Biosurfactants for Microbubble Preparation and Application

Abstract

:1. Introduction

2. Type of Biosurfactants

2.1. Microbially Derived Surfactants

2.2. Animal-Derived Surfactants

2.3. Plant-Derived Biosurfactants

3. Microbubble Technology and Its Applications

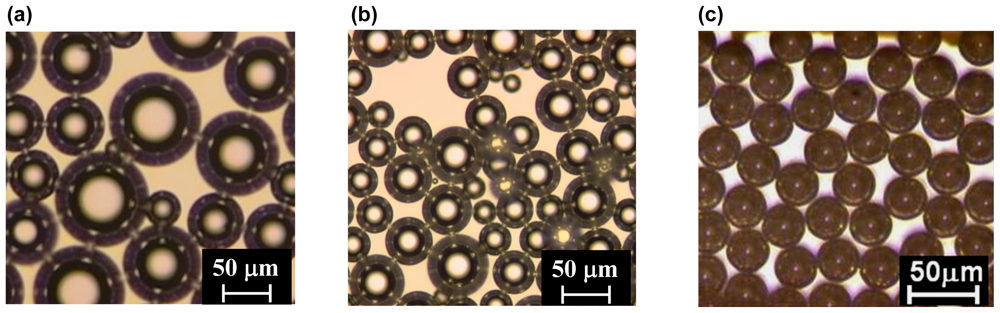

4. Properties of Some Biosurfactant-Stabilized Microbubbles

5. Applications of Biosurfactant-Stabilized Microbubbles

6. Conclusions

Acknowledgment

References

- Urum, K; Pekdemir, T. Evaluation of biosurfactants for crude oil contaminated soil washing. Chemosphere 2004, 57, 1139–1150. [Google Scholar]

- Holmberg, K. Natural surfactants. Curr. Opin. Colloid In 2001, 6, 148–159. [Google Scholar]

- Rodrigues, L; Banat, IM; Teixeira, J; Oliveira, R. Biosurfactants: Potential applications in medicine. J. Antimicrob. Chem 2006, 57, 609–618. [Google Scholar]

- Mukherjee, S; Das, P; Sen, R. Towards commercial production of microbial surfactants. Trends Biotechnol 2006, 11, 509–515. [Google Scholar]

- Endres, JG. Soy Protein Products: Characteristics, Nutritional Aspects, and Utilization, Revised and Expanded Edition; AOCS Press: Champaign, IL, USA, 2001. [Google Scholar]

- Li, R. Soy product off-flavor generating, masking, and flavor creating. In Soy Applications in Food; Riaz, MN, Ed.; Taylor & Francis: Boca Raton, FL, USA, 2006; pp. 227–248. [Google Scholar]

- Nitschke, M; Costa, SGVAO. Biosurfactants in food industry. Trends Food Sci. Tech 2007, 18, 252–259. [Google Scholar]

- Xu, QY; Nakajima, M; Ichikawa, S; Nakamura, N; Shiina, T. A comparative study of microbubble generation by mechanical agitation and sonication. Innov. Food Sci. Emerg 2008a, 9, 489–494. [Google Scholar]

- Sebba, F. Applications of colloidal gas aphrons. In Foams and Biliquid Foams, Aphrons; John Wiley & Sons: Chichester, UK, 1987; pp. 135–153. [Google Scholar]

- Mulligan, CN; Yong, RN; Gibbs, BF. Surfactant-enhanced remediation of contaminated soil: A review. Eng. Geol 2001, 60, 371–380. [Google Scholar]

- Fiechter, A. Biosurfactants: Moving towards industrial application. Trends Biotechnol 1992, 10, 208–217. [Google Scholar]

- Ron, EZ; Rosenberg, E. Biosurfactants and oil bioremediation. Curr. Opin. Biotech 2002, 13, 249–252. [Google Scholar]

