2. Results and Discussion

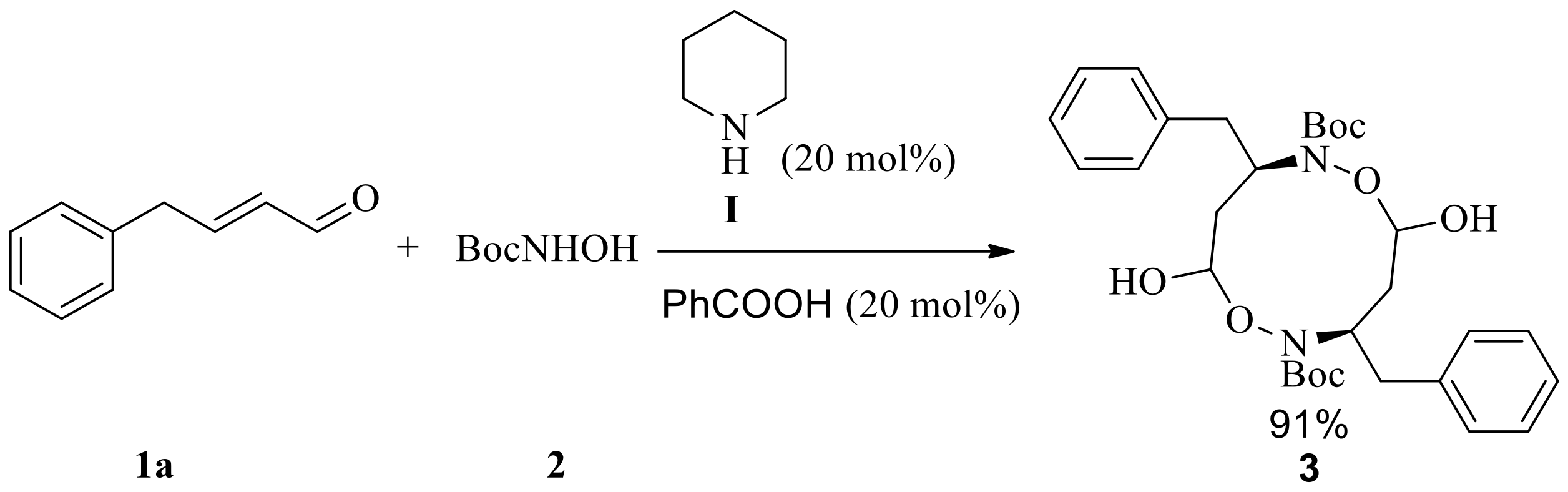

Initially, the model aza-Michael addition reaction that we studied, between (

E)-4-phenylbut-2-enal

1a and

N-Boc-protected hydroxylamine or

N-Cbz-protected hydroxylamine catalyzed by organocatalyst I or II in chloroform at 0 °C did not take place and obtained the starting materials were only. However, when the mixture of 20 mol % benzoic acid (pKa = 4.19) [

20] and 20 mol % piperidine were used as a catalyst, the tandem aza-Michael/hemiacetal reaction took place to give an unexpected macro-cyclic compound

3 in 91% isolated yield (

Scheme 1). In contrast, macro-cyclic compound

3 and

N-Boc hemiacetal

4a was isolated in 11% and 71% yields, respectively, by using 20 mol % chiral secondary amine II together with 20 mol % benzoic acid as catalyst, and the enantiomeric excess (ee) of

N-Boc hemiacetal

4a up to 89% (

Scheme 2). Obviously, the tandem aza-Michael/hemiacetal reaction adduct is different from the outcome of tandem aza-Michael/hemiacetal reaction between cinnamaldehyde and

N-Boc-protected hydroxylamine in the literature with regard to distinguishable products [

17]. We suppose that formyl group of aza-Michael addition adduct was activated by Brønsted acid (benzoic acid) to facilitate intramolecular hemiacetal formation to complete the tandem aza-Michael/hemiacetal reaction. We assume the acidity of Brønsted acid had great effect on the outcome of tandem aza-Michael/hemiacetal reaction.

The evaluation on the influence of different Brønsted acid was shown in

Table 1. When the stronger Brønsted acids, such as phosphoric acid (pKa = 2.12), trifluoroacetic acid (pKa = 0.23) and

p-toluenesulfonic acid (pKa = −2.8), were used as additives, macro-cyclic compound

3 could not be found, however,

N-Boc hemiacetal

4a and double Boc derivative

5 were isolated. Meanwhile, the enantioselectivities were low at the presence of stronger Brønsted acids. Fortunately, hemiacetal

4a was isolated as single product in 84% yield with 92% ee using 20 mol %

p-nitrobenzoic acid (PNBA, pKa = 3.47) as an additive, together with 20 mol % (

S)-diphenylprolinol-TMS II. It seems that Brønsted acid can effectively activate the formyl group of the aza-Michael addition adduct to facilitate the sequence, and acidity of Brønsted acid can mediate the outcome of tandem aza-Michael/hemiacetal reaction. In other solvents, such as diethyl ether, methanol, toluene, and dichloromethane, tandem aza-Michael/hemiacetal reaction catalyzed by (

S)-diphenylprolinol-TMS II together with

p-nitrobenzoic acid worked smoothly (

Table 1, entries 5–8). Dichloromethane was the best solvent, as 90% yield and 92% ee can be obtained even when the loading amount of (

S)-diphenylprolinol-TMS II and additive was reduced to 10 mol % (entry 9). Catalyst III and IV were also tested (entries 10–11), and it was found that catalyst III, containing a 3,5-ditrifluoromethylphenyl group, gave 45% ee, while catalyst IV afforded product in low yield with poor enantioselectivity.

