A Liquid Level Measurement Technique Outside a Sealed Metal Container Based on Ultrasonic Impedance and Echo Energy

Abstract

:1. Introduction

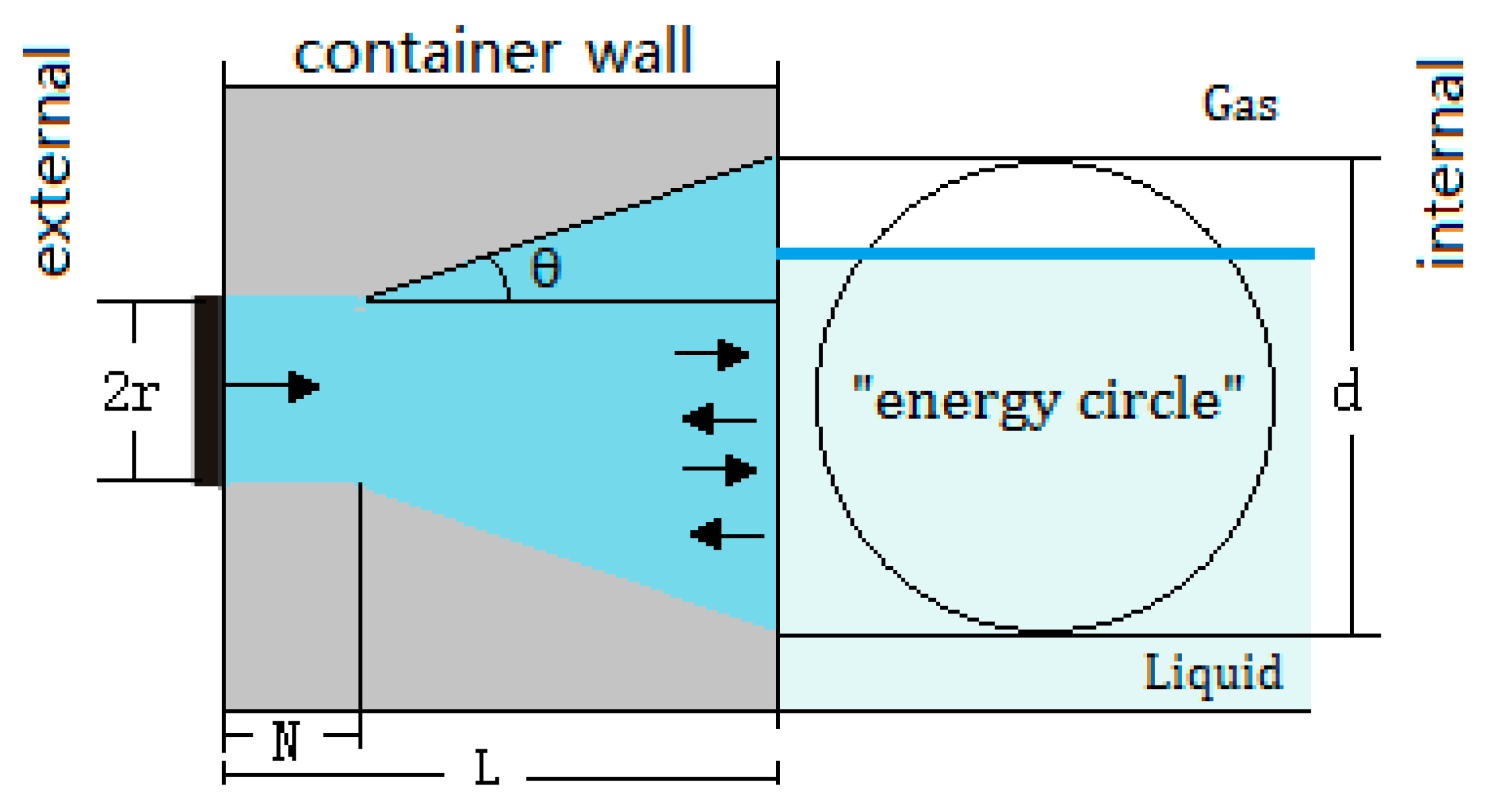

2. Theory and Methods

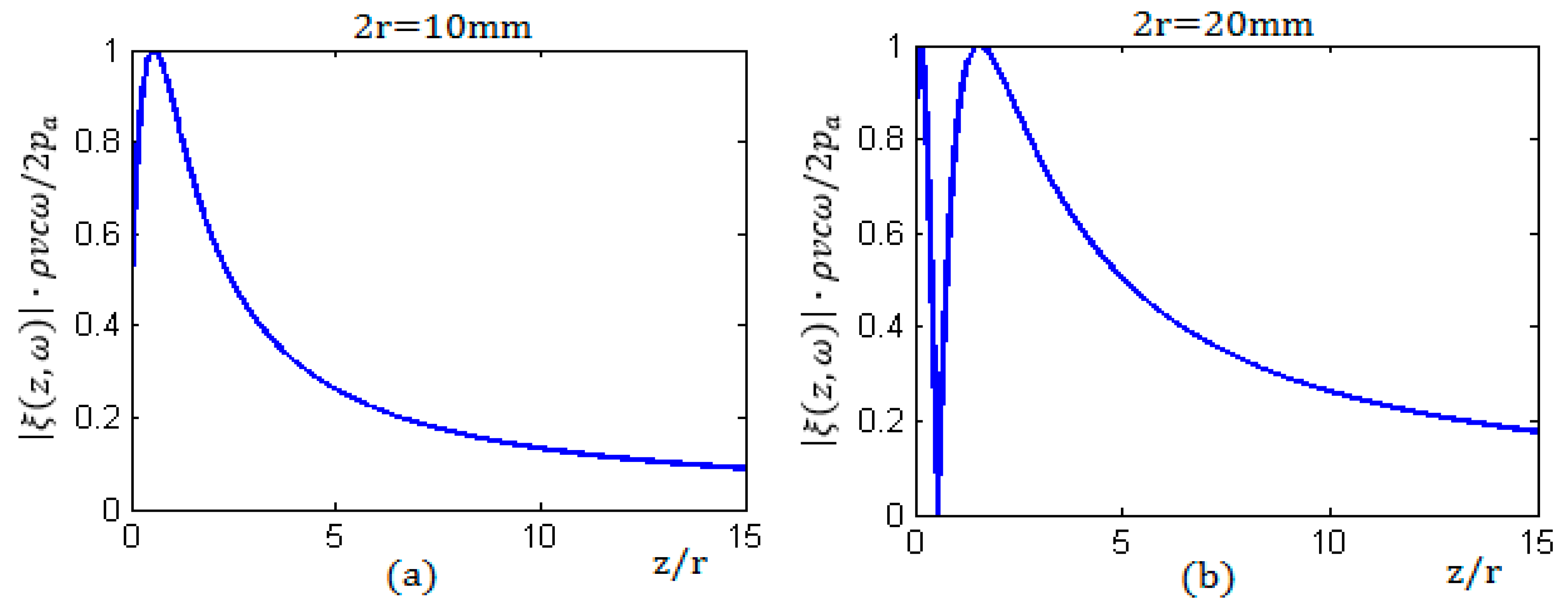

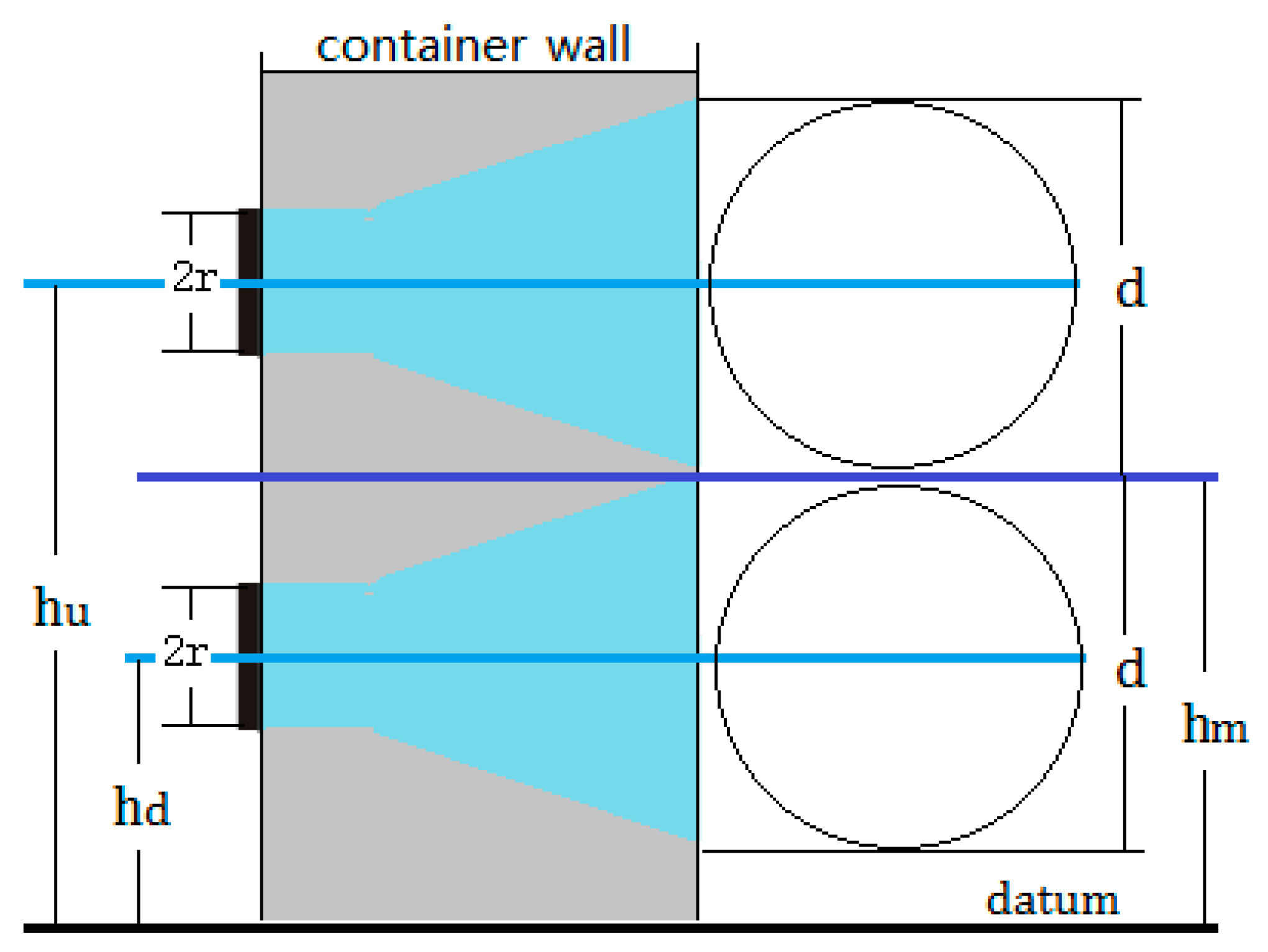

