Designing and Testing a UAV Mapping System for Agricultural Field Surveying

Abstract

:1. Introduction

2. Materials

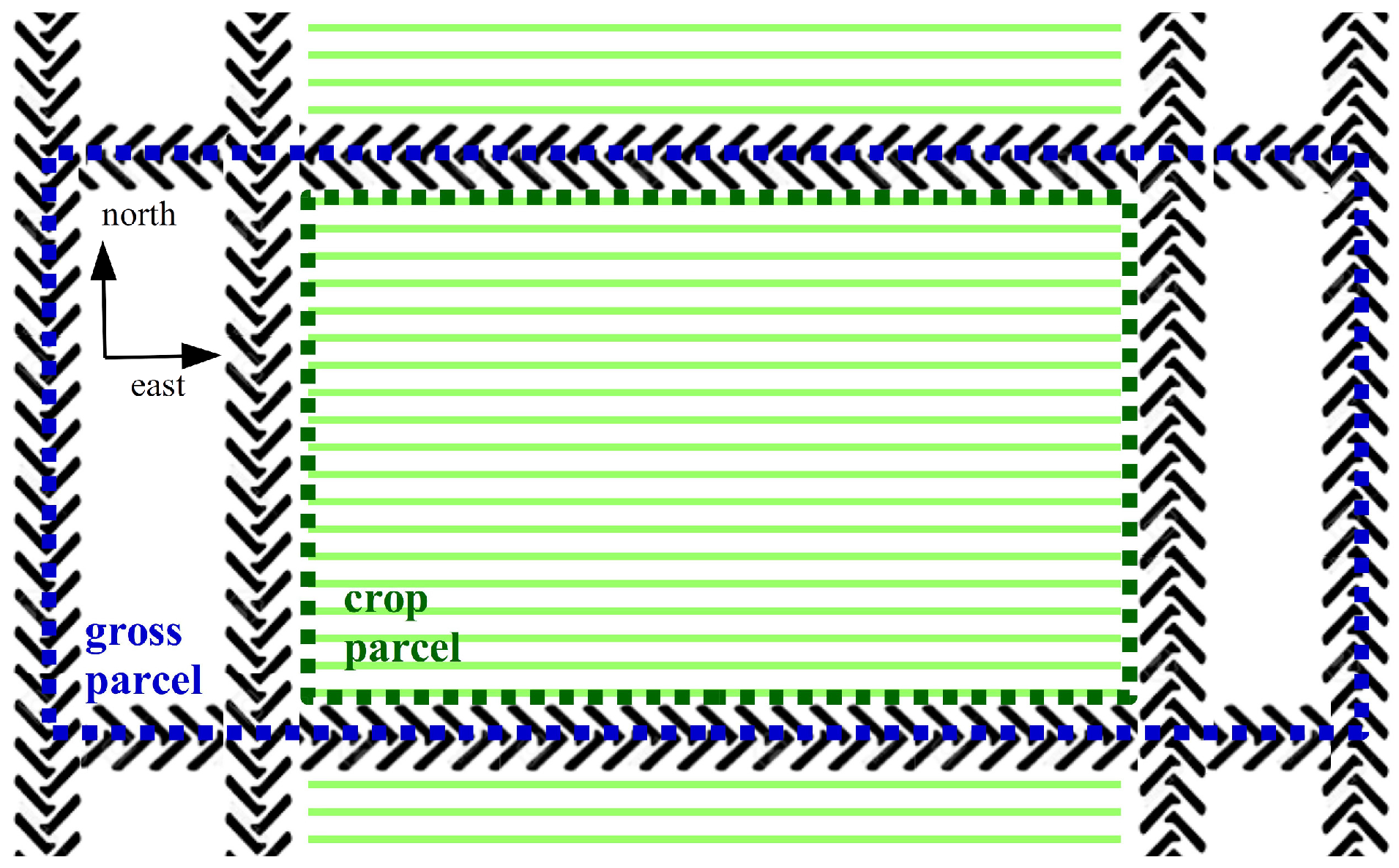

2.1. Crop Area for Recording Data

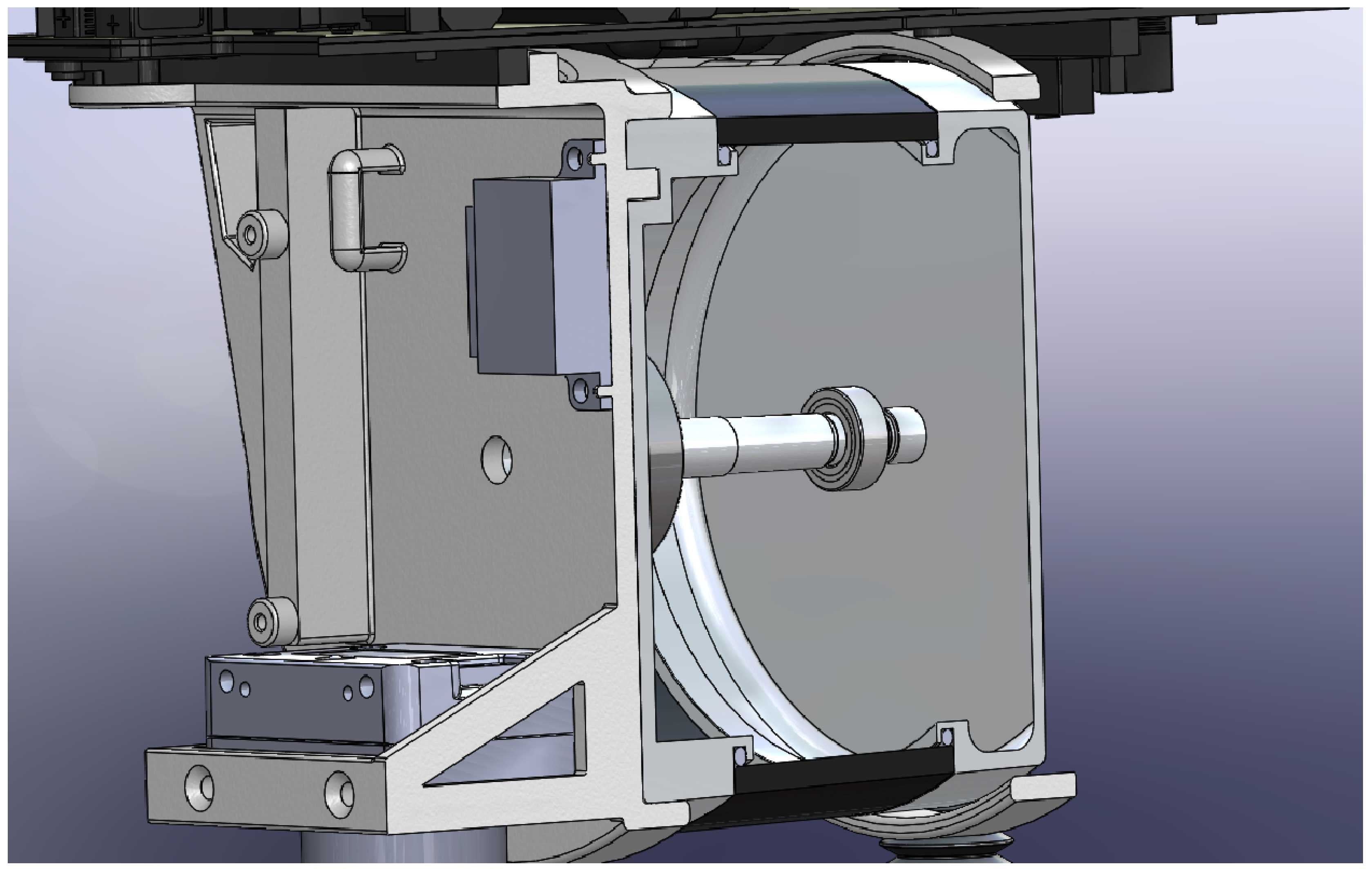

2.2. UAV and Sensor Setup

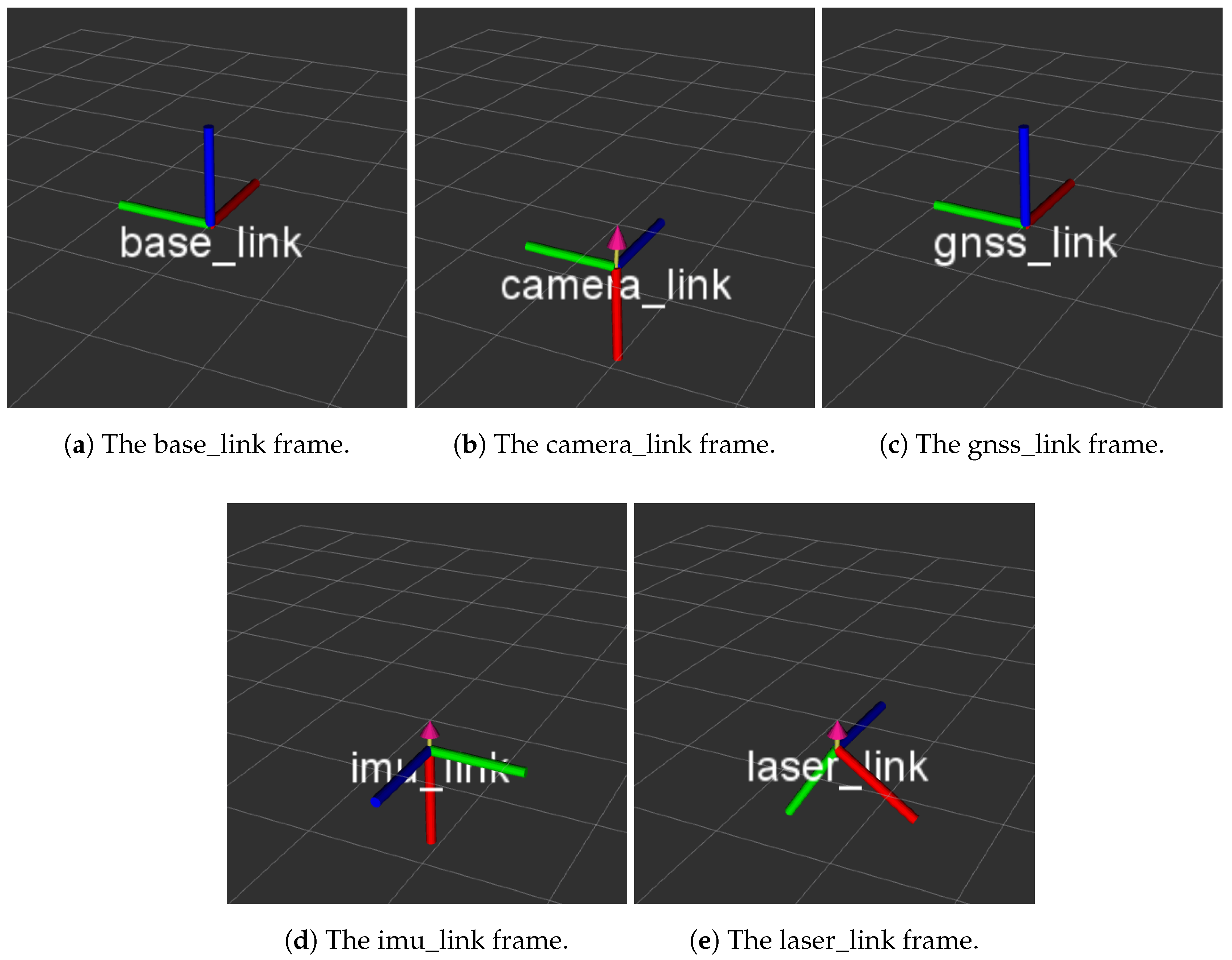

2.3. Recording Software Setup

2.4. UAV Steering Using Litchi

3. Methods

3.1. Data Recording

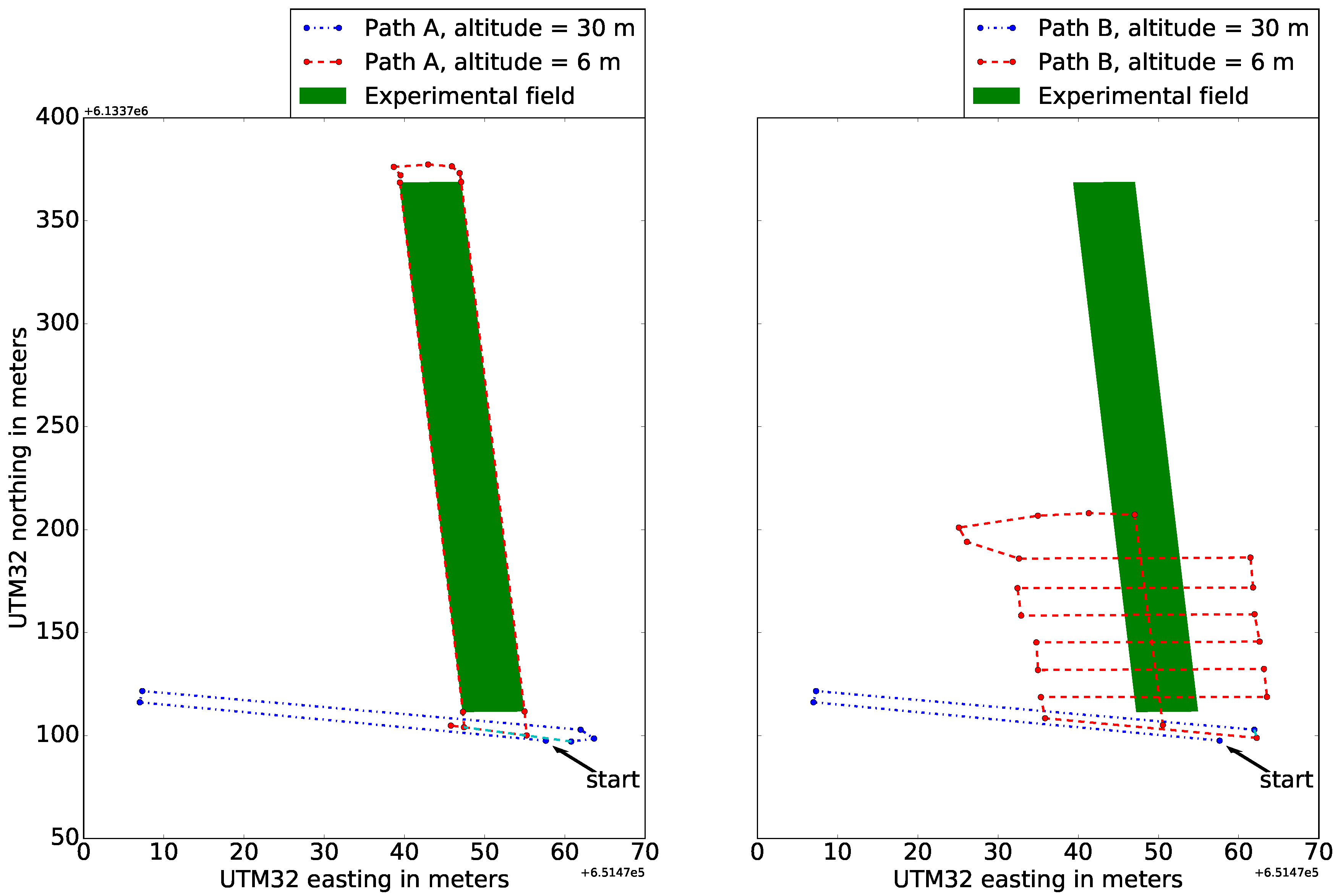

3.2. Flight and Recording Procedure

3.3. Pose Estimation Post Processing

Merging GNSS, IMU and DJI Data

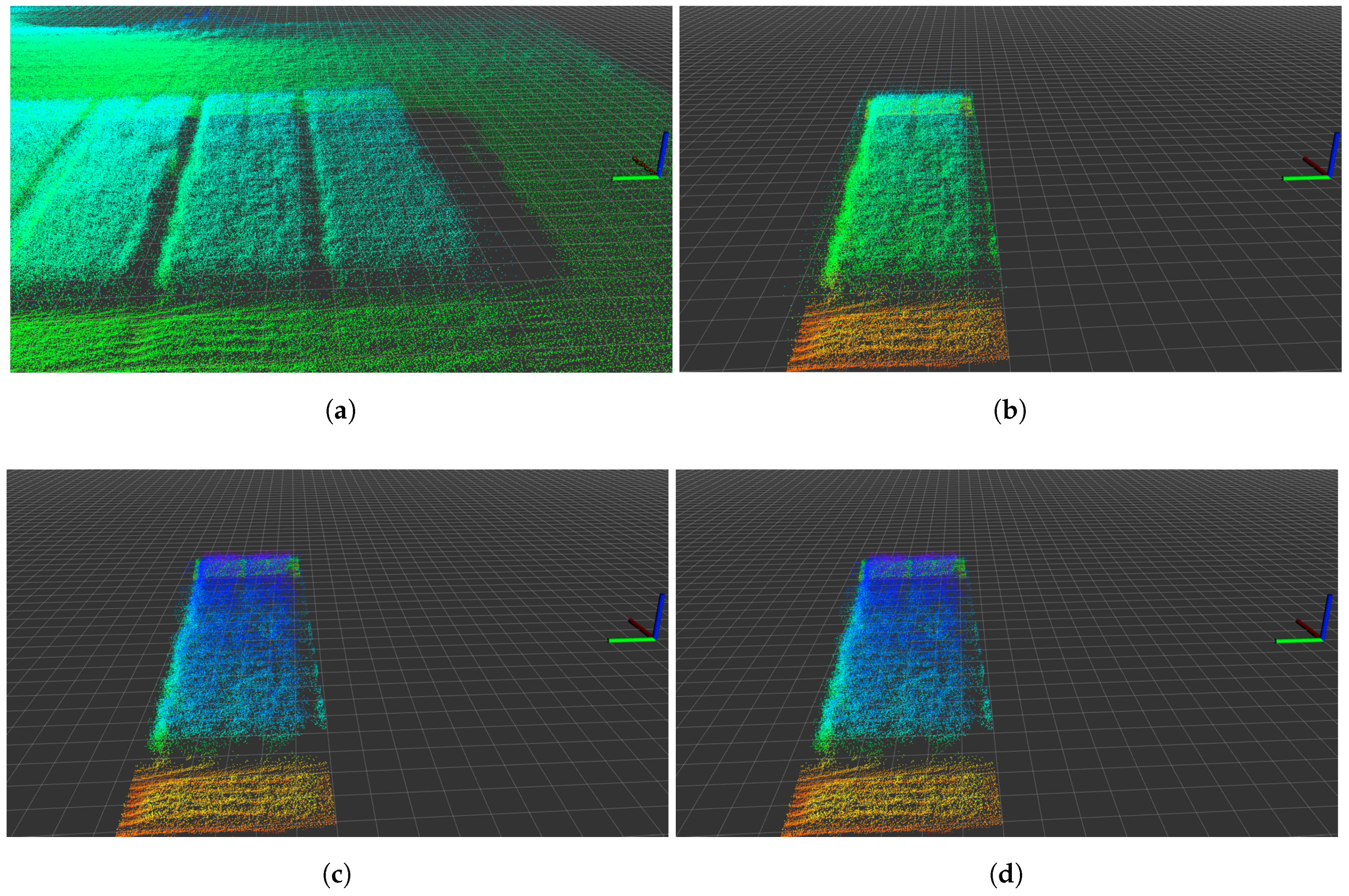

3.4. LiDAR Point-Cloud Mapping and Processing

3.4.1. Area Extraction Using Point-In-Polygon

3.4.2. Statistical Outlier Removal

3.4.3. Voxelisation

3.5. Voxel Grid Processing and Crop Parcel Parameter Estimation

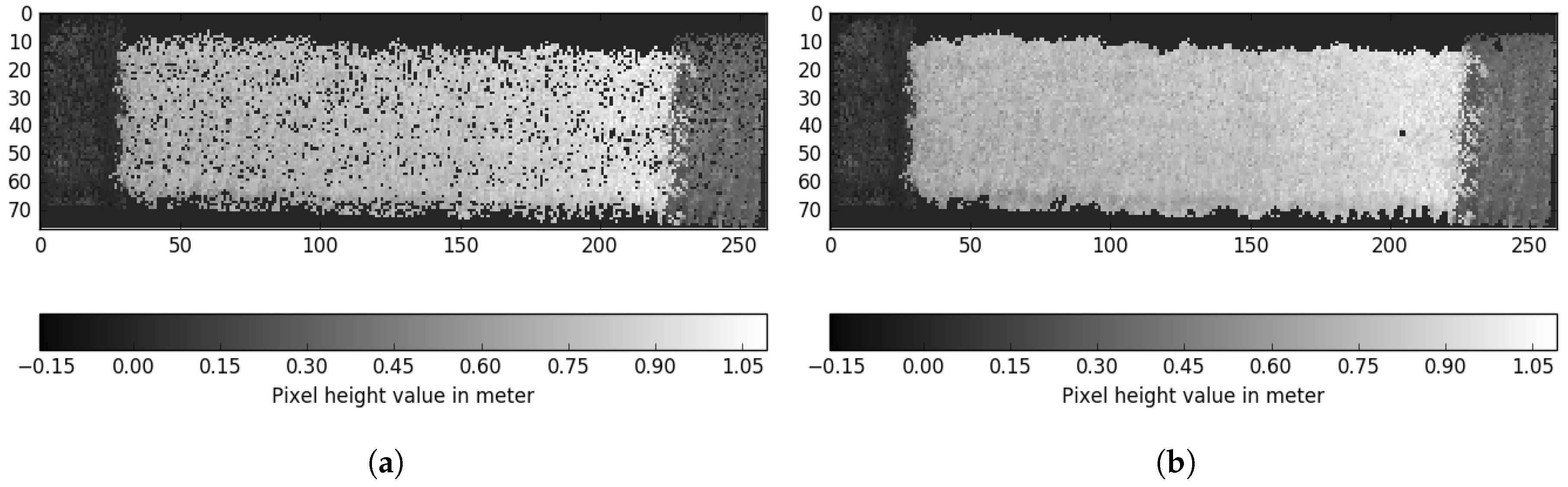

3.5.1. Conversion from Voxel to Pixel Grid

3.5.2. Interpolation of Missing Grid Pixels

