Silica Sulfuric Acid/ NaNO2 as a Novel Heterogeneous System for the Nitration of Phenols under Mild Conditions

Abstract

:Introduction

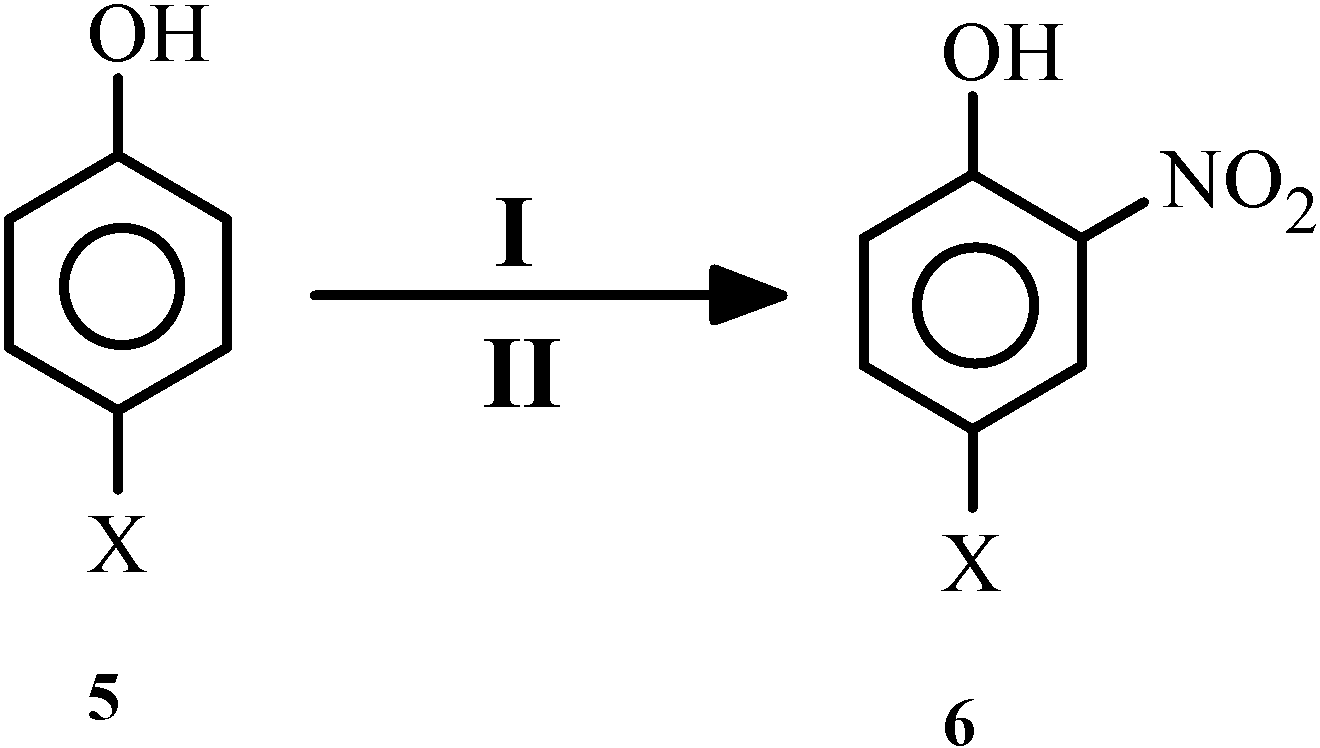

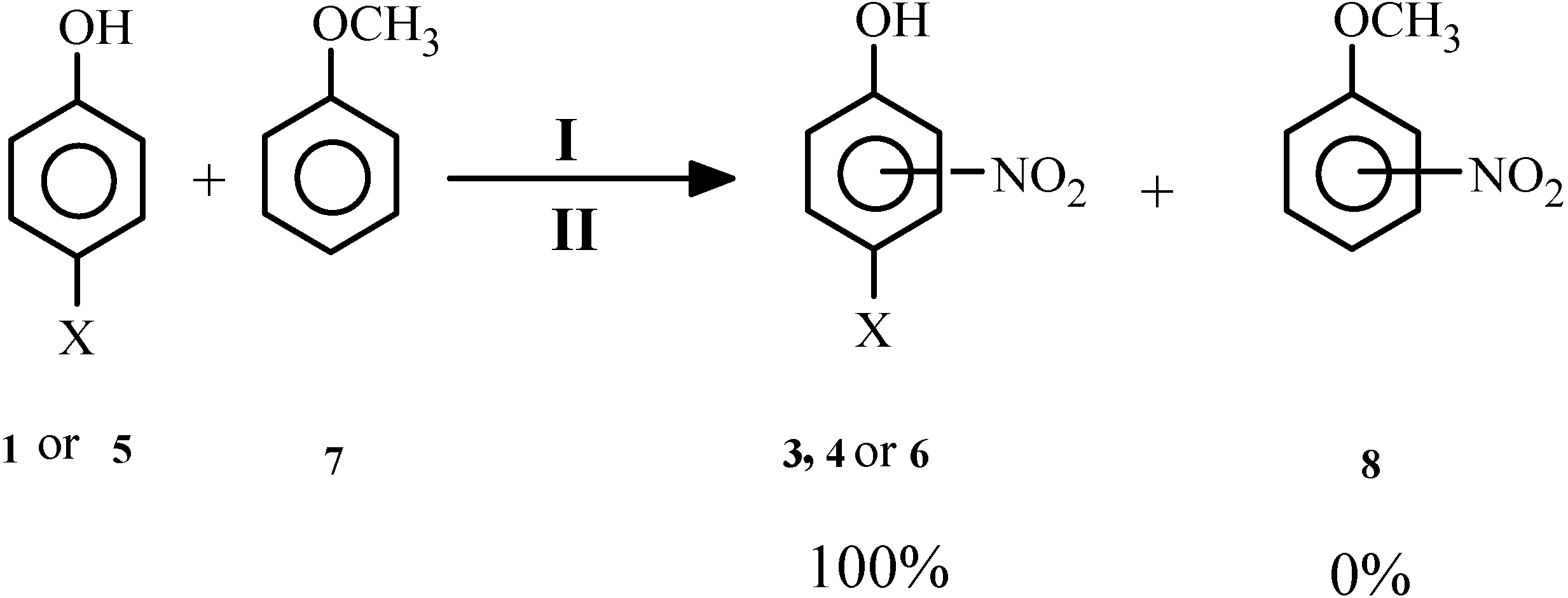

Results and Discussion

| Entry | Substrate | Products | Time (h) | Yieldsb % | M.p. (oC) | |

|---|---|---|---|---|---|---|

| Found | Reported | |||||

| 1 | 1 | 3 4 | 1.5 | 20 30 | 110-113 | 115 [10] |

| 44-45 | 44 [10] | |||||

| 2 | 5a | 6a | 1.5 | 30 | 73 | 73-74 [7c] |

| 3 | 5b | 6b | 2 | 45 | 89 | 91 [14,31] |

| 4 | 5c | 6c | 2 | 90 | 87 | 84 [14,31] |

| 5 | 5d | 6d | 2 | 80 | 140-142 | 145 [7c,31] |

| 6 | 5e | 6e | 2 | 86 | 61-63 | 66 [34] |

| 7 | 5f | 6f | 2 | 70 | 29-31 | 31 [14,31] |

| 8 | 5g | 6g | 2 | 54 | 54-56 | -- [31,35] |

| 9 | 5h | 6h | 3 | 62 | 122-124 | 123 [14,31] |

| 10 | 5i | 6i | 3 | 70 | 61-6 | ---[35] |

| 11 | 5j | 6j | 24 | 60 | 180 | ---[16,37] |

| 12 | 5k | 6k | 3 | 25 | 180-184 | ---[34] |

| 13 | 1 | 3, 4 | 24(h) | No reactionc | --- | --- |

Conclusions

Acknowledgements

Experimental

General

Preparation of silica sulfuric acid (I) [38]

Typical procedure for the mononitration of phenol (1) with silica sulfuric acid (I), NaNO2 (II) and wet SiO2

Typical procedure for the mononitration of 4-chlorophenol (5b) with silica sulfuric acid (I), NaNO2 (II) and wet SiO2.

References

- Riego, J.M.; Sedin, Z.; Zaldivar, J.M.; Marziano, N.C.; Tortato, C. Tetrahedron Lett 1996, 37, 513.

- Turro, N.J. Tetrahedron 1987, 43, 1589.