2.1. Analysis of the Sound Field and Axial Response of the Sensor

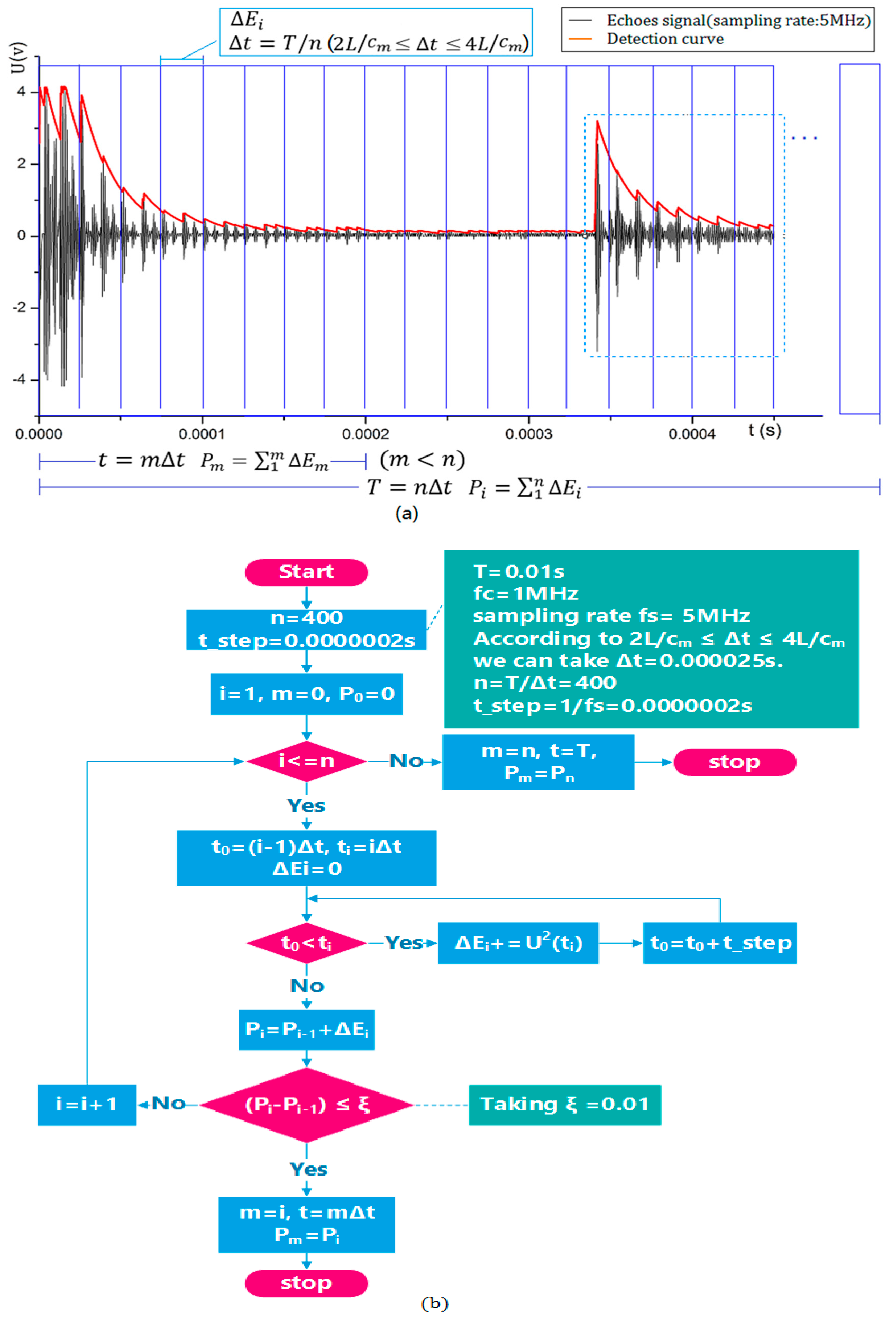

2.2. Calculation of Echo Energy

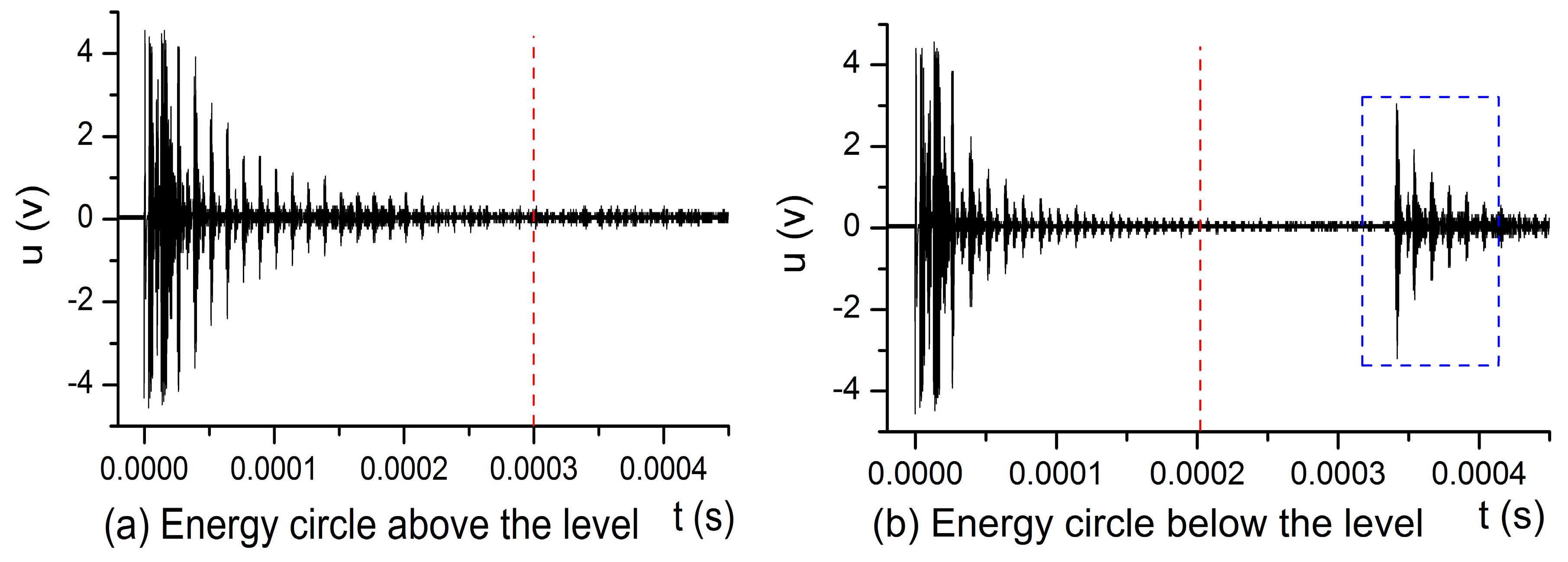

2.2.1. The Energy Circle below or above the Liquid Level

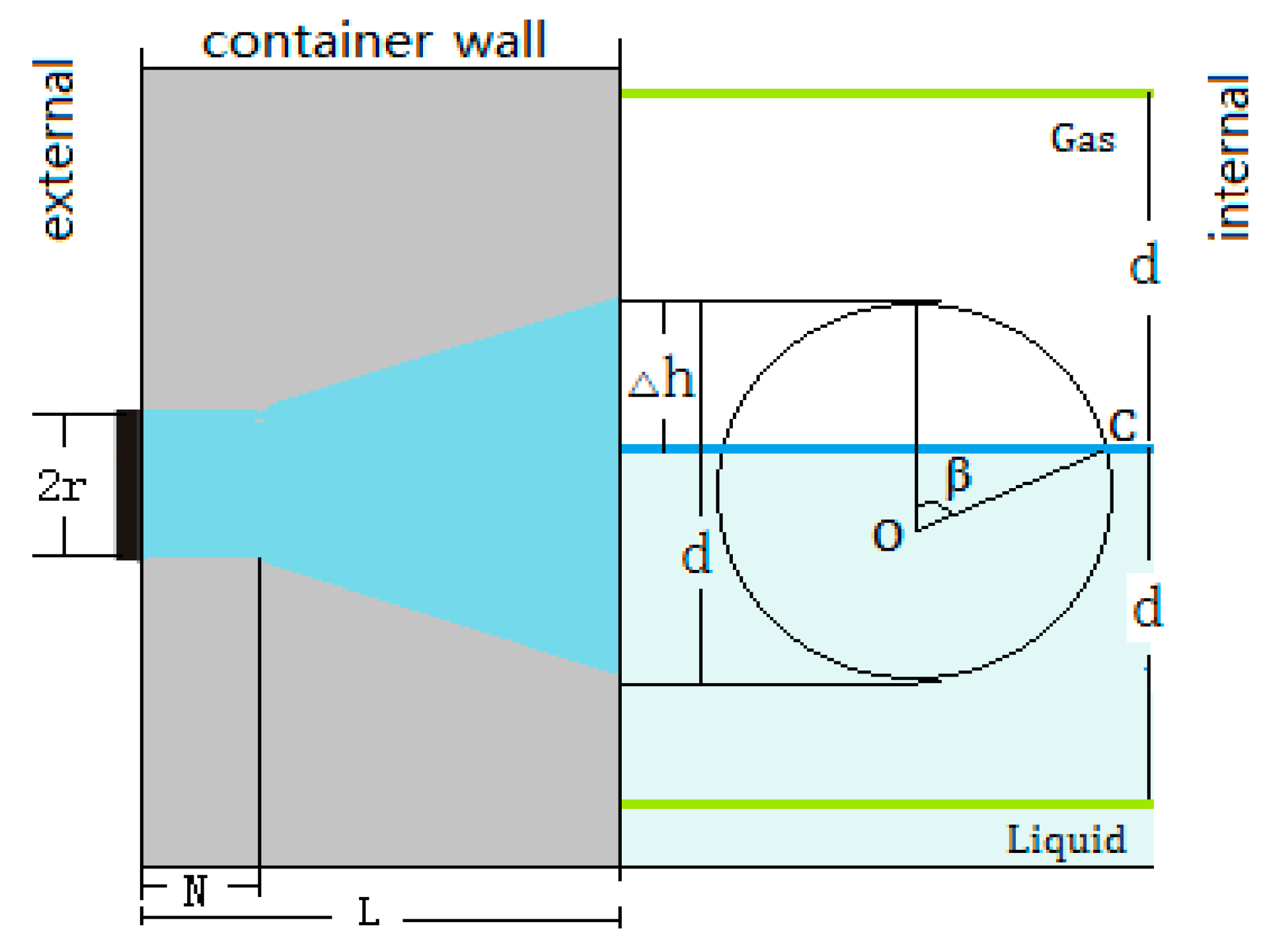

