Hazard Screening Methods for Nanomaterials: A Comparative Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data

2.2. Bayesian Network Methodology

2.3. Quantitative Weight of Evidence Methodology

- LOE index values based on physico-chemical properties: Physico-chemical criterion (BET surface area, primary particle size, aspect ratio, surface coating, ζ-potential, purity, composition, bioaccumulation) are evaluated according a state-specific scoring system in the [0,100] range. These discretised states, or classes, refer to the segregation of the criteria into their components of increased/decreased hazard (i.e., aspect ratio ≥ 1:3 = high hazard = 100; aspect ratio < 1:3 = low hazard = 25). The LOE-specific index is subsequently determined by the arithmetic mean of each score given to , …, .

- LOE index values based on toxicity: Five hazard classes () of increasing evidence of toxicity to humans according to US EPA guidelines are specified and mapped onto a scoring system within the [0,100] range [23]. Specific rules apply for the study, or LOE, to be categorised into a specific class. For example, for class , there must be convincing causal evidence between the NM and biological effect. LOE may fall into one or more classes based on the conclusions provided by the author. Hence, a percentage would be assigned according to the likelihood the conclusions fit into a certain class. The LOE-specific index value is then calculated by the following equation:

- Total LOE index values: The LOE indices for physico-chemical data and toxicity are aggregated to form a global LOE index () representing intrinsic hazard demonstrated by the study. Since both do not have equal weight in the hazard assessment, a weighted sum (WS) operator is applied. The weights < imply that toxicity evidence explains more about the intrinsic hazard potential of a NM than physico-chemical evidence. The following equation illustrates the aggregation of the indices:

- LOE weight: The weight () of each LOE is established according to a Logic model that uses regulatory data quality criteria (adequacy, reliability, statistical power, toxicological significance) to infer the study’s relevance to measuring the hazard potential of a NM [20]. Each weight is normalised by dividing them by their total sum:

- Weighted LOE index value: The impact of each LOE on the total hazard assessment is calculated by obtaining the product of the global LOE index value () and normalised study quality weight ():

- The probability distributions for the input criterion were set at the full range of the normalisation scale, that is, [0,100] for and and [0,1] for .

- Four sampling scenarios were investigated. Three of which involved sampling input values of one of the criterion (, , ) from their probability distributions while holding the others constant. The fourth sampled input values from the probability distributions of all three criterion. The sampling was uniformly distributed within the interval.

- Each sampling scenario was simulated 10,000 times and the total weighted LOE index value recorded at each iteration.

