Sixteen plies of Tenax-112 prepreg (Toho Tenax co., Ltd., Japan) were stacked in accordance with [0/90]

4s. Cross-ply carbon fiber reinforced plastic (CFRP) laminates were fabricated and cut into beams with dimensions of

L 245 mm ×

W 25 mm ×

TH 2.27 mm, to ensure identical properties for all CFRP beams. In practical applications, three kinds of joint methods have been applied to join different parts of a structure, namely, mechanical joints using bolts or rivets, weld using arc or spot welding, and joints using adhesives. In the present study, the adhesive method was used to join two pieces of the above-mentioned CFRP beams, to fabricate CFRP specimen with lap splice joints for the purpose of FOD-sensor-based debonding damage detection. Epoxy was selected as the adhesive. Properties of the CFRP beams and the epoxy applied in the present study are listed in

Table 2.

To fabricate the specimen with lap splice joint, firstly, two of the above-mentioned CFRP beams were joined by using epoxy Araldite

® Adhesive 2011 (Huntsman International LLC.) and fastened with a clamp. Curing process was subsequently implemented, comprising two steps: 1) curing at room temperature for 24 hours with the clamp; 2) post curing at 40 °C for 16 hours without the clamp. Sketch of the specimen is shown in

Figure 5(a). Length of the joint section and thickness of the epoxy layer are 30 mm and 0.15 mm, respectively. Moreover, two kinds of CFRP specimens were fabricated in this study,

viz. intact specimen (completely bonded condition at the lap splice joint area) and specimen with debonding at the adhered section. Debonding was introduced by inserting thin Teflon

® films in the lap splice joint. Detail description of the debonding is in Section 3.1.

3.1. Elastic Analysis of Lap Splice Joint in CFRP Structure

To investigate the characteristics of the lap splice joints in the CFRP structures, finite element analyses (FEA) were performed on the MSC.Marc Mentat (MSC.Software Corporation) software platform to simulate and complete elastic analysis for the specimens. Further, the transducer network can also be optimized based on the simulation results for the purpose of damage assessment. In the simulation, extension forces were added at the two ends of the specimen, which are changed from 0 kgf (kilogram-force) to 640 kgf with the step of 80 kgf. To minimize the torque effect on the lap splice joints, two tablets was added at the both ends of the specimen, as shown in

Figure 5(b). Without losing generality, only part of the specimen, including the lap splice joint, was used to illustrate the simulation results, shown the

x-axis in

Figure 5(a). Simulation results are shown in

Figure 6, in which strain distributions of the adhered boundary [as shown in

Figure 5(a)] on the epoxy side were addressed in three directions, namely, longitude, peel and shear directions.

According to the simulation results, in the cases of all the three directions, maximum strain happens at the left end [point

A in

Figure 5(a)] of the joint section. Moreover, strain at the right end of the joint section is also relatively larger than that of the middle adhered section. These simulation results disclose that, in the case of lap splice joint condition addressed in this study, the strain distributions in all directions at the joint section have a concave shape, implying that debonding damage usually happens first from the ends [

A,

B,

C and

D in the zoom-in view in

Figure 5(a)] of the joint section. Therefore, in the specimen fabrication process, debonding damages were introduced by inserting thin Teflon

® films in the lap splice joint. Debonding lengths,

L, was measured from point

A [as shown in

Figure 5(c)], and were 0 mm (for the intact case), 5 mm, 15 mm and 25 mm in the experiments.

3.2. Transducer Network Setup

In guided-wave-based SHM system, at least one actuator is usually necessary to excite guided waves propagating in the host structures. In this study, a piece of piezoelectric (PZT) disc (

D 6.9 mm ×

TH 0.5 mm) was bonded on surface of each CFRP specimen, functioning as the actuator of the SHM system. The spiral FOD sensor was used to acquire guided wave signals for debonding damage detection. The CFRP structures were fixed at one end and the actuator was bonded close to the encastra boundary of the structure, as shown in

Figure 7.

The CFRP structures consist of three parts, viz. CFRP-#1, CFRP-#2 and the lap splice joint, as shown in

Figure 7. It is evident that when guided waves are generated by the PZT actuator, they will propagate along the CFRP-#1 and then to the lap splice joint. Since the joint combine the CFRP-#1 and CFRP-#2 into one structure, the joint section will function as a medium or an actuator for the CFRP-#2. Therefore the guided waves will subsequently propagate in CFRP-#2. For the structures in this study, the FOD sensor can be bonded on the CFRP-#1, the lap splice joint or the CFRP-#2. However, for the CFRP-#2, as the joint just functions as a medium or an actuator, its size change usually cannot greatly influence the excited guided waves. Moreover, the joint can also result in the guided waves much more complicated, making it difficult for signal interpretation and damage detection. Therefore, it is not the optimal selection to capture guided wave signals on the CFRP-#2 for damage assessment. On the other hand, signal components reflected from the joint can be used for debonding damage detection if the guided wave signals are captured on the CFRP-#1. However, multiple modes and dispersion of guided waves are impediments in this case. Therefore, the FOD sensors were bonded on the joint area of the CFRP structures in this study. Moreover, one more FOD sensor was also bonded on surface of the CFRP-#1, in which only transmitted guided wave was used as baseline (reference) for damage detection.

