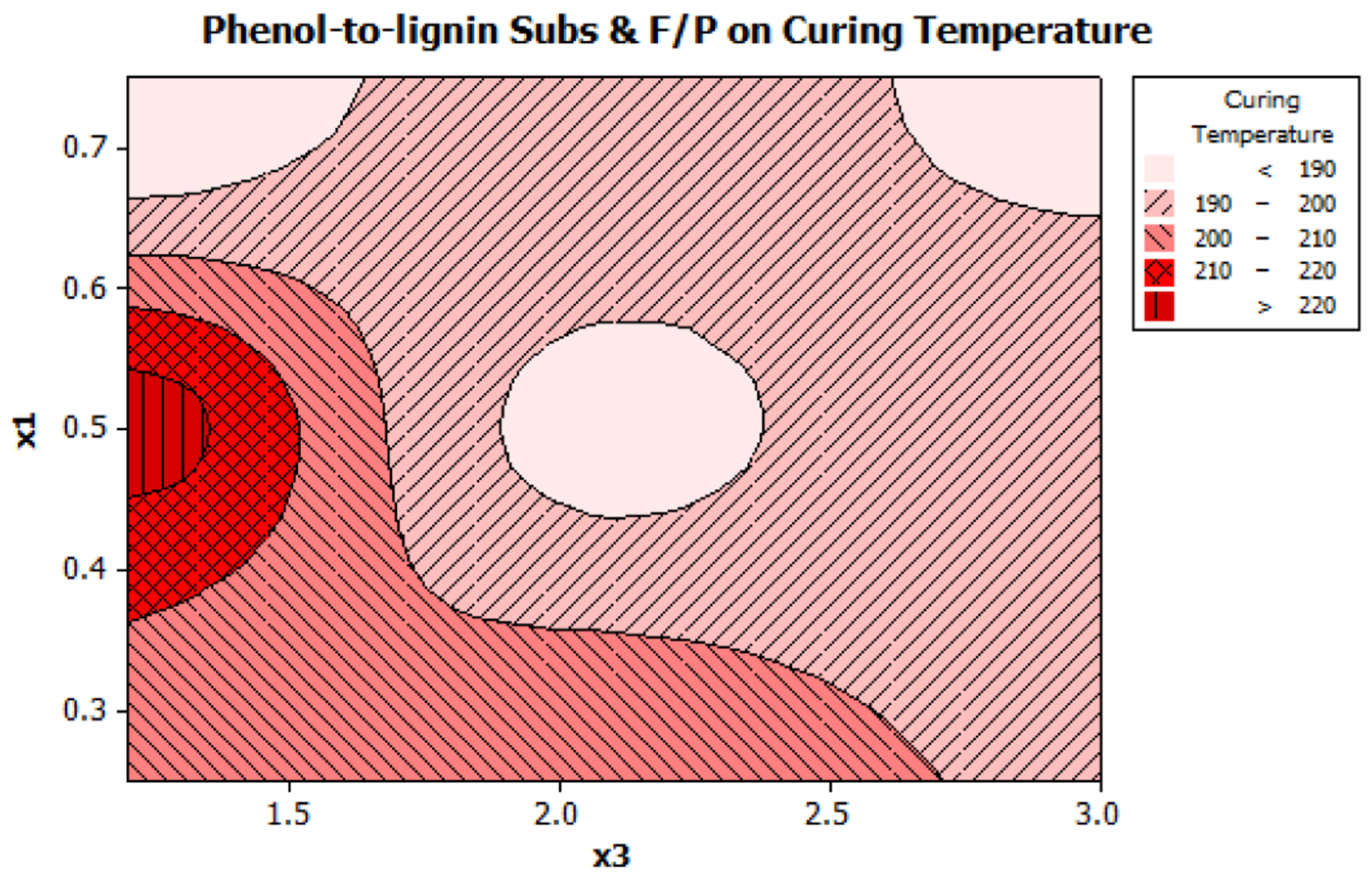

Figure 15.

Contour plot for substitution of phenol with lignin (X1) and F/P (X3) on curing temperatures of BPF resoles.

Figure 15.

Contour plot for substitution of phenol with lignin (X1) and F/P (X3) on curing temperatures of BPF resoles.

