Classification of Multiple Chinese Liquors by Means of a QCM-based E-Nose and MDS-SVM Classifier

Abstract

:1. Introduction

2. Experiments and Methods

2.1. Chinese Liquor Samples

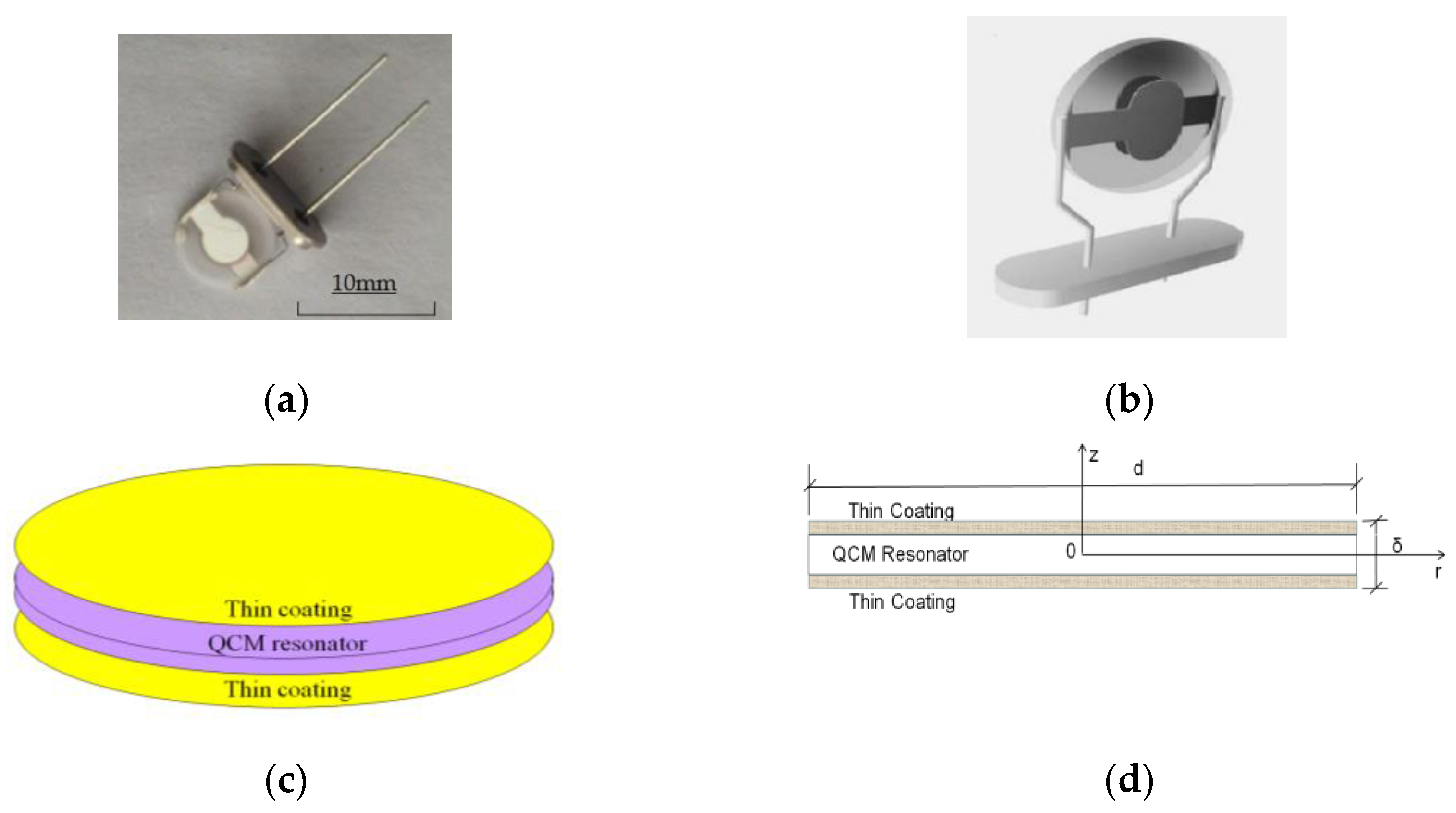