- Olah, G.A.; Molhotra, R.; Narang, S.C. J. Org. Chem. 1987, 43, 4628. [CrossRef]

- Gu, S.; Jing, H.; Wu, J.; Liang, Y. Synth. Commun. 1997, 27, 2793. [CrossRef]

- Smith, K.; Musson, A.; DeBoos, G.A. Chem. Commun. 1996, 469.

- Waller, F.G.; Barrett, A.G.M.; Braddock, D.C.; Ramprasad, D. Chem. Commun. 1997, 613, and references cited therein.

- Delaude, L.; Laszlo, P.; Smith, K. Acc. Chem. Res. 1993, 26, 607.Laszlo, P. Acc.Chem. Res. 1986, 19, 121.Cornelis, A.; Laszlo, P.; Pennetreau, P. Bull. Soc. Chim. Belg. 1984, 93, 961.

- Zeegers, P.J. J. Chem. Ed. 1993, 70, 1036. [CrossRef]

- Pervas, H.; Onysiuka, S.O.; Rees, L.; Rooney, J.R.; Suckling, G.J. Tetrahedron 1988, 44, 4555.

- Furniss, B.S.; Hannaford, A.J.; Smith, P.W.G.; Tatchell, A.R. Vogel’s Text Book of Practical Organic Chemistry, 4th Ed ed; Longman: London & New York, 1986. [Google Scholar]

- Bruice, T.C.; Gregor, M.G.; Walters, S.L. J. Am. Chem. Soc. 1986, 90, 1612. [CrossRef]

- Crivello, J.V. J. Org. Chem. 1981, 46, 3056. [CrossRef]

- Oueartani, M.; Girad, P.; Kagan, H.B. Tetrahedron Lett. 1982, 23, 4315.

- Poirier, J.M.; Vottero, C. Tetrahedron 1989, 45, 1415.

- Thompson, M.J.; Zeegers, P.J. Tetrahedron 1989, 45, 191.

- Tapia, R.; Torres, G.; Valderrama, J.A. Synth. Commun. 1986, 16, 681.

- Gaude, D.; Goallar, R.L.; Pierre, J.L. Synth. Commun. 1986, 16, 63.

- Gigante, B.; Prazeres, A.O.; Marcelo-Curto, M.J. J. Org. Chem. 1995, 60, 3445. [CrossRef]

- Rodrigues, J.A.R.; Filho, A.P.O.; Moran, P.J.S. Tetrahedron 1999, 55, 6733.

- Riego, J.M.; Sedin, Z.; Zaldivar, J.M.; Marziano, N.C.; Tortato, C. Tetrahedron Lett. 1996, 37, 513.

- Zolfigol, M.A.; Iranpoor, N.; Firouzabadi, H. Orient. J. Chem. 1998, 14, 369.Firouzabadi, H.; Iranpoor, N.; Zolfigol, M.A. Iran. J. Chem. & Chem. Eng. 1997, 16, 48.Firouzabadi, H.; Iranpoor, N.; Zolfigol, M.A. Synth. Commun. 1997, 27, 3301.Iranpoor, N.; Firouzabadi, H.; Zolfigol, M.A. ibid. 1998, 28, 2773.

- Firouzabadi, H.; Iranpoor, N.; Zolfigol, M.A. Synth. Commun. 1998, 28, 377.Firouzabadi, H.; Iranpoor, N.; Zolfigol, M.A. ibid. 1998, 28, 1179.Iranpoor, N.; Firouzabadi, H.; Zolfigol, M.A. ibid. 1998, 28, 367.Firouzabadi, H.; Iranpoor, N.; Zolfigol, M.A. Bull. Chem. Soc. Jpn. 1998, 71, 2169.Iranpoor, N.; Firouzabadi, H.; Zolfigol, M.A. ibid. 1998, 71, 905.

- Laszlo, P.; Cornelis, A. Aldrichimica Acta 1988, 21, 97.Cornelis, A.; Laszlo, P. Synthesis 1985, 909.Laszlo, P.; Cornelis, A. Synlett 1994, 155.

- Zolfigol, M.A. Synth. Commun 1999, 29, 905.Zolfigol, M.A.; Nematollahi, D.; Mallakpour, S.E. ibid. 1999, 29, 2277.Zolfigol, M.A.; Mallakpour, S.E. ibid. 1999, 29, 4061.Zolfigol, M.A.; Kiany-Borazjani, M.; Sadeghi, M.M.; Mohammadpoor-Baltork, I.; Memarian, H.R. ibid. 2000, 30, 551.Zolfigol, M.A. ibid. 2000, 30, 1593.Zolfigol, M.A.; Ghaemi, E.; Madrakian, E. ibid. 2000, 30, 1689.