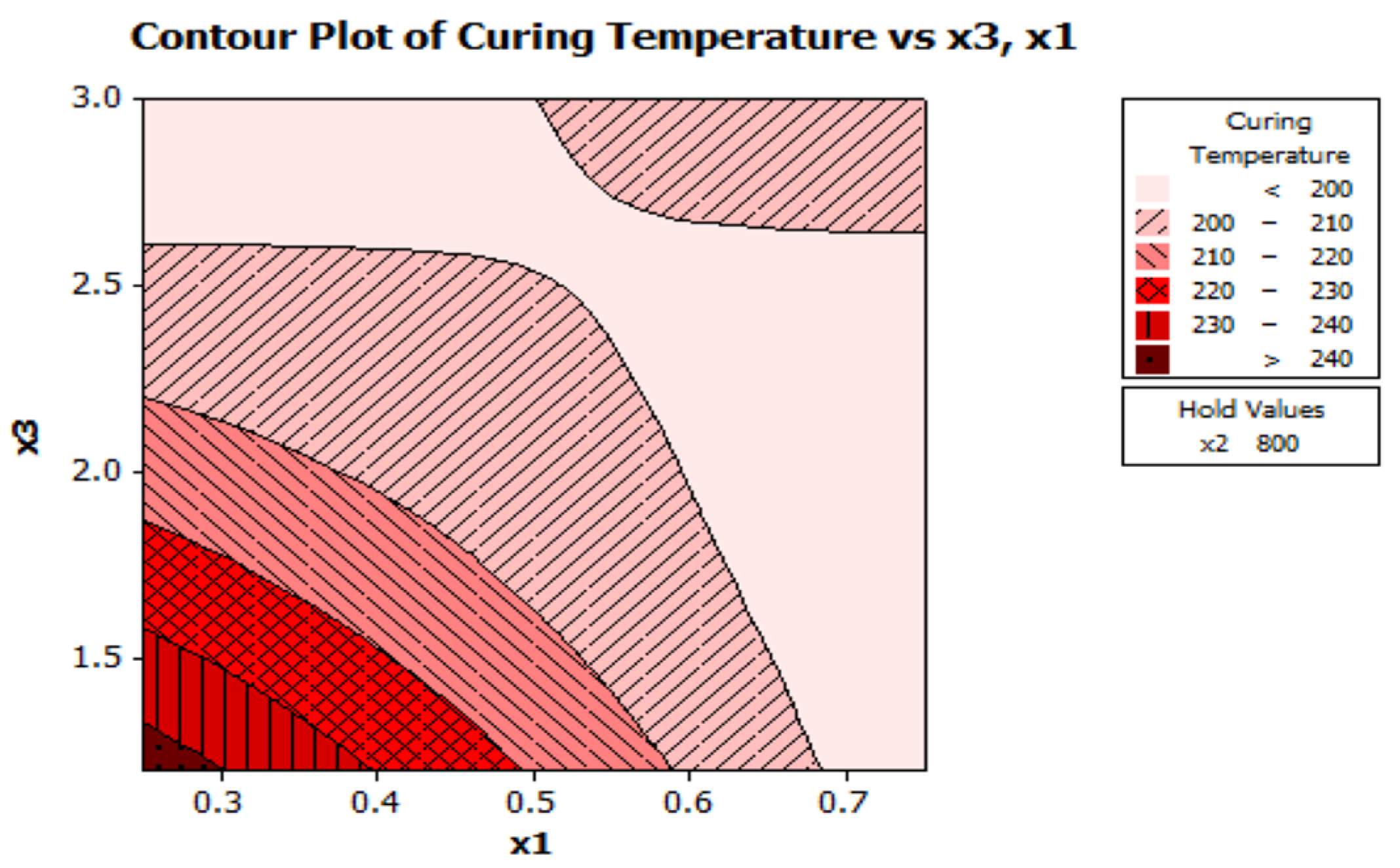

Figure 16.

Contour plot for substitution of phenol with lignin (X1) and F/P (X3) on curing temperatures of BPF resoles at lignin Mw of 800 g/mol.

Figure 16.

Contour plot for substitution of phenol with lignin (X1) and F/P (X3) on curing temperatures of BPF resoles at lignin Mw of 800 g/mol.