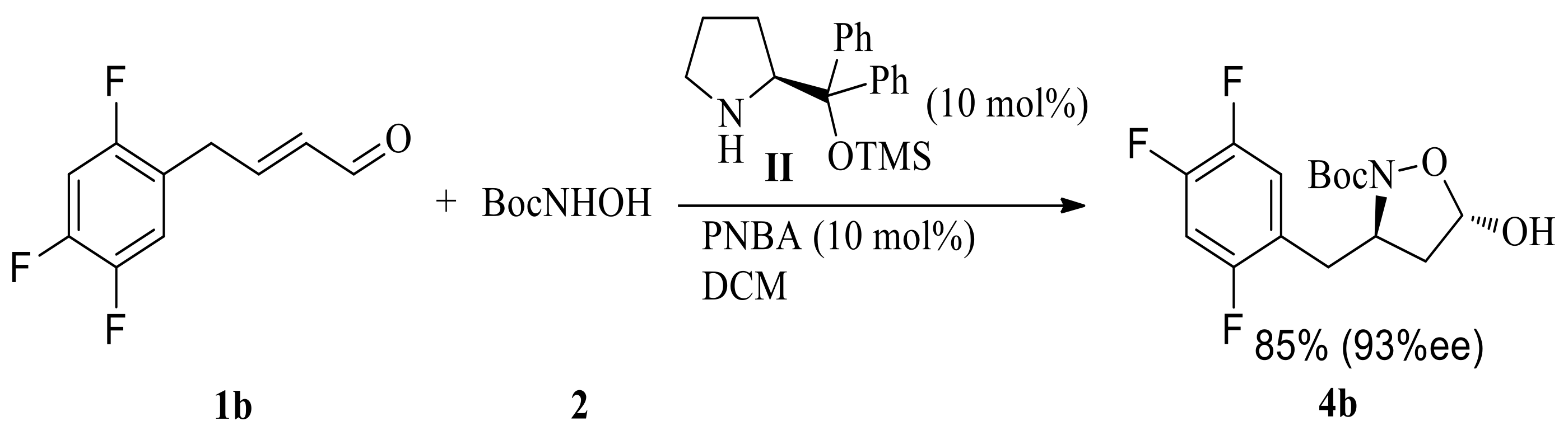

(

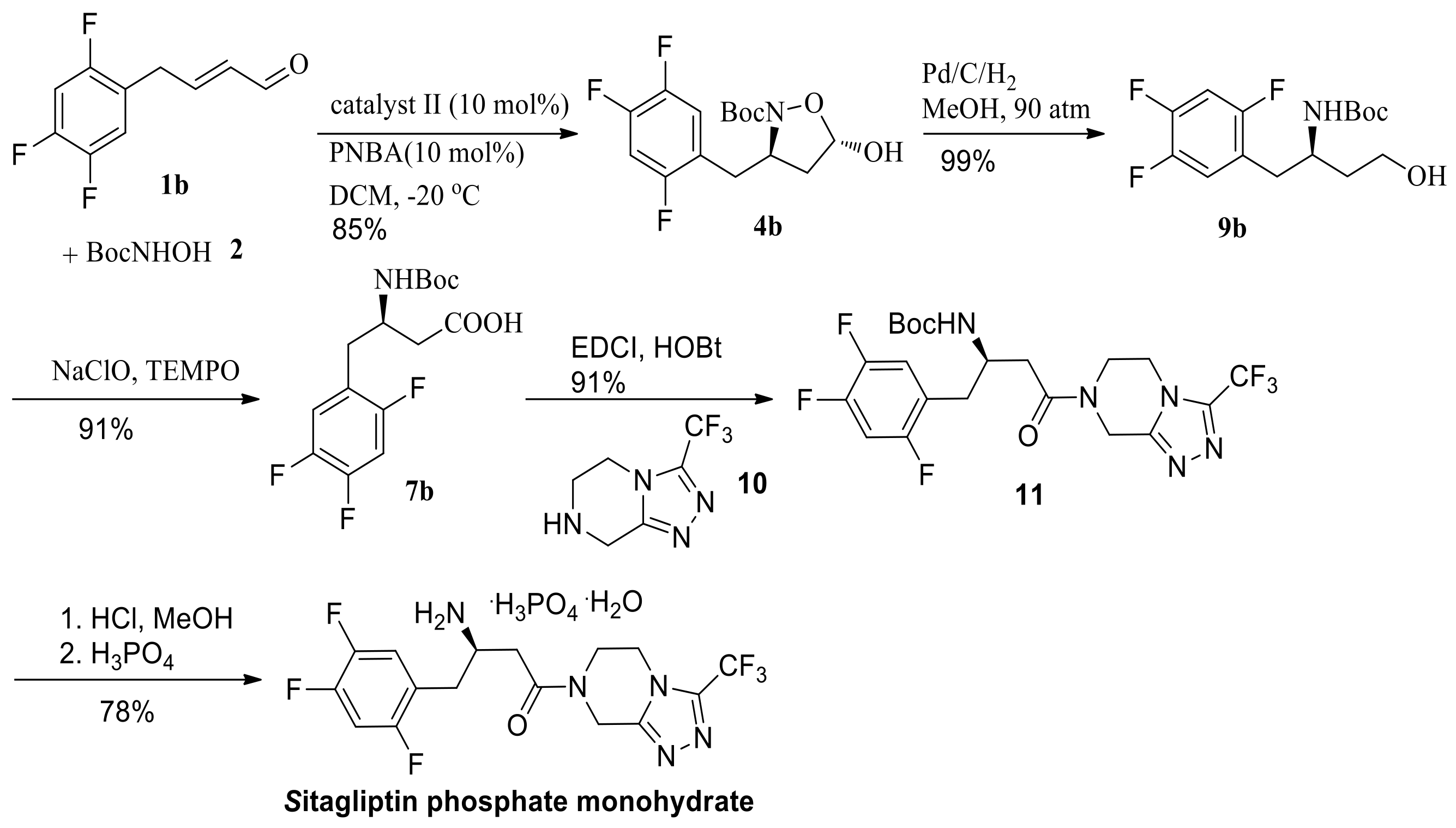

E)-4-(2,4,5-Trifluorophenyl)but-2-enal

1b was obtained via either the cross-metathesis reaction between 1-allyl-2,4,5-trifluorobenzene and crotonaldehyde or the coupling reaction between 1-bromo-2,4,5-trifluorobenzene and (

E)-4-bromo-1,1-dimethoxybut-2-ene [

21]. Tandem aza-Michael/hemiacetal reaction between (

E)-4-(2,4,5-trifluorophenyl)but-2-enal

1b and

N-Boc-hydroxylamine catalyzed by 10 mol % (

S)-diphenylprolinol-TMS II and 10 mol % p-nitrobenzoic acid gave (3

R,5

S)-

N-Boc-5-hydroxy-3-(2,4,5-trifluorobenzyl)isoxazolidine

4b in 85% yield and 93% ee (

Scheme 3). Decreasing the reaction temperature to −20 °C improved the enantioselectivty. The ee was up to 96% with an extended reaction time (15 h), and yield was up to 85%.