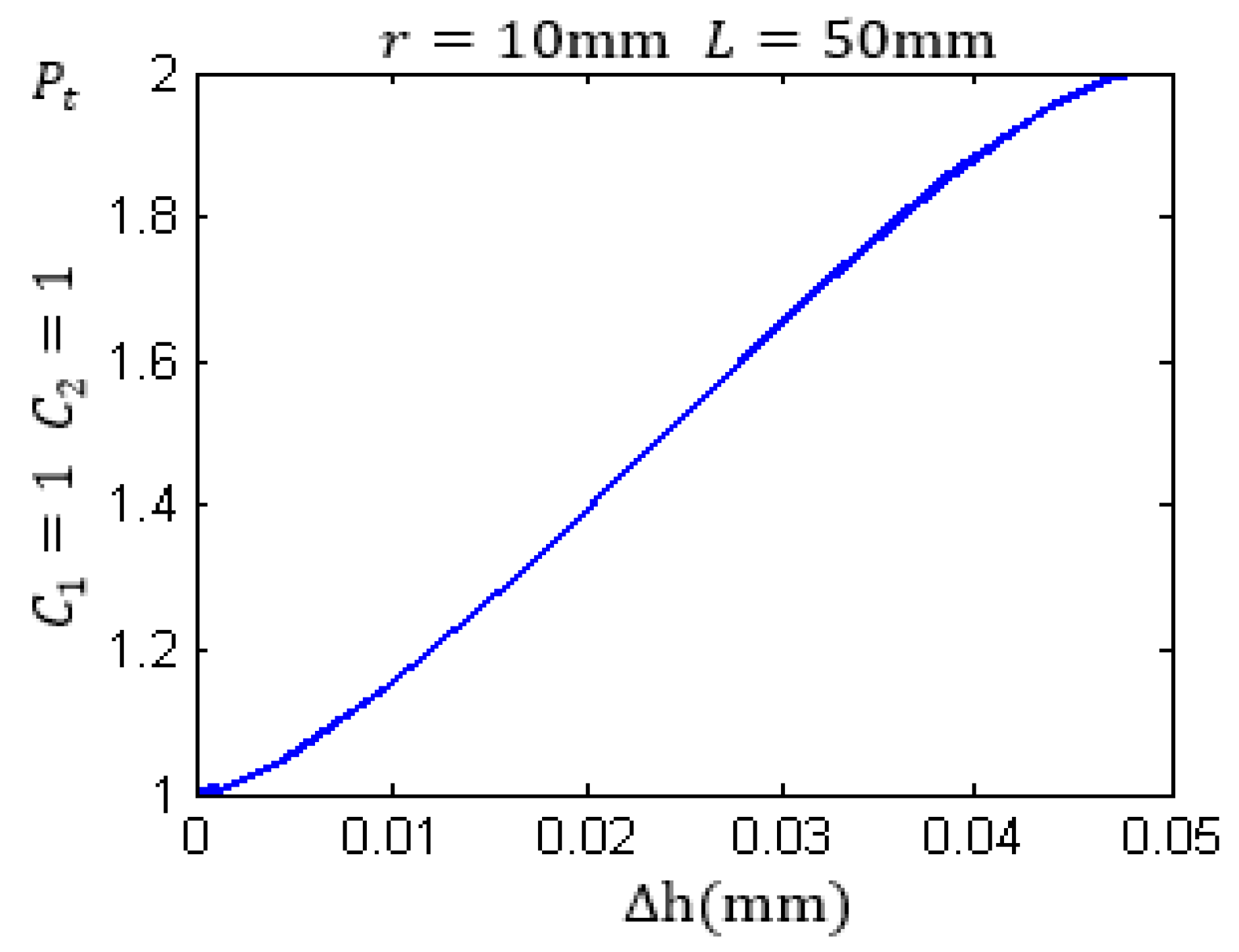

2.2.2. Two Parts of the Energy Circle Divided by the Liquid Level

2.2.3. The Critical State

2.2.4. Calibration of a Liquid Level

3. Experimental Results

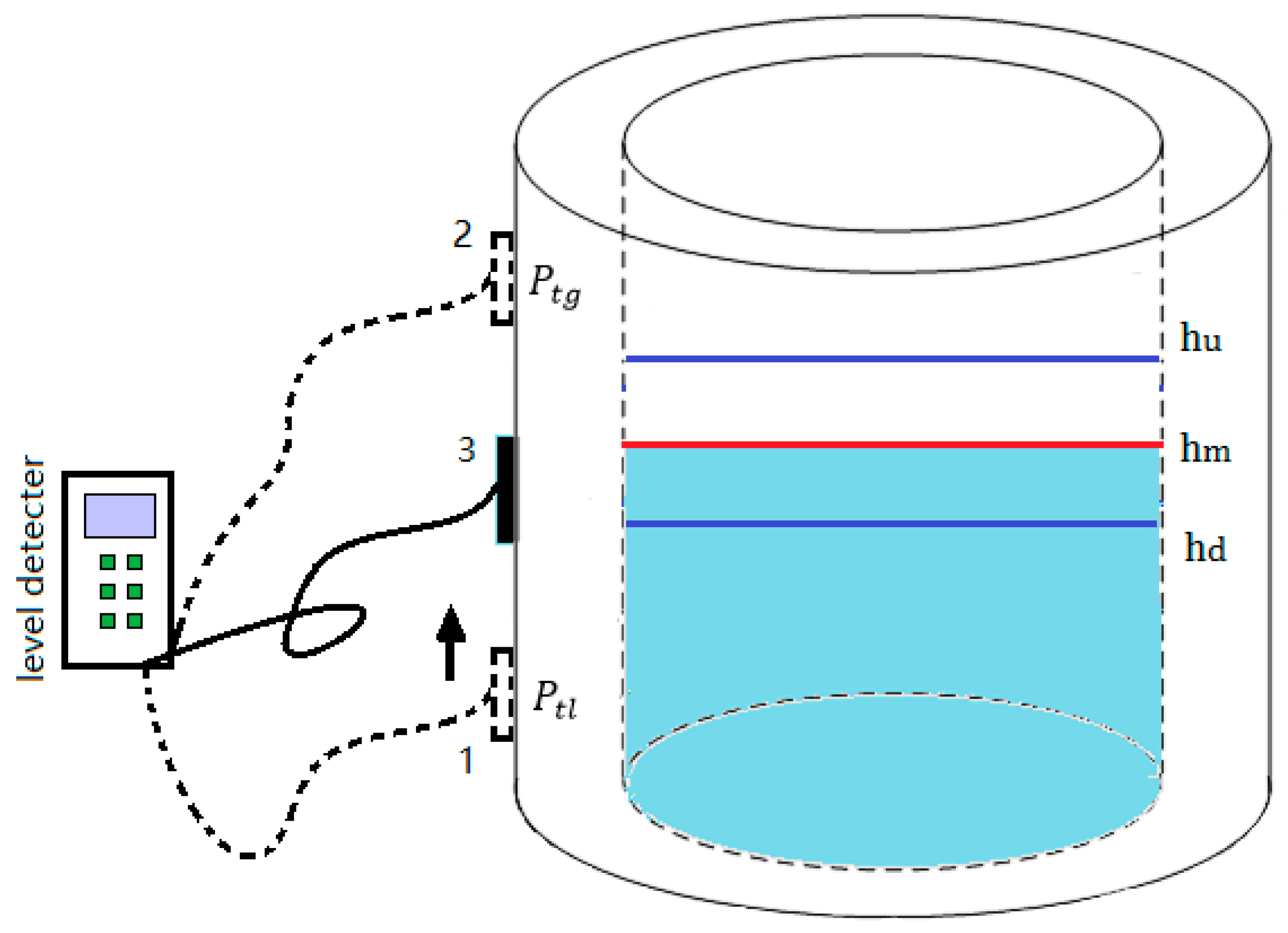

3.1. Configuration of Experimental Environment and Initial Conditions