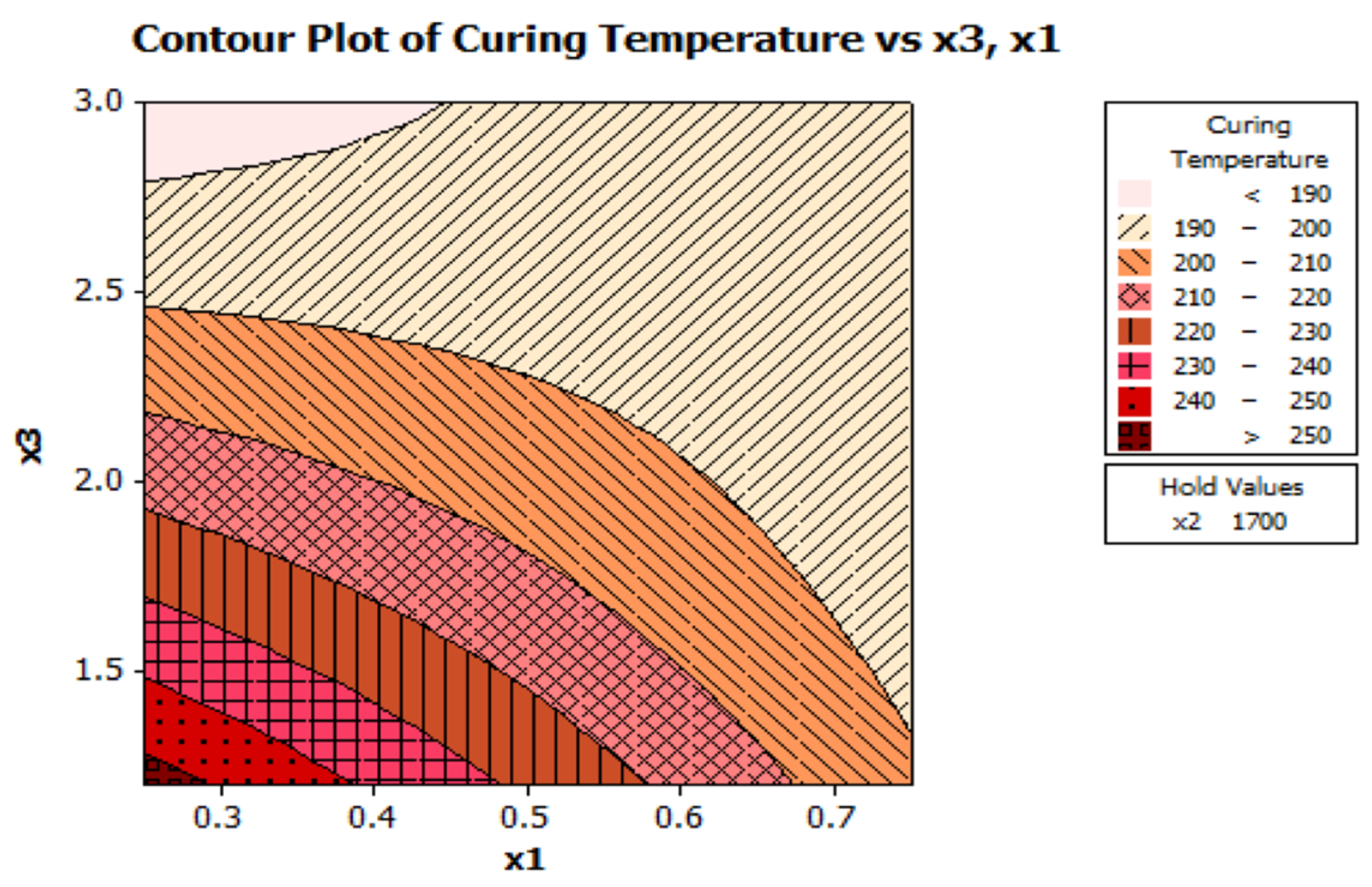

Figure 17.

Contour plot for substitution of phenol with lignin (X1) and F/P (X3) on curing temperatures of BPF resoles at lignin Mw of 1700 g/mol.

Figure 17.

Contour plot for substitution of phenol with lignin (X1) and F/P (X3) on curing temperatures of BPF resoles at lignin Mw of 1700 g/mol.

