Effective Fingerprint Quality Estimation for Diverse Capture Sensors

Abstract

:1. Introduction

2. Fingerprint Sensor Technology and Representative Quality Assessment Measures

2.1. Fingerprint Sensor Technology

- Geometry characteristics

- Biological characteristics

- Physical characteristics

2.2. Representative Quality Estimation Measures

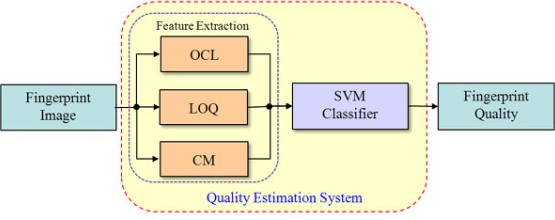

3. Proposed Features for Estimation System

3.1. Orientation Certainty Calculation

3.2. Consistency Measure (CM)

3.3. Local Orientation Quality (LOQ)

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

3.4. Classifier

4. Experimental Results

4.1. Database Description

4.2. Classification of Fingerprints in the Database According to Their Quality

4.3. Quality Estimation Performance

5. Conclusions

Acknowledgments

References

- Yang, JC; Shin, JW; Min, BJ; Park, JB; Park, DS. Fingerprint Matching Using Invariant Moment FingerCode and Learning Vector Quantization Neural Network. Comput. Intell. Security 2006, 1, 735–738. [Google Scholar]

- Alonso-Fernandez, F; Fabio, R; Fierrez, J; Ortega-Garcia, J. Comparison of fingerprint quality measures using an optical and a capacitive sensor. Proceedings of Biometrics: Theory, Applications, and Systems, First IEEE International Conference, BTAS 2007, Washington, DC, USA, 27–29 September; 2007. [Google Scholar]

- Maltoni, D; Maio, D; Jain, AK; Prabhakar, S. Handbook of Fingerprint Recognition, 2nd ed; Springer: New York, NY, USA, 2009; pp. 59–74. [Google Scholar]

- Overview of Capacitive Sensors. Available online: http://www.lionprecision.com/capacitive-sensors/index.html (accessed on 23 March 2010).

- Alonso-Fernandez, F; Fierrez, J; Ortega-Garcia, J; Gonzalez-Rodriguez, J; Fronthaler, H; Kollreider, K; Bigun, J. A Comparative Study of Fingerprint Image-Quality Estimation Methods. IEEE Trans. Inf. Foren. Sec 2007, 2, 734–743. [Google Scholar]

- Lim, E; Jiang, XD; Yau, WY. Fingerprint Quality and Validity Analysis. Proceedings of International Conference on Image Processing, New York, NY, USA, 22–25 September 2002; 1, pp. 466–469.

- Lim, E; Toh, KA; Suganthan, PN; Jiang, XD; Yau, WY. Fingerprint Image Quality Analysis. Proceedings of International Conference on Image Processing, Singapore, 24–27 October 2004; 2, pp. 1241–1244.

- Chen, T; Jiang, X; Yau, W. Fingerprint Image Quality Analysis. Proceedings of Conference of Image Process, Singapore, 24–27 October 2004; 2, pp. 1253–1256.

- Tabassi, E; Wilson, C; Watson, C. Fingerprint Image Quality, NIST research report NISTIR7151; NIST: Gaithersburg, MD, USA, 2004. [Google Scholar]

- Tabassi, E; Wilson, C. A Novel Approach to Fingerprint Image Quality. Proceedings of International Conference on Image Processing, Genoa, Italy, 11–14 September 2005; 2, pp. 37–40.

- Wu, J; Xie, SJ; Song, DH; Lee, WD. A New Approach for Classification of Fingerprint Image Quality. Proceedings of Cognitive Informatics, 7th IEEE International Conference on Digital Object Identifier, ICCI, California, USA, 14–16 August 2008; pp. 375–383.

- Lee, SH; Lee, CH; Kim, JH. Model-based quality estimation of fingerprint images. Lect. Note. Comput. Sci 2005, 3832, 229–235. [Google Scholar]

- Suykens, JAK. Nonlinear Modeling and Support Vector Machines. Proceedings of IEEE Instrumentation and Measurement Technology Conference, Budapest, Hungary; 2001; pp. 287–294. [Google Scholar]

- Xie, SJ; Yang, JC; Yoon, S; Park, DS. An Optimal Orientation Certainty Level Approach for Fingerprint Quality Estimation. Proceedings of 2nd International Symposium on IITA ‘08, Shanghai, China; 2008; 3, pp. 722–726. [Google Scholar]

- Xie, SJ; Yoon, S; Yang, JC; Park, DS. Rule-based Fingerprint Quality Estimation System Using the Optimal Orientation Certainty Level Approach. Proceedings of 2nd International Conference on Biomedical Engineering and Informatics, Tianjin, China, 17–19 October 2009; pp. 1–5.