- Crowley, MM. Solutions, emulsions, suspensions, and extracts. In Remington: The Science and Practice of Pharmacy, 21st ed; Troy, DB, Ed.; Lippincott Williams & Wilkins: Philadelphia, PA, USA, 2006; pp. 745–775. [Google Scholar]

- Dickinson, E. Towards more natural emulsifiers. Trends Food Sci. Tech 1993, 4, 330–334. [Google Scholar]

- Garti, N. Food emulsifiers: Structure-reactivity relationships, design, and applications. In Physical Properties of Lipids; Marangoni, AG, Narine, S, Eds.; Marcel Dekker, Inc: New York, NY, USA, 2002; pp. 265–386. [Google Scholar]

- Wang, G; Wang, T. Oxidative stability of egg and soy lecithin as affected by transition metal ions and pH in emulsion. J. Agric. Food Chem 2008, 56, 11424–11431. [Google Scholar]

- Karim, AA; Bhat, R. Gelatin alternatives for the food industry: Recent developments, challenges and prospects. Trends Food Sci. Tech 2008, 19, 644–656. [Google Scholar]

- Koczo, K; Nikolov, AD; Wasan, DT; Borwankar, RP; Gonsalvest, A. Layering of sodium caseinate submicelles in thin liquid films—A new stability mechanism for food dispersions. J. Colloid Interface Sci 1996, 178, 694–702. [Google Scholar]

- McClements, DJ. Food Emulsions: Principles, Practices, and Techniques, 2nd ed; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Demetriades, K; Coupland, JN; McClements, DJ. Physical properties of whey protein stabilized emulsions as related to pH and NaCl. J. Food Sci 1997, 62, 342–347. [Google Scholar]

- Chanamai, R; McClements, DJ. Comparison of gum arabic, modified starch, and whey protein isolate as emulsifiers: Influence of pH, CaCl2 and temperature. J. Food Sci 2002, 67, 120–125. [Google Scholar]

- McEvily, AJ; Zaks, A. Emulsifiers and surfactants. In Biotechnology and Food Ingredients; Goldberg, I, Williams, R, Eds.; Van Nostrand Reinhold: New York, NY, USA, 1991; pp. 193–222. [Google Scholar]

- Serrano, AG; Gil, JP. Protein-lipid interactions and surface activity in the pulmonary surfactant system. Chem. Phys Lipids 2006, 141, 105–118. [Google Scholar]

- Zuo, YY; Veldhuizen, RAW; Neumann, AW; Petersen, NO; Possmayer, F. Current perspectives inpulmonary surfactant—Inhibition, enhancement and evaluation. Biochim. Biophys Acta 2008, 1778, 1947–1977. [Google Scholar]

- Oakenfull, D. Saponins in food—A review. Food Chem 1981, 6, 19–40. [Google Scholar]

- Vincken, JP; Heng, L; Groot, A; Gruppen, H. Saponins, classification and occurrence in the plant kingdom. Phytochemistry 2007, 68, 275–297. [Google Scholar]

- Iwabuchi, S; Yamauchi, F. Determination of glycinin and beta-conglycinin in soybean proteins by immunological methods. J. Agr. Food Chem 1987, 35, 200–205. [Google Scholar]

- Kinsella, JE. Functional properties of proteins: Possible relationships between structure and function in foams. Food Chem 1981, 7, 273–288. [Google Scholar]

- Guo, Y; Hardesty, JH; Mannari, VM; Massingill, JL. Hydrolysis of epoxidized soybean oil in the presence of phosphoric acid. J. Am. Oil Chem. Soc 2007, 84, 929–935. [Google Scholar]

- Biresaw, G; Liu, ZS; Erhan, SZ. Investigation of the surface properties of polymeric soaps obtained by ring-opening polymerization of epoxidized soybean oil. J. Appl. Polym. Sci 2008, 108, 1976–1985. [Google Scholar]

- Liu, ZS; Erhan, SZ. Soy-based thermosensitive hydrogels for controlled release systems. United States Patent 769, 1946. [Google Scholar]