3. Results

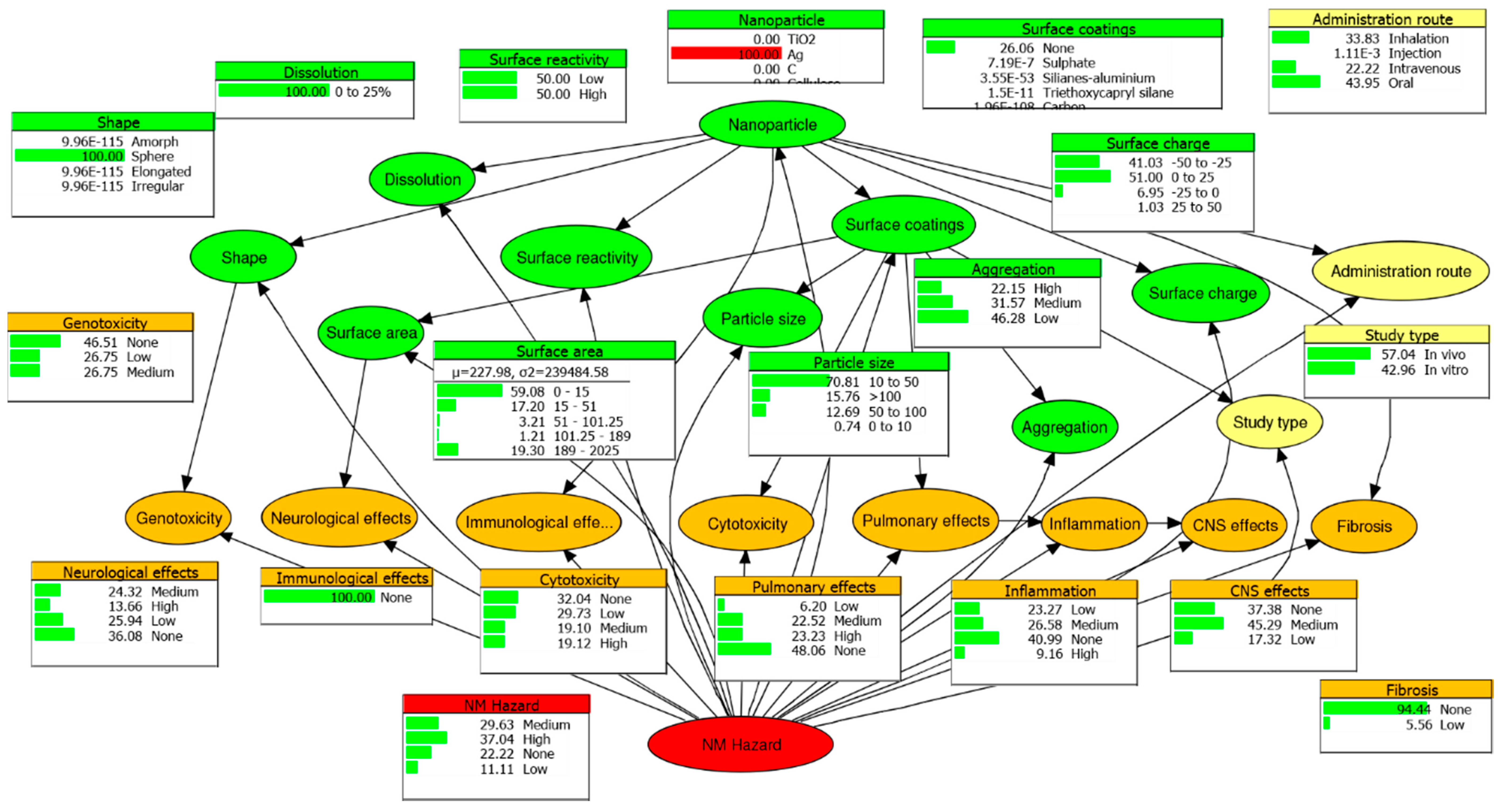

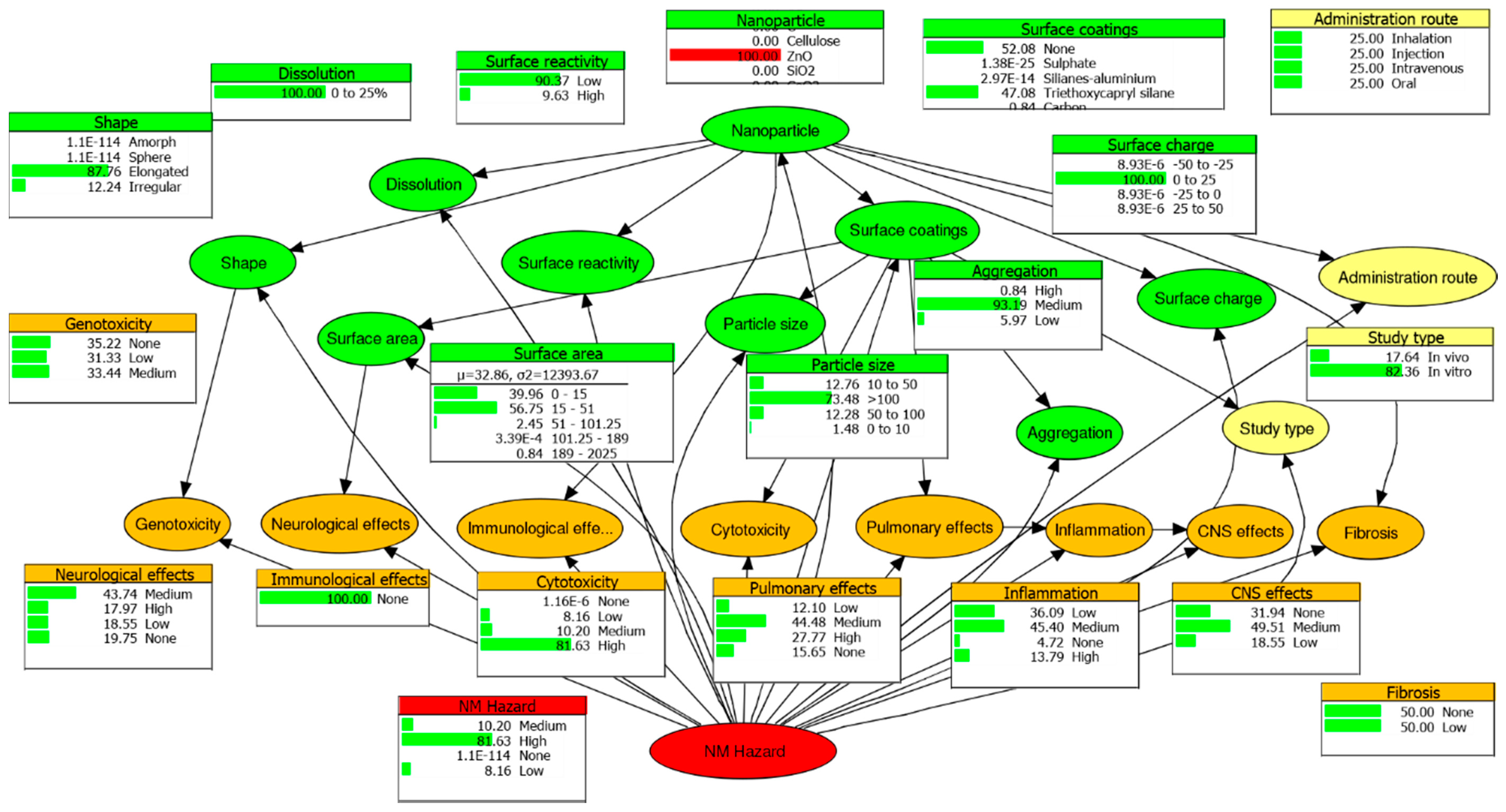

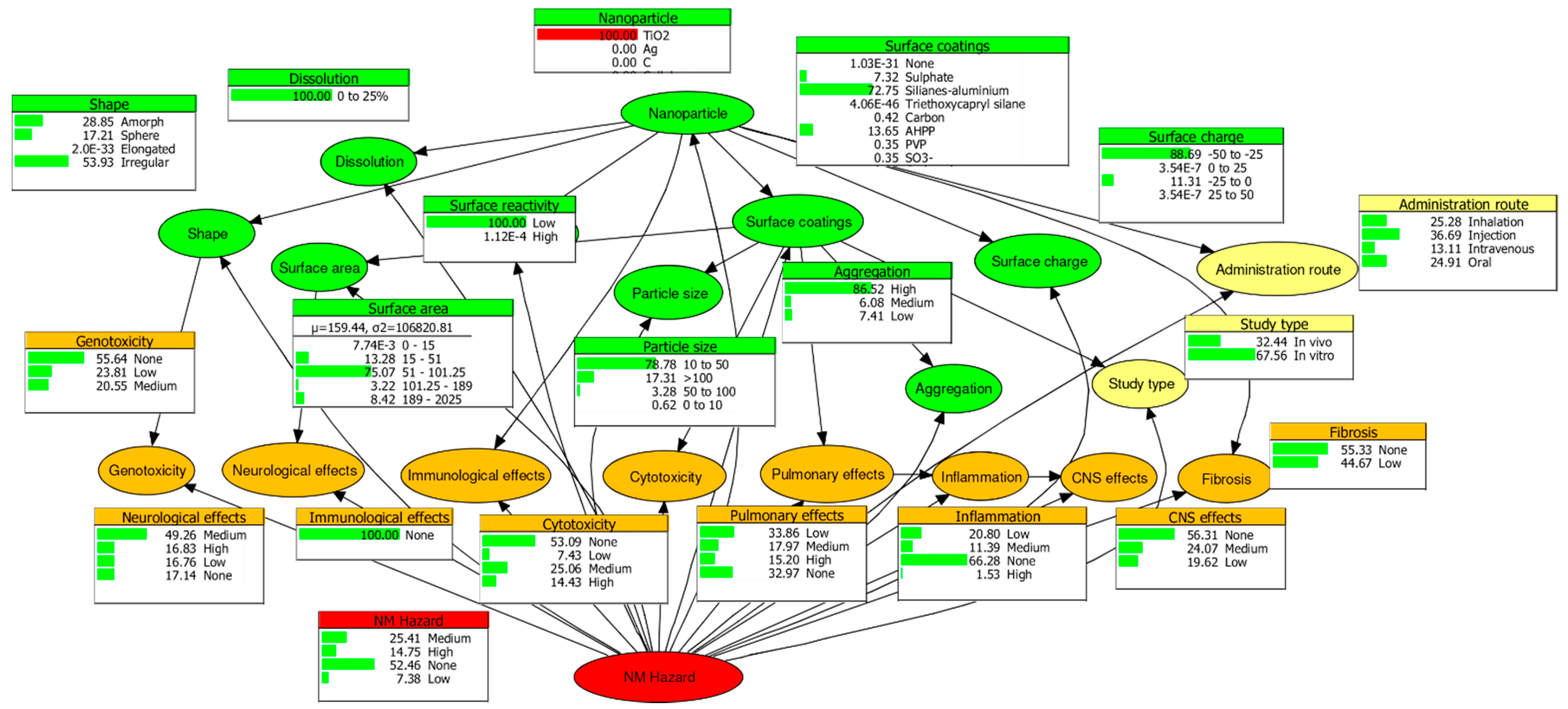

3.1. Hazard Ranking of Nanoparticles Composed of TiO2, Ag and ZnO

3.2. Evaluation of the Performances of Bayesian Networks (BN) and WoE

3.3. Sensitivity and Uncertainty Analysis of BN and WoE

- Vary LOE-specific index of physico-chemical properties (), while keeping all other input parameters constant.

- Vary LOE-specific index of toxicity (), while keeping all other input parameters constant.

- Vary the study quality weights (), while keeping all other input parameters constant.

- Vary all input parameters , , and

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| NM | nanomaterial |

| BN | Bayesian network |

| CPT | conditional probability table |

| CNS | central nervous system |

| OEL | occupational exposure limit |

| REL | recommended exposure limit |

| WoE | weight of evidence |

| MCDA | multi-criteria decision analysis |

| CB | control banding |

| WS | weighted sum |

| VOI | value of information |

| NM | nanomaterial |

Appendix A

Appendix B

Appendix C

| ID | Reference | LOE Index Values Based on Physico-Chemical Properties () | LOE Index Values Based on Toxicity () | Total LOE Index Values () | Study Quality Weight () | Normalised Study Quality Weight () | Weighted LOE Index Values () |

|---|---|---|---|---|---|---|---|

| 1 | Braakhuis et al. [48] | 47.22 | 62.50 | 57.92 | 0.84 | 0.07 | 4.25 |

| 2 | Braakhuis et al. [48] | 33.33 | 12.50 | 18.75 | 0.74 | 0.06 | 1.21 |

| 3 | Braakhuis et al. [48] | 47.22 | 12.50 | 22.92 | 0.60 | 0.05 | 1.21 |

| 4 | Braakhuis et al. [53] | 41.67 | 25.00 | 30.00 | 0.72 | 0.06 | 1.90 |

| 5 | Braakhuis et al. [53] | 36.11 | 62.50 | 54.58 | 0.71 | 0.06 | 3.41 |