3.5.3. Estimating Ground Level below the Crop Parcels

3.5.4. Crop Parcel Extraction

3.6. Correlating Crop Height to N-Application

4. Results

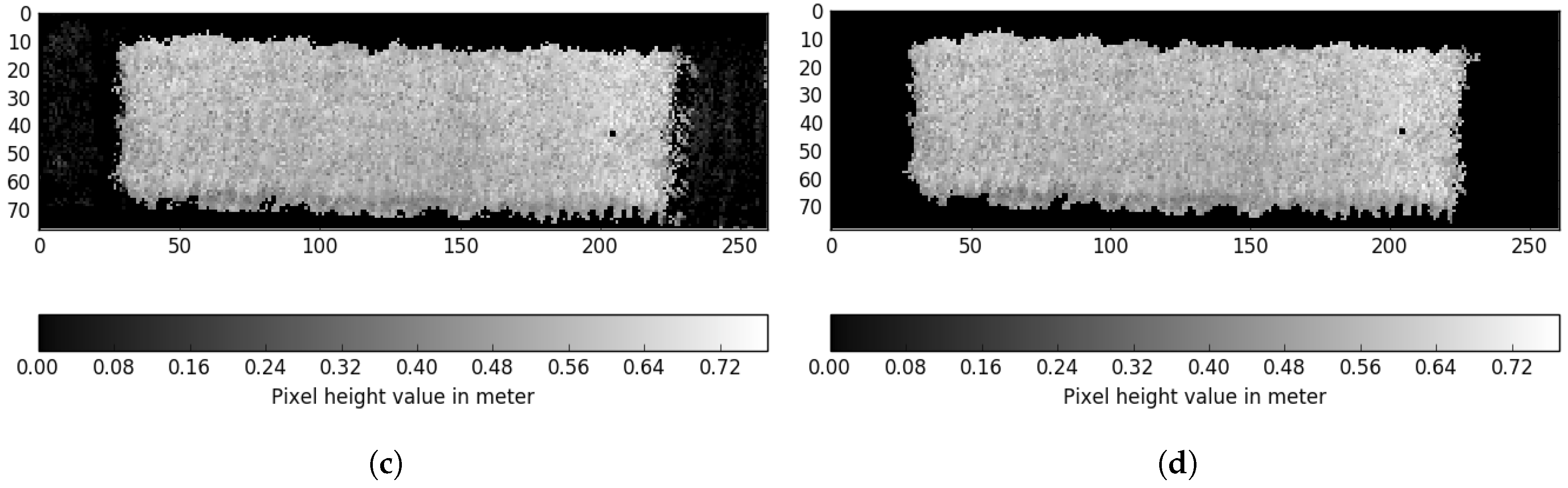

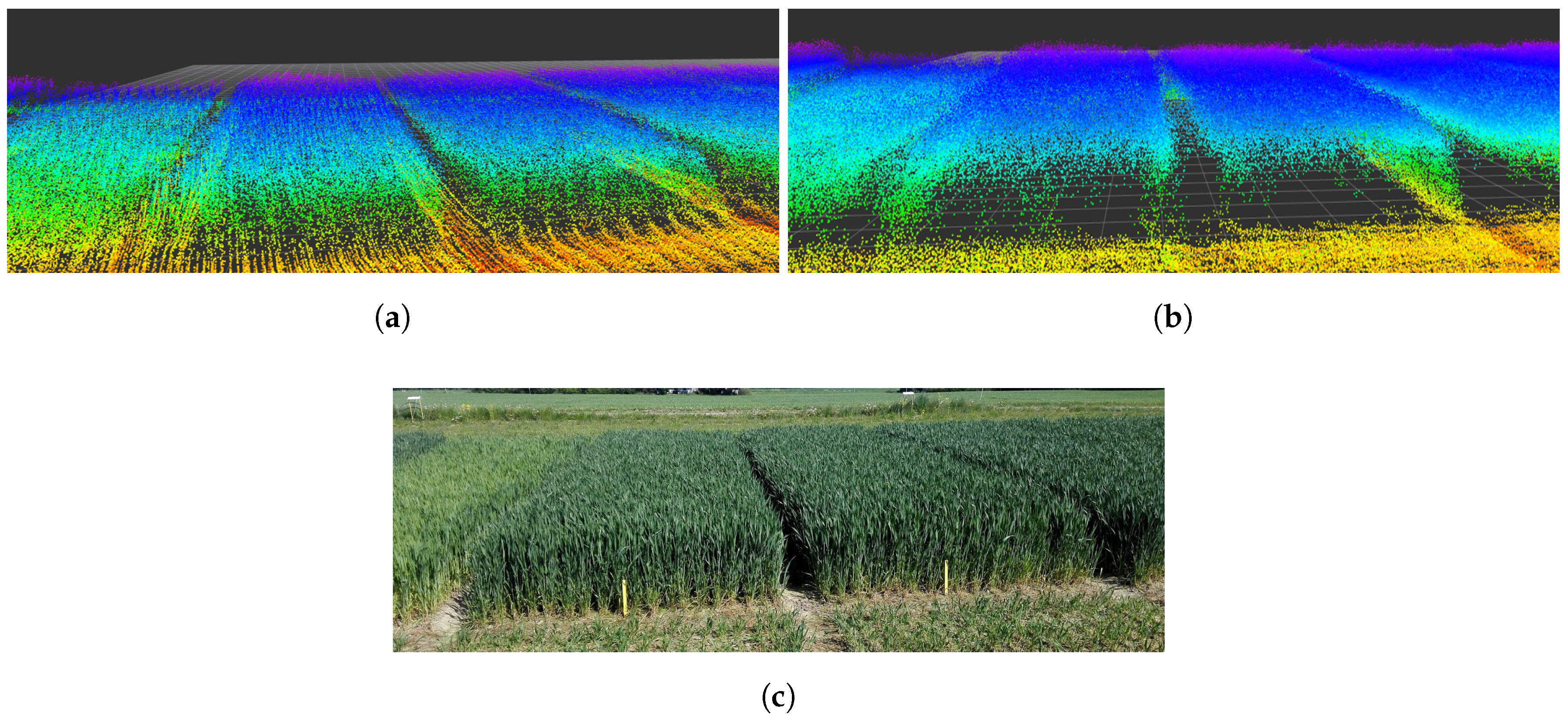

4.1. Experimental Field Mapping

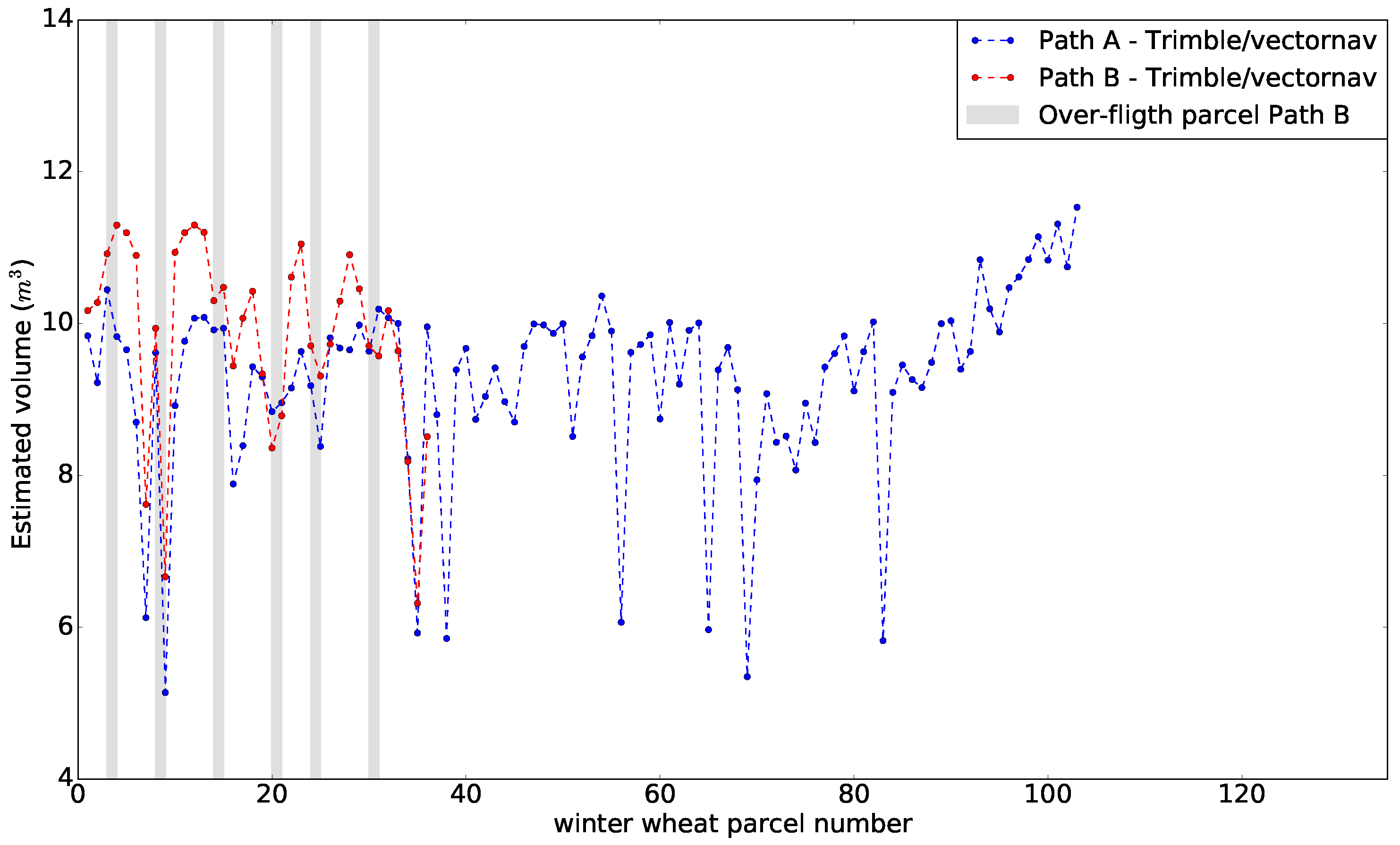

4.2. Crop Parcel Comparison

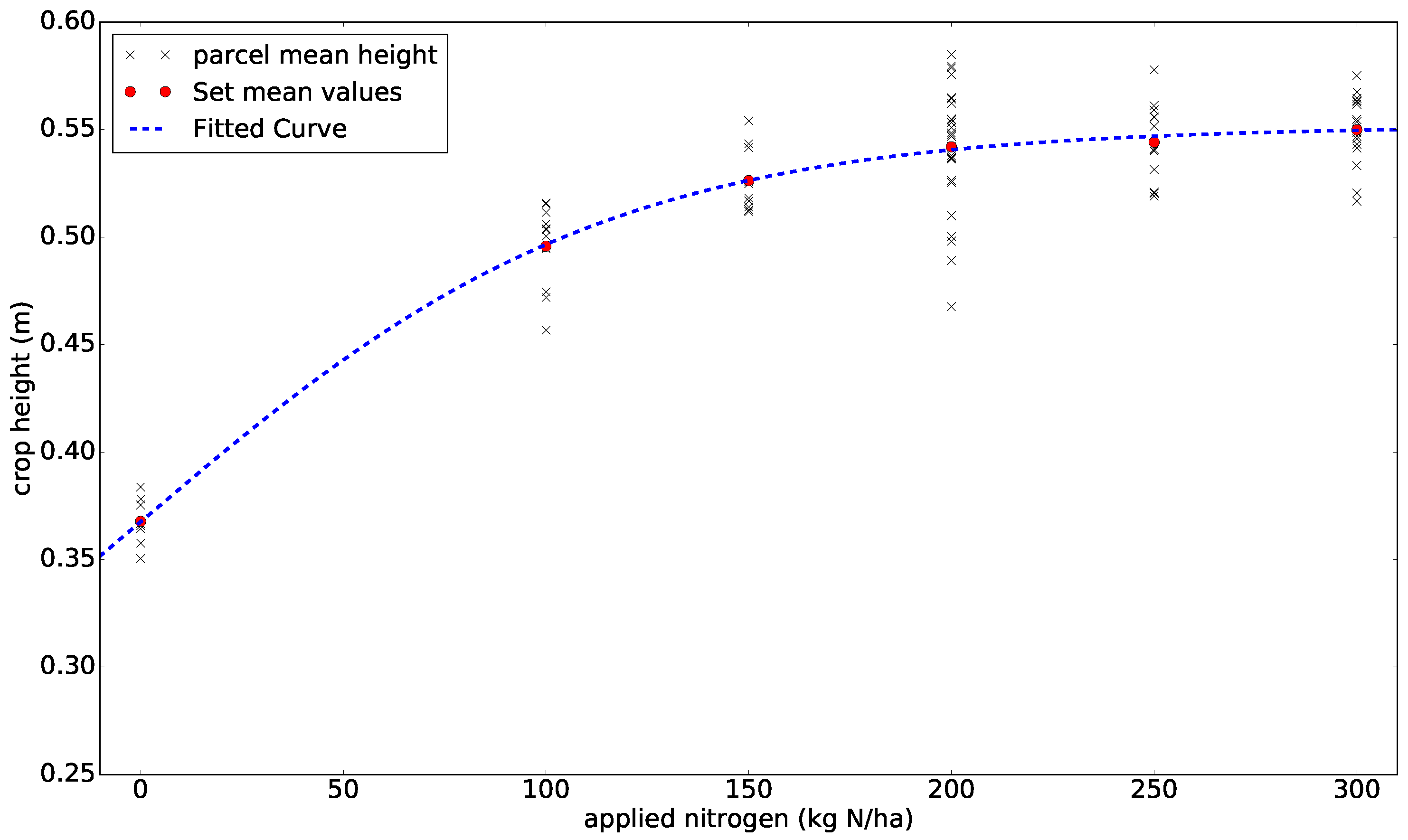

4.3. Crop Height and Nitrogen Correlation

4.4. Volume Estimates

5. Discussion

6. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| CAD | Computer-Aided Design |

| DJI | Dà-Jiāng Innovations Science and Technology Co. |

| GNSS | Global Navigation Satellite System |

| LiDAR | Light Detection and Ranging |

| IMU | Inertial Measurement Unit |

| IO | Input/Output |

| PPS | Pulse-Per-Second |

| PCL | Point Cloud Library |

| RGB | Red, Green and Blue |

| REP | ROS Enhancement Proposal |

| RMS | Root Mean Square |

| ROS | Robot Operating System |

| RTK | Real Time Kinematic |