- Xu, QY; Liu, ZS; Nakajima, M; Ichikawa, S; Nakamura, N; Roy, P; Okadome, H; Shiina, T. Characterization of a soybean oil-based biosurfactant and evaluation of its ability to form microbubbles. Bioresource Technol 2010, 101, 3711–3717. [Google Scholar]

- Liu, ZS. Synthesis of soybean oil-based polymeric surfactants in supercritical carbon dioxide and investigation of their surface properties. 2011. [Google Scholar]

- Wong, HL; Rauth, AM; Bendayan, R; Manias, JL; Ramaswamy, M; Liu, Z; Erhan, SZ; Wu, XY. A new polymer-lipid hybrid nanoparticle system increases cytotoxicity of doxorubicin against multidrug-resistant human breast cancer cells. Pharm. Res.-Dordr 2006, 23, 1574–1585. [Google Scholar]

- Xu, J; Liu, Z; Erhan, SZ. Viscoelastic properties of a biological hydrogel produced from soybean oil. J. Am. Oil Chem. Soc 2008b, 85, 285–290. [Google Scholar]

- Kim, JH; Park, K; Nam, HY; Lee, S; Kim, K; Kwon, IC. Polymers for bioimaging. Prog. Polym. Sci 2007, 32, 1031–1053. [Google Scholar]

- Kaufmann, BA; Lindner, JR. Molecular imaging with targeted contrast ultrasounds. Curr. Opin. Biotech 2007, 18, 11–16. [Google Scholar]

- Morawski, AM; Lanza, GA; Wickline, SA. Targeted contrast agents for magnetic resonance imaging and ultrasound. Curr. Opin. Biotech 2005, 16, 89–92. [Google Scholar]

- Laing, ST; McPherson, DD. Cardiovascular therapeutic uses of targeted ultrasound contrast agents. Cardiovasc. Res 2009, 83, 626–635. [Google Scholar]

- Chu, L; Xing, X; Yu, A; Zhou, Y; Sun, X; Jurcik, B. Enhanced ozonatin of simulated dyestuff wastewater by microbubbles. Chemosphere 2007, 68, 1854–1860. [Google Scholar]

- Bredwell, MD; Srivastava, P; Worden, RM. Reactor design issues for synthesis-gas fermentations. Biotechnol. Prog 1999, 15, 834–844. [Google Scholar]

- Onari, H. Microbubbles and its application to the fisheries technology. In Concepts in Basic Bubble and Foam Engineering; Ishii, T, Tamura, T, Tsukada, T, Tsujii, K, Eds.; Techno System: Tokyo Japan, 2005; pp. 475–484. [Google Scholar]

- Hoage, JB; Messer, LA. Apparatus for aeration without significant agitation to deplete and biodegrade sludge. United States Patent 6884353, 2005. [Google Scholar]

- Jauregi, P; Varley, J. Colloidal gas aphrons: Potential applications in biotechnology. Trends Biotechnol 1999, 17, 389–395. [Google Scholar]

- Feng, W; Singhal, N; Swift, S. Drainage mechanism of microbubble dispersion and factors influencing its stability. J. Colloid Interface Sci 2009, 337, 548–554. [Google Scholar]

- Pattle, RE. Properties, function, and origin of the alveolar lining layer. P. Roy. Soc. B-Biol. Sci 1958, 148, 217–240. [Google Scholar]

- Pattle, RE. The relation between surface tension and area in the alveolar lining film. J. Physiol 1977, 269, 591–604. [Google Scholar]

- Kommalapati, RR; Roy, D; Valsaraj, KT; Constant, WD. Characterization of colloidal gas aphron suspensions generated from plant-based natural surfactant solutions. Sep. Sci. Technol 1996, 31, 2317–2333. [Google Scholar]

