Precise Measurement of Gas Volumes by Means of Low-Offset MEMS Flow Sensors with μL/min Resolution

Abstract

:1. Introduction

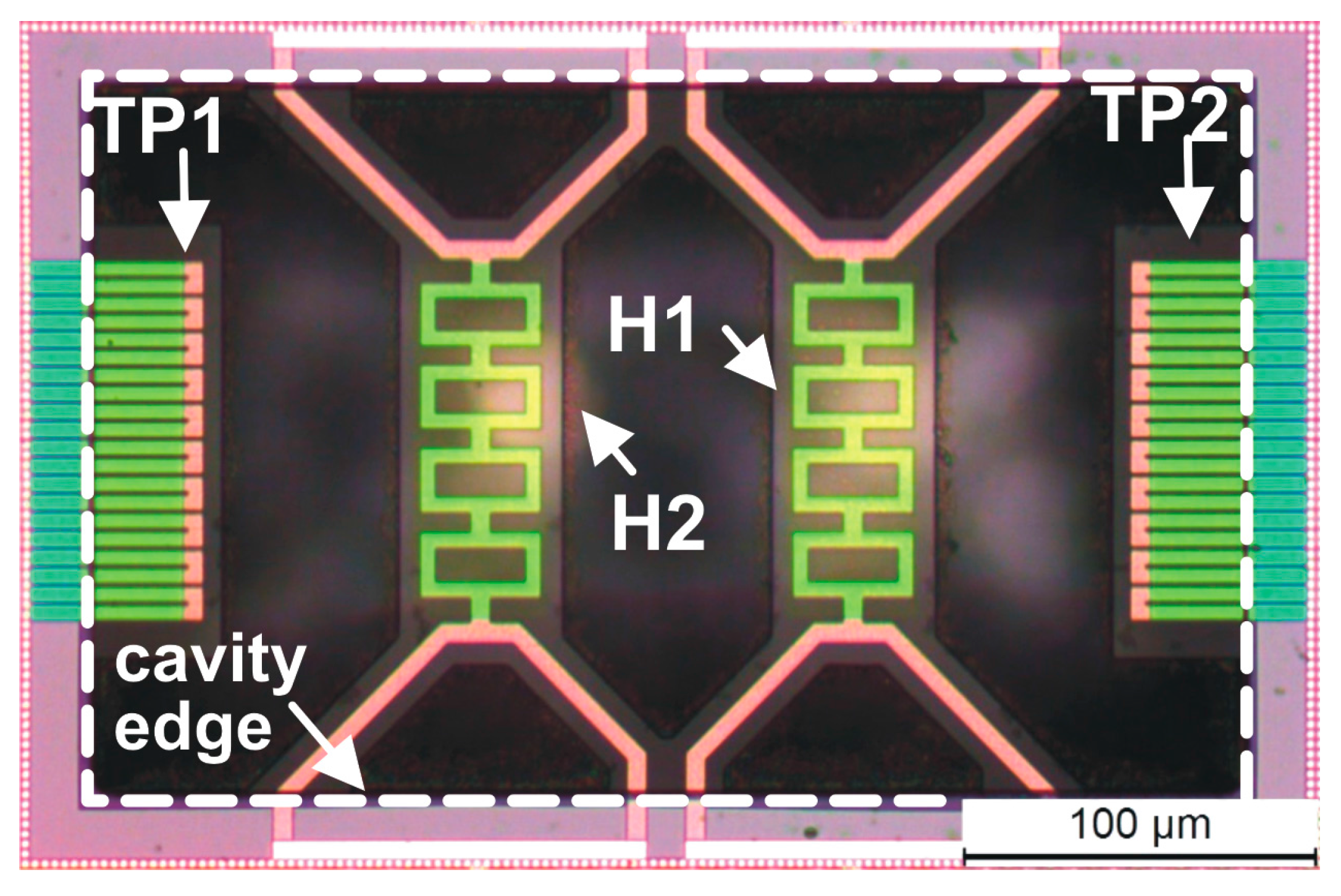

2. Description of the Sensor Architecture and Fabrication

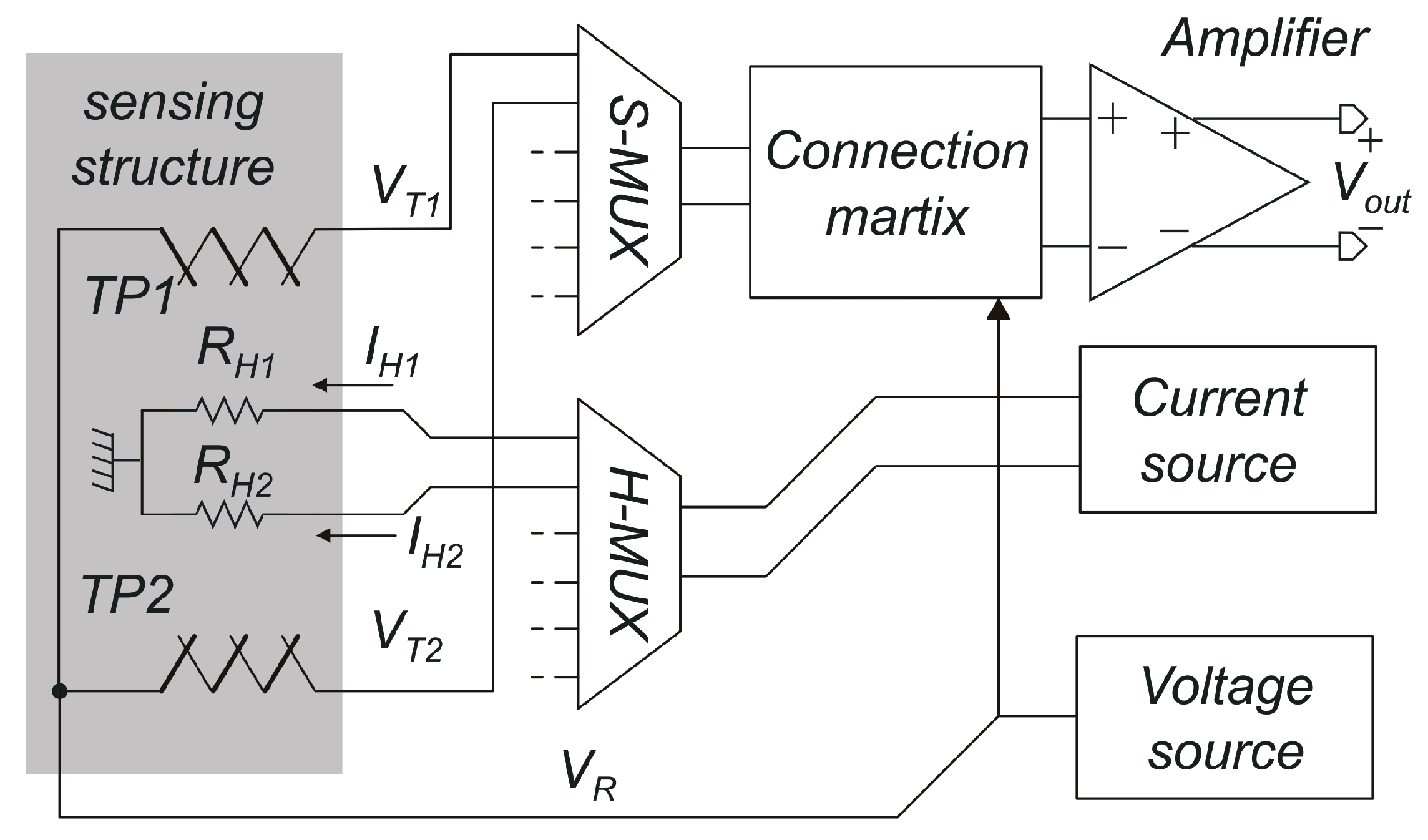

2.1. System Architecture

