An Optical Fiber Sensor and Its Application in UAVs for Current Measurements

Abstract

:1. Introduction

2. Unmanned Aerial Vehicle Characteristics

3. Theory

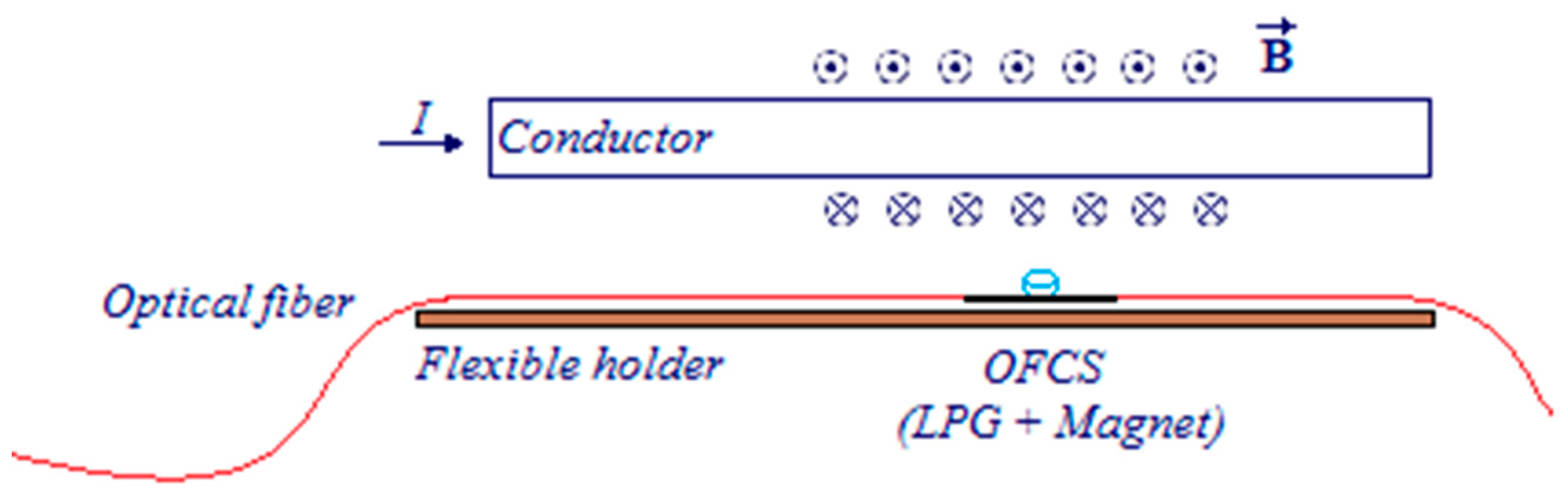

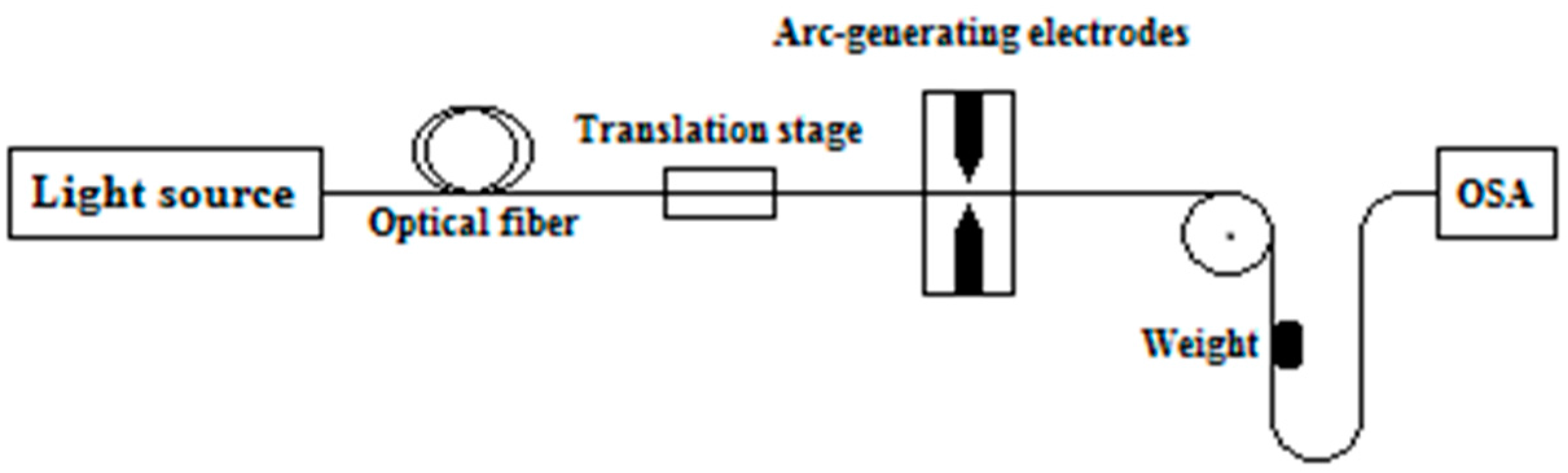

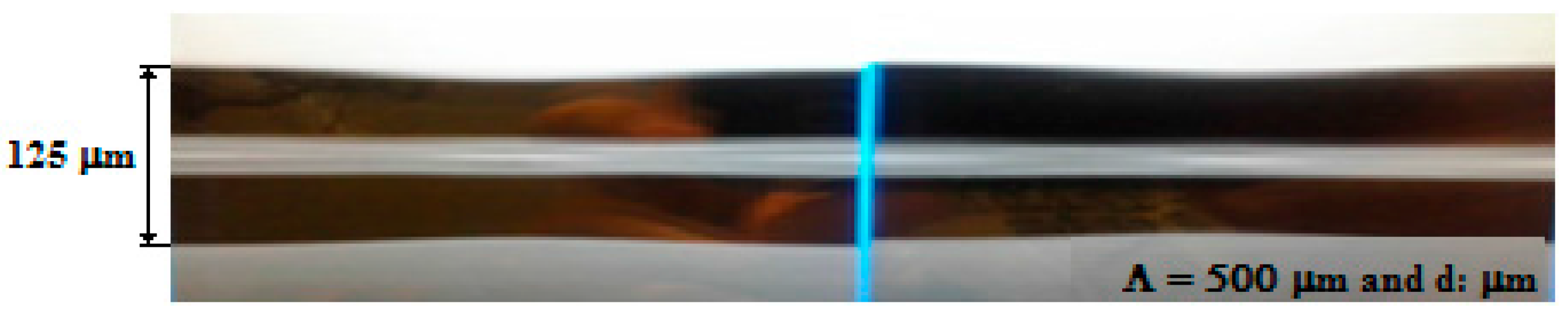

4. Experimental Setup and Sensing Principle