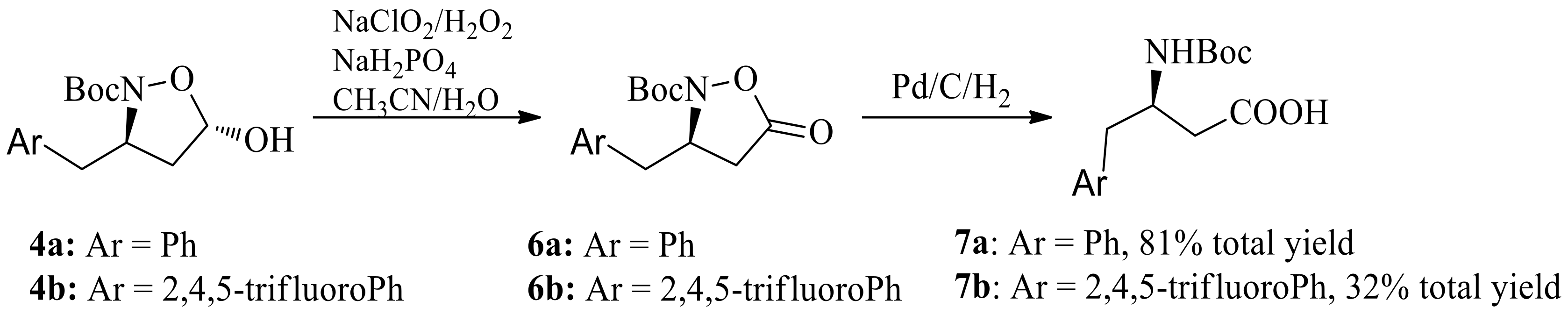

We next converted this key chiral unit to chiral

β-amino acid. Oxidation/reductive cleavage of N-O bond sequence are a common methodology for this conversion. Chiral (

R)-

N-Boc-

β-benzyl-

β-amino acid

7a was obtained via NaClO

2/H

2O

2/NaH

2PO

4 oxidation/hydrogenation, starting from hemiacetal

4a in 82% yield, without the loss of enantiomeric purity (

Scheme 4). However, NaClO

2/H

2O

2/NaH

2PO

4 oxidation/hydrogenation sequence starting from hemiacetal

4b gave (

R)-

N-Boc-

β-(2,4,5-trifluorobenzyl)-

β-amino acid

7b in poor yield (32% in total).

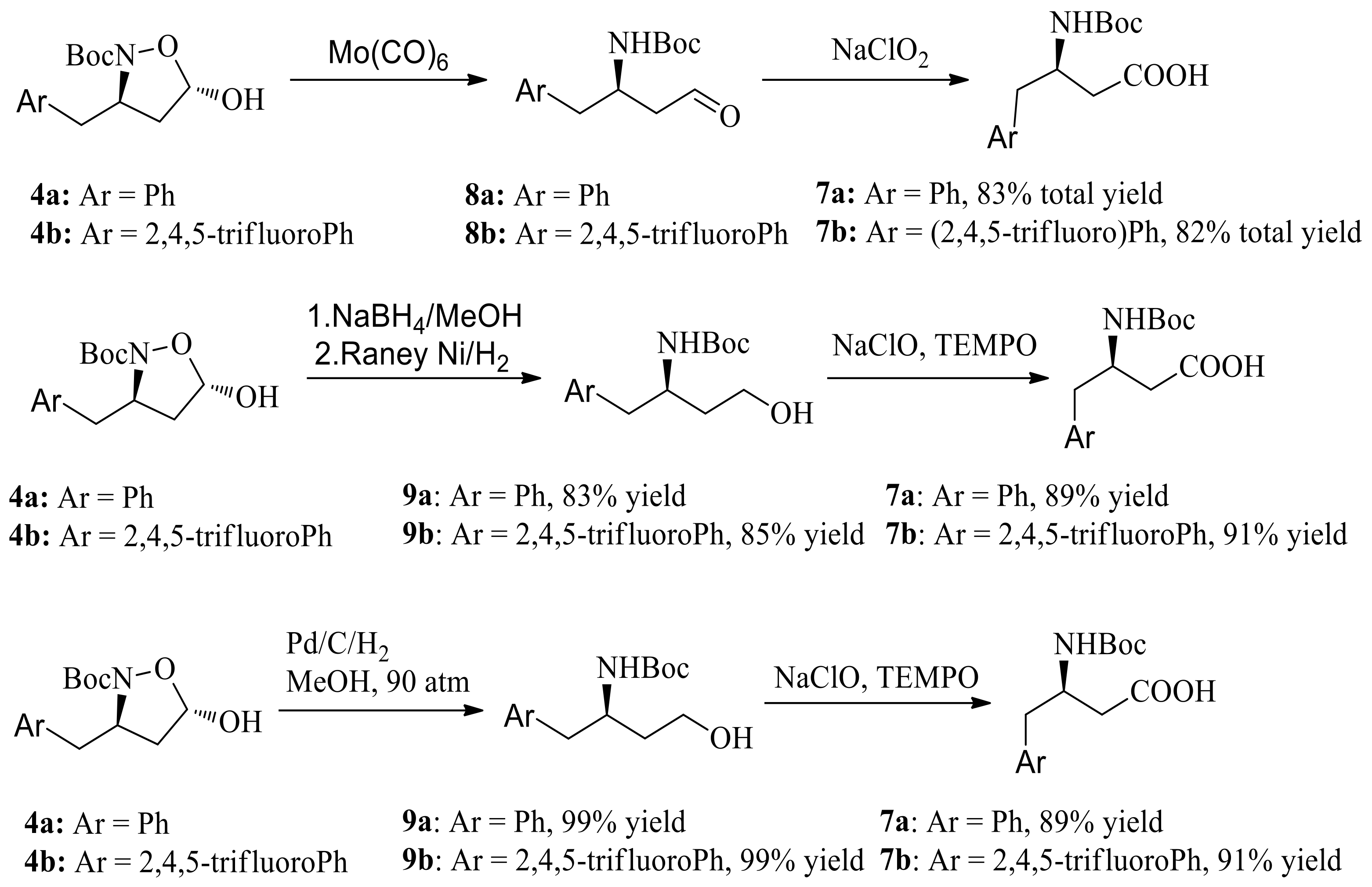

We then turned our attention to obtain chiral

β-amino acid via reductive cleavage of the N-O bond/oxidation sequence (

Scheme 5). N-O bond reductive cleavage using Mo(CO)

6 as the reducing agent, followed by oxidation, gave the

β-amino acid

7a and

7b in 83% and 82% yields, respectively. Moreover, reduction with NaBH

4, followed by N-O bond cleavage via hydrogenation with Raney Ni gave the

β-amino alcohol

7a and

7b in 83% and 82% yields respectively. At a pressure of 90 atm of hydrogen and Pd/C, the

β-amino alcohol

9a and

9b were obtained in 99% yield. Further oxidation of

β-amino alcohol

9a and

9b with NaClO/TEMPO gave the

β-amino acid

7a and

7b in 92% and 91% yield respectively. Compared with N-O bond reductive cleavage using expensive Mo(CO)

6 or NaBH

4/hydrogenation sequence, N-O bond reductive cleavage using hydrogenation have industrial potential.