| SPI | Serial Peripheral Interface-bus |

| UAV | Unmanned Aerial Vehicle |

| UTM | Universal Transverse Mercator |

| WGS | World Geodetic System |

Appendix A

| Treatment | Treatment Plan | Test Parcels |

|---|---|---|

| 1 | 0 kg N/ha | 7,33,54,67 |

| 2 | 50 kg N/ha (16th March) + 50 kg N/ha (20th April) | 18,42,60,82 |

| 3 | 50 kg N/ha (16th March) + 100 kg N/ha (20th April) | 20,35,50,83 |

| 4 | 50 kg N/ha (16th March) + 150 kg N/ha (20th April) | 1,38,48,84 |

| 5 | 50 kg N/ha (16th March) + 200 kg N/ha (20th April) | 13,30,57,66 |

| 6 | 50 kg N/ha (16th March) + 250 kg N/ha (20th April) | 9,31,52,77 |

| 7 | 50 kg N/ha (16th March) + 50 kg N/ha (20th April) + 100 kg N/ha (5th May) | 8,40,47,70 |

| 8 | 50 kg N/ha (16th March) + 50 kg N/ha (20th April) + 150 kg N/ha (5th May) | 17,25,53,64 |

| 9 | 50 kg N/ha (16th March) + 50 kg N/ha (20th April) + 200 kg N/ha (5th May) | 2,26,56,71 |