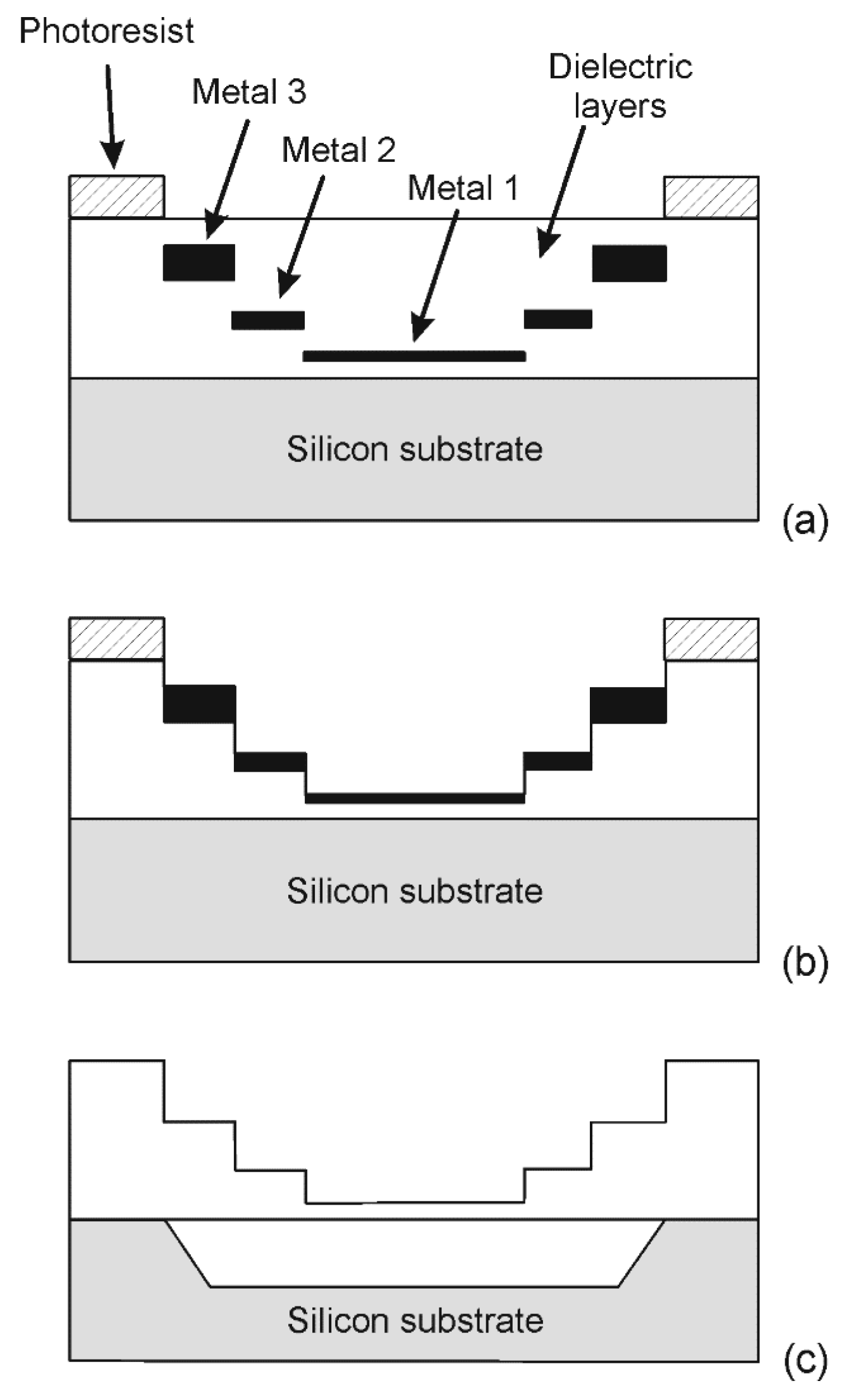

2.2. Fabrication Process

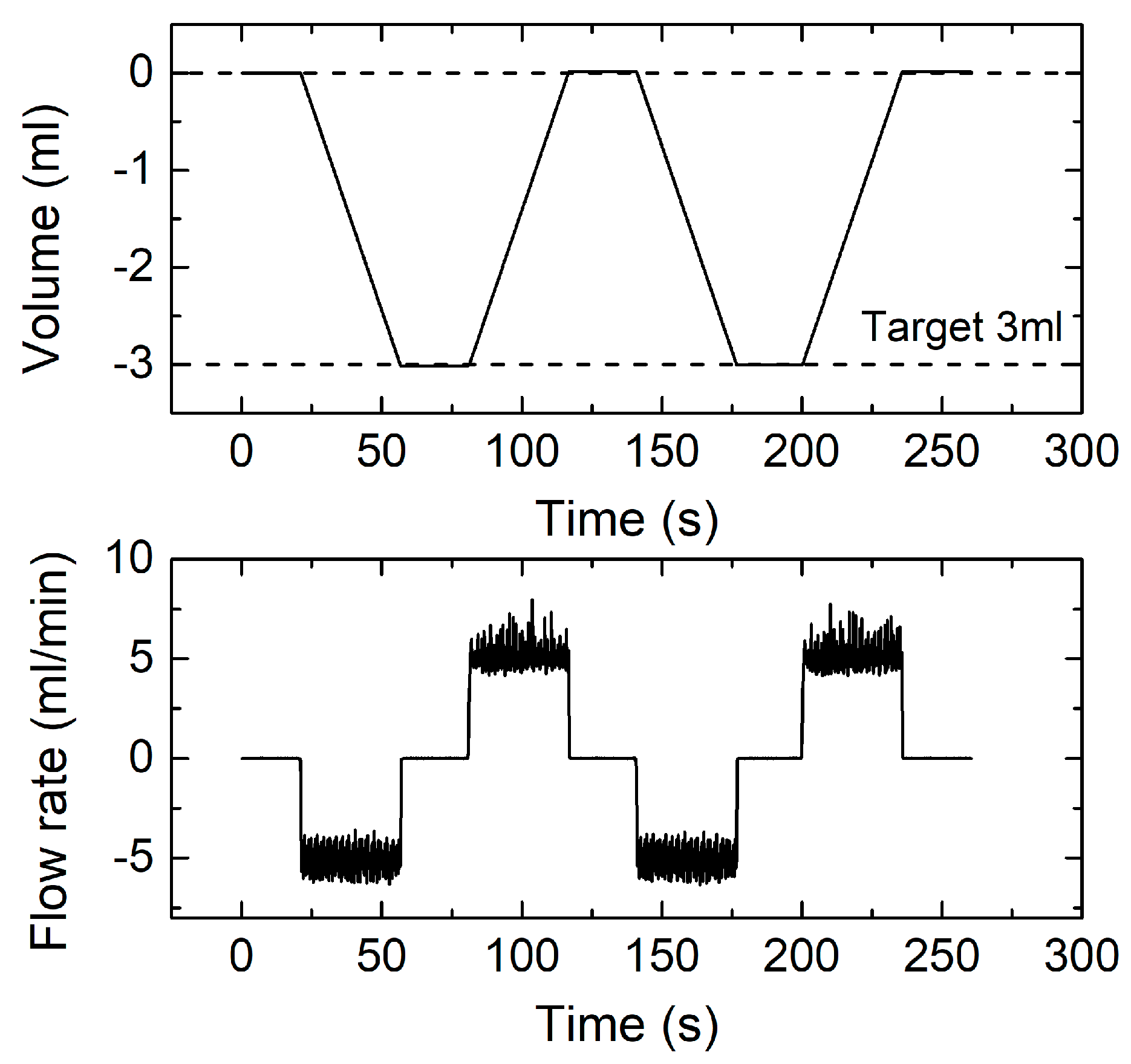

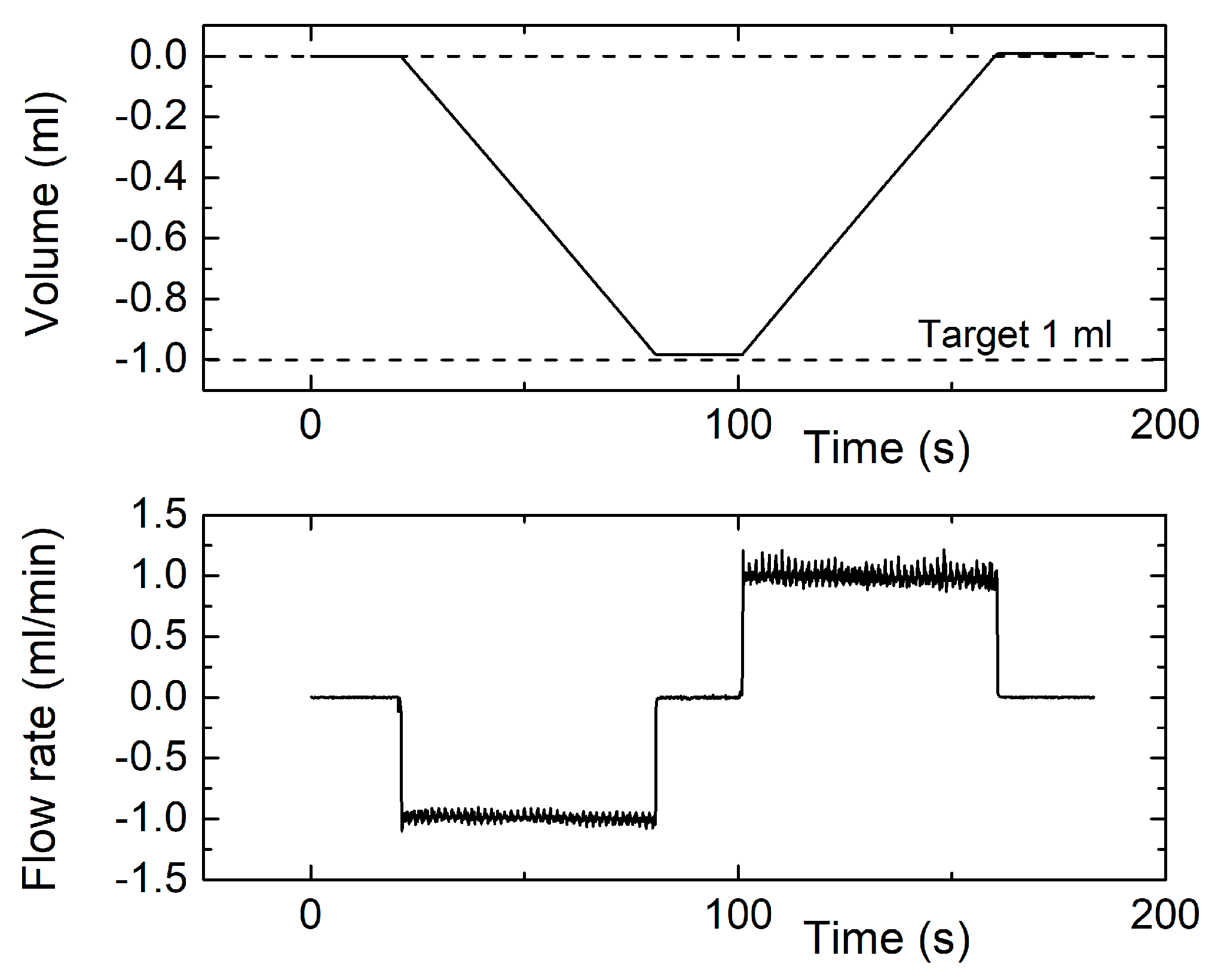

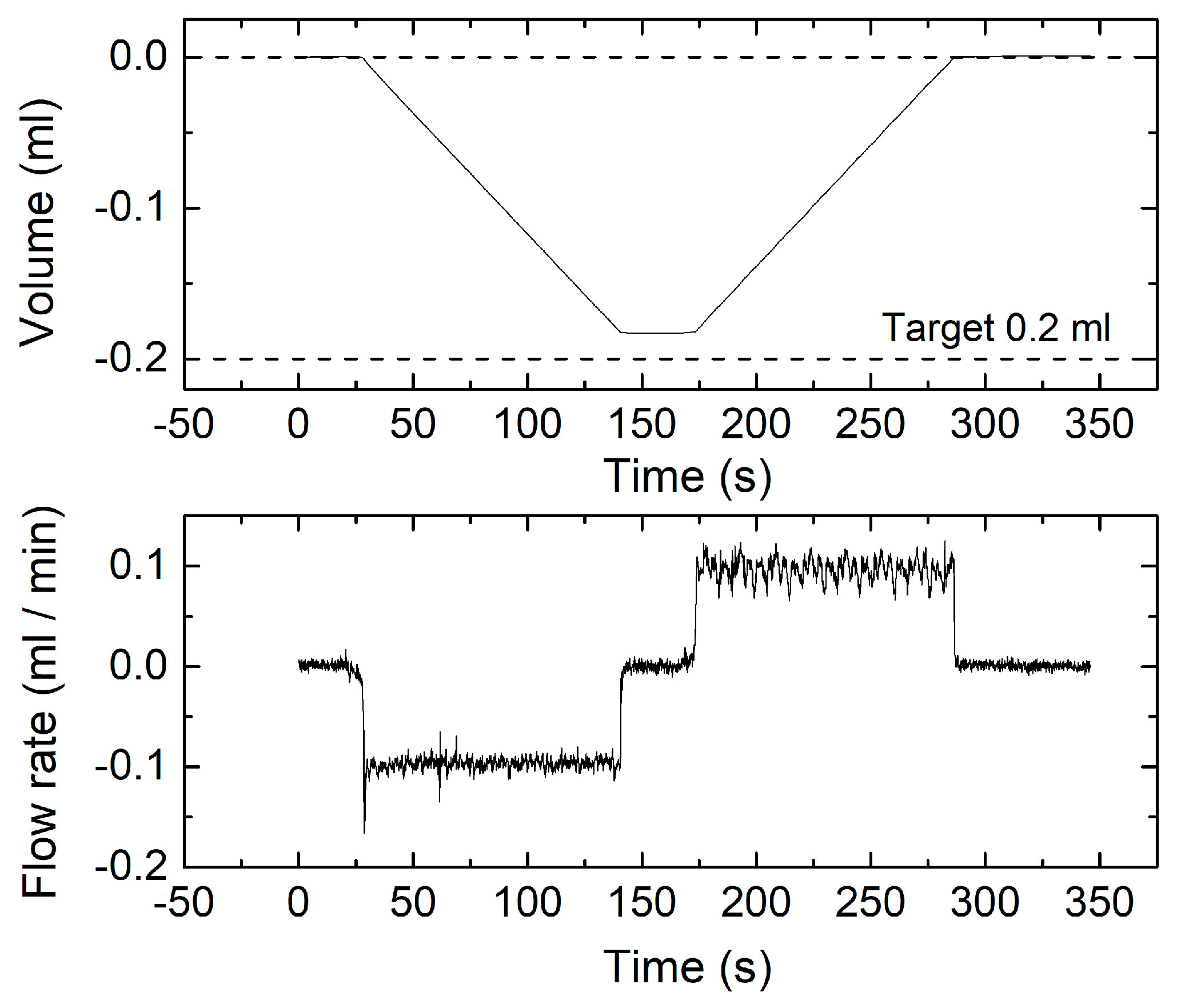

3. Results and Discussion

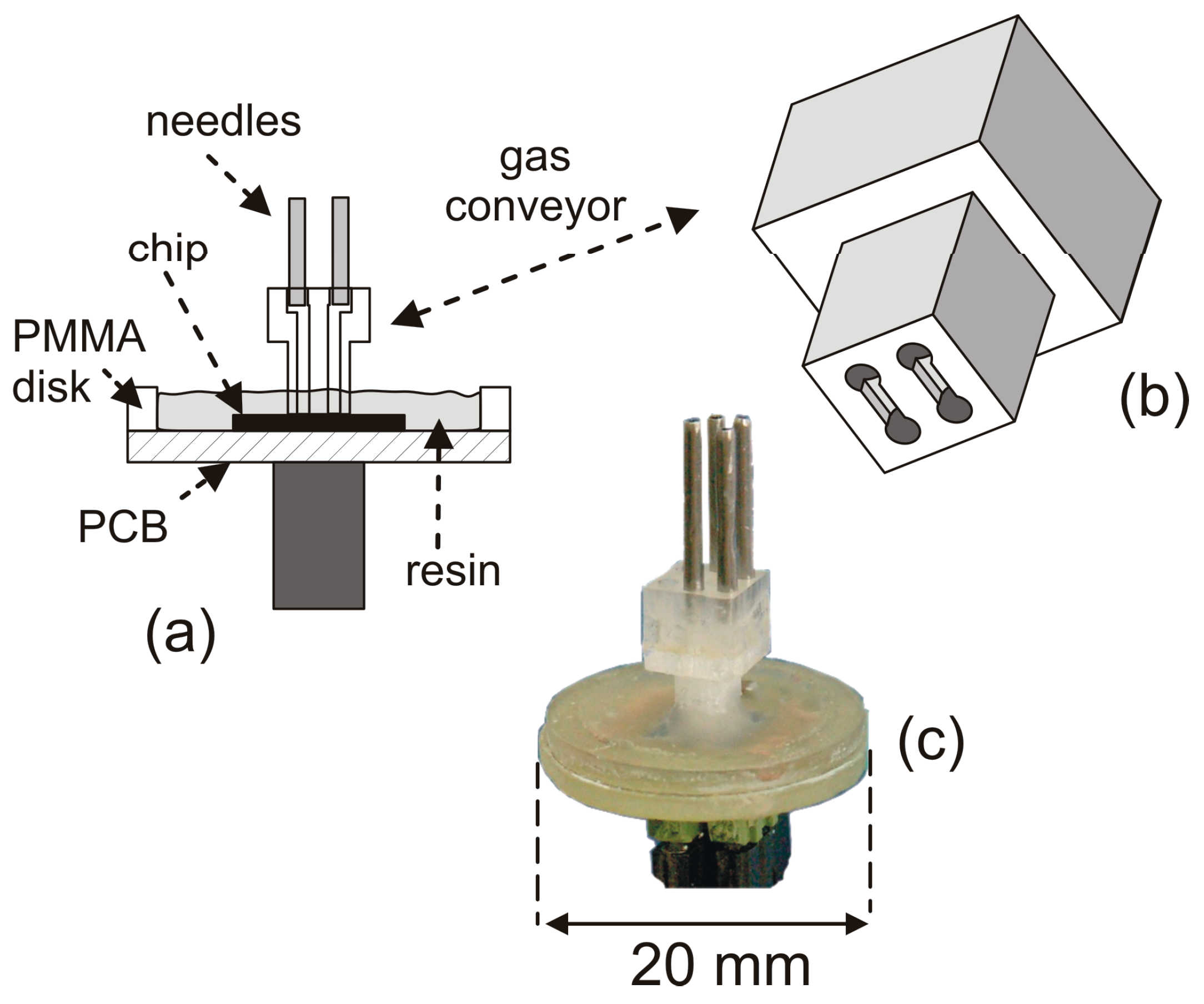

