Novel High-Sensitivity Racetrack Surface Plasmon Resonance Sensor Modified by Graphene

Abstract

:1. Introduction

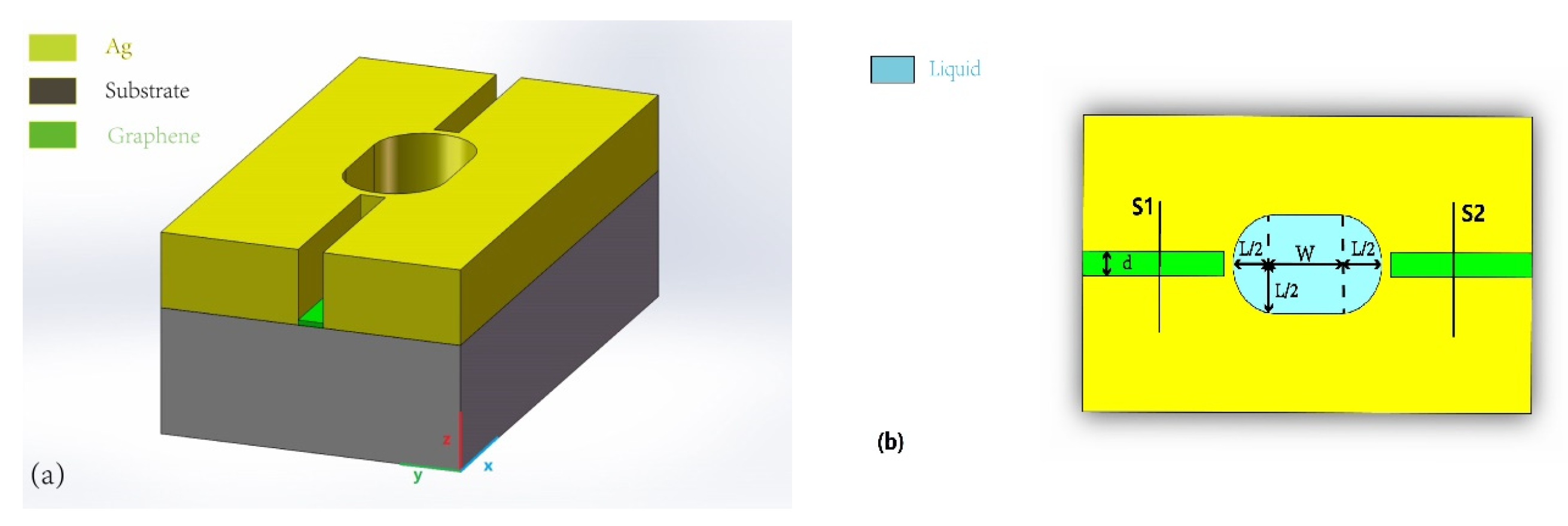

2. Sensor Structure and Theoretical Analysis

2.1. Sensor Structure

2.2. Theoretical Analysis

3. Results and Analysis

3.1. Graphene Properties

3.1.1. The Conductivity of Graphene

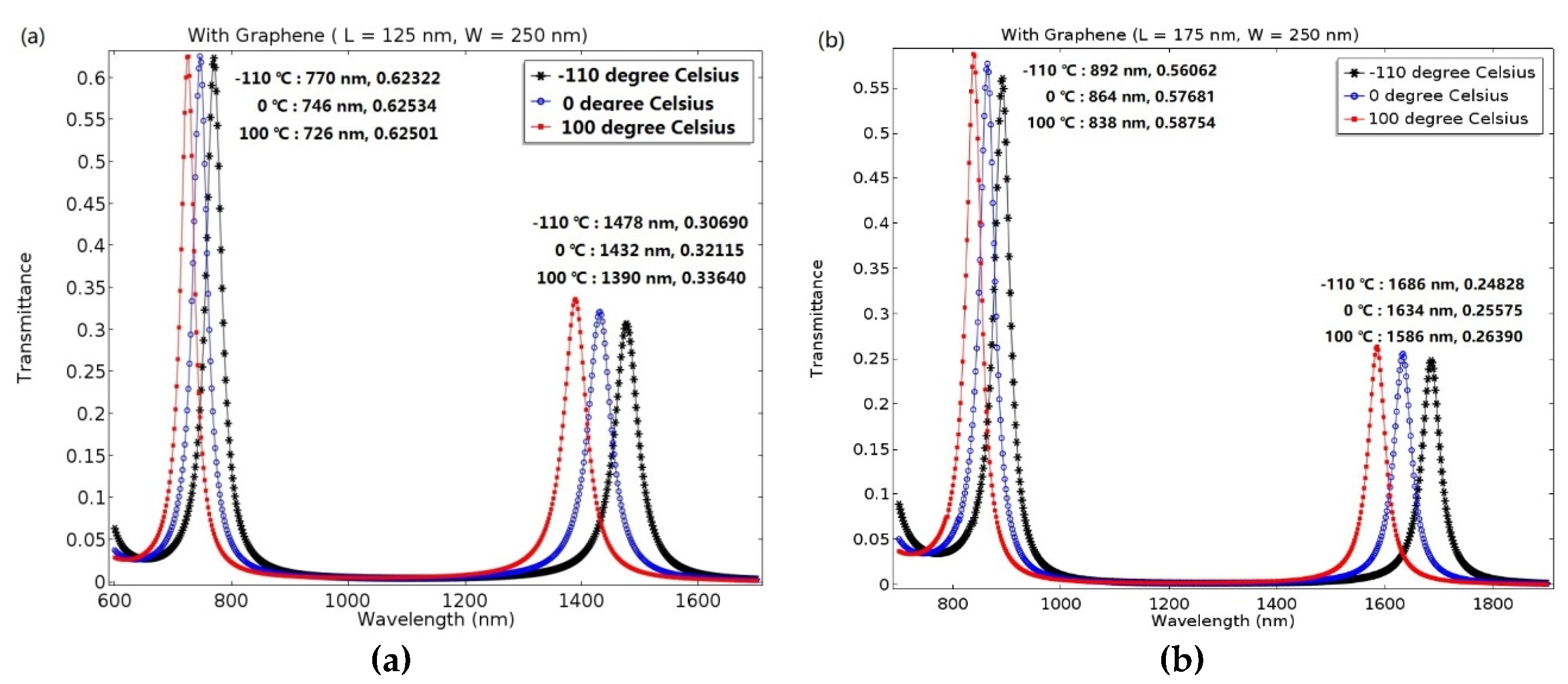

3.1.2. Analysis of Transmittance of Plasmonic Resonator Sensor

3.1.3. The Q-Factor of Plasmonic Resonator

3.2. Sensing Characteristics

3.2.1. Length Adjustment

3.2.2. Width Adjustment

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Gramotnev, D.K.; Bozhevolnyi, S.I. Plasmonics beyond the diffraction limit. Nat. Photonics 2010, 4, 83–91. [Google Scholar] [CrossRef]

- Maier, S.A.; Brongersma, M.L.; Kik, P.G.; Meltzer, S.; Requicha, A.A.G.; Atwater, H.A. Plasmonics-a route to nanoscale optical devices. Adv. Mater. 2001, 13, 1501–1505. [Google Scholar] [CrossRef]

- Barnes, W.L.; Dereux, A.; Ebbesen, T.W. Surface plasmon subwavelength optics. Nature 2003, 424, 824–830. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Shao, L.; Li, Q.; Wang, J. Gold nanorods and their plasmonic properties. Chem. Soc. Rev. 2013, 42, 2679–2724. [Google Scholar] [CrossRef] [PubMed]

- Zeng, S.; Baillargeat, D.; Ho, H.-P.; Yong, K.-T. Nanomaterials enhanced surface plasmon resonance for biological and chemical sensing applications. Chem. Soc. Rev. 2014, 43, 3426. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wang, Y.; Liao, C.; Liu, S.; Zhou, J.; Zhong, X.; Liu, Y.; Yang, K.; Wang, Q.; Yin, G. Temperature-insensitive refractive index sensor based on in-fiber Michelson interferometer. Sens. Actuators B Chem. 2014, 199, 31–35. [Google Scholar] [CrossRef]