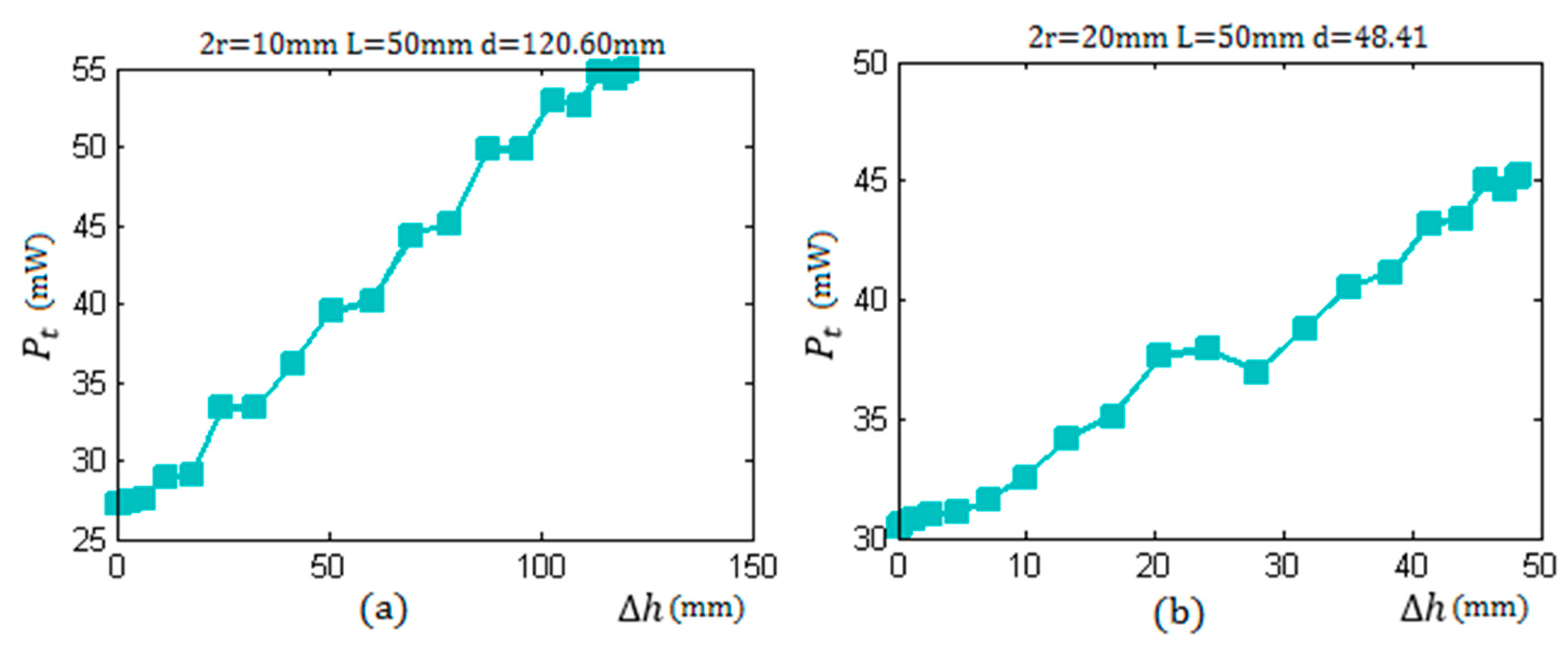

3.2. The Results of the Experiment

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- McCulloch, R.W. Measurement of liquid level in demanding environments using thermal differential technology. Proc. Adv. Instrum. 1990, 45, 1859–1867. [Google Scholar]

- Zhang, J.L.; Shan, Y.L. Research on Ultrasonic Liquid Level Non-contact Measurement in Sealed Vessel. Piezoelectric Acoustooptics 2009, 133, 366–370. [Google Scholar]

- Hernandez, A.; Urena, J.; Mazo, M.; Garcia, J.J.; Jimenez, A.; Alvarez, F.J. Reduction of blind zone in ultrasonic transmitter/receiver sensors. Sens. Actuators A Phys. 2007, 133, 96–103. [Google Scholar] [CrossRef]

- Zhang, M.J.; Li, S.W. A Method of the Untouched Ultrasonic Liquid Level Measurement with High Accuracy. In Proceedings of the 2010 International Conference on Computer Application and System Modeling, Taiyuan, China, 22–24 October 2010.

- Hao, H.H.; Xiong, J.Q. A Method of Liquid Level Measurement Based on Ultrasonic Echo Characteristics. In Proceedings of the 2010 International Conference on Computer Application and System Modeling, Taiyuan, China, 22–24 October 2010.