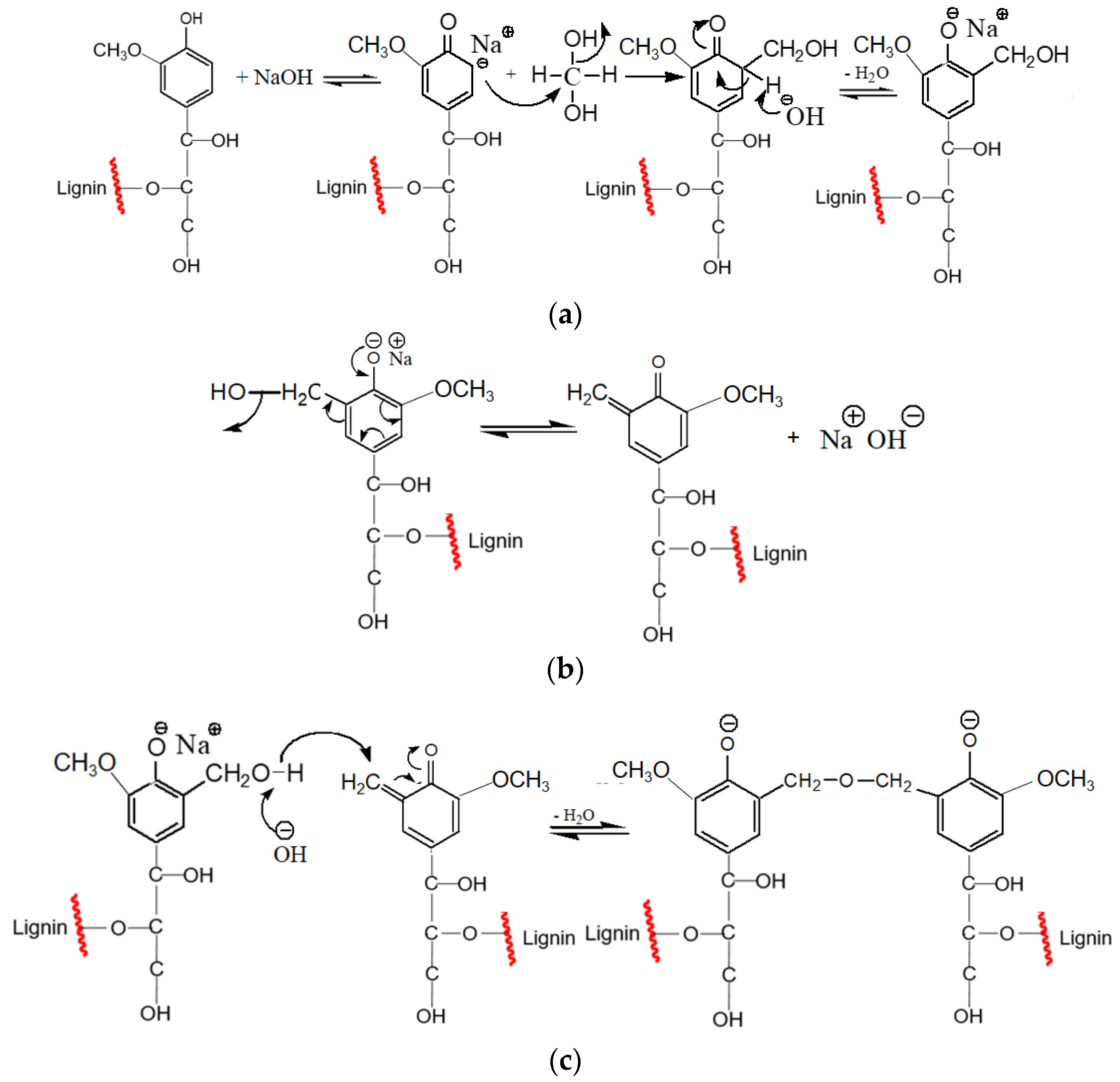

Scheme 1.

The proposed reaction mechanism of lignin-based bio-phenol formaldehyde resin formation. (a) Formation of monosubstituted methylolated phenols through addition reaction; (b) Formation of quinone methide intermediates; (c) Formation of diphenyl-methylene.