| 10 | 50 kg N/ha (16th March) + 100 kg N/ha (20th April) + 50 kg N/ha (5th May) | 3,29,62,73 |

| 11 | 50 kg N/ha (16th March) + 100 kg N/ha (20th April) + 100 kg N/ha (5th May) | 10,22,59,76 |

| 12 | 50 kg N/ha (16th March) + 100 kg N/ha (20th April) + 150 kg N/ha (5th May) | 12,24,45,75 |

| 13 | 50 kg N/ha (16th March) + 50 kg N/ha (20th April) + 100 kg N/ha (05th May) + 50 kg N/ha (7th June) | 6,37,61,78 |

| 14 | 100 kg N/ha (16th March) | 14,39,49,72 |

| 15 | 200 kg N/ha (16th March) | 11,27,51,80 |

| 16 | 0 kg N/ha + JumpStart2.0 | 5,36,63,81 |

| 17 | 50 kg N/ha (16th March) + 50 kg N/ha (20th April) + JumpStart2.0 | 19,32,43,74 |

| 18 | 50 kg N/ha (16th March) + 100 kg N/ha (20th April) + JumpStart2.0 | 4,41,44,79 |

| 19 | 50 kg N/ha (16th March) + 150 kg N/ha (20th April) + JumpStart2.0 | 21,28,55,65 |

| 20 | 50 kg N/ha (16th March) + 150 kg N/ha (20th April) | 16,34,46,69 |

| 21 | 50 kg N/ha (16th March) + 150 kg N/ha (20th April) + 100 kg N/ha (5th May) | 15,23,58,68 |