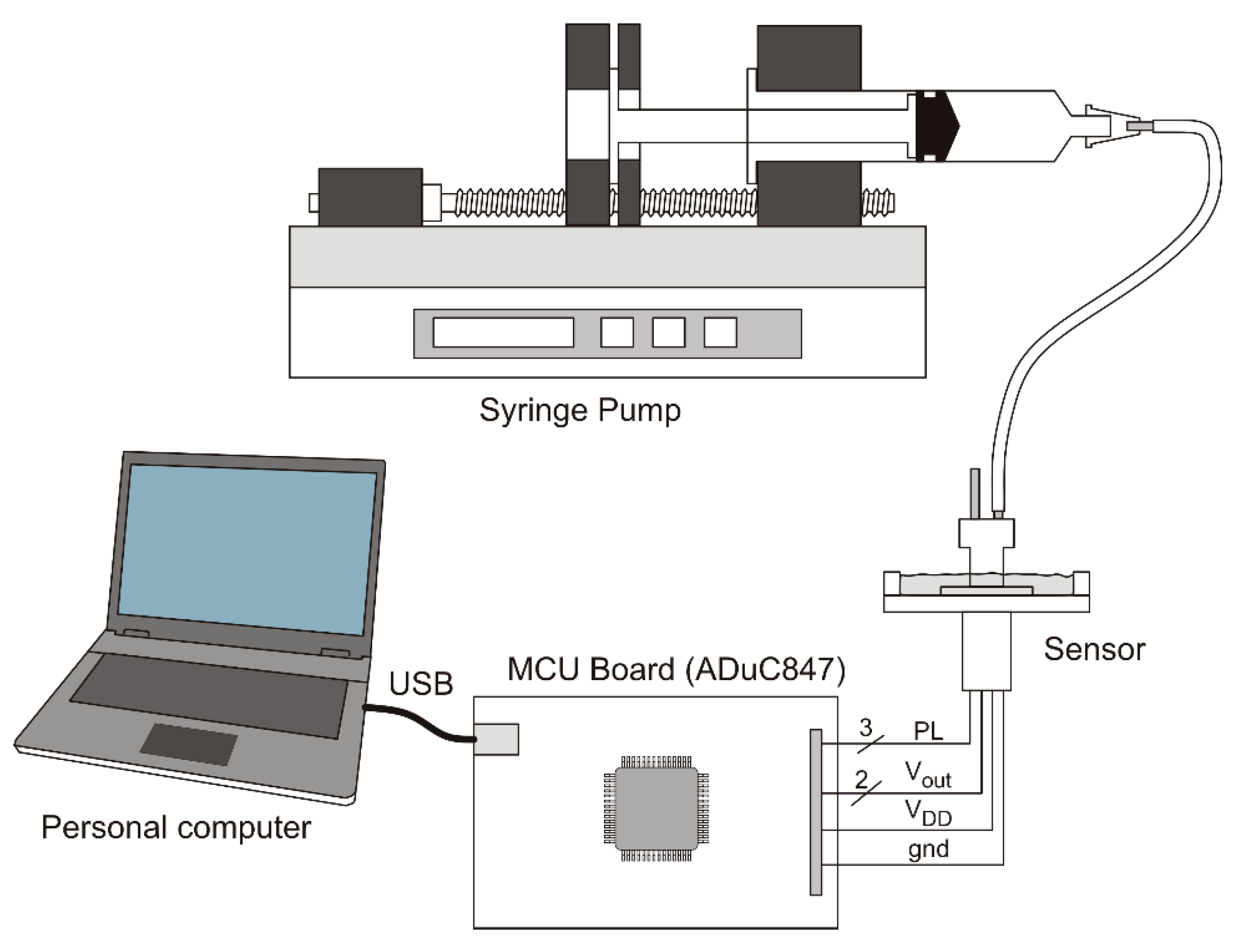

3.1. Experimental Setup

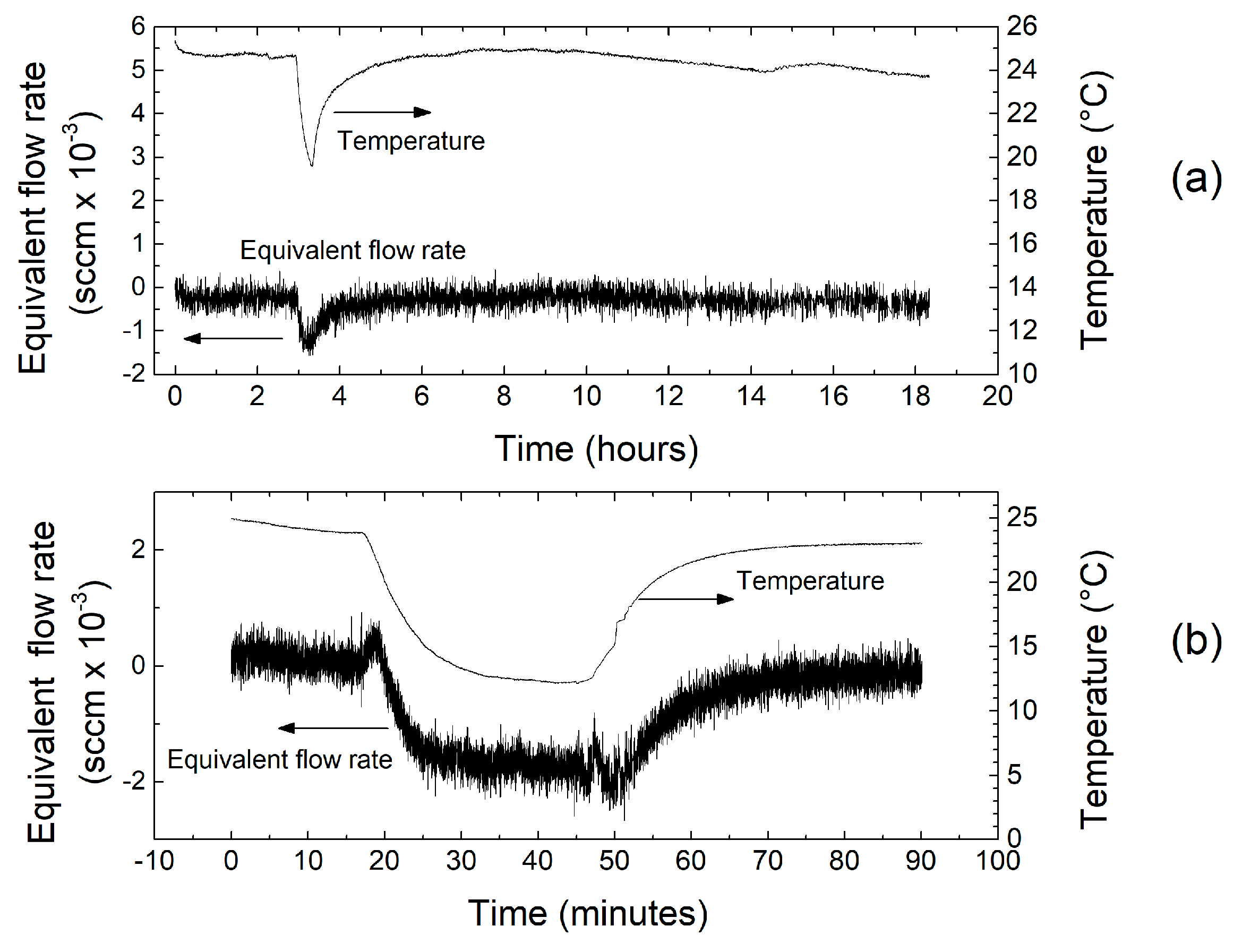

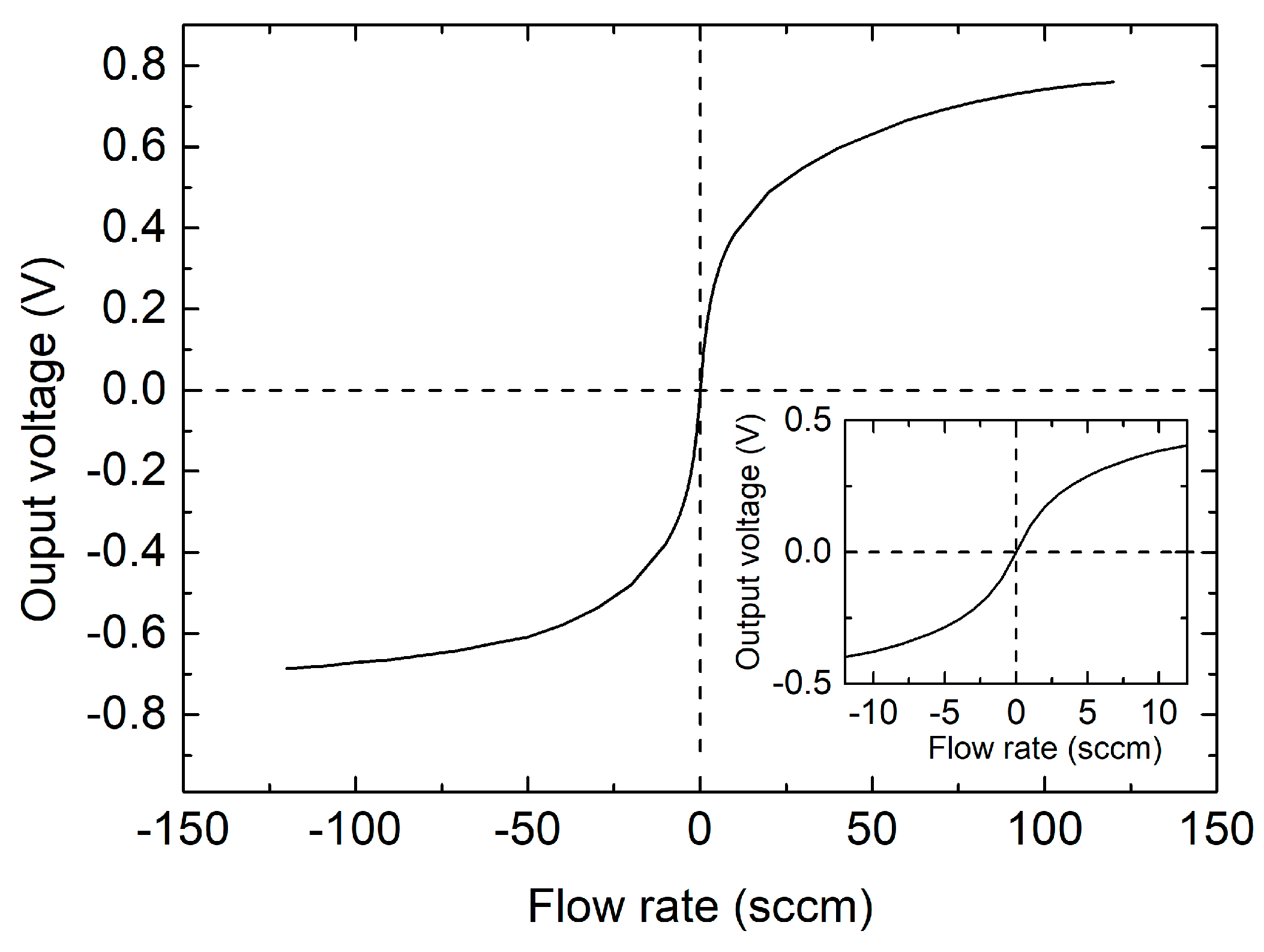

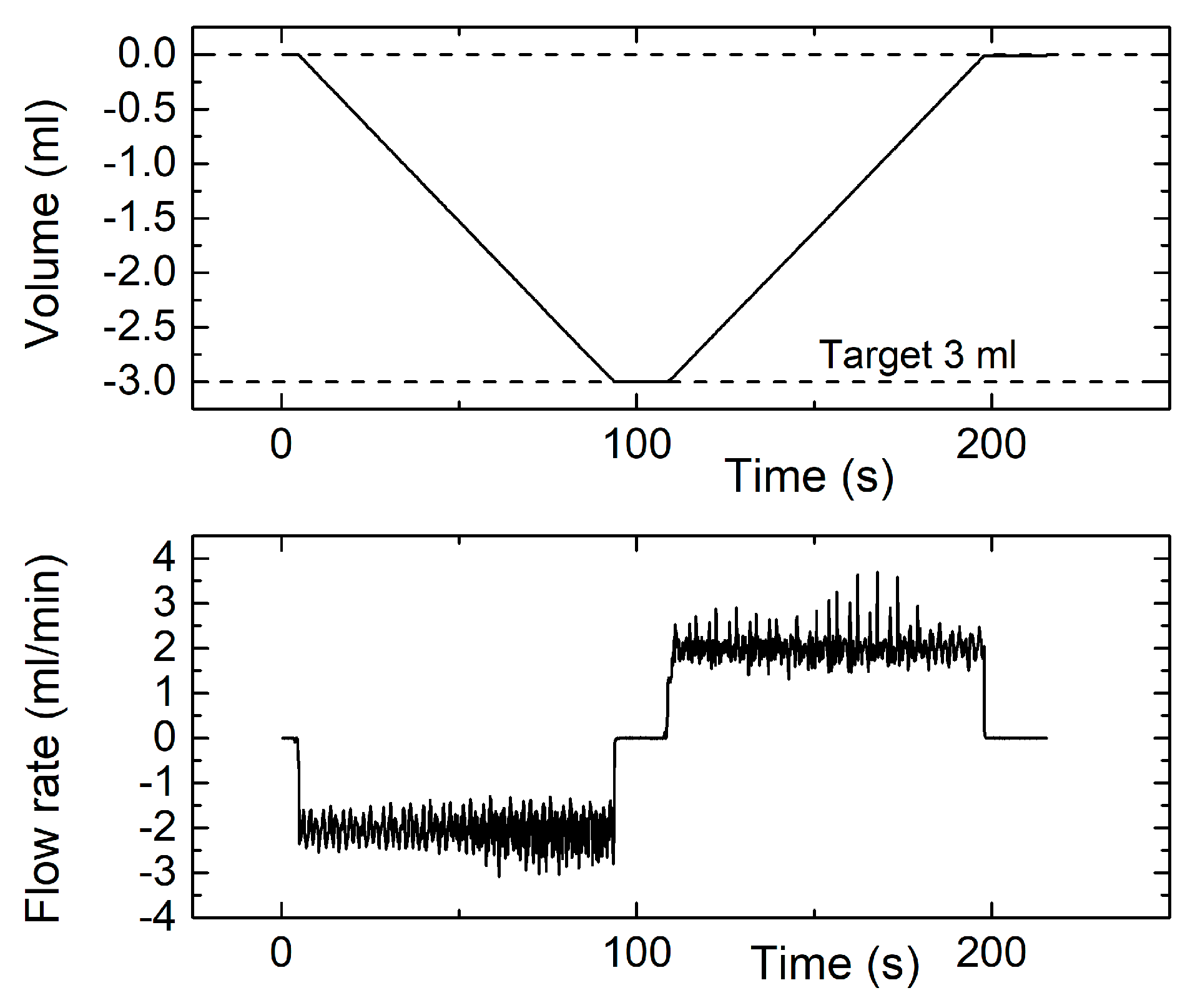

3.2. Sensor Calibration and Characterization

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tison, S.A. A