| 6 | Braakhuis et al. [53] | 33.33 | 62.50 | 53.75 | 0.71 | 0.06 | 3.36 |

| 7 | Braakhuis et al. [53] | 33.33 | 12.50 | 18.75 | 0.66 | 0.01 | 0.20 |

| 8 | Gaiser at al. [54] | 47.22 | 75.00 | 66.67 | 0.79 | 0.07 | 4.60 |

| 9 | Gaiser at al. [54] | 47.22 | 75.00 | 66.67 | 0.63 | 0.05 | 3.65 |

| 10 | Haberl et al. 2013 [55] | 38.89 | 75.00 | 64.17 | 0.60 | 0.05 | 3.39 |

| 11 | Lankveld et al. 2010 [56] | 44.44 | 37.50 | 39.58 | 0.47 | 0.04 | 1.63 |

| 12 | Lee et al. 2013 [57] | 52.78 | 62.50 | 59.58 | 0.73 | 0.06 | 3.83 |

| 13 | Loeschner et al. 2011 [58] | 52.78 | 37.50 | 42.08 | 0.48 | 0.04 | 1.77 |

| 14 | Nymark et al. 2013 [59] | 58.33 | 50.00 | 52.50 | 0.58 | 0.05 | 2.67 |

| 15 | Van der Zande et al. 2012 [60] | 44.44 | 25.00 | 30.83 | 0.61 | 0.05 | 1.66 |

| 16 | Van der Zande et al. 2012 [60] | 61.11 | 25.00 | 35.83 | 0.61 | 0.05 | 1.93 |

| 17 | Yun at al. 2015 [61] | 44.44 | 62.50 | 57.08 | 0.92 | 0.08 | 4.59 |

| Hazard Score | |||||||

Appendix D

| ID | Reference | LOE Index Values Based on Physico-Chemical Properties () | LOE Index Values Based on Toxicity () | Total LOE Index Values () | Study Quality Weight () | Normalised Study Quality Weight () | Weighted LOE Index Values () |

|---|---|---|---|---|---|---|---|

| 1 | Farcal et al. [28] | 50.00 | 50.00 | 50.00 | 0.76 | 0.29 | 14.63 |

| 2 | Farcal et al. [28] | 52.78 | 50.00 | 50.83 | 0.76 | 0.29 | 14.87 |

| 3 | Lu et al. [62] | 38.89 | 62.50 | 55.42 | 0.59 | 0.23 | 12.68 |

| 4 | Zhang et al. [63] | 36.11 | 62.50 | 54.58 | 0.48 | 0.19 | 10.15 |

| Hazard Score | |||||||

References

- National Research Council. Science and Decisions: Advancing Risk Assessment; National Academies Press: Washington, DC, USA, 2009. [Google Scholar]