Appendix B

| Transform | x | y | z | |||

|---|---|---|---|---|---|---|

| base_link->camera_link | −0.0545 | 0 | −0.424 | 0 | 0 | |

| base_link->gnss_link | 0 | 0 | 0 | 0 | 0 | 0 |

| base_link->imu_link | −0.039 | −0.008 | −0.294 | 0 | ||

| base_link->laser_link | 0 | 0.013 | −0.304 | − | 0.593233 | − |

References

- Senay, G.; Ward, A.; Lyon, J.; Fausey, N.; Nokes, S. Manipulation of high spatial resolution aircraft remote sensing data for use in site-specific farming. Trans. ASAE 1998, 41, 489. [Google Scholar] [CrossRef]

- Rudd, J.D.; Roberson, G.T.; Classen, J.J. Application of satellite, unmanned aircraft system, and ground-based sensor data for precision agriculture: A review. In 2017 ASABE Annual International Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017; p. 1. [Google Scholar]

- Matese, A.; Toscano, P.; Di Gennaro, S.F.; Genesio, L.; Vaccari, F.P.; Primicerio, J.; Belli, C.; Zaldei, A.; Bianconi, R.; Gioli, B. Intercomparison of UAV, aircraft and satellite remote sensing platforms for precision viticulture. Remote Sens. 2015, 7, 2971–2990. [Google Scholar] [CrossRef]

- Madsen, S.L.; Dyrmann, M.; Laursen, M.S.; Jørgensen, R.N. RoboWeedSupport-Semi-Automated Unmanned Aerial System for Cost Efficient High Resolution in Sub-Millimeter Scale Acquisition of Weed Images. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2017, 11, 835–839. [Google Scholar]

- Jørgensen, R.; Brandt, M.; Schmidt, T.; Laursen, M.; Larsen, R.; Nørremark, M.; Midtiby, H.; Christiansen, P. Field trial design using semi-automated conventional machinery and aerial drone imaging for outlier identification. In Precision Agriculture’15; Wageningen Academic Publishers: Wageningen, The Netherlands, 2015; pp. 146–151. [Google Scholar]

- DJI Phantom 2 Series. Available online: http://www.dji.com/products/phantom-2-series (accessed on 20 November 2017).