(

R)-

N-Boc-

β-(2,4,5-trifluorobenzyl)-

β-amino acid

7b was synthesized starting from (

E)-4-(2,4,5-trifluorophenyl)but-2-enal in 76% total yield in a three-step procedure (

Scheme 6). (

R)-

tert-butyl 4-oxo-4-(3-(trifluoromethyl)-5,6-dihydro-[1,2,4]triazolo[4,3-a]pyrazin-7(8H)-yl)-1-(2,4,5-tri-fluorophenyl) butan-2-ylcarbamate

11 was obtained in 91% yield via the coupling reaction between triazole (

10) and (

R)-

N-Boc-

β-(2,4,5-trifluorobenzyl)-

β-amino acid

7b, using HOBt-EDCI as the coupling agent. Finally, >99.9% ee of sitagliptin phosphate monohydrate was provided in 78% yield following the known literature procedure (as shown in

Scheme 6) [

6].

3. Materials and Methods

3.1. General

Unless otherwise noted, all commercial reagents were used as purchased from Aladdin and Tansoole (Chinese chemical reagents supplier). All the reactions were monitored by thin-layer chromatography (TLC) that was performed on silica gel plates GF254. Visualization was achieved under a UV lamp, and by developing the plates with Potassium Permanganate in water. Flash chromatography was performed using silica gel (200–300 mesh) with solvents indicated in the text. NMR spectra were registered in a Bruker Advance 400 Ultrashield spectrometer at room temperature, operating at 400 MHz (

1H) and 100 MHz (

13C). The experiments of high performance liquid chromatography (HPLC) was performed on a Shimadzu chromatograph (Essentia LC-16, Shimadzu Corp., Kyoto, Japan) by using Chiralcel columns as illustrated in

supporting information.

3.2. Synthesis of (E)-4-Phenylbut-2-enal (1a)

A solution of allylbenzene (591 mg, 5 mmol) and crotonaldehyde (700 mg, 10 mmol) together with 0.1 mol % Grubbs-II catalyst (4.2 mg, 0.005 mmol) in dichloromethane (20 mL) was refluxed for 12 h, and then cooled to 0 °C. The mixture solution was concentrated under reduced pressure and purified over silica gel column chromatography (PE/EtOAc, 20:1–10:1) to give

1a as a liquid (650 mg, 89%).

1H-NMR (400 MHz, CDCl

3) δ 9.52 (d,

J = 8.2 Hz, 1H), 7.34–7.31 (m, 2H), 7.27–7.23 (m, 1H), 7.17 (d,

J = 8.5 Hz, 2H), 6.99–6.91 (m, 1H), 6.10 (dd,

J = 8.1 Hz and 8 Hz, 1H), 3.64 (d,

J = 4.2 Hz, 2H) (

Supplementary Material Figure S1).

3.3. Synthesis of (E)-4-(2,4,5-Trifluorophenyl)but-2-enal (1b)

A solution of 1-allyl-2,4,5-trifluorobenzene (860 mg, 5 mmol) and crotonaldehyde (700 mg, 10 mmol), together with 0.1 mol % Grubbs-II catalyst (4.2 mg, 0.005 mmol) in dichloromethane (20 mL), was refluxed for 12 h, and then it was cooled to 0 °C. The mixture solution was concentrated under reduced pressure and purified over silica gel column chromatography (PE/EtOAc, 20:1–10:1) to give

1b as a liquid (830 mg, 83%).

1H-NMR (400 MHz, CDCl

3) δ 9.52 (d,

J = 8.6 Hz, 1H), 7.02–6.83 (m, 3H), 6.08–6.02 (m, 1H), 3.60 (d,

J = 4.4 Hz, 2H) (

Supplementary Material Figure S2).

3.4. Synthesis of Di-tert-butyl 3,8-Dibenzyl-5,10-dihydroxy-1,6,2,7-dioxadiazecane-2,7-dicarboxylate (3)

(

E)-4-phenylbut-2-enal

1a (146 mg, 1 mmol) was dissolved in dichloromethane (5 mL), and then

N-Boc-hydroxylamine

2 (199 mg, 1.5 mmol), piperidine (17 mg, 0.2 mmol), and benzoic acid (24 mg, 0.2 mmol) were added to the resulting solution at 0 °C. The reaction mixture was stirred for 8 h at 0 °C. The mixture solution was diluted with dichloromethane (20 mL) and washed with saturated sodium bicarbonate aqueous solution (5 mL) and brine (5 mL). The resulting organic phase was dried over Na

2SO

4, filtered and concentrated under reduced pressure. The crude product was purified over silica gel column chromatography (PE/EtOAc, 10:1–4:1) to give

3 as a white solid (254 mg, 91%). mp: 123–124 °C;

1H-NMR (400 MHz, CDCl

3) δ 7.32–7.22 (m, 10H), 5.73–5.69 (m, 2H), 4.66–4.59 (m, 1H), 4.31–4.24 (m, 1H), 3.43 (s, 1H), 3.21–3.17 (m, 2H), 3.11 (dd,

J = 4.2 Hz, 12 Hz, 1H), 2.94 (dd,

J = 4.2 Hz, 12 Hz, 1H), 2.74 (dd,

J = 4.1 Hz, 12 Hz, 1H), 2.58–2.51 (m, 1H), 2.24 (dd,

J = 4.1 Hz, 12 Hz, 1H), 2.16–2.09 (m, 1H), 2.06–1.99 (m, 1H), 1.53 (s, 9H), 1.51 (s, 9H) (

Supplementary Material Figure S3);

13C-NMR (100 MHz, CDCl

3) δ 155.0, 154.0, 137.0, 136.8, 129.2, 129.2, 128.5, 128.5, 126.7, 126.6, 83.5, 82.5, 82.5, 81.9, 81.5, 79.8, 41.8, 41.0, 39.2, 38.8, 28.3, 28.2 (

Supplementary Material Figure S4); HR-MS (C

30H

42N

2O

8Na) calcd. 581.2833 ([M + Na]

+), Found 581.2798. Compound

3 was further characterized by heteronuclear multiple quantum coherence (HMQC) and heteronuclear multiple bond correlation (HMBC).