- Oberdörster, G.; Maynard, A.; Donaldson, K.; Castranova, V.; Fitzpatrick, J.; Ausman, K.; Carter, J.; Karn, B.; Kreyling, W.; Lai, D. Principles for characterizing the potential human health effects from exposure to nanomaterials: Elements of a screening strategy. Part. Fibre Toxicol. 2005, 2, 8. [Google Scholar] [CrossRef] [PubMed]

- Taniguchi, N. On the basic concept of Nano-technology. In Proceedings of the International Conference on Production Engineering, Tokyo, Japan, 26–29 August 1974; Japan Society of Precision Engineering: Tokyo, Japan, 1974. Part II. Volume 2, pp. 18–23. [Google Scholar]

- Stone, V.; Önlü, S.; Bergamaschi, E.; Carlander, D.; Costa, A.; Engelmann, W.; Ghanem, A.; Hartl, S.; Hristozov, D.; Scott-Fordsmand, J.J. Research Priorities Relevant to Development or Updating of Nano-Relevant Regulations and Guidelines; NanoSafetyCluster Research Regulatory Roadmap; January 2017; Available online: http://www.safenano.org/news/news-articles/eu-nanosafety-cluster-publishes-research-regulatory-roadmap/ (accessed on 25 February 2018). [CrossRef]

- Van Leeuwen, C.J.; Vermeire, T.G. Risk Assessment of Chemicals: An Introduction; Springer Science & Business Media: Dordrecht, The Netherlands, 2007. [Google Scholar]

- Murphy, F.; Mullins, M.; Hester, K.; Gelwick, A.; Scott-Fordsmand, J.J.; Maynard, T. Insuring nanotech requires effective risk communication. Nat. Nanotechnol. 2017, 12, 717–719. [Google Scholar] [CrossRef] [PubMed]

- Money, E.S.; Reckhow, K.H.; Wiesner, M.R. The use of Bayesian networks for nanoparticle risk forecasting: Model formulation and baseline evaluation. Sci. Total Environ. 2012, 426, 436–445. [Google Scholar] [CrossRef] [PubMed]

- Murphy, F.; Sheehan, B.; Mullins, M.; Bouwmeester, H.; Marvin, H.J.; Bouzembrak, Y.; Costa, A.L.; Das, R.; Stone, V.; Tofail, S.A. A Tractable Method for Measuring Nanomaterial Risk Using Bayesian Networks. Nanoscale Res. Let. 2016, 11, 503. [Google Scholar] [CrossRef] [PubMed]

- Marvin, H.J.; Bouzembrak, Y.; Janssen, E.M.; van der Zande, M.; Murphy, F.; Sheehan, B.; Mullins, M.; Bouwmeester, H. Application of Bayesian networks for hazard ranking of nanomaterials to support human health risk assessment. Nanotoxicology 2017, 11, 123–133. [Google Scholar] [CrossRef] [PubMed]

- Tsang, M.P.; Hristozov, D.; Zabeo, A.; Koivisto, A.J.; Jensen, A.C.O.; Jensen, K.A.; Pang, C.; Marcomini, A.; Sonnemann, G. Probabilistic risk assessment of emerging materials: Case study of titanium dioxide nanoparticles. Nanotoxicology 2017, 11, 558–568. [Google Scholar] [CrossRef] [PubMed]

- National Research Council. Review of EPA’s Integrated Risk Information System (IRIS) Process; National Academies Press: Washington, DC, USA, 2014. [Google Scholar]

- Leso, V.; Fontana, L.; Chiara Mauriello, M.; Iavicoli, I. Occupational Risk Assessment of Engineered Nanomaterials: Limits, Challenges and Opportunities. Curr. Nanosci. 2017, 13, 55–78. [Google Scholar] [CrossRef]

- Hristozov, D.; Gottardo, S.; Semenzin, E.; Oomen, A.; Bos, P.; Peijnenburg, W.; van Tongeren, M.; Nowack, B.; Hunt, N.; Brunelli, A.; et al. Frameworks and tools for risk assessment of manufactured nanomaterials. Environ. Int. 2016, 95, 36–53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hristozov, D.R.; Zabeo, A.; Foran, C.; Isigonis, P.; Critto, A.; Marcomini, A.; Linkov, I. A weight of evidence approach for hazard screening of engineered nanomaterials. Nanotoxicology 2014, 8, 72–87. [Google Scholar] [CrossRef] [PubMed]

- Zuin, S.; Micheletti, C.; Critto, A.; Pojana, G.; Johnston, H.; Stone, V.; Tran, L.; Marcomini, A. Weight of evidence approach for the relative hazard ranking of nanomaterials. Nanotoxicology 2011, 5, 445–458. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, T.D.; Jensen, F.V. Bayesian Networks and Decision Graphs, 2nd ed.; Springer Science & Business Media: New York, NY, USA, 2009; ISBN 0-387-68281-3. [Google Scholar]

- Wiesner, M.R.; Bottero, J.-Y. A risk forecasting process for nanostructured materials, and nanomanufacturing. C. R. Phys. 2011, 12, 659–668. [Google Scholar] [CrossRef]

- Linkov, I.; Welle, P.; Loney, D.; Tkachuk, A.; Canis, L.; Kim, J.; Bridges, T. Use of multicriteria decision analysis to support weight of evidence evaluation. Risk Anal. 2011, 31, 1211–1225. [Google Scholar] [CrossRef] [PubMed]

- Linkov, I.; Loney, D.; Cormier, S.; Satterstrom, F.K.; Bridges, T. Weight-of-evidence evaluation in environmental assessment: Review of qualitative and quantitative approaches. Sci. Total Environ. 2009, 407, 5199–5205. [Google Scholar] [CrossRef] [PubMed]

- Klimisch, H.-J.; Andreae, M.; Tillmann, U. A systematic approach for evaluating the quality of experimental toxicological and ecotoxicological data. Regul. Toxicol. Pharmacol. 1997, 25, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Kjærulff, U.B.; Madsen, A.L. Value of Information Analysis. In Bayesian Networks and Influence Diagrams: A Guide to Construction and Analysis; Springer: New York, NY, USA, 2013; pp. 327–339. ISBN 978-1-4614-5103-7. [Google Scholar]

- Chen, S.H.; Pollino, C.A. Good practice in Bayesian network modelling. Environ. Model. Softw. 2012, 37, 134–145. [Google Scholar] [CrossRef]

- US EPA. Guidelines for Carcinogen Risk Assessment; US Environmental Protection Agency: Washington, DC, USA, 1995.