- Bendig, J.; Bolten, A.; Bennertz, S.; Broscheit, J.; Eichfuss, S.; Bareth, G. Estimating biomass of barley using crop surface models (CSMs) derived from UAV-based RGB imaging. Remote Sens. 2014, 6, 10395–10412. [Google Scholar] [CrossRef]

- Bendig, J.; Yu, K.; Aasen, H.; Bolten, A.; Bennertz, S.; Broscheit, J.; Gnyp, M.L.; Bareth, G. Combining UAV-based plant height from crop surface models, visible, and near infrared vegetation indices for biomass monitoring in barley. Int. J. Appl. Earth Obs. Geoinf. 2015, 39, 79–87. [Google Scholar] [CrossRef]

- Lin, Y.; Hyyppa, J.; Jaakkola, A. Mini-UAV-borne LIDAR for fine-scale mapping. IEEE Geosci. Remote Sens. Lett. 2011, 8, 426–430. [Google Scholar] [CrossRef]

- Wallace, L.; Lucieer, A.; Watson, C.; Turner, D. Development of a UAV-LiDAR System with Application to Forest Inventory. Remote Sens. 2012, 4, 1519–1543. [Google Scholar] [CrossRef]

- Tullda, H.M.; Bissmarck, F.; Larsson, H.; Grönwall, C.; Tolt, G. Accuracy evaluation of 3D lidar data from small UAV. In Proceedings of the SPIE Conference on Electro-Optical Remote Sensing, Photonic Technologies, and Applications IX, Toulouse, France, 16 October 2015; pp. 964903–964911. [Google Scholar]

- Khan, S.; Aragão, L.; Iriarte, J. A UAV–lidar system to map Amazonian rainforest and its ancient landscape transformations. Int. J. Remote Sens. 2017, 38, 2313–2330. [Google Scholar]

- Guo, Q.; Su, Y.; Hu, T.; Zhao, X.; Wu, F.; Li, Y.; Liu, J.; Chen, L.; Xu, G.; Lin, G.; et al. An integrated UAV-borne lidar system for 3D habitat mapping in three forest ecosystems across China. Int. J. Remote Sens. 2017, 38, 2954–2972. [Google Scholar] [CrossRef]

- Sankey, T.T.; McVay, J.; Swetnam, T.L.; McClaran, M.P.; Heilman, P.; Nichols, M. UAV hyperspectral and lidar data and their fusion for arid and semi-arid land vegetation monitoring. Remote Sens. Ecol. Conserv. 2017. [Google Scholar] [CrossRef]

- Jozkow, G.; Totha, C.; Grejner-Brzezinska, D. UAS Topographic Mapping with Velodyne Lidar Sensor. ISPRS Ann. Photogram. Remote Sens. Spatial Inf. Sci. 2016, 3, 201–208. [Google Scholar] [CrossRef]

- Anthony, D.; Elbaum, S.; Lorenz, A.; Detweiler, C. On crop height estimation with UAVs. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014), Chicago, IL, USA, 14–18 September 2014; pp. 4805–4812. [Google Scholar]

- Anthony, D.; Detweiler, C. UAV Localization in Row Crops. J. Field Robot. 2017, 34, 1275–1296. [Google Scholar] [CrossRef]

- Jensen, T.; Munkholm, L.J.; Green, O.; Karstoft, H. A mobile surface scanner for soil studies. In Proceedings of the Second International Conference on Robotics and Associated High-Technologies and Equipment for Agriculture and Forestry, Madrid, Spain, 21–23 May 2014; pp. 187–194. [Google Scholar]

- Andújar, D.; Rueda-Ayala, V.; Moreno, H.; Rosell-Polo, J.R.; Valero, C.; Gerhards, R.; Fernández-Quintanilla, C.; Dorado, J.; Griepentrog, H.W.; et al. Discriminating crop, weeds and soil surface with a terrestrial LIDAR sensor. Sensors 2013, 13, 14662–14675. [Google Scholar] [CrossRef] [PubMed]

- Reiser, D.; Vázquez Arellano, M.; Garrido Izard, M.; Griepentrog, H.W.; Paraforos, D.S. Using Assembled 2D LiDAR Data for Single Plant Detection. In Proceedings of the 5th International Conference on Machine Control & Guidance, Vichy, France, 5–6 October 2016. [Google Scholar]

- Jensen, T.; Karstoft, H.; Green, O.; Munkholm, L.J. Assessing the effect of the seedbed cultivator leveling tines on soil surface properties using laser range scanners. Soil Tillage Res. 2017, 167, 54–60. [Google Scholar] [CrossRef]

- Jaeger-Hansen, C.L.; Griepentrog, H.W.; Andersen, J.C. Navigation and tree mapping in orchards. In Proceedings of the International Conference of Agricultural Engineering, Valencia, Spain, 8–12 July 2012. [Google Scholar]

- Underwood, J.P.; Jagbrant, G.; Nieto, J.I.; Sukkarieh, S. Lidar-Based Tree Recognition and Platform Localization in Orchards. J. Field Robot. 2015, 32, 1056–1074. [Google Scholar] [CrossRef]

- Andújar, D.; Rosell-Polo, J.R.; Sanz, R.; Rueda-Ayala, V.; Fernández-Quintanilla, C.; Ribeiro, A.; Dorado, J. A LiDAR-based system to assess poplar biomass. Gesunde Pflanz. 2016, 68, 155–162. [Google Scholar] [CrossRef]

- Maguire, R.; Alley, M.M.; Flowers, W. Fertilizer Types and Calculating Application Rates; Communications and Marketing, College of Agriculture and Life Sciences, Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 2009. [Google Scholar]

- Santi, C.; Bogusz, D.; Franche, C. Biological nitrogen fixation in non-legume plants. Ann. Bot. 2013, 111, 743–767. [Google Scholar] [CrossRef] [PubMed]

- Marschner, H. Marschner’s Mineral Nutrition of Higher Plants, 2nd ed.; Academic Press: Cambridge, MA, USA, 1995; Chapter 11–12. [Google Scholar]

- Mulla, D.; Schepers, J. Key processes and properties for site-specific soil and crop management. In The State of Site-Specific Management for Agriculture; ACSESS: Madison, WI, USA, 1997; pp. 1–18. [Google Scholar]

- Gislum, R.; Boelt, B. Validity of accessible critical nitrogen dilution curves in perennial ryegrass for seed production. Field Crops Res. 2009, 111, 152–156. [Google Scholar] [CrossRef]

- Eitel, J.U.; Magney, T.S.; Vierling, L.A.; Brown, T.T.; Huggins, D.R. LiDAR based biomass and crop nitrogen estimates for rapid, non-destructive assessment of wheat nitrogen status. Field Crops Res. 2014, 159, 21–32. [Google Scholar] [CrossRef]

- Schirrmann, M.; Giebel, A.; Gleiniger, F.; Pflanz, M.; Lentschke, J.; Dammer, K.H. Monitoring Agronomic Parameters of Winter Wheat Crops with Low-Cost UAV Imagery. Remote Sens. 2016, 8, 706. [Google Scholar] [CrossRef]

- DJI Matrice 100. Available online: https://www.dji.com/matrice100 (accessed on 20 November 2017).