Scheme 1.

The proposed reaction mechanism of lignin-based bio-phenol formaldehyde resin formation. (a) Formation of monosubstituted methylolated phenols through addition reaction; (b) Formation of quinone methide intermediates; (c) Formation of diphenyl-methylene.

Table 1.

GPC-UV derived relative Mw and percent yield of the three depolymerized lignin levels.

Table 1.

GPC-UV derived relative Mw and percent yield of the three depolymerized lignin levels.

| Mw of DL | Reaction Temp. (°C) | Residence Time (min) | Mw (g/mol) | DL Yield (wt.%) |

|---|

| Level (−1) | 250 | 45 | 1700 | 83.3 ± 3.7 |

| Level (0) | 300 | 60 | 1200 | 71.1 ± 1.7 |

| Level (+1) | 350 | 45 | 800 | 31.3 ± 2.4 |

Table 2.

Elemental compositions of KL and DKL products obtained from hydrolytic depolymerization reactions at various severities corresponding to different levels (−1 and +1) of Mw.

Table 2.

Elemental compositions of KL and DKL products obtained from hydrolytic depolymerization reactions at various severities corresponding to different levels (−1 and +1) of Mw.

| KL or DKL Level | Elemental Composition |

|---|

| C | H | N | S | O a |

|---|

| KL b | 63.8 | 5.4 | 0.02 | 5.2 | 25.6 |

| DKL, Level (−1) | 63.6 ± 1.8 | 5.3 ± 0.02 | 0.07 ± 0.03 | 1.8 ± 0.11 | 29.2 ± 0.17 |

| DKL, Level (+1) | 75.5 ± 0.16 | 5.9 ± 0.02 | 0.11 ± 0.01 | 0.21 ± 0.04 | 18.2 ± 0.18 |

Table 3.

Viscosity of all BPF resoles synthesized in this study.

Table 3.

Viscosity of all BPF resoles synthesized in this study.

| Sample ID | Viscosity (cP) |

|---|

| LPF-25,(−1),2.1 | 26 ± 1.2 |

| LPF-50,(−1),1.2 | 229 ± 8.5 |

| LPF-50,(−1),3 | 165 ± 7.2 |

| LPF-75,(−1),2.1 | 191 ± 3.5 |

| LPF-25,(+1),2.1 | 124 ± 0.4 |

| LPF-50,(+1),1.2 | 288 ± 0.8 |

| LPF-50,(+1),3 | 137 ± 1.2 |

| LPF-75,(+1),2.1 | 348 ± 0.6 |

| LPF-25,(0),1.2 | 124 ± 0.1 |

| LPF-25,(0),3 | 16 ± 0.1 |

| LPF-50,(0),2.1 | 40 ± 0.1 |

| LPF-75,(0),1.2 | >5000 |

| LPF-75,(0),3 | >5000 |

Table 4.

NVC of BPF resoles with varying phenol percent substitutions (left to right).

Table 4.

NVC of BPF resoles with varying phenol percent substitutions (left to right).

| 25% Substitution | NVC (wt.%) | 75% Substitution | NVC (wt.%) |

|---|

| BPF-25,(−1),2.1 | 36 | BPF-75,(−1),2.1 | 26 |

| BPF-25,(+1),2.1 | 34 | BPF-75,(+1),2.1 | 30 |

Table 5.

NVC of BPF resoles with varying phenol percent substitutions (left to right).

Table 5.

NVC of BPF resoles with varying phenol percent substitutions (left to right).

| F/P of 1.2 | NVC (wt.%) | F/P of 3 | NVC (wt.%) |

|---|

| BPF-50,(−1),1.2 | 44 | BPF-50,(−1),3 | 33 |

| BPF-50,(+1),1.2 | 35 | BPF-50,(+1),3 | 28 |

| BPF-25,(0),1.2 | 35 | BPF-25,(0),3 | 30 |

| BPF-75,(0),1.2 | 41 | BPF-75,(0),3 | 39 |

Table 6.

NVC of BPF resoles with increasing Mw of DL (left to right).

Table 6.