critical evaluation of thermal mass flow meters. J. Vac. Sci. Technol. A 1996, 14, 2582–2591. [Google Scholar] [CrossRef]

- Van Oudheusden, B.W. Silicon thermal flow sensors. Sens. Actuators A Phys. 1992, 30, 5–26. [Google Scholar] [CrossRef]

- Nguyen, N.T. Micromachined flow sensors—A review. Flow Meas. Instrum. 1997, 8, 7–16. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Chen, C.-P.; Chang, C.-M.; Lin, C.-P.; Lin, C.-H.; Fu, L.-M.; Lee, C.-Y. MEMS-based gas flow sensors. Microfluid. Nanofluid. 2009, 6, 333–346. [Google Scholar] [CrossRef]

- Kuo, J.T.W.; Yu, L.; Meng, E. Micromachined Thermal Flow Sensors—A Review. Micromachines 2012, 3, 550–573. [Google Scholar] [CrossRef]

- Yoon, E.; Wise, K.D. An integrated mass flow sensor with on-chip CMOS interface circuitry. IEEE Trans. Electron. Dev. 1992, 39, 1376–1386. [Google Scholar] [CrossRef]

- Hogenbirk, E.J.; Verhoeven, H.-J.; Huijsing, J.H. An integrated smart sensor for flow and temperature with I2 C bus interface: FTS2. In Proceedings of the IEEE I International Symposium on Circuits and Systems, Seattle, WA, USA, 30 April–3 May 1995; pp. 2225–2228. [Google Scholar] [CrossRef]