- UAV LiDAR Project Homepage. Available online: https://vision.eng.au.dk/future-cropping/uav_lidar/ (accessed on 20 November 2017).

- Quigley, M.; Conley, K.; Gerkey, B.P.; Faust, J.; Foote, T.; Leibs, J.; Wheeler, R.; Ng, A.Y. ROS: An open-source Robot Operating System. In Proceedings of the ICRA Workshop on Open Source Software, Kobe, Japan, 12–17 May 2009. [Google Scholar]

- Carvalho, J.P.; Jucá, M.A.; Menezes, A.; Olivi, L.R.; Marcato, A.L.M.; dos Santos, A.B. Autonomous UAV Outdoor Flight Controlled by an Embedded System Using Odroid and ROS. In CONTROLO 2016: Proceedings of the 12th Portuguese Conference on Automatic Control; Garrido, P., Soares, F., Moreira, A.P., Eds.; Springer: Berlin, Germany, 2017; pp. 423–437. [Google Scholar]

- ROS REP-103. Available online: http://www.ros.org/reps/rep-0103.html (accessed on 20 November 2017).

- Velodyne LiDAR. VLP-16. In VLP-16 Manual: User’s Manual and Programming Guide; Velodyne LiDAR, Inc.: San Jose, CA, USA, 2016. [Google Scholar]

- VectorNav. VN-200 GPS/INS; VectorNav Technologies: Dallas, TX, USA; Available online: https://www.vectornav.com/products/vn-200 (accessed on 20 November 2017).

- Litchi for DJI Mavic/Matrice/Phantom/Inspire/Spark. Available online: https://flylitchi.com/ (accessed on 25 September 2017).

- Hsieh, C.T. An efficient development of 3D surface registration by Point Cloud Library (PCL). In Proceedings of the 2012 International Symposium on Intelligent Signal Processing and Communications Systems (ISPACS), Taipei, Taiwan, 4–7 November 2012; pp. 729–734. [Google Scholar]

- Popescu, S.C.; Zhao, K. A voxel-based lidar method for estimating crown base height for deciduous and pine trees. Remote Sens. Environ. 2008, 112, 767–781. [Google Scholar] [CrossRef]

- Wu, B.; Yu, B.; Yue, W.; Shu, S.; Tan, W.; Hu, C.; Huang, Y.; Wu, J.; Liu, H. A voxel-based method for automated identification and morphological parameters estimation of individual street trees from mobile laser scanning data. Remote Sens. 2013, 5, 584–611. [Google Scholar] [CrossRef]

- Parker, J.A.; Kenyon, R.V.; Troxel, D.E. Comparison of interpolating methods for image resampling. IEEE Trans. Med. Imaging 1983, 2, 31–39. [Google Scholar] [CrossRef] [PubMed]

- Revol, C.; Jourlin, M. A new minimum variance region growing algorithm for image segmentation. Pattern Recognit. Lett. 1997, 18, 249–258. [Google Scholar] [CrossRef]

- Richards, F. A flexible growth function for empirical use. J. Exp. Bot. 1959, 10, 290–301. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, S. Features and partial derivatives of Bertalanffy-Richards growth model in forestry. Nonlinear Anal. Model. Control 2004, 9, 65–73. [Google Scholar]

- Li, B.; Zhang, T.; Xia, T. Vehicle detection from 3d lidar using fully convolutional network. arXiv, 2016; arXiv:1608.07916. [Google Scholar]

- Becker, C.; Häni, N.; Rosinskaya, E.; d’Angelo, E.; Strecha, C. Classification of Aerial Photogrammetric 3D Point Clouds. arXiv, 2017; arXiv:1705.08374. [Google Scholar]

- Hackel, T.; Savinov, N.; Ladicky, L.; Wegner, J.D.; Schindler, K.; Pollefeys, M. Semantic3D. net: A new Large-scale Point Cloud Classification Benchmark. arXiv, 2017; arXiv:1704.03847. [Google Scholar]

- FutureCropping Reseach Project. Available online: https://futurecropping.dk/ (accessed on 20 November 2017).

- ROS REP-105. Available online: http://www.ros.org/reps/rep-0105.html (accessed on 20 November 2017).

| Sensor Output | Sampling Rate | Notes |

|---|---|---|

| DJI ROS sdk | 50 Hz | (DJI OS time, attitude Quaternion), Baud = 230400 |

| VectorNav IMU (1) | 50 Hz | (Gyro, Acceleration, Quaternion, TimeGps), Baud = 115200 |

| VectorNav IMU (2) | 20 Hz | (INS, TimeUTC, TimeGps, TimeSyncIn), Baud = 115200 |

| VectorNav IMU (3) | 4 Hz | (GPS, TimeUTC, TimeGps, Fix, sats), Baud = 115200 |

| Velodyne LiDAR | 10 Hz | RPM = 600, strongest return |

| Point Grey Camera | 10 Hz | Resolution = , 8 bits per pixel |

| Trimble GNSS (1) | 10 Hz | GPGGA, Baud-rate = 115200, usb-serial |

| Trimble GNSS (2) | 20 Hz | GPRMC, Baud-rate = 115200, usb-serial |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Christiansen, M.P.; Laursen, M.S.; Jørgensen, R.N.; Skovsen, S.; Gislum, R. Designing and Testing a UAV Mapping System for Agricultural Field Surveying. Sensors 2017, 17, 2703. https://doi.org/10.3390/s17122703

Christiansen MP, Laursen MS, Jørgensen RN, Skovsen S, Gislum R. Designing and Testing a UAV Mapping System for Agricultural Field Surveying. Sensors. 2017; 17(12):2703. https://doi.org/10.3390/s17122703

Chicago/Turabian StyleChristiansen, Martin Peter, Morten Stigaard Laursen, Rasmus Nyholm Jørgensen, Søren Skovsen, and René Gislum. 2017. "Designing and Testing a UAV Mapping System for Agricultural Field Surveying" Sensors 17, no. 12: 2703. https://doi.org/10.3390/s17122703