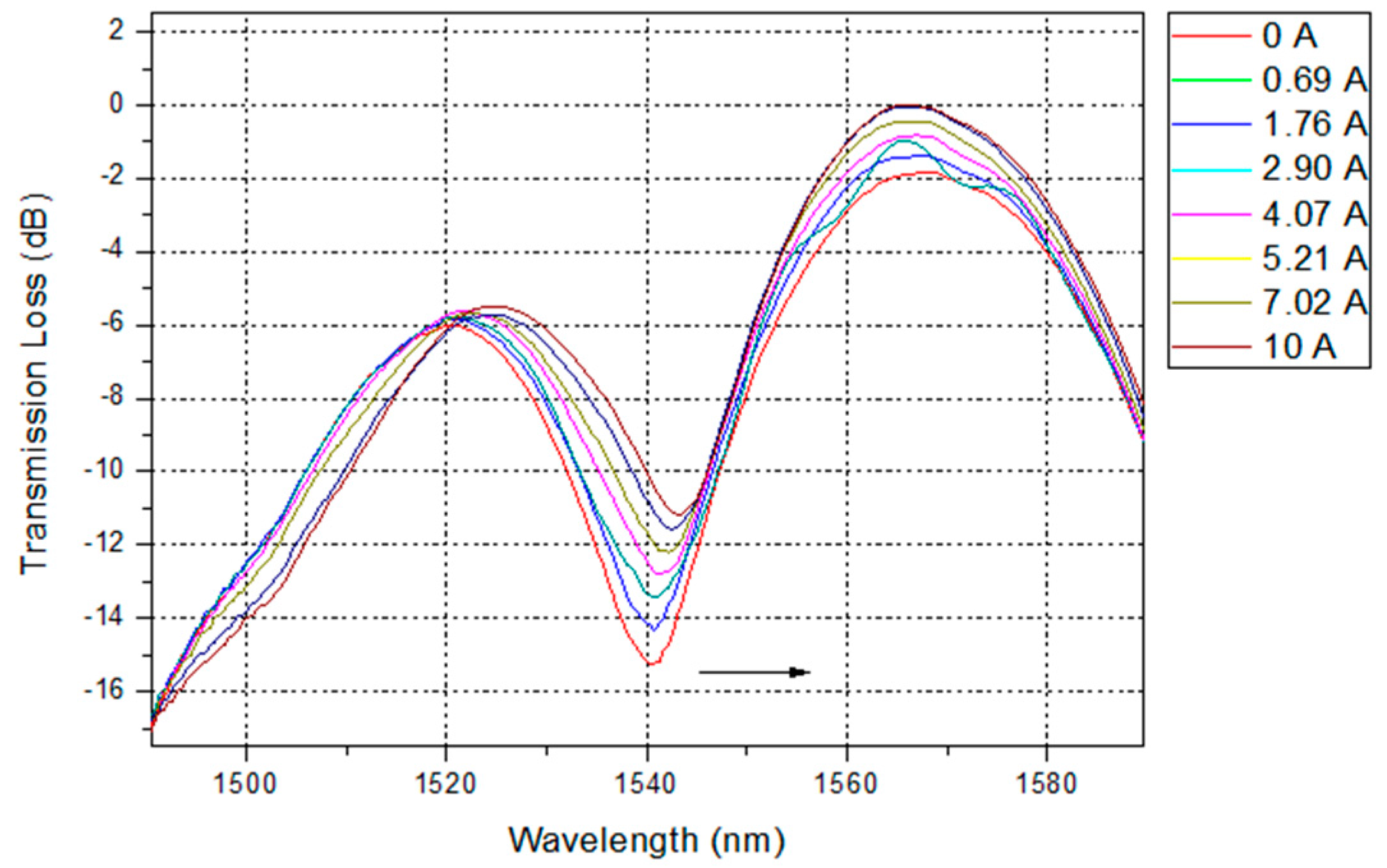

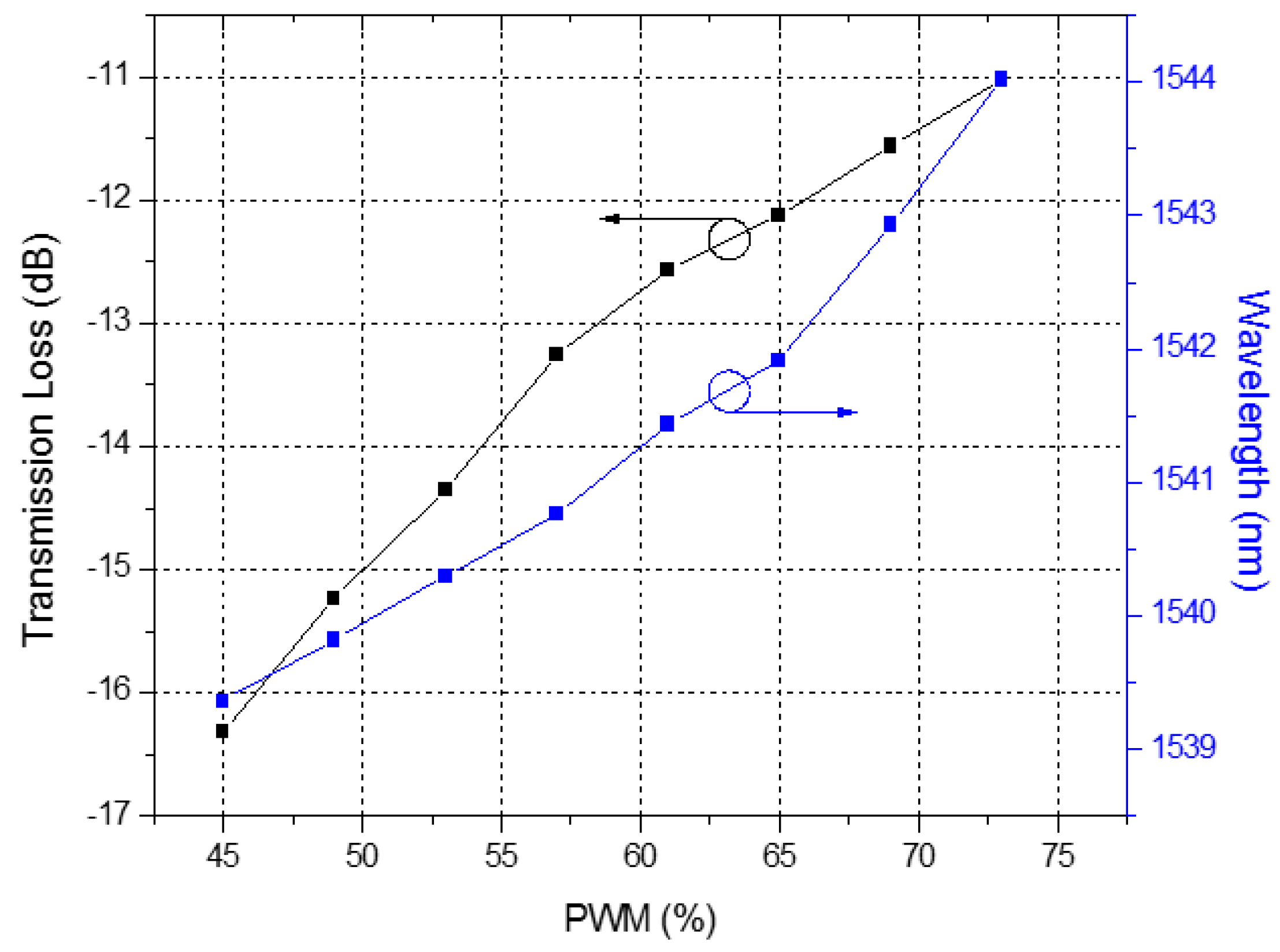

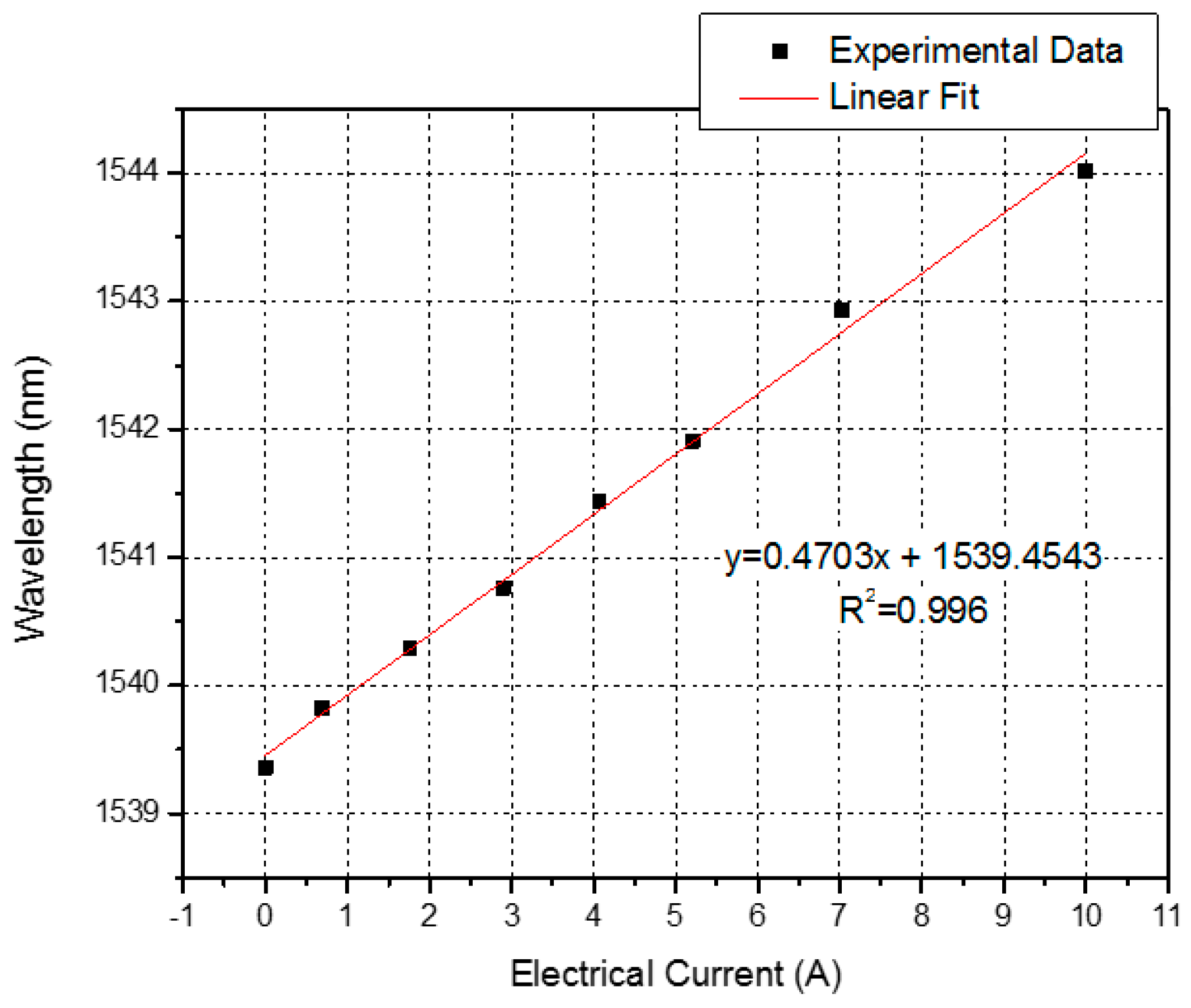

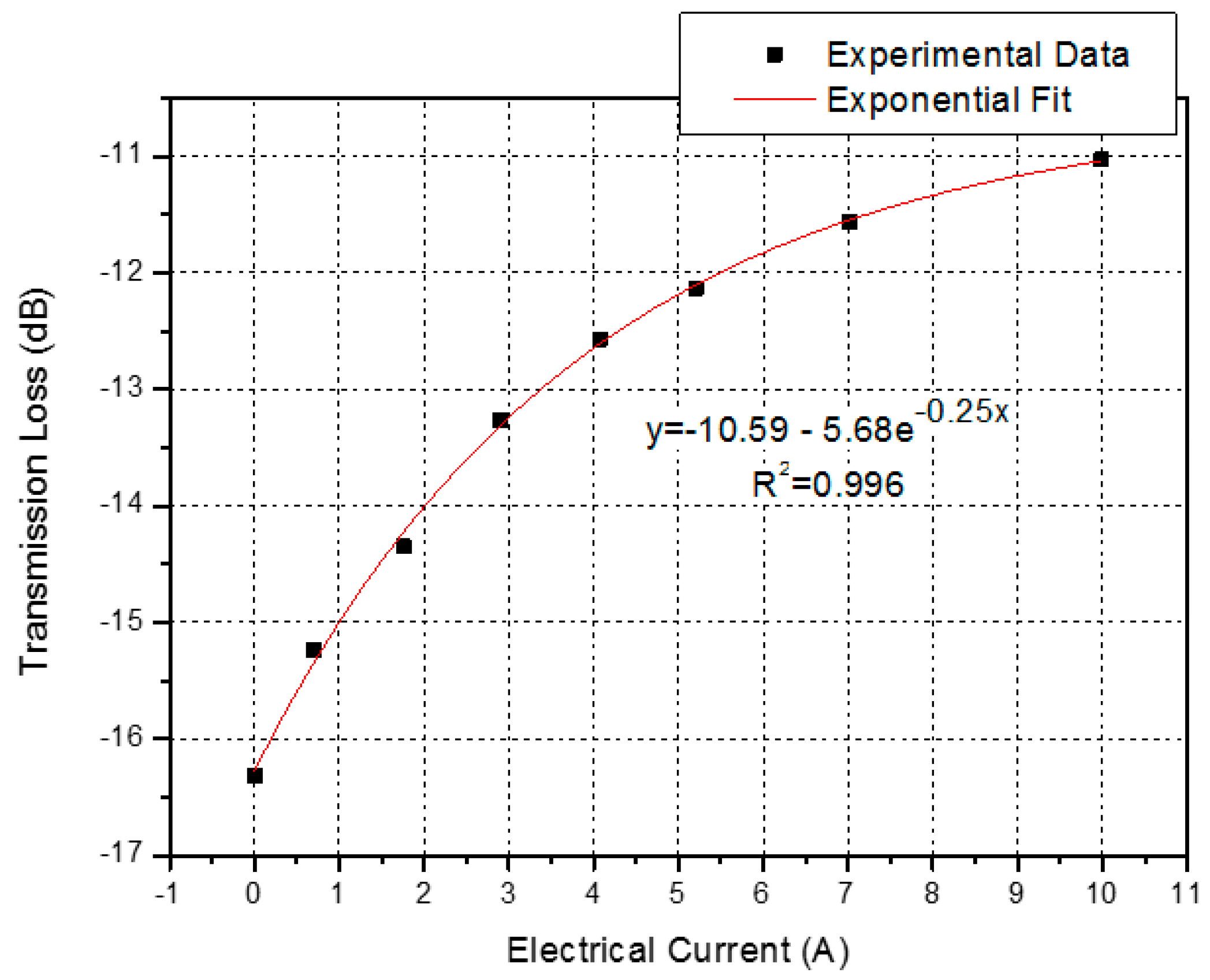

5. Experimental Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Santos, J.L.; Frazão, O.; Baptista, J.M.; Jorge, P.A.S. Optical fibre sensing networks. In