2.2. QCM-Based Sensor

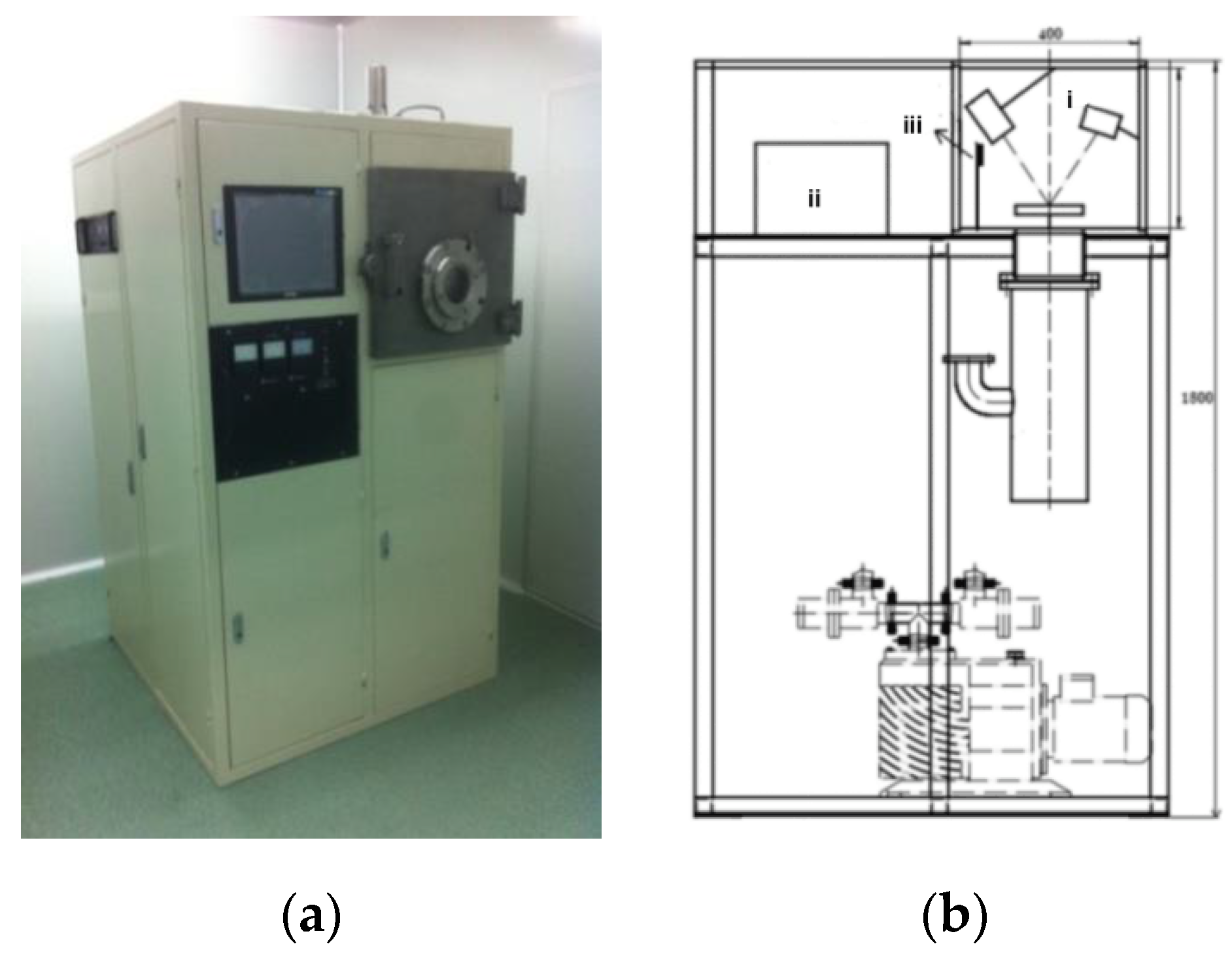

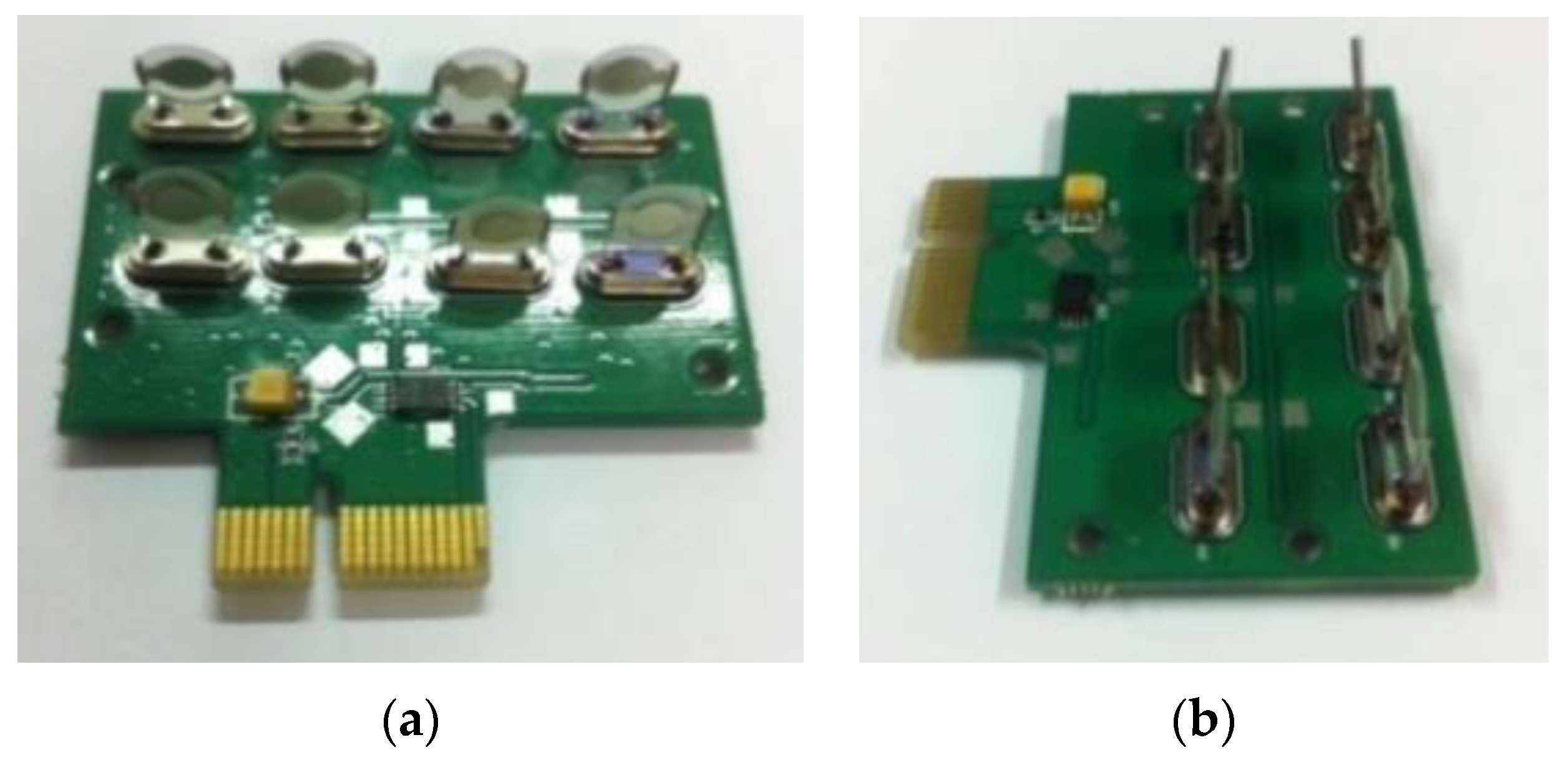

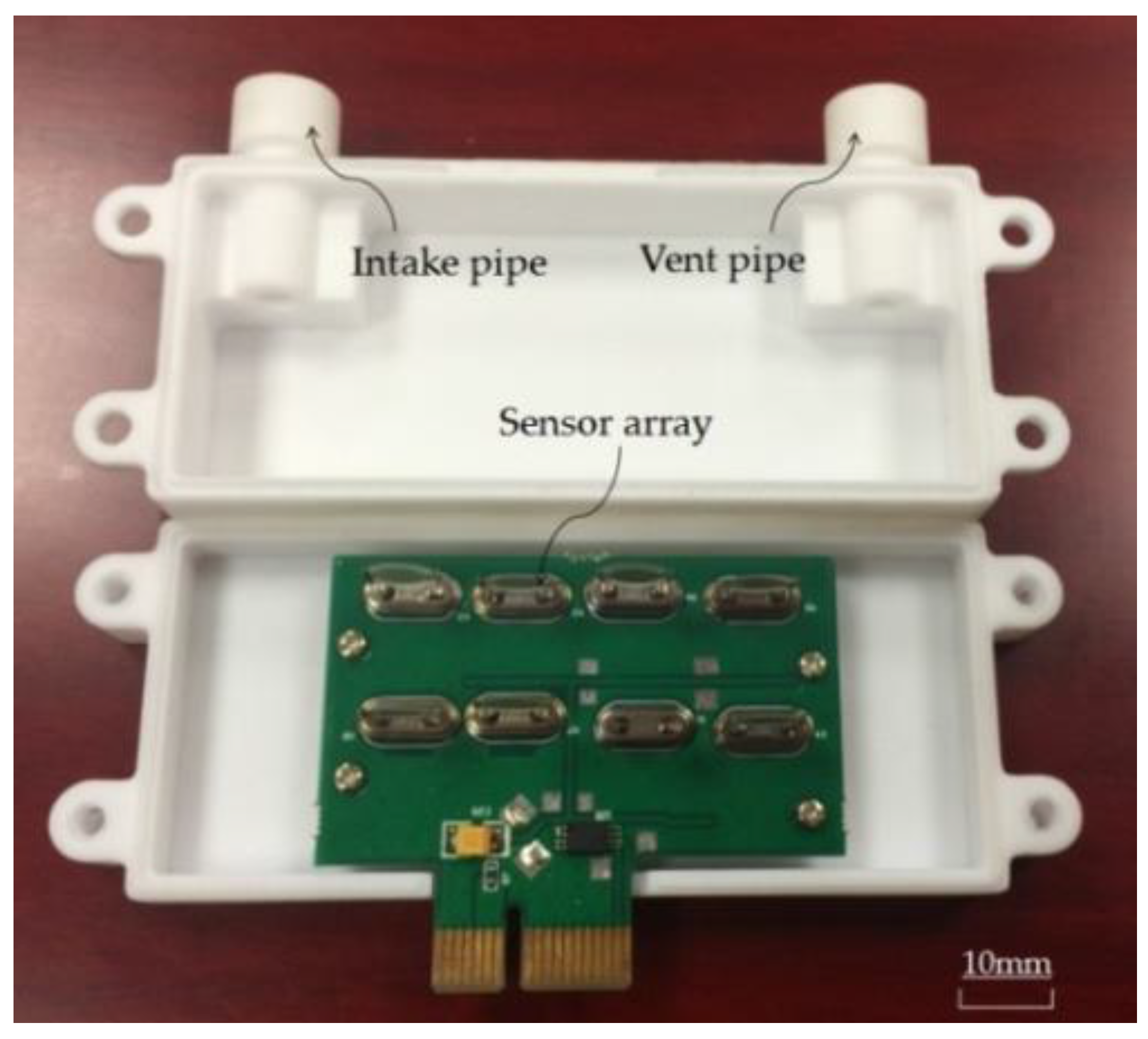

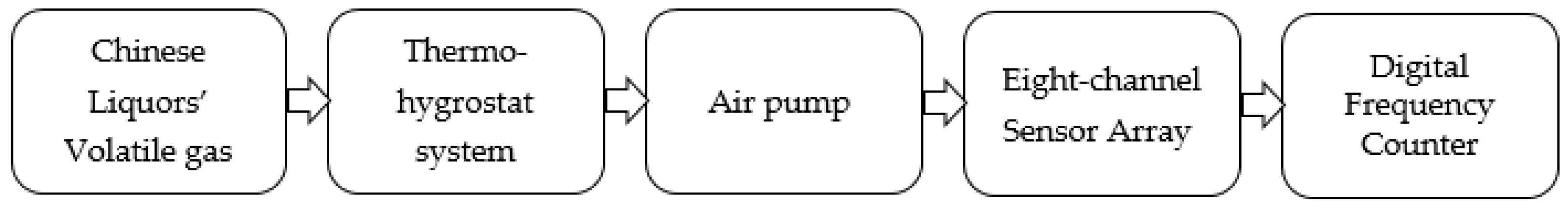

2.3. QCM-Based E-Nose