- Baisch, B.L.; Corson, N.M.; Wade-Mercer, P.; Gelein, R.; Kennell, A.J.; Oberdorster, G.; Elder, A. Equivalent titanium dioxide nanoparticle deposition by intratracheal instillation and whole body inhalation: The effect of dose rate on acute respiratory tract inflammation. Part. Fibre Toxicol. 2014, 11, 5. [Google Scholar] [CrossRef] [PubMed]

- Catalan, J.; Jarventaus, H.; Vippola, M.; Savolainen, K.; Norppa, H. Induction of chromosomal aberrations by carbon nanotubes and titanium dioxide nanoparticles in human lymphocytes in vitro. Nanotoxicology 2012, 6, 825–836. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Dong, X.; Zhao, J.; Tang, G. In vivo acute toxicity of titanium dioxide nanoparticles to mice after intraperitioneal injection. J. Appl. Toxicol. 2009, 29, 330–337. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.; Li, N.; Liu, C.; Liu, H.; Cui, Y.; Wang, H.; Hong, F. Interaction between nanoparticulate anatase TiO2 and lactate dehydrogenase. Biol. Trace Elem. Res. 2010, 136, 302–313. [Google Scholar] [CrossRef] [PubMed]

- Farcal, L.; Torres Andon, F.; Di Cristo, L.; Rotoli, B.M.; Bussolati, O.; Bergamaschi, E.; Mech, A.; Hartmann, N.B.; Rasmussen, K.; Riego-Sintes, J.; et al. Comprehensive In Vitro Toxicity Testing of a Panel of Representative Oxide Nanomaterials: First Steps towards an Intelligent Testing Strategy. PLoS ONE 2015, 10, e0127174. [Google Scholar] [CrossRef] [PubMed]

- Fisichella, M.; Berenguer, F.; Steinmetz, G.; Auffan, M.; Rose, J.; Prat, O. Intestinal toxicity evaluation of TiO2 degraded surface-treated nanoparticles: A combined physico-chemical and toxicogenomics approach in caco-2 cells. Part. Fibre Toxicol. 2012, 9, 18. [Google Scholar] [CrossRef] [PubMed]

- Gurr, J.R.; Wang, A.S.; Chen, C.H.; Jan, K.Y. Ultrafine titanium dioxide particles in the absence of photoactivation can induce oxidative damage to human bronchial epithelial cells. Toxicology 2005, 213, 66–73. [Google Scholar] [CrossRef] [PubMed]

- Hu, R.; Gong, X.; Duan, Y.; Li, N.; Che, Y.; Cui, Y.; Zhou, M.; Liu, C.; Wang, H.; Hong, F. Neurotoxicological effects and the impairment of spatial recognition memory in mice caused by exposure to TiO2 nanoparticles. Biomaterials 2010, 31, 8043–8050. [Google Scholar] [CrossRef] [PubMed]

- Leppanen, M.; Korpi, A.; Miettinen, M.; Leskinen, J.; Torvela, T.; Rossi, E.M.; Vanhala, E.; Wolff, H.; Alenius, H.; Kosma, V.M.; et al. Nanosized TiO(2) caused minor airflow limitation in the murine airways. Arch. Toxicol. 2011, 85, 827–839. [Google Scholar] [CrossRef] [PubMed]

- Lindberg, H.K.; Falck, G.C.; Catalan, J.; Koivisto, A.J.; Suhonen, S.; Jarventaus, H.; Rossi, E.M.; Nykasenoja, H.; Peltonen, Y.; Moreno, C.; et al. Genotoxicity of inhaled nanosized TiO(2) in mice. Mutat. Res. 2012, 745, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, M.; Tainaka, H.; Oba, T.; Mizuo, K.; Umezawa, M.; Takeda, K. Maternal exposure to nanoparticulate titanium dioxide during the prenatal period alters gene expression related to brain development in the mouse. Part. Fibre Toxicol. 2009, 6, 20. [Google Scholar] [CrossRef] [PubMed]

- Tassinari, R.; Cubadda, F.; Moracci, G.; Aureli, F.; D’Amato, M.; Valeri, M.; de Berardis, B.; Raggi, A.; Mantovani, A.; Passeri, D.; et al. Oral, short-term exposure to titanium dioxide nanoparticles in Sprague-Dawley rat: Focus on reproductive and endocrine systems and spleen. Nanotoxicology 2014, 8, 654–662. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Chen, Z.; Ba, T.; Pu, J.; Chen, T.; Song, Y.; Gu, Y.; Qian, Q.; Xu, Y.; Xiang, K.; et al. Susceptibility of young and adult rats to the oral toxicity of titanium dioxide nanoparticles. Small 2013, 9, 1742–1752. [Google Scholar] [CrossRef] [PubMed]

- Hristozov, D.R.; Gottardo, S.; Cinelli, M.; Isigonis, P.; Zabeo, A.; Critto, A.; van Tongeren, M.; Tran, L.; Marcomini, A. Application of a quantitative weight of evidence approach for ranking and prioritising occupational exposure scenarios for titanium dioxide and carbon nanomaterials. Nanotoxicology 2014, 8, 117–131. [Google Scholar] [CrossRef] [PubMed]

- Schulte, P.A.; Iavicoli, I.; Rantanen, J.H.; Dahmann, D.; Iavicoli, S.; Pipke, R.; Guseva Canu, I.; Boccuni, F.; Ricci, M.; Polci, M.L.; et al. Assessing the protection of the nanomaterial workforce. Nanotoxicology 2016, 10, 1013–1019. [Google Scholar] [CrossRef] [PubMed]

- Del Castillo, A.M.P. Nanomaterials and Workplace Health & Safety: What Are the Issues for Workers? European Trade Union Institute: Brussels, Belgium, 2013; ISBN 978-2-87452-288-8. [Google Scholar]

- Zion Market Research. Nanomaterials Market (Metal Oxide, Metals, Chemicals & Polymers and Others) for Construction, Chemical Products, Packaging, Consumer Goods, Electrical and Electronics, Energy, Health Care, Transportation and Other Applications: Global Market Perspective, Comprehensive Analysis and Forecast, 2016–2022. Available online: https://www.zionmarketresearch.com/report/nanomaterials-market (accessed on 22 February 2018).