- Mullins, M.; Bayford, R.; Van Putten, A.; Butcher, J. Design and fabrication of single-chip intelligent silicon thermal flow sensors in standard CMOS technology. In Proceedings of the IEE Colloquium on Advances in Sensors for Fluid Flow Measurement, London, UK, 18 April 1996; p. 14. [Google Scholar] [CrossRef]

- Mayer, F. CMOS based sensors: From a sample to real products. In Proceedings of the IEEE 21st International Conference on Micro Electro Mechanical Systems, Wuhan, China, 13–17 January 2008; pp. 1–5. [Google Scholar] [CrossRef]

- Piotto, M.; Dei, M.; Buttim, F.; Pennellim, G.; Bruschim, P. Smart flow sensor with on-chip CMOS interface performing offset and pressure effect compensation. IEEE Sens. J. 2012, 12, 3309–3317. [Google Scholar] [CrossRef]

- Huang, L. City Natural Gas Metering. In Natural Gas—Extraction to End Use; Gupta, S.B., Ed.; InTech: Rijeka, Croatia, 2012; pp. 181–208. Available online: https://www.intechopen.com/books/natural-gas-extraction-to-end-use/city-natural-gas-metering (accessed on 30 October 2017). [CrossRef]

- Ficco, G.; Celenza, L.; Dell’Isola, M.; Frattolillo, A.; Vigo, P. Experimental evaluation of thermal mass smart meters influence factors. J. Nat. Gas Sci. Eng. 2016, 32, 556–565. [Google Scholar] [CrossRef]

- Hedrich, F.; Kliche, K.; Storz, M.; Billat, S.; Ashauer, M.; Zengerle, R. Thermal flow sensors for MEMS spirometric devices. Sens. Actuators A 2010, 162, 373–378. [Google Scholar] [CrossRef]

- Laghrouche, M.; Saddaoui, R.; Mellal, I.; Nachef, M.; Ameura, S. Low-cost Embedded Spirometer Based on commercial Micro machined Platinum Thin Film. Procedia Eng. 2016, 168, 1681–1684. [Google Scholar] [CrossRef]

- Ghafar-Zadeh, E.; Gholamzadeh, B.; Ayala-Charca, G.; Raveri, P.B.; Matynia, M.; Sawan, M.; Awwad, F.; Magierowski, S. Toward spirometry-on-chip: Design, implementation and experimental results. Microsyst. Technol. 2017, 23, 4591–4598. [Google Scholar] [CrossRef]

- Liao, S.-H.; Chen, W.-J.; Lu, M.S.-C. A CMOS MEMS Capacitive Flow Sensor for Respiratory Monitoring. IEEE Sens. J. 2013, 13, 1401–1402. [Google Scholar] [CrossRef]

- Habibiabad, S.; Doğrusöz, Y.S.; Beyazc, M.İ. Characterization and performance estimation of a MEMS spirometer. Procedia Eng. 2016, 168, 1020–1023. [Google Scholar] [CrossRef]

- Piotto, M.; Del Cesta, F.; Bruschi, P. Integrated smart gas flow sensor with 2.6 mW total power consumption and 80 dB dynamic range. Microelectron. Eng. 2016, 159, 159–163. [Google Scholar] [CrossRef]

- Ashauer, M.; Glosch, H.; Hedrich, F.; Hey, N.; Sandmaier, H.; Lang, W. Thermal flow sensor for liquids and gases based on combinations of two principles. Sens. Actuators A Phys. 1999, 73, 7–13. [Google Scholar] [CrossRef]

- Bruschi, P.; Dei, M.; Piotto, M. An offset compensation method with low residual drift for integrated thermal flow sensors. IEEE Sens. J. 2011, 11, 1162–1167. [Google Scholar] [CrossRef]

- Piotto, M.; Longhitano, A.N.; Del Cesta, F.; Bruschi, P. Automatic compensation of pressure effects on smart flow sensors in the analog and digital domain. Sens. Actuators A Phys. 2014, 206, 171–177. [Google Scholar] [CrossRef]

- Van den Dool, B.J.; Huijsing, J.H. Indirect current feedback instrumentation amplifier with a common-mode input range that includes the negative rail. IEEE J. Solid-State Circuits 1993, 28, 743–749. [Google Scholar] [CrossRef]

- Butti, F.; Piotto, M.; Bruschi, P. A chopper instrumentation amplifier with input resistance boosting by means of synchronous dynamic element matching. IEEE Trans. Circuits Syst. I: Regul. Pap. 2016, 64, 753–764. [Google Scholar] [CrossRef]

- Bruschi, P.; Dei, M.; Piotto, M. A single chip, double channel thermal flow meter. Microsyst. Technol. 2009, 15, 1179–1186. [Google Scholar] [CrossRef]

- Bruschi, P.; Piotto, M.; Bacci, N. Postprocessing, readout and packaging methods for integrated gas flow sensors. Microelectron. J. 2009, 40, 1300–1307. [Google Scholar] [CrossRef]

- Issa, S.; Lang, W. Minimum detectable air velocity by thermal flow sensors. Sensors 2013, 13, 10944–10953. [Google Scholar] [CrossRef] [PubMed]

- Elwenspoek, M.; Wiegerink, R. Mechanical Microsensors, 1st ed.; Springer: Berlin, Germany, 2001; pp. 153–208. ISBN 978-3-642-08706-6. [Google Scholar]

| Code | Amplifier Input Voltage |

|---|---|

| 0 | VT1 |

| 1 | 0 (input short circuited) |

| 2 | VT2 |

| 3 | VT1–VT2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piotto, M.; Del Cesta, S.; Bruschi, P. Precise Measurement of Gas Volumes by Means of Low-Offset MEMS Flow Sensors with μL/min Resolution. Sensors 2017, 17, 2497. https://doi.org/10.3390/s17112497

Piotto M, Del Cesta S, Bruschi P. Precise Measurement of Gas Volumes by Means of Low-Offset MEMS Flow Sensors with μL/min Resolution. Sensors. 2017; 17(11):2497. https://doi.org/10.3390/s17112497

Chicago/Turabian StylePiotto, Massimo, Simone Del Cesta, and Paolo Bruschi. 2017. "Precise Measurement of Gas Volumes by Means of Low-Offset MEMS Flow Sensors with μL/min Resolution" Sensors 17, no. 11: 2497. https://doi.org/10.3390/s17112497