3.5. Synthesis of (3R,5S)-Tert-butyl 3-benzyl-5-hydroxyisoxazolidine-2-carboxylate (4a)

(

E)-4-phenylbut-2-enal

1a (146 mg, 1 mmol) was dissolved in dichloromethane (5 mL), and then

N-Boc-hydroxylamine

2 (199 mg, 1.5 mmol), (

S)-diphenylprolinol-TMS II (33 mg, 0.1 mmol), and

p-nitrobenzoic acid (16 mg, 0.1 mmol, 10 mol %) were added to the resulting solution at 0 °C. The reaction mixture was stirred for 15 h at 0 °C. The mixture solution was diluted with dichloromethane (20 mL) and washed with saturated sodium bicarbonate aqueous solution (5 mL) and brine (5 mL). The resulting organic phase was dried over Na

2SO

4, filtered and concentrated under reduced pressure. The crude product was purified over silica gel column chromatography (PE/EtOAc, 10:1–4:1) to give 4a as a white solid (251 mg, 90%). mp: 138–139 °C; [α]

D22 +16.50 (c 1.0, CHCl

3);

1H-NMR (400 MHz, CDCl

3) δ 7.29–7.18 (m, 5H), 5.71 (d,

J = 4.4 Hz, 1H), 4.49–4.42 (m, 1H), 3.00 (dd,

J = 8.3 Hz, 12 Hz, 1H), 2.70 (dd,

J = 8.3 Hz, 12 Hz, 1H), 2.28 (dd,

J = 8.4 Hz, 12 Hz, 1H), 2.00–1.94 (m, 1H), 1.35 (s, 9H) (

Supplementary Material Figures S5 and S7);

13C-NMR (100 MHz, CDCl

3) δ 158.8, 138.2, 129.4, 128.3, 126.4, 98.7, 82.0, 59.4, 42.1, 41.3, 28.0 (

Supplementary Material Figures S6 and S8); HR-MS (C

15H

21NO

4Na) calcd. 302.1363 ([M + Na]

+), Found 302.1370; 92% ee; Chiral HPLC condition: SHIMADZU Essentia LC-16 HPLC, Chiralcel AD-H column (250 × 4.6 mm, i.d.) with a mixture of hexane and 2-propanol (95:5) at a flow rate of 1.0 mL/min as the mobile phase, oven temperature was 28 °C, 210 nm, tminor = 6.66 min, tmajor = 6.00 min. A quintuple scale of this reaction was also carried out and a similar result was observed (88% yield, 92% ee).

3.6. Synthesis of (3R)-Tert-butyl 3-benzyl-5-(tert-butoxycarbonyloxy)isoxazolidine-2-carboxylate (5)

(

E)-4-phenylbut-2-enal

1a (146 mg, 1 mmol) was dissolved in dichloromethane (5 mL), and then

N-Boc-hydroxylamine

2 (199 mg, 1.5 mmol), (

S)-diphenylprolinol-TMS II (33 mg, 0.1 mmol), and

p-Toluenesulfonic acid (34 mg, 0.2 mmol, 10 mol %) were added to the resulting solution at 0 °C. The reaction mixture was stirred for 8 h at 0 °C. The mixture solution was diluted with dichloromethane (20 mL) and washed with saturated sodium bicarbonate aqueous solution (5 mL) and brine (5 mL). The resulting organic phase was dried over Na

2SO

4, filtered, and concentrated under reduced pressure. The crude product was purified over silica gel column chromatography (PE/EtOAc, 10:1–4:1) to give

5 as a wax solid (246 mg, 65%); [α]

D22 +13.80 (c 1.0, CHCl

3);

1H-NMR (400 MHz, CDCl

3) δ 7.30–7.20 (m, 5H), 6.11–6.08 (m, 1H), 4.62–4.55 (m, 1H), 2.99 (dd,

J = 8.6 Hz, 12 Hz, 1H), 2.71 (dd,

J = 8.5 Hz, 12 Hz, 1H), 2.63–2.57 (m, 1H), 2.25–2.19 (m, 1H), 1.50 (s, 9H), 1.39 (s, 9H) (

Supplementary Material Figure S11);

13C-NMR (100 MHz, CDCl

3) δ 158.3, 155.6, 137.7, 129.3, 128.3, 126.4, 88.5, 82.8, 82.2, 61.2, 41.3, 35.2, 28.1, 27.9; HR-MS (C

20H

29NO

6Na) calcd. 402.1893 ([M + Na]

+), Found 402.1891. 43% ee; Chiral HPLC condition: SHIMADZU Essentia LC-16 HPLC, Chiralcel AD-H column (250 × 4.6 mm, i.d.) with a mixture of hexane and 2-propanol (95:5) at a flow rate of 1.0 mL/min as the mobile phase, oven temperature was 28 °C, 210 nm, tminor = 10.02 min, tmajor = 8.08 min.

3.7. Synthesis of (3R,5S)-Tert-butyl 5-hydroxy-3-(2,4,5-trifluorobenzyl)isoxazolidine-2-carboxylate (4b)

(

E)-4-(2,4,5-trifluorophenyl)but-2-enal (200 mg, 1 mmol) was dissolved in dichloromethane (5 mL), and then

N-Boc-hydroxylamine

2 (159 mg, 1.2 mmol), (

S)-diphenylprolinol-TMS II (33 mg, 0.1 mmol), and p-nitrobenzoic acid (16 mg, 0.1 mmol, 10 mol %) were added to the resulting solution at −20 °C. The reaction mixture was stirred for 15 h at −20 °C. The mixture solution was diluted with dichloromethane (20 mL) and washed with saturated sodium bicarbonate aqueous solution (5 mL) and brine (5 mL). The resulting organic phase was dried over Na

2SO

4, filtered and concentrated under reduced pressure. The crude product was purified over silica gel column chromatography (PE/EtOAc, 10:1–4:1) to give