- Schulte, P.A.; Geraci, C.L.; Murashov, V.; Kuempel, E.D.; Zumwalde, R.D.; Castranova, V.; Hoover, M.D.; Hodson, L.; Martinez, K.F. Occupational safety and health criteria for responsible development of nanotechnology. J. Nanopart. Res. 2014, 16, 2153. [Google Scholar] [CrossRef] [PubMed]

- Foss Hansen, S.; Larsen, B.H.; Olsen, S.I.; Baun, A. Categorization framework to aid hazard identification of nanomaterials. Nanotoxicology 2007, 1, 243–250. [Google Scholar] [CrossRef]

- Shin, S.; Song, I.; Um, S. Role of Physicochemical Properties in Nanoparticle Toxicity. Nanomaterials 2015, 5, 1351–1365. [Google Scholar] [CrossRef] [PubMed]

- Kreyling, W.G.; Hirn, S.; Möller, W.; Schleh, C.; Wenk, A.; Celik, G.; Lipka, J.; Schäffler, M.; Haberl, N.; Johnston, B.D.; et al. Air-Blood Barrier Translocation of Tracheally Instilled Gold Nanoparticles Inversely Depends on Particle Size. ACS Nano 2014, 8, 222–233. [Google Scholar] [CrossRef] [PubMed]

- Gatoo, M.A.; Naseem, S.; Arfat, M.Y.; Mahmood dar, A.; Qasim, K.; Zubair, S. Physicochemical Properties of Nanomaterials: Implication in Associated Toxic Manifestations. BioMed Res. Int. 2014, 2014, 8. [Google Scholar] [CrossRef] [PubMed]

- Worth, A.; Aschberger, K.; Asturiol Bofill, D.; Bessems, J.; Gerloff, K.; Graepel, R.; Joossens, E.; Lamon, L.; Palosaari, T.; Richarz, A. Evaluation of the Availability and Applicability of Computational Approaches in the Safety Assessment of Nanomaterials; EUR 28617 EN; Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-68708-2. [Google Scholar]

- Eom, H.-J.; Jeong, J.-S.; Choi, J. Effect of aspect ratio on the uptake and toxicity of hydroxylated-multi walled carbon nanotubes in the nematode, Caenorhabditis elegans. Environ. Health Toxicol. 2015, 30, e2015001. [Google Scholar] [CrossRef] [PubMed]

- Braakhuis, H.M.; Gosens, I.; Krystek, P.; Boere, J.A.F.; Cassee, F.R.; Fokkens, P.H.B.; Post, J.A.; van Loveren, H.; Park, M.V.D.Z. Particle size dependent deposition and pulmonary inflammation after short-term inhalation of silver nanoparticles. Part. Fibre Toxicol. 2014, 11, 49. [Google Scholar] [CrossRef] [PubMed]

- Perelshtein, I.; Lipovsky, A.; Perkas, N.; Gedanken, A.; Moschini, E.; Mantecca, P. The influence of the crystalline nature of nano–metal oxides on their antibacterial and toxicity properties. Nano Res. 2015, 8, 695–707. [Google Scholar] [CrossRef]

- Mullins, M.; Murphy, F.; Baublyte, L.; McAlea, E.M.; Tofail, S.A. The insurability of nanomaterial production risk. Nat. Nanotechnol. 2013, 8, 222–224. [Google Scholar] [CrossRef] [PubMed]

- Bouillard, J.X.; Vignes, A. Nano-Evaluris: An inhalation and explosion risk evaluation method for nanoparticle use. Part I: Description of the methodology. J. Nanopart. Res. 2014, 16, 2149. [Google Scholar] [CrossRef]

- Jensen, K.A.; Saber, A.T.; Kristensen, H.V.; Koponen, I.K.; Liguori, B.; Wallin, H. NanoSafer vs. 1.1-nanomaterial risk assessment using first order modeling. In Proceedings of the 6th International Symposium on Nanotechnology, Occupational and Environmental Health, Nagoya, Japan, 28–31 October 2013; p. 120. [Google Scholar]

- Braakhuis, H.M.; Cassee, F.R.; Fokkens, P.H.; de la Fonteyne, L.J.; Oomen, A.G.; Krystek, P.; de Jong, W.H.; van Loveren, H.; Park, M.V. Identification of the appropriate dose metric for pulmonary inflammation of silver nanoparticles in an inhalation toxicity study. Nanotoxicology 2016, 10, 63–73. [Google Scholar] [CrossRef] [PubMed]

- Gaiser, B.K.; Hirn, S.; Kermanizadeh, A.; Kanase, N.; Fytianos, K.; Wenk, A.; Haberl, N.; Brunelli, A.; Kreyling, W.G.; Stone, V. Effects of silver nanoparticles on the liver and hepatocytes in vitro. Toxicol. Sci. 2013, 131, 537–547. [Google Scholar] [CrossRef] [PubMed]

- Haberl, N.; Hirn, S.; Wenk, A.; Diendorf, J.; Epple, M.; Johnston, B.D.; Krombach, F.; Kreyling, W.G.; Schleh, C. Cytotoxic and proinflammatory effects of PVP-coated silver nanoparticles after intratracheal instillation in rats. Beilstein J. Nanotechnol. 2013, 4, 933–940. [Google Scholar] [CrossRef] [PubMed]

- Lankveld, D.P.; Oomen, A.G.; Krystek, P.; Neigh, A.; Troost-de Jong, A.; Noorlander, C.W.; van Eijkeren, J.C.; Geertsma, R.E.; de Jong, WH. The kinetics of the tissue distribution of silver nanoparticles of different sizes. Biomaterials 2010, 31, 8350–8361. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Kim, Y.S.; Song, K.S.; Ryu, H.R.; Sung, J.H.; Park, J.D.; Park, H.M.; Song, N.W.; Shin, B.S.; Marshak, D.; et al. Biopersistence of silver nanoparticles in tissues from Sprague-Dawley rats. Part. Fibre Toxicol. 2013, 10, 36. [Google Scholar] [CrossRef] [PubMed]