2.4. Characteristic Information Acquisition by the QCM-Based E-Nose

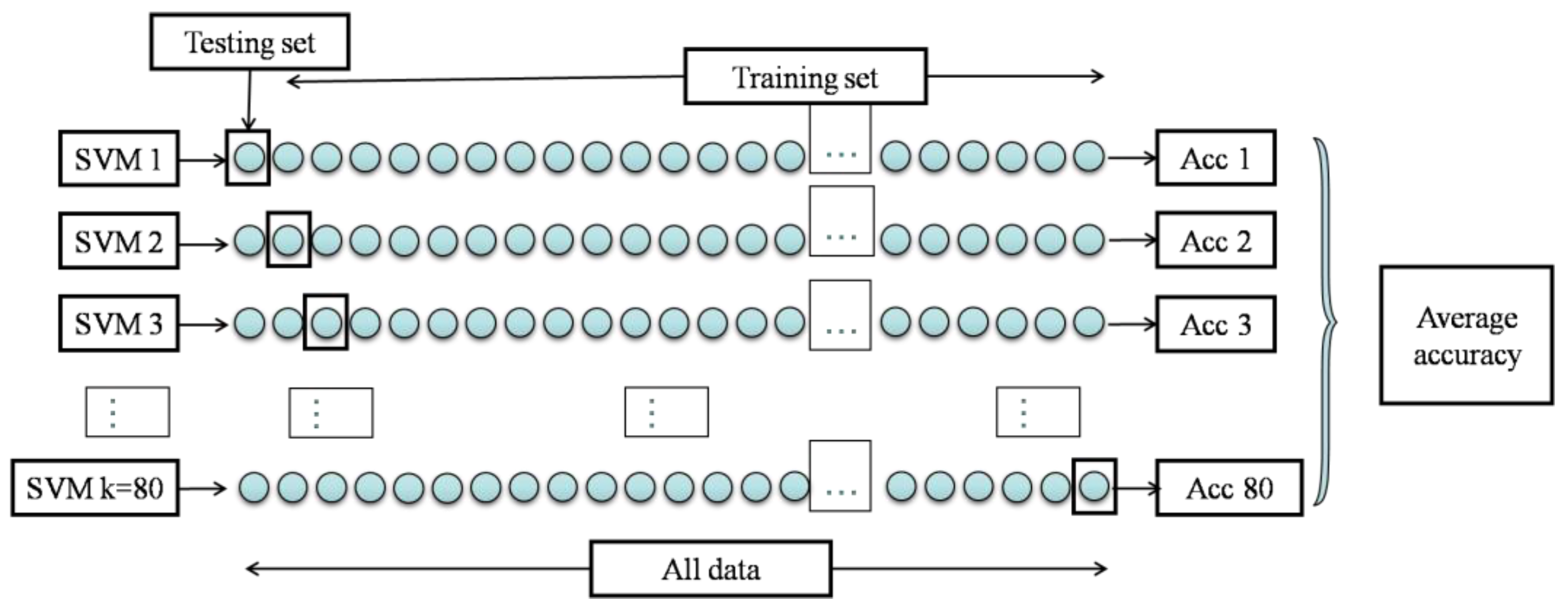

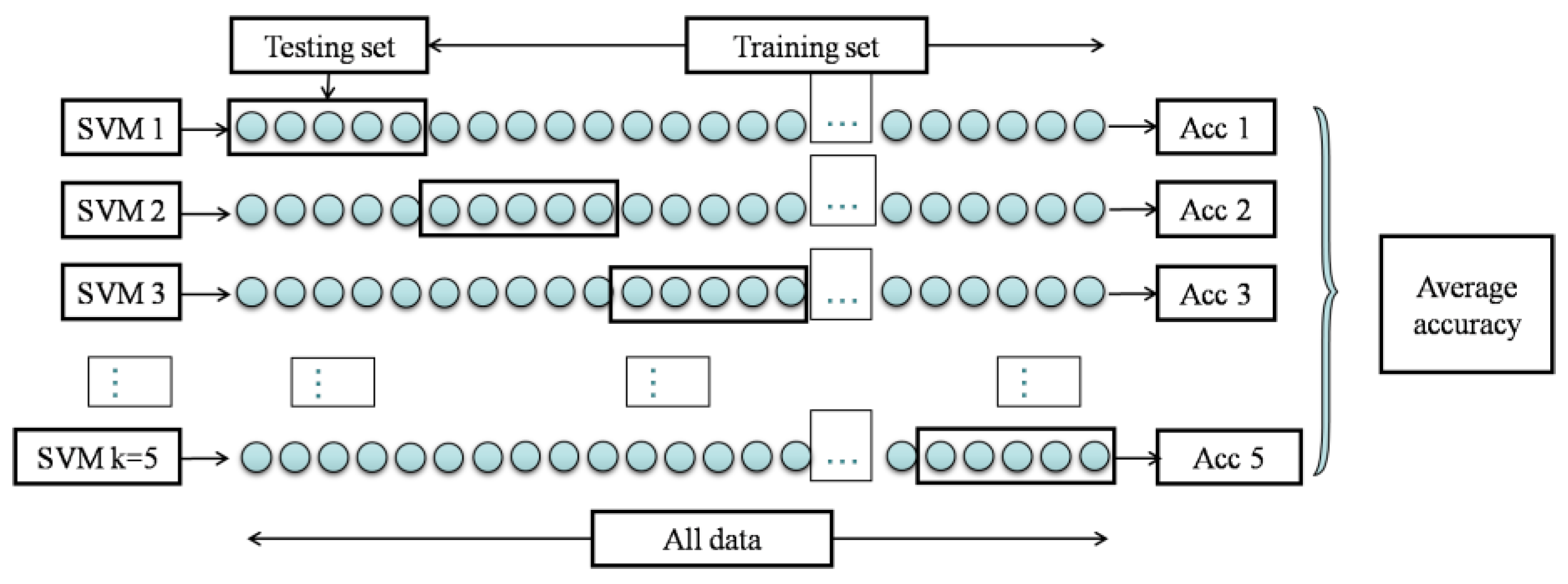

2.5. Pattern Recognition System

2.5.1. Data Pre-Processing with MDS

2.5.2. Classification with SVM