4b as a white solid (283 mg, 85%). mp: 156–157 °C; [α]

D22 +22.70 (c 1.0, CHCl

3);

1H-NMR (400 MHz, CDCl

3) δ 7.09–7.03 (m, 1H), 6.91–6.85 (m, 1H), 5.70 (d,

J = 4.3 Hz, 1H), 4.51–4.44 (m, 1H), 2.80 (d,

J = 8.8 Hz, 2H), 2.37 (dd,

J = 8.7 Hz, 12 Hz, 1H), 1.98–1.92 (m, 1H), 1.35 (s, 9H) (

Supplementary Material Figure S9);

13C-NMR (100 MHz, CDCl

3) δ 158.7, 156.1, 148.8, 145.1, 121.4, 119.2, 105.1, 98.7, 82.3, 57.9, 41.2, 34.5, 27.9 (

Supplementary Material Figure S10); HR-MS (C

15H

18F

3NO

4Na) calcd. 356.1086 ([M + Na]

+), Found 356.1087; 96% ee; Chiral HPLC condition: SHIMADZU Essentia LC-16 HPLC, Chiralcel AD-H column (250 × 4.6 mm, i.d.) with a mixture of hexane and 2-propanol (95:5) at a flow rate of 1.0 mL/min as the mobile phase, oven temperature was 28 °C, 210 nm, tminor = 11.02 min, tmajor = 9.30 min.

3.8. Synthesis of (R)-N-Boc-3-benzyl-5-oxoisoxazolidine (6a) and (R)-N-Boc-3-trifluorobenzyl-5-oxoisoxazolidine (6b)

A solution of NaClO

2 (127 mg, 1.4 mmol) in water (1.4 mL) was added dropwise to a stirred solution of (3

R,5

S)-

tert-butyl-3-benzyl-5-hydroxyisoxazolidine-2-carboxylate

4a (279 mg, 1 mmol, 92% ee) in acetonitrile (5 mL) and NaH

2PO

4 (24 mg, 0.2 mmol) in water (1 mL) and H

2O

2 (35 W% in water, 0.14 mL, 1.4 mmol) at 10 °C. The solution was diluted with dichloromethane (20 mL) and washed with saturated sodium bicarbonate aqueous solution (5 mL) and brine (5 mL). The resulting organic phase was dried over Na

2SO

4, filtered and concentrated under reduced pressure. The crude product was purified over silica gel column chromatography (PE/EtOAc, 5:1–3:1) to give (

R)-

N-Boc-3-benzyl-5-oxoisoxazolidine

6a (227 mg, 82% yield) as a white solid. [α]

D22 +40.10 (c 1.0, CHCl

3);

1H-NMR (400 MHz, CDCl

3) δ 7.22–7.30 (m, 5H), 4.58–4.65 (m, 1H), 3.04 (dd,

J = 8.5 Hz, 12 Hz, 1H), 2.74–2.85 (m, 2H), 2.57 (dd,

J = 4.7 Hz, 16 Hz, 1H), 1.27 (s, 9H). Spectroscopic data are in agreement with reference [

22]. 92% ee; Chiral HPLC condition: SHIMADZU Essentia LC-16 HPLC, Chiralcel AD-H column (250 × 4.6 mm, i.d.) with a mixture of hexane and 2-propanol (95:5) at a flow rate of 1.2 mL/min as the mobile phase, oven temperature was 28 °C, 210 nm, tminor = 14.91 min, tmajor = 11.82 min.

Prepared from 4b (333 mg, 1 mmol), according to the procedure of the synthesis of 6a, 6b was obtained as a white solid (109 mg, 33%). 1H-NMR (400 MHz, CDCl3) δ 7.29–7.18 (m, 5H), 5.71 (d, J = 4.1 Hz, 1H), 4.49–4.42 (m, 1H), 3.00 (dd, J = 8.4 Hz, 12 Hz, 1H), 2.70 (dd, J = 8.5 Hz, 12 Hz, 1H), 2.28 (dd, J = 8.4 Hz, 12 Hz, 1H), 2.00–1.94 (m, 1H), 1.35 (s, 9H); 13C-NMR (100 MHz, CDCl3) δ 173.1, 158.2, 156.7, 148.1, 146.6, 123.4, 121.9, 107.1, 82.8, 59.2, 42.3, 36.1, 28.9; HR-MS (C15H16F3NO4Na) calcd. 354.0929 ([M + Na]+), Found 354.0927. 96% ee; Chiral HPLC condition: SHIMADZU Essentia LC-16 HPLC, Chiralcel AD-H column (250 × 4.6 mm, i.d.) with a mixture of hexane and 2-propanol (95:5) at a flow rate of 1.2 mL/min as the mobile phase, oven temperature was 28 °C, 210 nm, tminor = 15.31 min, tmajor = 12.72 min.

3.9. Synthesis of (R)-N-Boc-β-benzyl-β-amino acid 7a and (R)-N-Boc-β-(2,4,5-trifluorobenzyl)-β-amino acid 7b via oxidation/reductive cleavage of N-O bond sequence

To a solution of (

R)-

N-Boc-3-benzyl-5-oxoisoxazolidine

6a (277 mg, 1 mmol, 92% ee) in MeOH (15 mL), Pd/C (20%

w/

w, 55 mg) was added. The reaction mixture was hydrogenated under 90 atm for 24 h. The reaction mixture was filtered through celite with ethyl acetate and concentrated to give (

R)-

N-Boc-

β-benzyl-

β-amino acid

7a (276 mg, 99%) as a white solid. mp: 111–113 °C; [α]

D22 +18.10 (c 1.0, CHCl

3);

1H-NMR (400 MHz, CDCl

3) δ 7.33–7.24 (m, 5H), 5.04–4.97 (m, 1H), 2.98 (dd,

J = 8.4 Hz, 16, 1H), 2.87–2.84 (m, 2H), 2.62 (dd,

J = 4.3 Hz, 16 Hz, 1H), 1.30 (s, 9H) (

Supplementary Material Figure S12). Spectroscopic data are in agreement with reference [

23].

Prepared from

6b (331 mg, 1 mmol) according to the procedure of the synthesis of

7a,

7b was obtained as a white solid (330 mg, 99%). mp: 121–123 °C; [α]

D22 −29.80 (c 1.0, CHCl

3) (

Supplementary Material Figure S13);

1H-NMR (400 MHz, CDCl

3) δ 7.12–7.08 (m, 1H), 6.96–6.90 (m, 1H), 5.09–5.07 (m, 1H), 4.18–4.15 (m, 1H), 2.92–2.90 (m, 2H), 2.65–2.57 (m, 2H), 1.41 (s, 9H); Spectroscopic data are in agreement with reference [

8].