- Loeschner, K.; Hadrup, N.; Qvortrup, K.; Larsen, A.; Gao, X.; Vogel, U.; Mortensen, A.; Lam, H.R.; Larsen, EH. Distribution of silver in rats following 28 days of repeated oral exposure to silver nanoparticles or silver acetate. Part. Fibre Toxicol. 2011, 8, 18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nymark, P.; Catalan, J.; Suhonen, S.; Jarventaus, H.; Birkedal, R.; Clausen, P.A.; Jensen, K.A.; Vippola, M.; Savolainen, K.; Norppa, H. Genotoxicity of polyvinylpyrrolidone-coated silver nanoparticles in BEAS 2B cells. Toxicology 2013, 313, 38–48. [Google Scholar] [CrossRef] [PubMed]

- Van der Zande, M.; Vandebriel, R.J.; van Doren, E.; Kramer, E.; Herrera Rivera, Z.; Serrano-Rojero, C.S.; Gremmer, E.R.; Mast, J.; Peters, R.J.; Hollman, P.C.; et al. Distribution, elimination, and toxicity of silver nanoparticles and silver ions in rats after 28-day oral exposure. ACS Nano 2012, 6, 7427–7442. [Google Scholar] [CrossRef] [PubMed]

- Yun, J.W.; Kim, S.H.; You, J.R.; Kim, W.H.; Jang, J.J.; Min, S.K.; Kim, H.C.; Chung, D.H.; Jeong, J.; Kang, B.C.; et al. Comparative toxicity of silicon dioxide, silver and iron oxide nanoparticles after repeated oral administration to rats. J. Appl. Toxicol. 2015, 35, 681–693. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.; Zhang, W.; Zhang, R.; Liu, P.; Wang, Q.; Shang, Y.; Wu, M.; Donaldson, K.; Wang, Q. Comparison of cellular toxicity caused by ambient ultrafine particles and engineered metal oxide nanoparticles. Part. Fibre Toxicol. 2015, 12, 5. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Ji, Z.; Xia, T.; Meng, H.; Low-Kam, C.; Liu, R.; Pokhrel, S.; Lin, S.; Wang, X.; Liao, Y.P.; et al. Use of metal oxide nanoparticle band gap to develop a predictive paradigm for oxidative stress and acute pulmonary inflammation. ACS Nano 2012, 6, 4349–4368. [Google Scholar] [CrossRef] [PubMed]

| ID () | Reference | LOE Index Values Based on Physico-Chemical Properties () | LOE Index Values Based on Toxicity () | Total LOE Index Values () | Study Quality Weight () | Normalised Study Quality Weight () | Weighted LOE Index Values () |

|---|---|---|---|---|---|---|---|

| 1 | Baisch et al. [24] | 41.67 | 87.50 | 73.75 | 0.61 | 0.04 | 3.24 |

| 2 | Baisch et al. [24] | 41.67 | 75.00 | 65.00 | 0.84 | 0.06 | 3.91 |

| 3 | Baisch et al. [24] | 50.00 | 75.00 | 67.50 | 0.84 | 0.06 | 4.06 |

| 4 | Catalan et al. [25] | 38.89 | 37.50 | 37.92 | 0.71 | 0.05 | 1.94 |

| 5 | Catalan et al. [25] | 38.89 | 62.50 | 55.42 | 0.79 | 0.06 | 3.13 |

| 6 | Catalan et al. [25] | 38.89 | 37.50 | 37.92 | 0.65 | 0.05 | 1.78 |

| 7 | Chen et al. [26] | 30.56 | 75.00 | 61.67 | 0.48 | 0.03 | 2.14 |

| 8 | Duan et al. [27] | 44.44 | 25.00 | 30.83 | 0.47 | 0.03 | 1.04 |

| 9 | Duan et al. [27] | 44.44 | 25.00 | 30.83 | 0.32 | 0.02 | 0.71 |

| 10 | Farcal et al. [28] | 61.11 | 25.00 | 35.83 | 0.77 | 0.06 | 1.99 |

| 11 | Farcal et al. [28] | 47.22 | 37.50 | 40.42 | 0.76 | 0.05 | 2.20 |

| 12 | Fisichella et al. [29] | 30.56 | 12.50 | 17.92 | 0.52 | 0.04 | 0.66 |

| 13 | Fisichella et al. [29] | 38.89 | 12.50 | 20.42 | 0.56 | 0.04 | 0.81 |

| 14 | Gurr et al. [30] | 33.33 | 62.50 | 53.75 | 0.50 | 0.04 | 1.94 |

| 15 | Gurr et al. [30] | 33.33 | 37.50 | 36.25 | 0.50 | 0.04 | 1.31 |

| 16 | Hu et al. [31] | 47.22 | 62.50 | 57.92 | 0.54 | 0.04 | 2.23 |

| 17 | Leppanen et al. [32] | 41.67 | 12.50 | 21.25 | 0.62 | 0.04 | 0.95 |

| 18 | Lindberg et al. [33] | 41.67 | 0.00 | 12.50 | 0.63 | 0.05 | 0.57 |

| 19 | Lindberg et al. [33] | 41.67 | 50.00 | 47.50 | 0.56 | 0.04 | 1.91 |

| 20 | Shimizu et al. [34] | 33.33 | 62.50 | 53.75 | 0.76 | 0.05 | 2.93 |

| 21 | Tassinari et al. [35] | 52.78 | 12.50 | 24.58 | 0.56 | 0.04 | 0.98 |

| 22 | Wang et al. [36] | 41.67 | 62.50 | 56.25 | 0.94 | 0.07 | 3.80 |

| Hazard Score | |||||||

| Case | Test Data | NM Hazard | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Shape | Nanop-Article | Dissolution | Surface Area (m2/g) | Surface Charge (mV) | Surface Coatings | Surface Reactivity | Aggregation | Particle Size (nm) | Administration Route | Study Type | Actual | Predicted | |