- Ando, S. Image field categorization and edge/corner detection from gradient covariance. IEEE Trans. Patt. Anal. Mach. Int 2000, 22, 179–190. [Google Scholar]

- Obayashi, S; Sasaki, D; Oyama, A. Finding Tradeoffs by Using Multi-Objective Optimization Algorithms. Trans. Jpn. Son. Aeronaut. Space Sci 2004, 47, 51–58. [Google Scholar]

- Ostu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst 1979, 9, 62–66. [Google Scholar]

- FVC 2000. Fingerprint Verification. Available online: http://bias.csr.unibo.it/fvc2000/databases.asp (accessed on 10 March 2010).

- FVC 2002. Fingerprint Verification. Available online: http://bias.csr.unibo.it/fvc2002/databases.asp (accessed on 10 March 2010).

- FVC 2004. Fingerprint Verification. Available online: http://bias.csr.unibo.it/fvc2004/databases.asp (accessed on 10 March 2010).

| Local Features-based | OCL: Orientation certainty level FREC: Ridge frequency, ridge thickness, ridge-to-valley thickness. LOQ: Local orientation quality LCS: Local clarity score |

| Power Spectrum-based | Energy: Energy concentration in ring-shaped regions of the spectrum. |

| Classifier-based | NFIS: Matcher performance, use the degree of separation between the match and non-match distributions |

| OCL Range | Classification Level |

|---|---|

| 0.8 ≤ OCL ≤ 1 | Good block |

| 0.4 ≤ OCL < 0.8 | Normal block |

| 0.01 ≤OCL< 0.4 | Bad block |

| 0 ≤ OCL < 0.01 | Very bad block or background |

| Optical sensor | Capacitive sensor | Thermal sensor | |

|---|---|---|---|

| FVC2000 | DB1_B, DB3_B | DB2_B | - |

| FVC2002 | DB1_A,DB2_A | DB3_A | - |

| FVC2004 | DB1_A,DB2_A | - | DB3_A |

| Original method | Proposed method | |||||

|---|---|---|---|---|---|---|

| OCL | CM | LOQ | OCL | CM | LOQ | |

| Optical | 80.05% | 81.68% | 77.86% | 87.50% | 81.99% | 81.86% |

| Capacitive | 83.18% | 74.62% | 87.79% | 90.56% | 81.61% | 89.10% |

| Thermal | 78.84% | 77.90% | 78.72% | 81.96% | 89.42% | 83.04% |

| OCL + CM | CM + LOQ | LOQ + OCL | LOQ + OCL + CM | |

|---|---|---|---|---|

| Optical | 92.62% | 91.25% | 91.00% | 95.62% |

| Capacitive | 93.25% | 91.88% | 92.38% | 95.50% |

| Thermal | 94.00% | 93.95% | 86.14% | 96.25% |

| Proposed method | NFIS method | ||||||

|---|---|---|---|---|---|---|---|

| Good | Medium | Bad | Good (1) | Medium (2–3) | Bad (4–5) | ||

| Subjective Quality | Good | 44 | 1 | 0 | 43 | 2 | 0 |

| Medium | 2 | 21 | 0 | 4 | 19 | 0 | |

| Bad | 0 | 0 | 14 | 2 | 2 | 10 | |

© 2010 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Xie, S.J.; Yoon, S.; Shin, J.; Park, D.S. Effective Fingerprint Quality Estimation for Diverse Capture Sensors. Sensors 2010, 10, 7896-7912. https://doi.org/10.3390/s100907896

Xie SJ, Yoon S, Shin J, Park DS. Effective Fingerprint Quality Estimation for Diverse Capture Sensors. Sensors. 2010; 10(9):7896-7912. https://doi.org/10.3390/s100907896

Chicago/Turabian StyleXie, Shan Juan, Sook Yoon, Jinwook Shin, and Dong Sun Park. 2010. "Effective Fingerprint Quality Estimation for Diverse Capture Sensors" Sensors 10, no. 9: 7896-7912. https://doi.org/10.3390/s100907896