Proceedings of the 2009 SBMO/IEEE MTT-S International Microwave and Optoelectronics Conference (IMOC), Belém, Brazil, 3–6 November 2009; pp. 290–298.

- Annamdas, V.G.M. Review on developments in fiber optical sensors and applications. Int. J. Mater. Eng. 2011, 1, 1–16. [Google Scholar] [CrossRef]

- Lin, W.; Zhang, L.L.; Liang, S. Review on development and applications of fiber-optic sensors. In Proceedings of the 2012 Symposium on Photonics and Optoelectronics (SOPO), Shanghai, China, 21–23 May 2012; pp. 1–4.

- Ascorbe, J.; Corres, J.M.; Arregui, F.J.; Matías, I.R. Optical fiber current transducer using lossy mode resonances for high voltage networks. J. Lightwa. Technol. 2015, 33, 2504–2510. [Google Scholar] [CrossRef]

- Ding, Z.; Du, Y.; Liu, T.; Liu, K.; Feng, B.; Jiang, J. Distributed optical fiber current sensor based on magnetostriction in OFDR. IEEE Photon. Technol. Lett. 2015, 27, 2055–2058. [Google Scholar] [CrossRef]

- Lopez-Higuera, J.M. Handbook of Optical Fibre Sensing Technology; Wiley: New York, NY, USA, 2002. [Google Scholar]

- Delgado, F.S.; Silveira, D.D.; Coelho, T.V.N.; Bessa dos Santos, A. Mathematical modelling for correlation between temperature and mechanical strain in long period gratings. In Proceedings of the 2014 IEEE Sensors, Valencia, Spain, 2–5 November 2014; pp. 1900–1903.