3. Results and Discussion

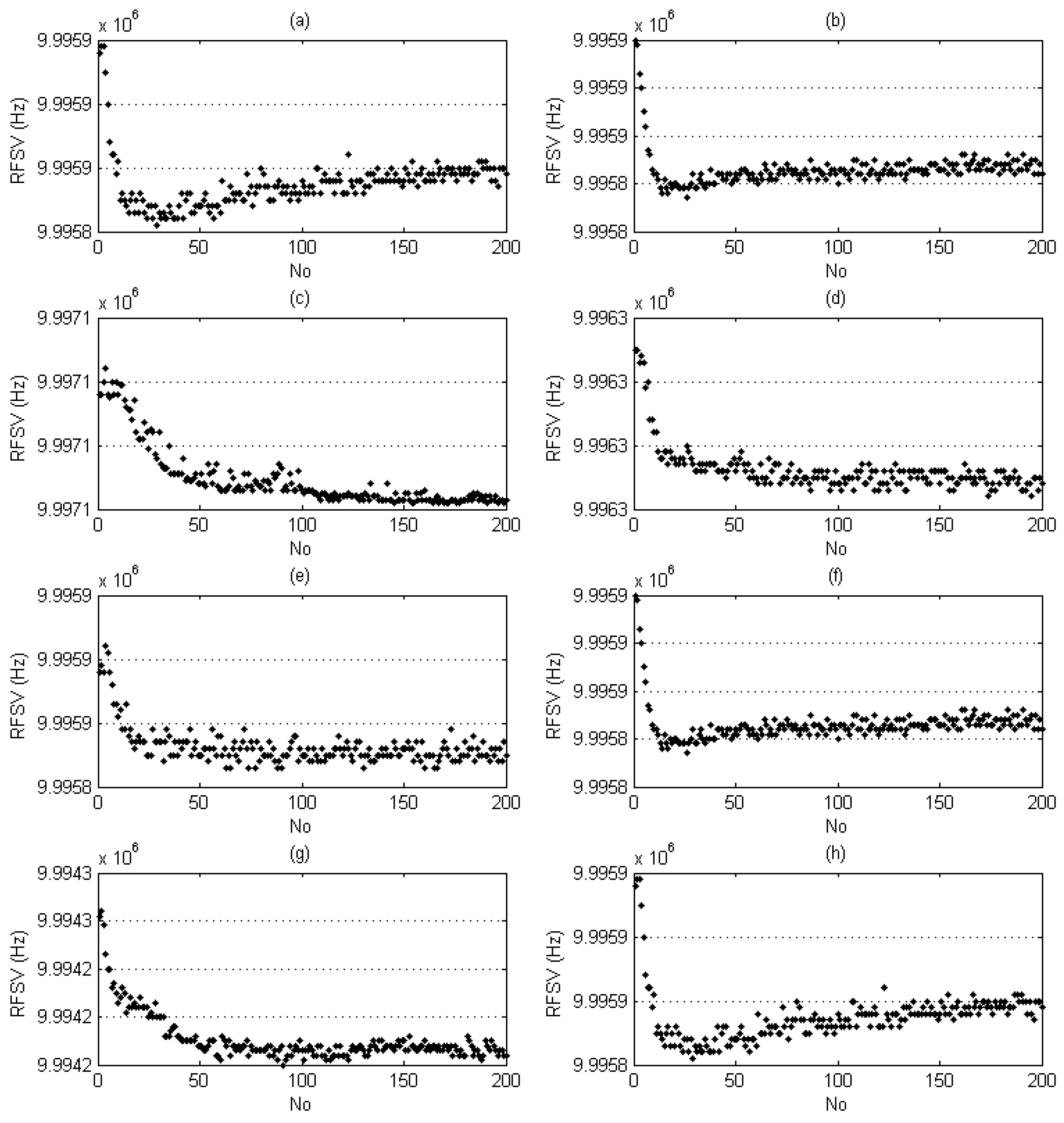

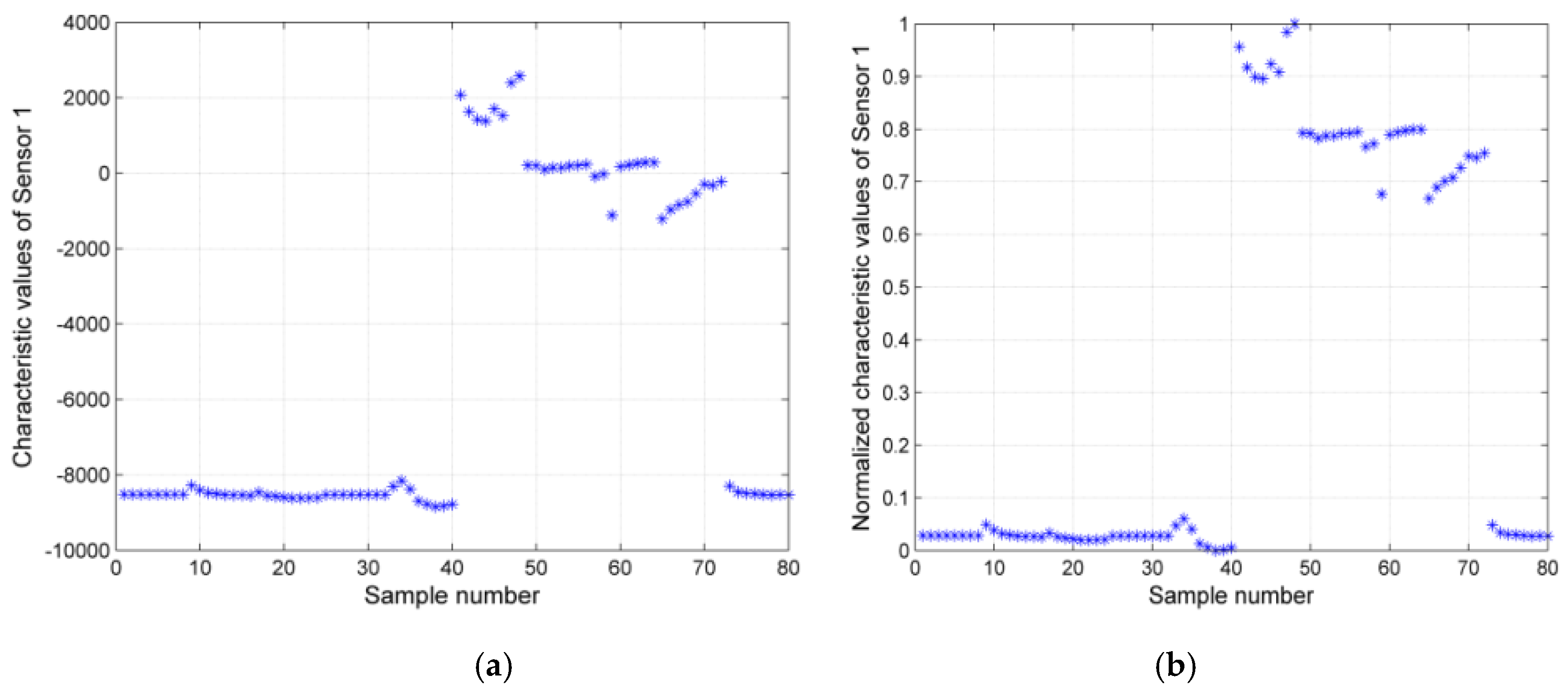

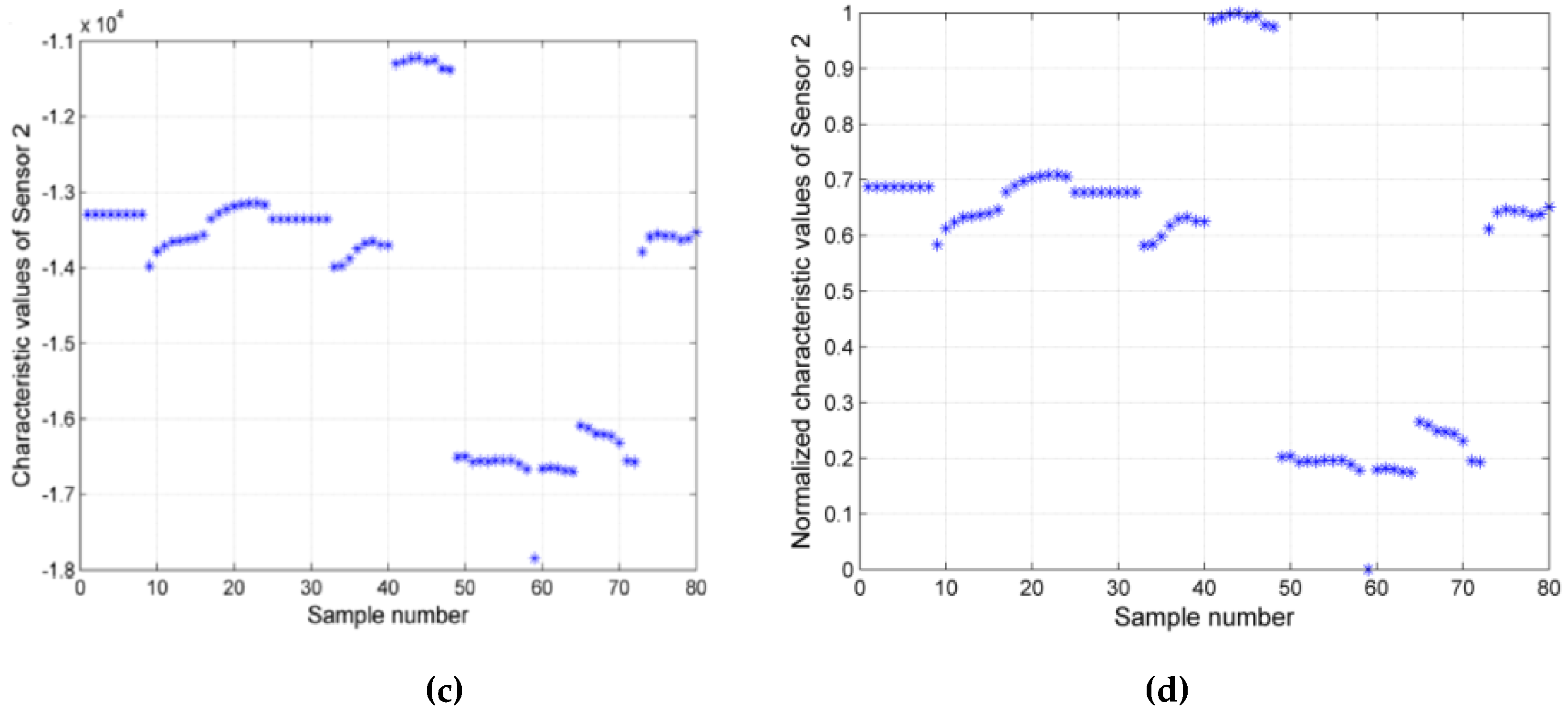

3.1. Raw Data of Characteristic Information

3.2. Liquor Classification