- Maleski, R.J. Synth. Commun. 1993, 23, 343.Maleski, R.J. ibid. 1995, 25, 2327.Ross, D.S.; Hum, G.P.; Blucher, W.G. J. Chem. Soc. Chem. Comm. 1980, 532.Al-Obaidi, V.; Moodie, R.B. J. Chem. Soc. Perkin Trans. 2 1985, 467.

- Suboch, G.A.; Belyaev, E.Y. Russ. J. Org. Chem. 1998, 34, 288.

- Ishikawa, T.; Watanabe, T.; Tanigawa, H.; Saito, T.; Kotake, K.I.; Ohashi, Y.; Ishii, H. J. Org. Chem. 1996, 61, 2774.Beake, B.D.; Moodie, R.B. J. Chem. Soc. Perkin Trans. 2 1985, 1, and references cited therein.

- Zolfigol, M.A.; Zebarjadian, M.H.; Chehardoli, G.; Mallakpour, S.E.; Shamsipur, M. Tetrahedron 2001, 57, 1627.Zolfigol, M.A.; Zebarjadian, M.H.; Chehardoli, G.; Keypour, H.; Salehzadeh, S.; Shamsipur, M. J. Org. Chem. 2001, 66, 3619.Zolfigol, M.A.; Zebarjadian, M.H.; Sadeghi, M.M.; Memarian, H.R.; Mohammadpoor-Baltork, I.; Shamsipur, M. Synth. Commun. 2001, 30, 929.

- Mallakpour, S.E.; Zolfigol, M.A. Indian J. Chem. 1995, 34B, 183.Mallakpour, S.E.; Zolfigol, M.A. J. Sci. I. R. Iran 1993, 4, 199.

- Dorfman, Y.A.; Aleshkova, M.M. Russ. J. Org. Chem. 1998, 34, 217.

- Nonoyama, N.; Chiba, K.; Hisatome, K.; Suzuki, H.; Shintani, F. Tetrahedron Lett. 1999, 40, 6923.

- Lehnig, M. Tetrahedron Lett. 1999, 40, 2299.

- Coombes, R.G.; Diggele, A.W. Tetrahedron Lett. 1994, 34, 6373.

- Raiford, L.C.; Colbert, J.C. J. Am. Chem. Soc. 1925, 47, 1454. [CrossRef]

- Guay, V.; Brassard, P. J. Heterocyclic Chem. 1987, 24, 1649. [CrossRef]

- Anderson, R.A.; Dalgleish, D.T.; Nonhebel, D.C.; Pauson, P.L. J. Chem. Res. 1977, 12.

- Hancock, C.K.; Clagve, A.D. J. Am. Chem. Soc. 1964, 86, 4942. [CrossRef]

- Zolfigol, M.A. Tetrahedron 2001, 57, 9509.

- Sample Availability: Samples of compounds 3, 4, 6a, 6b, 6d, 6h, 6k, 3-nitro-4-hydroxybenzoic acid and 3-nitro-4-hydroxybenzaldehyde are available from MDPI.

© 2002 by MDPI (http://www.mdpi.org). Reproduction is permitted for noncommercial purposes.

Share and Cite

Zolfigol, M.A.; Madrakian, E.; Ghaemi, E. Silica Sulfuric Acid/ NaNO2 as a Novel Heterogeneous System for the Nitration of Phenols under Mild Conditions. Molecules 2002, 7, 734-742. https://doi.org/10.3390/71000734

Zolfigol MA, Madrakian E, Ghaemi E. Silica Sulfuric Acid/ NaNO2 as a Novel Heterogeneous System for the Nitration of Phenols under Mild Conditions. Molecules. 2002; 7(10):734-742. https://doi.org/10.3390/71000734

Chicago/Turabian StyleZolfigol, Mohammad Ali, Elahe Madrakian, and Ezat Ghaemi. 2002. "Silica Sulfuric Acid/ NaNO2 as a Novel Heterogeneous System for the Nitration of Phenols under Mild Conditions" Molecules 7, no. 10: 734-742. https://doi.org/10.3390/71000734