- Corvis, Y; Brezesinski, G; Rink, R; Walcarius, A; Heyden, AVD; Mutelet, F; Rogalska, E. Analytical investigation of the interactions between SC3 hydrophobin and lipid layers: Elaborating of nanostructured matrixes for immobilizing redox systems. Anal. Chem 2006, 78, 4850–4864. [Google Scholar]

- Cox, AR; Cagnol, F; Russell, AB; Izzard, MJ. Surface properties of class II hydrophobins from Trichoderma reesei and influence on bubble stability. Langmuir 2007, 23, 7995–8002. [Google Scholar]

- Bloch, SH; Short, RE; Ferrara, KW; Wisner, ER. The effect of size on the acoustic response of polymer-shelled contrast agents. Ultrasound Med. Biol 2005, 31, 439–444. [Google Scholar]

- Bekeredjian, R; Grayburn, PA; Shohet, RV. Use of ultrasound contrast agents for gene or drug delivery in cardiovascular medicine. J. Am. Coll. Cardiol 2005, 45, 329–335. [Google Scholar]

- Teupe, C; Richter, S; Fisslthaler, B; Randriamboavonjy, V; Ihling, C; Fleming, I; Busse, R; Zeiher, AM; Dimmeler, S. Vascular gene transfer of phosphomimetic endothelial nitric oxide synthase (S1177D) using ultrasound-enhanced destruction of plasmid-loaded microbubbles improves vasoreactivity. Circulation 2010, 105, 1104–1109. [Google Scholar]

- Wang, S; Mulligan, CN. An evaluation of surfactant foam technology in remediation of contaminated soil. Chemosphere 2004, 57, 1079–1089. [Google Scholar]

- Mulligan, CN; Wang, S. Remediation of a heavy metal-contaminated soil by a rhamnolipid foam. Eng. Geol 2006, 85, 75–81. [Google Scholar]

- Ripley, MB; Harrison, AB; Betts, WB; Dart, RK; Wilson, AJ. Enhanced degradation of a model oil compound in soil using a liquid foam-microbe formulation. Environ. Sci. Technol 2000, 34, 489–496. [Google Scholar]

- Ripley, MB; Harrison, AB; Betts, WB; Dart, RK. Mechanisms for enhanced biodegradation of petroleum hydrocarbons by a microbe-colonized gas-liquid foam. J. Appl. Microbiol 2002, 92, 22–31. [Google Scholar]

- Kommalapati, RR; Valsaraj, KT; Constant, WD; Roy, D. Soil flushing using colloidal gas aphron suspensions generated from a plant-based surfactant. J. Hazard. Mater 1998, 60, 73–87. [Google Scholar]

- Choi, YJ; Kim, YJ; Nam, K. Enhancement of aerobic biodegradation in an oxygen-limiting environment using a saponin-based microbubble suspension. Environ. Pollut 2009, 157, 2197–2202. [Google Scholar]

- Park, JY; Choi, YJ; Moon, S; Shin, DY; Nam, K. Microbubble suspension as a carrier of oxygen and acclimated bacteria for phenanthrene biodegradation. J. Hazard. Mater 2009, 163, 761–767. [Google Scholar]

© 2011 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Xu, Q.; Nakajima, M.; Liu, Z.; Shiina, T. Biosurfactants for Microbubble Preparation and Application. Int. J. Mol. Sci. 2011, 12, 462-475. https://doi.org/10.3390/ijms12010462

Xu Q, Nakajima M, Liu Z, Shiina T. Biosurfactants for Microbubble Preparation and Application. International Journal of Molecular Sciences. 2011; 12(1):462-475. https://doi.org/10.3390/ijms12010462

Chicago/Turabian StyleXu, Qingyi, Mitsutoshi Nakajima, Zengshe Liu, and Takeo Shiina. 2011. "Biosurfactants for Microbubble Preparation and Application" International Journal of Molecular Sciences 12, no. 1: 462-475. https://doi.org/10.3390/ijms12010462