- Zou, F.; Liu, Y.; Zhu, S.; Deng, C.; Dong, Y.; Wang, T. Temperature sensitivity enhancement of the nano-film coated long-period fiber gratings. IEEE Sens. J. 2016, 16, 2460–2465. [Google Scholar] [CrossRef]

- Saeed, M.A.; Ahmed, R.; Ashiq, M. Long period grating as strain sensor. J. Ovon. Res. 2012, 8, 113–120. [Google Scholar]

- Patrick, H.J.; Kersey, A.D.; Bucholtz, F. Analysis of the response of long period gratings to external index of refraction. J. Lightwa. Technol. 1998, 16, 1601–1611. [Google Scholar] [CrossRef]

- Smietana, M.; Bock, W.J.; Mikulic, P.; Chen, J. Tuned pressure sensitivity of dual resonant long-period gratings written in boron co-doped optical fiber. J. Lightwa. Technol. 2012, 30, 1080–1084. [Google Scholar] [CrossRef]

- Liu, H.; Liang, H.; Sun, M.; Ni, K.; Jin, Y. Simultaneous measurement of humidity and temperature based on a long-period fiber grating inscribed in fiber loop mirror. IEEE Sens. J. 2014, 14, 893–896. [Google Scholar] [CrossRef]

- Palmieri, L.; Sarchi, D.; Galtorossa, A. Polarization optical fiber sensor for distributed current monitoring. In Proceedings of the 23rd International Conference on Optical Fibre Sensor, Santander, Spain, 2–6 June 2014.

- Casey, E.J.; Titus, C.H. Magneto-Optical Electric Current Sensing Arrangement. U.S. Patent 3,324,393, 6 June 1967. [Google Scholar]

- Smith, A.M. Polarization and magneto optic properties of single-mode optical fiber. Appl. Opt. 1978, 17, 52–56. [Google Scholar] [CrossRef] [PubMed]

- Aerssens, M.; Gusarov, A.; Brichard, B.; Massaut, V.; Mégret, P.; Wuilpart, M. Faraday effect based optical fiber current sensor for tokamaks. In Proceedings of the 2011 2nd International Conference on Advancements in Nuclear Instrumentation Measurement Methods and their Applications (ANIMMA), Ghent, Belgium, 6–9 June 2011; pp. 1–6.

- Souza, L.S.; Silveira, D.D.; Coelho, T.V.N.; Santos, A.B. Desenvolvimento de um sensor à fibra óptica LPFG utilizado na medição de corrente elétrica. In Proceedings of the 2014 MOMAG, Curitiba, Brazil, 31 August–3 September 2014.

- Lee, Y.W.; Yoon, I.; Lee, B. A simple fiber-optic current sensor using a long-period fiber grating inscribed on a polarization-maintaining fiber as a sensor demodulator. Sens. Actuators A Phys. 2004, 112, 308–312. [Google Scholar] [CrossRef]

- Zhang, R.; Yao, X.S.; Liu, T.; Li, L. The effect of linear birefringence on fiber optic current sensor based on Faraday mirror. In Proceedings of the 2014 SPIE 9274, Advanced Sensor Systems and Applications VI, 92741N, Beijing, China, 9–11 October 2014.

- Chenda, G.; Xiao, H.; Huang, Y.; Zhou, Z.; Zhang, Y. A novel long-period fiber grating sensor for large strain measurement. In Proceedings of the 2009 Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, San Diego, CA, USA, 8 March 2009.

- James, S.W.; Tatam, R.P. Optical fiber long-period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14, R49–R61. [Google Scholar] [CrossRef]

- Vengsarkar, A.M.; Lemaire, P.J.; Judkins, J.B.; Bhatia, V.; Erdogan, T.; Sipe, J.E. Long-period fiber gratings as band-rejection filters. J. Lightwa. Technol. 1996, 14, 58–65. [Google Scholar] [CrossRef]

- Ahmed, F.; Joe, H.E.; Min, B.K.; Jun, M.B.G. Characterization of refractive index change and fabrication of long period gratings in pure silica fiber by femtosecond laser radiation. Opt. Laser Technol. 2015, 74, 119–124. [Google Scholar] [CrossRef]