3.10. Synthesis of (R)-N-Boc-β-benzyl-β-amino acid 7a and (R)-N-Boc-β-(2,4,5-trifluorobenzyl)-β-amino acid 7b via reductive cleavage of N-O bond/oxidation sequence

3.10.1. Method A

To a solution of (3R,5S)-tert-butyl 3-benzyl-5-hydroxyisoxazolidine-2-carboxylate 4a (279 mg, 1 mmol, 92% ee) in CH3CN/H2O (6 mL, 9:1, degassed under nitrogen) was added Mo(CO)6 (1.2 equiv., 1.2 mmol). The reaction mixture was vigorously stirred and heated to reflux for 4 h. The resulting solution was then filtered through a short column of silica gel (washed by ethyl acetate). The resulting after evaporation was dissolved in dichloromethane (2 mL) and then it was cooled down to 4 °C. The resulting solution was added isobutene (1 mL), tert-butanol (4 mL), H2O (2 mL), KH2PO4 (544 mg, 4 mmol), and NaClO2 (360 mg, 4 mmol), sequentially. The reaction was stirred at this temperature for 12 h. The mixture was diluted with 20 W% NaOH aqueous solution (10 mL) and dichloromethane (10 mL). The organic phase was decanted. The aqueous phase was adjusted to pH = 4–5 and then extracted with dichloromethane and the combined organic phase was washed with brine, dried over Na2SO4, and evaporated to give (R)-N-Boc-β-benzyl-β-amino acid 7a as a white solid (231 mg, 83%).

(R)-N-Boc-β-(2,4,5-trifluorobenzyl)-β-amino acid 7b was prepared from 4b (333 mg, 1 mmol) according to the procedure of the synthesis of 7a, and 7b was obtained as a white solid (273 mg, 82%).

3.10.2. Method B

To a solution of (3R,5S)-tert-butyl 3-benzyl-5-hydroxyisoxazolidine-2-carboxylate 4a (279 mg, 1 mmol, 92% ee) in methanol (10 mL), NaBH4 (75.6 mg, 1 mmol) was added carefully at 4 °C, and the reaction mixture was allowed to stir at room temperature for 8 h, and then evaporated. The residue was diluted with water (20 mL), and then the water phase was extracted with dichloromethane. The combined organic phase was washed with brine, dried over Na2SO4, and evaporated to give a liquid. The obtained liquid was dissolved in methanol (20 mL) and the reaction mixture was hydrogenated with Raney Ni (100 mg) at normal pressure for 8 h. The resulting solution was filtered and evaporated. The residue was purified over silica gel column to give (R)-tert-butyl 4-hydroxy-1-phenylbutan-2-ylcarbamate 9a as white solid (220 mg, 83%). Compound 9a (220 mg, 1.5 mmol) was dissolved in the mixture solution of dichloromethane (11 mL) and aqueous sodium bicarbonate (2.5 mL, 5% w/w). 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO) (13.2 mg, 0.08 mmol) and sodium bromide (8.5 mg, 0.08 mmol) were added to this reaction mixture and it was cooled down to 0 °C. Sodium hypochlorite solution (3.7 mL, 2.5 mmol, 5% w/w) was added dropwise, and then the reaction mixture was stirred for 3 h. The reaction mixture was quenched with saturated aqueous thiosulfate solution (1 mL), followed by adding aqueous hydrochloric acid (2 M) until the pH = 4–5. The aqueous phase was extracted with dichloromethane (10 mL × 3). The combined organic phase was dried over Na2SO4 and concentrated to give compound 7a as a white solid (206 mg, 89%).

(R)-N-Boc-β-(2,4,5-trifluorobenzyl)-β-amino acid 7b was prepared from 4b (333 mg, 1 mmol) according to the procedure of the synthesis of 7a, and 7b was obtained as a white solid (256 mg, 77% over two steps).

3.10.3. Method C

To a solution of (3R,5S)-tert-butyl 3-benzyl-5-hydroxyisoxazolidine-2-carboxylate 4a (500 mg, 1.79 mmol, 92% ee) in MeOH (10 mL), Pd/C (20% w/w, 0.1 g) was added. The reaction mixture was hydrogenated under 90 atm for 24 h. The reaction mixture was filtered through celite with ethyl acetate and concentrated to give (R)-tert-butyl 4-hydroxy-1-phenylbutan-2-ylcarbamate 9a as a white solid (474 mg, 99%), which (474 mg, 1.79 mmol) was dissolved in the mixture solution of dichloromethane (24 mL) and aqueous sodium bicarbonate (5.4 mL, 5% w/w). TEMPO (28.8 mg, 0.18 mmol) and sodium bromide (18.6 mg, 0.18 mmol) were added to this reaction mixture and it was cooled down to 0 °C. Sodium hypochlorite solution (8 mL, 5.4 mmol, 5% w/w) was dropwise added, and then the reaction mixture was stirred for 3 h. The reaction mixture was quenched with saturated aqueous thiosulfate solution (2 mL), followed by adding aqueous hydrochloric acid (2 M) until the pH = 4–5. The aqueous phase was extracted with dichloromethane (20 mL × 3). The combined organic phase was dried over Na2SO4 and concentrated to give compound 7a as a white solid (440 mg, 89%).

(R)-N-Boc-β-(2,4,5-trifluorobenzyl)-β-amino acid 7b was prepared from 4b (333 mg, 1 mmol) according to the procedure of the synthesis of 7a, and 7b was obtained as a white solid (300 mg, 90%).