- Ran, Z.L.; Rao, Y.J.; Liu, W.J.; Liao, X.; Chiang, K.S. Laser-micromachined Fabry-Perot optical fiber tip sensor for high-resolution temperature-independent measurement of refractive index. Opt. Express 2008, 16, 2252. [Google Scholar] [CrossRef] [PubMed]

- Hao, F.; Nordlander, P.; Sonnefraud, Y.; Dorpe, P.V.; Maier, S.A. Tunability of Subradiant Dipolar and Metallic Ring/Disk Cavities: Implications. ACS Nano. 2009, 3, 643–652. [Google Scholar] [CrossRef] [PubMed]

- Liu, N.; Weiss, T.; Mesch, M.; Langguth, L.; Eigenthaler, U.; Hirscher, M.; Sönnichsen, C.; Giessen, H. Planar Metamaterial Analogue of Electromagnetically Induced Transparency for Plasmonic Sensing. Nano Lett. 2010, 10, 1103–1107. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Zhou, J.; Liu, T.; Tao, Y.; Jiang, R.; Liu, M.; Xiao, G.; Zhu, J.; Zhou, Z.K.; Wang, X.; et al. Plasmonic gold mushroom arrays with refractive index sensing figures of merit approaching the theoretical limit. Nat. Commun. 2013, 4, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Caballero, B.; García-Martín, A.; Cuevas, J.C. Hybrid Magnetoplasmonic Crystals Boost the Performance of Nanohole Arrays as Plasmonic Sensors. ACS Photonics 2016, 3, 203–208. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, B.; Zhang, K.; Yuan, K.; Wan, Y.; Xie, Z.; Xu, X.; Zhang, H.; Song, Q.; Yao, L.; et al. Refractive Index Sensor Based on Leaky Resonant Scattering of Single Semiconductor Nanowire. ACS Photonics 2017, 4, 688–694. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, H.; Li, D.; Zhang, Z.; Zhang, S.; Yi, J.; Wang, W. Magnetic plasmons in a simple metallic nanogroove array for refractive index sensing. Opt. Express 2018, 26, 9148. [Google Scholar] [CrossRef] [PubMed]