NVC of BPF resoles with increasing Mw of DL (left to right).

| Low Mw of DL | NVC (wt.%) | High Mw of DL | NVC (wt.%) |

|---|

| BPF-25,(−1),2.1 | 36 | BPF-25,(+1),2.1 | 34 |

| BPF-50,(−1),1.2 | 44 | BPF-50,(+1),1.2 | 35 |

| BPF-50,(−1),3 | 33 | BPF-50,(+1),3 | 28 |

| BPF-75,(−1),2.1 | 26 | BPF-75,(+1),2.1 | 30 |

Table 7.

BBD Matrix for the effect of phenol-to-lignin substitution, (X1) Lignin Mw (X2). F/P molar ratio (X3) on the Curing Temperature (°C) of BPF resoles including experimental results.

Table 7.

BBD Matrix for the effect of phenol-to-lignin substitution, (X1) Lignin Mw (X2). F/P molar ratio (X3) on the Curing Temperature (°C) of BPF resoles including experimental results.

| Sample ID 1 | Experiment Number | Variable Levels | Response (Curing T) (°C) |

|---|

| X1 | X2 | X3 |

|---|

| BPF-25,(0),1.2 | 1 | −1 | 0 | −1 | 139.27 |

| BPF-25,(0),3 | 2 | −1 | 0 | +1 | 193.95 |

| BPF-75,(0),1.2 | 3 | +1 | 0 | −1 | 180.14 |

| BPF-75,(0),3 | 4 | +1 | 0 | +1 | 185.99 |

| BPF-50,(−1),1.2 | 5 | 0 | −1 | −1 | 219.50 |

| BPF-50,(−1),3 | 6 | 0 | −1 | +1 | 200.09 |

| BPF-50,(+1)1.2 | 7 | 0 | +1 | −1 | 227.66 |

| BPF-50,(+1),3 | 8 | 0 | +1 | +1 | 190.90 |

| BPF-25,(−1),2.1 | 9 | −1 | −1 | 0 | 211.17 |

| BPF-75,(−1)2.1 | 10 | +1 | −1 | 0 | 194.96 |

| BPF-25,(+1),2.1 | 11 | −1 | +1 | 0 | 216.20 |

| BPF-75,(+1),2.1 | 12 | +1 | +1 | 0 | 191.75 |

| BPF-50,(0),2.1 (1) | 13 | 0 | 0 | 0 | 189.57 |

| BPF-50,(0),2.1 (2) | 14 | 0 | 0 | 0 | 186.91 |

| BPF-50,(0),2.1 (3) | 15 | 0 | 0 | 0 | 181.44 |

Table 8.

Statistical significance of the coefficient of regression.

Table 8.

Statistical significance of the coefficient of regression.

| Model Term | Parameter Estimate | Standard Error | T-Value | p-Value |

|---|

| Constant | 185.55 | 1.77 | 105.03 | 0.00 |

| X1 | −9.68 | 1.30 | −7.43 | 0.002 |

| X2 | 0.10 | 1.10 | 0.09 | 0.933 |

| X3 | −14.04 | 1.55 | −9.04 | 0.001 |

| X12 | 0.04 | 1.78 | 0.02 | 0.982 |

| X22 | 17.77 | 1.76 | 10.07 | 0.001 |

| X32 | 6.39 | 1.94 | 3.29 | 0.030 |

| X1X2 | −2.11 | 1.55 | −1.36 | 0.244 |

| X1X3 | 16.49 | 2.70 | 6.12 | 0.004 |

| X2X3 | −4.34 | 1.55 | −2.79 | 0.049 |

Table 9.

ANOVA for the regression.

Table 9.

ANOVA for the regression.

| Source | df | Sum of Squares | Mean Squares | F-Value |

|---|

| Regression | 7 | 2840.88 | 405.84 | 43.07 |

| Residual | 6 | 56.54 | 9.42 | |

| Total | 13 | 2897.42 | | |

Table 10.

Coded Values of the Variables for the Box-Behnken Design.

Table 10.

Coded Values of the Variables for the Box-Behnken Design.

| Parameter | Variable | Level (−1) | Level (0) | Level (+1) |

|---|

| Phenol substitution (%) | X | 25 | 50 | 75 |

| Mw (g/mol) | X | 800 | 1200 | 1700 |

| F/P ratio | X | 1.2 | 2.1 | 3.0 |