3.11. Synthesis of (R)-tert-butyl 4-oxo-1-phenylbutan-2-ylcarbamate (8a) and Synthesis of (R)-tert-butyl 4-oxo-1-2,4,5-trifluorobenzylbutan-2-ylcarbamate (8b)

To a solution of (3

R,5

S)-

tert-butyl 3-benzyl-5-hydroxyisoxazolidine-2-carboxylate

4a (112 mg, 0.4 mmol, 92% ee) in CH

3CN/H

2O (4.0 mL, 9:1, degassed under nitrogen), Mo(CO)

6 (126.7 mg, 0.48 mmol, 1.2 equiv.) was added. The reaction was stirred and heated to reflux for 8 h. The reaction mixture was filtered through a short column of silica gel (washed by EtOAc). The obtained solution was evaporated and purified over silica gel column chromatography (PE/EtOAc, 5:1) to give compound 8a as a white solid. 89% yield (93 mg); [α]

D22 +18.10 (c 1.0, CHCl

3);

1H-NMR (400 MHz, CDCl3) δ 9.69 (s, 1H), 7.31–7.21 (m, 3H), 7.15 (d,

J = 8.2 Hz, 2H), 4.75 (s, 1H), 4.25 (s, 1H), 2.95–2.90 (m, 1H), 2.79 (dd,

J = 8.2 Hz, 12 Hz, 1H), 2.63–2.48 (m, 2H), 1.30 (s, 9H) [

24].

(

R)-

tert-butyl 4-oxo-1-2,4,5-trifluorobenzylbutan-2-ylcarbamate

8b was prepared from

4b (333 mg, 1 mmol) according to the procedure of the synthesis of

8a,

8b was obtained as a white solid (276 mg, 87%):

1H-NMR (400 MHz, DMSO-

d6) δ 9.60 (s, 1H), 7.43–7.48 (m, 1H), 7.30–7.32 (m, 1H), 6.88 (d,

J = 4.7 Hz, 1H), 4.15–4.17 (m, 1H), 2.55–2.98 (m, 2H), 2.50–2.53 (m, 2H), 1.27 (s, 9H) [

25].

3.12. Synthesis of (R)-Tert-butyl 4-hydroxy-1-phenylbutan-2-ylcarbamate (9a) and (R)-tert-butyl 4-hydroxy-1-2,4,5-trifluorobenzylbutan-2-ylcarbamate (9b)

To a solution of (3

R,5

S)-

tert-butyl 3-benzyl-5-hydroxyisoxazolidine-2-carboxylate

4a (500 mg, 1.79 mmol, 92% ee) in MeOH (10 mL), Pd/C (20%

w/

w, 0.1 g) was added. The reaction mixture was hydrogenated under 90 atm for 24 h. The reaction mixture was filtered through celite with ethyl acetate and concentrated to give compound

9a as a white solid. 99% yield (474 mg); [α]

D22 −2.50 (c 1.0, CHCl

3);

1H-NMR (400 MHz, CDCl

3) δ 7.34–7.20 (m, 5H), 4.49 (d,

J = 12.1 Hz, 1H), 4.15–4.07 (m, 1H), 3.67 (s, 2H), 3.18–3.12 (m, 1H), 2.83 (d,

J = 4.7 Hz, 2H), 1.91–1.83 (m, 1H), 1.43 (s, 9H);

13C-NMR (100MHz, CDCl

3) δ 156.8, 138.8, 129.3, 128.2, 126.2, 81.0, 59.6, 58.2, 38.4, 33.9, 28.1 [

26].

(

R)-

tert-butyl 4-hydroxy-1-2,4,5-trifluorobenzylbutan-2-ylcarbamate

9b was prepared from

4b (333 mg, 1 mmol) according to the procedure of the synthesis of

9a, and

9b was obtained as a white solid (316 mg, 99%):

1H-NMR (400 MHz, CDCl

3) δ 7.03–7.10 (m, 1H), 6.90–6.96 (m, 1H),4.49 (d,

J = 12.5 Hz, 1H), 4.57 (d,

J = 12.6 Hz, 1H), 4.00–4.06 (m, 1H), 3.69 (d,

J = 4.2 Hz, 1H), 2.75–2.82 (m, 2H), 1.84–1.92 (m, 2H), 1.42 (s, 9H) [

13].

3.13. Synthesis of Sitagliptin Phosphate Monohydrate

To a solution of

7b (1 g, 3.0 mmol) in DCM (10 mL), EDCI (0.69 g, 3.6 mmol), HOBT (0.49 g, 3.6 mmol), 3-(trifluoromethyl)-5,6,7,8-tetrahydro-1,2,4-triazolo[4,3-

a]pyrazine

10 (0.58 g, 3.0 mmol), and DIPEA (0.39 g, 3.0 mmol) were added successively. The reaction mixture was stirred for 12 h at room temperature and then H

2O (10 mL) and ethyl acetate (20 mL) were added to the reaction mixture. The organic phase was washed with saturated aqueous NaHCO

3 solution (5 mL), aqueous HCl solution (5 mL, 1N), brine (5 mL), and dried over with anhydrous Na

2SO

4. The solvent was evaporated and the residue was purified over silica gel chromatography to afford

11 as a foamy solid (1.38 g, 91%). Compound

11 (1.38 g, 2.7 mmol) was dissolved in 60 mL of saturated methanolic hydrogen chloride solution and stirred for 1 h. The solution was concentrated and partitioned between ethyl acetate (40 mL) and 1 N aqueous sodium hydroxide solution (40 mL). The aqueous layer was extracted with ethyl acetate (3 × 40 mL). The combined organic phase was evaporated and immediately dissolved in isopropanol (4 mL). The solution was maintained at 40 °C for 1 h and then cooled down to 20–15 °C. Heptane (12 mL) was added dropwise over 30 min and filtered. The wet cake was washed with 20% isopropanol in heptanes and dried over vacuo to give free base of 11 (0.89 g, 81%, >99.9% ee). The obtained solid (0.89 g, 2.2 mmol) was dissolved in isopropanol (3.8 mL) and H

2O (1 mL) and 45% H

3PO

4 (2.5 mmol) were added dropwise. The mixture was heated to 70–80 °C to dissolve the solids and then cooled to 60–65 °C and seeded with trace sitagliptin phosphate monohydrate. The batch was aged for 1 h and cooled to ambient temperature. 2-Propanol (2.8 mL) was added to the batch slowly and then filtered. The wet cake was washed with aqueous isopropanol (20% water, 3 mL), and dried over vacuo at 60 °C to give sitagliptin phosphate monohydrate

1 (1.1 g, 96% yield, >99.9% ee). Chiral HPLC condition: SHIMADZU Essentia LC-16 HPLC, Chiralpak IC-3 column with a mixture of 40% hexanes (0.1% diethylamine), 60% 2-PrOH (0.1% diethylamine) at a flow rate of 0.5 mL/min as the mobile phase, oven temperature was 28 °C, 210 nm, tminor = 21.12 min, tmajor = 19.10 min. Data of sample was consistent with that of standard sample [

6].