- Sakharova, V.E.; Kuznetsova, S.A.; Zaitsevb, B.D.; Kuznetsovab, I.E.; Josh, S.G. Liquid level sensor using ultrasonic Lamb waves. Ultrasonics 2003, 41, 319–322. [Google Scholar] [CrossRef]

- Joshi, S.G.; Jin, Y. Propagation of ultrasonic Lamb waves in piezoelectric plates. J. Appl. Phys. 1991, 70, 4113–4120. [Google Scholar] [CrossRef]

- He, X.P.; Zhang, F.; Li, B.; Zhang, D. The calculation of the echo energy transmission coefficient in ultrasonic liquid level testing. J. Shaanxi Norm. Univ. 2008, 36, 49. [Google Scholar]

- Schmerr, L.W. Fundamentals of Ultrasonic Nondestructive Evaluation: A Modeling Approach; Plenum Press: New York, NY, USA, 1998. [Google Scholar]

- Schmerr, L.W.; Sedov, A. An Elastodynamic Model for Compressional and Shear Wave Transducers. J. Acoust. Soc. Am. 1989, 86, 1988–1999. [Google Scholar] [CrossRef]

- Vezzeti, D.J. Propagation of Bounded Ultrasonic Beams in Anisotropic Media. J. Acoust. Soc. Am. 1985, 78, 1103–1108. [Google Scholar] [CrossRef]

- Roa-Prada, S.; Scarton, H.A.; Saulnier, G.J.; Shoudy, D.A.; Ashdown, J.D.; Das, P.K.; Gavens, A.J. An Ultrasonic Through-Wall Communication (UTWC) System Model. J. Vib. Acoust. 2013, 135, 011004. [Google Scholar] [CrossRef]

- Bass, R. Diffractions Effects in the Ultrasonic Field of a Piston Source. J. Acoust. Soc. Am. 1958, 30, 602–605. [Google Scholar] [CrossRef]

| Symbol | Meaning |

|---|---|

| the radius of a sensor | |

| the diffusion angle | |

| the attenuation coefficient | |

| the center frequency of a sensor | |

| the thickness of a container wall | |

| the length of the near field | |

| the wavelength of compressional wave in a metal wall | |

| the diameter of the energy circle | |

| the density of a medium | |

| the wave speed in a medium | |

| the acoustic impedance of a liquid medium | |

| the acoustic impedance of a gaseous medium | |

| the acoustic impedance of a metal container wall | |

| the reflection coefficient at the surface between wall and gaseous medium | |

| the reflection coefficient at the surface between wall and liquid medium | |

| the reflection coefficient at the surface between wall and gas medium | |

| the subscripts associated with a metal, a gas, a liquid and an air medium | |

| the excitation voltage | |

| the repetition frequency of a pulse | |

| the repetition period | |

| the incident sound pressure | |

| the sound intensity at outer surface of a wall | |

| the total energy received by a sensor as the energy circle is divided by the liquid level | |

| the total energy received by a sensor as the energy circle is above the liquid level | |

| the total energy received by a sensor as the energy circle is below the liquid level | |

| the actual height of the liquid level | |

| , | the critical height above the liquid level and its average value |

| , | the critical height below the liquid level and its average value |

| , | the measured height of the liquid level and its average value |

| L | 2r | N | d | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 10 | 4 | 19.68 | 163.6 | 180.7 | 172.15 | 170 | 2.15 | 176.61 | 6.61 |

| 25 | 10 | 4 | 60.50 | 145.4 | 197.3 | 171.35 | 170 | 1.35 | 175.32 | 5.32 |

| 40 | 10 | 4 | 96.58 | 131.1 | 212.5 | 171.8 | 170 | 1.8 | 163.95 | −6.05 |

| 50 | 10 | 4 | 120.60 | 114.9 | 219.4 | 167.15 | 170 | −2.85 | 161.1 | −8.9 |

| 8 | 20 | 15.9 | 20.00 | 162.3 | 181.1 | 171.7 | 170 | 1.7 | 176.53 | 6.53 |

| 25 | 20 | 15.9 | 27.59 | 157.7 | 185 | 171.35 | 170 | 1.35 | 174.25 | 4.25 |

| 40 | 20 | 15.9 | 40.08 | 155.1 | 191.3 | 173.2 | 170 | 3.2 | 163.32 | −6.68 |

| 50 | 20 | 15.9 | 48.41 | 149.4 | 197.6 | 173.5 | 170 | 3.5 | 161.9 | −8.1 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Wei, Y.-J.; Liu, W.-Y.; Zhang, Y.-J.; Yao, Z.; Zhao, L.-H.; Xiong, J.-J. A Liquid Level Measurement Technique Outside a Sealed Metal Container Based on Ultrasonic Impedance and Echo Energy. Sensors 2017, 17, 185. https://doi.org/10.3390/s17010185

Zhang B, Wei Y-J, Liu W-Y, Zhang Y-J, Yao Z, Zhao L-H, Xiong J-J. A Liquid Level Measurement Technique Outside a Sealed Metal Container Based on Ultrasonic Impedance and Echo Energy. Sensors. 2017; 17(1):185. https://doi.org/10.3390/s17010185

Chicago/Turabian StyleZhang, Bin, Yue-Juan Wei, Wen-Yi Liu, Yan-Jun Zhang, Zong Yao, Li-Hui Zhao, and Ji-Jun Xiong. 2017. "A Liquid Level Measurement Technique Outside a Sealed Metal Container Based on Ultrasonic Impedance and Echo Energy" Sensors 17, no. 1: 185. https://doi.org/10.3390/s17010185