- García De Abajo, F.J. Graphene nanophotonics. Science 2013, 339, 917–918. [Google Scholar] [CrossRef]

- Karimi, F.; Davoody, A.H.; Knezevic, I. Dielectric function and plasmons in graphene: A self-consistent-field calculation within a Markovian master equation formalism. Phys. Rev. B 2016, 93, 1–14. [Google Scholar] [CrossRef]

- Karimi, F.; Knezevic, I. Plasmons in graphene nanoribbons. Phys. Rev. B 2017, 96, 1–12. [Google Scholar] [CrossRef]

- Boltasseva, A.; Bozhevolnyi, S.I.; Nikolajsen, T.; Leosson, K. Compact Bragg gratings for long-range surface plasmon polaritons. J. Light. Technol. 2006, 24, 912–918. [Google Scholar] [CrossRef] [Green Version]

- Dionne, J.A.; Sweatlock, L.A.; Atwater, H.A.; Polman, A. Plasmon slot waveguides: Towards chip-scale propagation with subwavelength-scale localization. Phys. Rev. B Condens. Matter Mater. Phys. 2006, 73, 1–9. [Google Scholar] [CrossRef]

- Gusynin, V.P.; Sharapov, S.G.; Carbotte, J.P. Magneto-optical conductivity in graphene. J. Phys. Condens. Matter 2007, 19. [Google Scholar] [CrossRef]

- Koussevitzky, S.; Nott, A.; Mockler, T.C.; Hong, F.; Sachetto-Martins, G.; Surpin, M.; Lim, J.; Mittler, R.; Chory, J. Signals from chloroplasts converge to regulate nuclear gene expression. Science 2007, 316, 715–719. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Y.; Tian, C.; Girit, C.; Zettl, A.; Crommie, M.; Shen, Y.R. Gate-variable optical transitions in graphene. Science. 2008, 320, 206–209. [Google Scholar] [CrossRef] [PubMed]

- Franco, M.A.R.; Serrao, V.A.; Sircilli, F. Side-polished microstructured optical fiber for temperature sensor application. IEEE Photonics Technol. Lett. 2007, 19, 1738–1740. [Google Scholar] [CrossRef]

- Weber, E.M.J.; Dotsenko, A V.; Glebov, L.B.; Tsekhomsky, V.A. Handbook of Optical; University of California: Berkeley, CA, USA, 2003; Volume 23. [Google Scholar]

- He, X.Y.; Liu, F.; Lin, F.T.; Shi, W.Z. Graphene patterns supported terahertz tunable plasmon induced transparency. Opt. Express 2018, 26, 1866–1878. [Google Scholar] [CrossRef] [PubMed]

- Bochenkov, V.E.; Frederiksen, M.; Sutherland, D.S. Enhanced refractive index sensitivity of elevated short-range ordered nanohole arrays in optically thin plasmonic Au films. Opt. Express 2013, 21, 14763. [Google Scholar] [CrossRef] [PubMed]

- Khaleque, A.; Mironov, E.G.; Osório, J.H.; Li, Z.; Cordeiro, C.M.B.; Liu, L.; Franco, M.A.R.; Liow, J.L.; Hattori, H.T. Integration of bow-tie plasmonic nano-antennas on tapered fibers. Opt. Express 2017, 25, 8986. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Sun, Q.; Wang, C.; Sun, Z.; Mou, C.; Zhou, K.; Liu, D.; Zhang, L. Refractive index and temperature sensitivity characterization of excessively tilted fiber grating. Opt. Express 2017, 25, 3336. [Google Scholar] [CrossRef] [PubMed]

- González-Vila, Á.; Ioannou, A.; Loyez, M.; Debliquy, M.; Lahem, D.; Caucheteur, C. Surface plasmon resonance sensing in gaseous media with optical fiber gratings. Opt. Lett. 2018, 43, 2308. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are not available from the authors. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Xu, Z.; Huang, Y. Novel High-Sensitivity Racetrack Surface Plasmon Resonance Sensor Modified by Graphene. Molecules 2018, 23, 1726. https://doi.org/10.3390/molecules23071726

Zhu J, Xu Z, Huang Y. Novel High-Sensitivity Racetrack Surface Plasmon Resonance Sensor Modified by Graphene. Molecules. 2018; 23(7):1726. https://doi.org/10.3390/molecules23071726

Chicago/Turabian StyleZhu, Jun, Zhengjie Xu, and Yuanmin Huang. 2018. "Novel High-Sensitivity Racetrack Surface Plasmon Resonance Sensor Modified by Graphene" Molecules 23, no. 7: 1726. https://doi.org/10.3390/molecules23071726