- Coelho, J.M.P.; Silva, C.; Nespereira, M.; Abreu, M.; Rebordão, J. Writing of long period fiber gratings using CO2 laser radiation. Adv. Opt. Fiber Technol. Fundam. Opt. Phenom. Appl. 2015. [Google Scholar] [CrossRef]

- Tan, S.Y.; Yong, Y.T.; Lee, S.C.; Rahman, F.A. Review on an arc-induced long-period fiber grating and its sensor applications. J. Electromagn. Waves Appl. 2015, 29, 703–726. [Google Scholar] [CrossRef]

- Fujimaki, M.; Ohki, Y.; Brebner, J.; Roorda, S. Fabrication of long-period optical fiber gratings by use of ion implantation. Opt. Lett. 2000, 25, 88–89. [Google Scholar] [CrossRef]

- Savin, S.; Digonnet, M.J.F.; Kino, G.S.; Shaw, H.J. Tunable mechanically induced long-period fiber gratings. Opt. Lett. 2000, 25, 710–712. [Google Scholar] [CrossRef] [PubMed]

- Bock, W.J.; Chen, J.; Mikulic, P.; Eftimov, T. A novel fiber-optic tapered long-period grating sensor for pressure monitoring. IEEE Trans. Instrum. Meas. 2007, 56, 1176–1180. [Google Scholar] [CrossRef]

- Ji, W.B.; Tjin, S.C.; Lin, B.; Ng, C.L. Highly sensitive refractive index sensor based on adiabatically tapered microfiber long period gratings. Sensors 2013, 13, 14055–14063. [Google Scholar] [CrossRef] [PubMed]

- Smietana, M.; Bock, W.J.; Mikulic, P.; Chen, J. Increasing sensitivity of arc-induced long-period gratings-pushing the fabrication technique toward its limits. Meas. Sci. Technol. 2011, 22, 015201. [Google Scholar] [CrossRef]

- Shu, X.; Zhang, L.; Bennion, I. Sensitivity characteristics of long-period fiber gratings. J. Lightwa. Technol. 2002, 20, 255–256. [Google Scholar]

- Wang, S.F.; Chiang, C.C. A notched long-period fiber grating magnetic field sensor based on nanoparticle magnetic fluid. Appl. Sci. 2016, 6, 9. [Google Scholar] [CrossRef]

- Tsuda, H.; Urabe, K. Characterization of long-period grating refractive index sensors and their applications. Sensors 2009, 9, 4559–4571. [Google Scholar] [CrossRef] [PubMed]

- Antunes, P.; Varum, H.; André, P. Uniaxial fiber Bragg grating accelerometer system with temperature and cross axis insensitivity. Measurement 2011, 44, 55–59. [Google Scholar] [CrossRef]

- Rego, G.; Okhotnikov, O.; Dianov, E.; Sulimov, V. High-temperature stability of long-period fiber gratings produced using an electric arc. J. Lightware Technol. 2001, 19, 1574–1579. [Google Scholar] [CrossRef]

- Ivanov, O.V.; Rego, G. Origin of coupling to antisymmetric modes in arc-induced long-period fiber gratings. Opt. Express 2007, 15, 13936–13941. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado, F.S.; Carvalho, J.P.; Coelho, T.V.N.; Dos Santos, A.B. An Optical Fiber Sensor and Its Application in UAVs for Current Measurements. Sensors 2016, 16, 1800. https://doi.org/10.3390/s16111800

Delgado FS, Carvalho JP, Coelho TVN, Dos Santos AB. An Optical Fiber Sensor and Its Application in UAVs for Current Measurements. Sensors. 2016; 16(11):1800. https://doi.org/10.3390/s16111800

Chicago/Turabian StyleDelgado, Felipe S., João P. Carvalho, Thiago V. N. Coelho, and Alexandre B. Dos Santos. 2016. "An Optical Fiber Sensor and Its Application in UAVs for Current Measurements" Sensors 16, no. 11: 1800. https://doi.org/10.3390/s16111800