| 1 | Irregular | TiO2 | 0–25% | 51–101.25 | from −50 to −25 | Silianes-aluminium | Low | High | 10–50 | - | In vitro | None | None |

| 2 | Amorph | TiO2 | - | - | - | - | - | - | >100 | Injection | In vivo | High | Medium |

| 3 | Sphere | TiO2 | - | - | - | AHPP | - | Low | 10–50 | - | In vitro | None | None |

| 4 | Irregular | TiO2 | - | 15–51 | - | - | - | High | >100 | Oral | In vivo | None | Medium |

| 5 | Irregular | TiO2 | - | 51–101.25 | from −50 to −25 | Hydroxyl | - | Medium | 50–100 | Oral | In vivo | None | Low |

| 6 | Sphere | Ag | - | - | - | - | - | - | 10–50 | Inhalation | In vivo | High | High |

| 7 | Sphere | Ag | - | - | - | PVP | - | Low | 50–100 | Inhalation | In vivo | High | Medium |

| 8 | Sphere | Ag | - | - | - | - | - | - | 10–50 | Intravenous | In vivo | None | None |

| 9 | Sphere | Ag | - | - | - | Citrate | - | - | 10–50 | Oral | In vivo | Medium | Medium |

| 10 | Sphere | Ag | - | 0–15 | from −50 to −25 | PVP | - | High | 10–50 | - | In vitro | None | Low |

| 11 | Sphere | Ag | 0–25% | - | - | - | - | Low | 10–50 | Oral | In vivo | Medium | Medium |

| 12 | Sphere | Ag | - | - | 0–25 | - | - | Low | 10–50 | Oral | In vivo | High | Medium |

| 13 | Elongated | ZnO | - | 0–15 | 0–25 | None | - | Medium | >100 | - | In vitro | High | High |

| 14 | Elongated | ZnO | 0–25% | 15–51 | - | Triethoxycapryl silane | - | Medium | >100 | - | In vitro | High | High |

| 15 | Irregular | ZnO | 0–25% | - | - | - | Low | - | 10–50 | - | In vitro | High | High |

| Input Variable | Nanomaterial | ||

|---|---|---|---|

| TiO2 | Ag | ZnO | |

| Surface coatings | 0.26 | 0.53 | 0.01 |

| Surface area | 0.22 | 0.26 | 0.02 |

| Particle size | 0.28 | 0.13 | 0.05 |

| Surface charge | 0.08 | 0.37 | 0 |

| Aggregation | 0.09 | 0.22 | 0.01 |

| Shape | 0.26 | 0 | 0 |

| Surface reactivity | 0 | 0 | 0.16 |

| Dissolution | 0 | 0 | 0 |

| Administration route | 0.19 | 0.64 | 0 |

| Study type | 0.34 | 0.07 | 0.02 |

| Particle Size | Nanomaterial Hazard Potential | ||

|---|---|---|---|

| TiO2 | Ag | ZnO | |

| from 0 to 10 | 100% | 50% | 86% |

| from 10 to 50 | 25% | 58% | 94% |

| from 50 to 100 | 42% | 55% | 100% |

| >100 | 73% | 77% | 89% |

| No Evidence | 34% | 61% | 91% |

| Surface Area | Nanomaterial Hazard Potential | ||

|---|---|---|---|

| TiO2 | Ag | ZnO | |

| from 0 to 15 | 56% | 54% | 94% |

| from 15 to 51 | 71% | 58% | 89% |

| from 51 to 101.25 | 28% | 27% | 88% |

| from 101.25 to 189 | 73% | 4% | 67% |

| from 189 to 2025 | 15% | 92% | 100% |

| No Evidence | 34% | 61% | 91% |

| Nanomaterial | Parameter | Variation of Input Parameters | |||

|---|---|---|---|---|---|

| , , and | |||||

| TiO2 | Mean (Standard Deviation) | 46.6 (1.9) | 47.6 (4.4) | 42.7 (2.2) | 49.9 (5.4) |

| Average Absolute Deviation | 2.6 | 4.5 | 2.2 | 6.5 | |

| Ag | Mean (Standard Deviation) | 47.7 (2.1) | 48.4 (4.9) | 45.4 (2.3) | 50.0 (6.2) |

| Average Absolute Deviation | 3.3 | 4.7 | 1.9 | 6.3 | |

| ZnO | Mean (Standard Deviation) | 53.6 (4.4) | 48.6 (10.3) | 52.7 (0.7) | 49.8 (12.5) |

| Average Absolute Deviation | 3.7 | 8.8 | 0.7 | 10.3 | |

| Alternative Orders | Rank from Lowest (1) to Highest (3) Hazard | Ranking % by Variations of Input Parameters | Total | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | , , and | |||||

| a | TiO2 | Ag | ZnO | 55% | 22% | 80% | 20% | 44% |

| b | TiO2 | ZnO | Ag | 6% | 11% | 0% | 9% | 7% |

| c | Ag | TiO2 | ZnO | 31% | 20% | 20% | 21% | 23% |

| d | Ag | ZnO | TiO2 | 2% | 8% | 0% | 10% | 5% |

| e | ZnO | TiO2 | Ag | 3% | 21% | 0% | 21% | 11% |

| f | ZnO | Ag | TiO2 | 2% | 17% | 0% | 19% | 10% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheehan, B.; Murphy, F.; Mullins, M.; Furxhi, I.; Costa, A.L.; Simeone, F.C.; Mantecca, P. Hazard Screening Methods for Nanomaterials: A Comparative Study. Int. J. Mol. Sci. 2018, 19, 649. https://doi.org/10.3390/ijms19030649

Sheehan B, Murphy F, Mullins M, Furxhi I, Costa AL, Simeone FC, Mantecca P. Hazard Screening Methods for Nanomaterials: A Comparative Study. International Journal of Molecular Sciences. 2018; 19(3):649. https://doi.org/10.3390/ijms19030649

Chicago/Turabian StyleSheehan, Barry, Finbarr Murphy, Martin Mullins, Irini Furxhi, Anna L. Costa, Felice C. Simeone, and Paride Mantecca. 2018. "Hazard Screening Methods for Nanomaterials: A Comparative Study" International Journal of Molecular Sciences 19, no. 3: 649. https://doi.org/10.3390/ijms19030649