The setup of the FOD sensors is shown in

Figure 7, in which three spiral FOD sensors are used, named

U,

M and

D, respectively. As already mentioned, baseline measurements,

i.e., data representing a ‘

no damage’ condition, are usually required in guided-wave-based SHM techniques [

4]. However, these parameters can change due to variable working conditions or bad coupling between the actuator and the structure. For the transducer network in the present study, both the baseline measurements and the current working condition can be measured at one excitation by using difference sensors, which is named self-calibration sensor network. For the sensor network shown in

Figure 7, guided wave signals acquired by the sensors

M and

D function as baseline measurements and, on the other hand, those acquired by the sensor

U function as signal for debonding damage detection. Moreover, the sensors

U and

M are located the same distance (210 mm) from the PZT actuator.

3.3. Debonding Damage Detection Using FOD Sensors

Signal processing approaches are usually required in guided-wave-based defect identification, since various affects, such as noise and dispersion of guided waves, usually result in the acquired ultrasonic signals much more complicated. In the previous study [

18,

20], a signal processing algorithm, based on finite impulse response (FIR) filter and Hilbert transform (HT), was proposed for the purpose of guided wave signal feature extraction. Envelopes of wave signals were consequently obtained to identify delamination defects in CFRP structures. The algorithm is successively applied to purify guided wave signals in this study.

As aforementioned, two kinds of specimens were fabricated in this study, namely the intact and debonding CFRP structures with lap splice joints. Amplitude features of the guided wave signals are not considered, as excitation situation of the PZT actuator on the four specimens may be different because of different bonding situation. Therefore, amplitudes of the envelopes were normalized in the signal processing. Central frequency of the incident wave and sampling frequency of the signal are 330 kHz and 4 MHz, respectively. Envelopes of the FOD-sensor-captured signals with normalized amplitudes are shown in

Figure 8. Guided wave signals in this section are measured by using the semiconductor interferometer. In the legends of

Figure 8, ‘BenΔ330k’ denotes the result of intact specimen (benchmark) using the sensor ‘Δ’ (

D,

M and

U), and, on the other hand, ‘D** Δ330k’ denotes the results of defected specimen with debonding length ‘**’ (5 mm, 15 mm and 25 mm) using the sensor ‘Δ’ (

D,

M and

U). To make it much clearer, only a part of each sampled signal was shown in the figures and, moreover, arrival time of the incident signal is 75 μs in the experiments.

According to the results of the intact specimen in

Figure 8(a), it is evident that several wave packages are present in wave signals, due to the multiple modes of guided waves and reflection from different discontinuities (such as lap splice joint and specimen ends). To avoid complicated signal interpretation and identification, in this study, only the first wave package of each signal is addressed for damage assessment. For the envelopes in

Figure 8(a), the most evident characteristic is the arrival moment of each envelope, shown as the dashed-line circled area. Starting sections of the first wave packages of the signals captured by sensors

M and

U superpose with each other, illustrating arrival times of the two signals are same because of the locations of the sensors

M and

U, as shown in

Figure 7. Group velocity of the first wave package can be estimated by using the arrival moments of the first envelopes in

Figure 8(a) and the distances between the actuator and the sensors, which is circa 5.93 mm·μs

−1.

For the CFRP structures with debonding in the lap splice joints, arrival moments of signals captured by sensors

D and

M remain invariable. In contrast, the first wave packages of the signals captured by sensors

U arrive a little later than those captured by sensors

M, as shown in

Figure 8(b–d), which is caused by the debondings. The most evident characteristic is that the first wave packages of signals acquired by sensors

M and

U do not superpose with each other like the intact case in

Figure 8(a). As already mentioned in Section 3.2, the lap splice joint of the CFRP structure serves as a medium transmitting the guided waves from CFRP-#1 to CFRP-#2 and the transmission starts when guided waves arrive point

A, as shown in

Figure 5(a). When debonding happens in the lap splice joint, as shown in

Figure 5(c), the transmission will happen a little later. Hence, guided waves will arrive a little later in the

U-captured ultrasonic signals provided that debonding happens. This time delay feature of the first wave package in the envelope of the

U-sensor-based guided wave signal can be applied for damage identification. Both the signals captured by sensors

D and

M can be the reference signals to calibrate the arrival time of the

U-sensor-based signal. Moreover, it is evident that it is much more distinct by using the

M-sensor-based signal than by using the

D-sensor-based signal, as shown in

Figures 8(b), (c) and (d).

The above results illustrate that both the baseline and damage-related measurements can be completed in only one experiment. A sensing setup with this characteristic is defined as a self-calibration sensor network. In the most widely used guided-wave-based SHM techniques [

4], baseline measurements (maybe tested a certain long time ago),

i.e., data representing a ‘

no damage’ condition, are usually required, in which working conditions of the baseline measurements, such as circumstances (e.g., temperature, humidity and surrounding noise) and coupling condition of the actuator, may differ from the working conditions of the current measurement for damage detection. In contrast, this drawback can be overcome by using the self-calibration sensor network proposed in this study, since both the baseline (reference) and the damage-related signal are measured using one excitation at the same time.

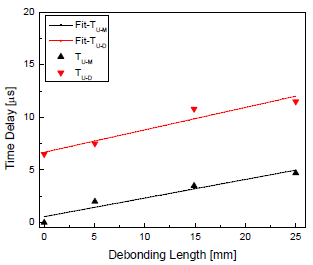

Further, under the excitation frequency 330 kHz, the relations and their linear fittings between the debonding length and the time delay are shown in

Figure 9(a), in which T

U-M and T

U-D denote the time delay between the sensors

U and

M and that between the sensors

U and

D, respectively. It reveals that the time delay is directly proportional to the debonding length. Considering the group velocity of the first wave package in the guided wave signals 5.93 mm·

μs

−1, debonding lengths are further estimated and listed in

Table 3. Moreover, for verification, experiments were subsequently conducted under different incident frequency 280 kHz with the results shown in

Figure 9(b), demonstrating that similar conclusions can be obtained.