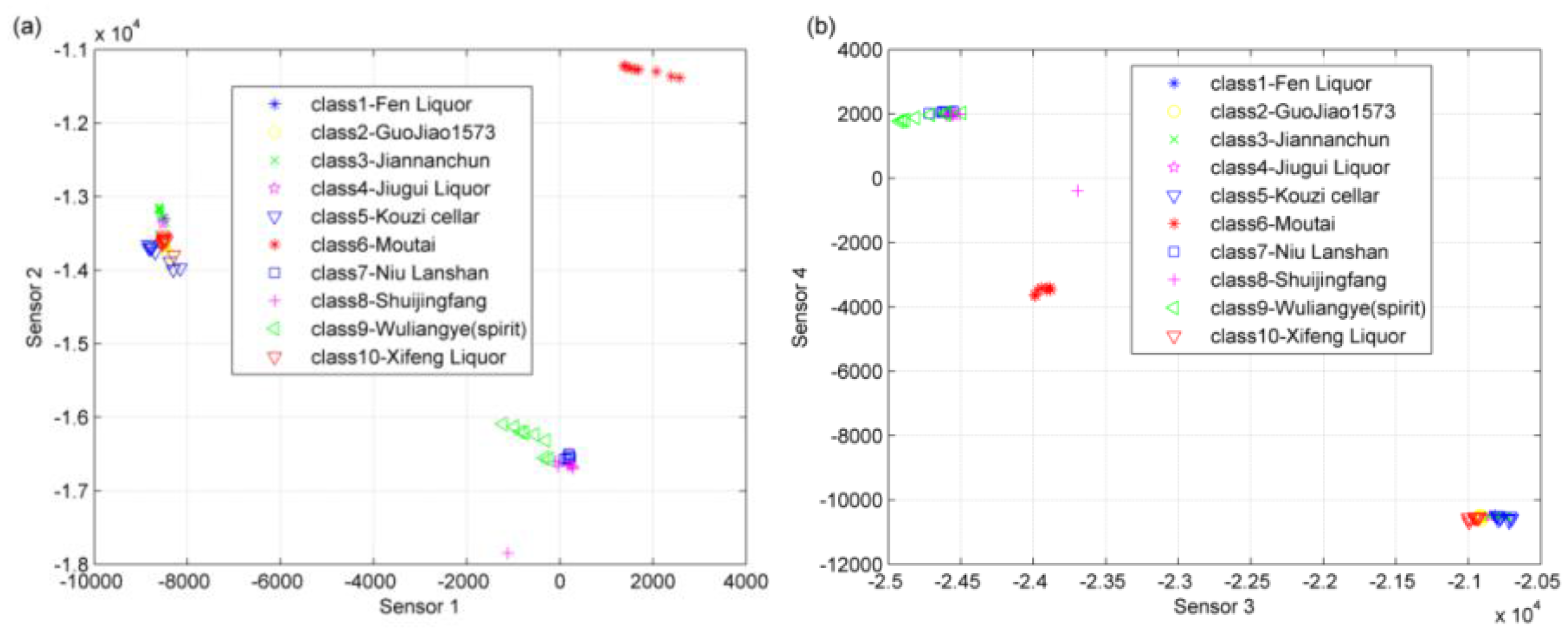

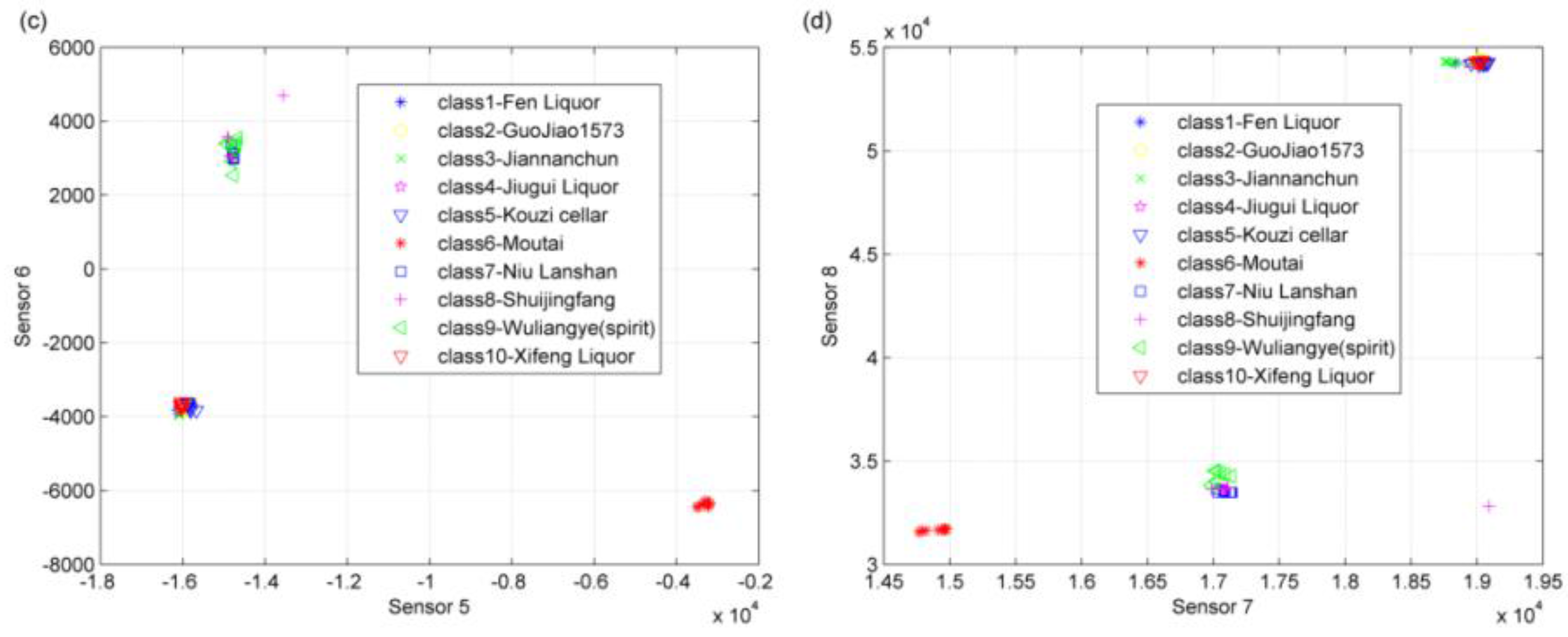

3.2.1. Data Pre-Processing Results with MDS

3.2.2. Classification Results with SVM

3.3. Test Experiments

3.4. Comparison of Classification Ability

4. Conclusions

- Good accuracy at the reasonably small size of samples,

- Low calibration cost,

- Objective analysis and comprehensive assessment of Chinese liquors,

- Good adaptability and prediction (generalization) performance on general working conditions.

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Wu, J.; Xu, Y. Comparison of pyrazine compounds in seven Chinese liquors using headspace solid-phase micro-extraction and GC-nitrogen phosphourus detection. Food Sci. Biotechnol. 2013, 22, 1–6. [Google Scholar] [CrossRef]

- Fan, W.; Qian, M.C. Characterization of aroma compounds of Chinese “Wuliangye” and “Jiannanchun” liquors by aroma extract dilution analysis. J. Agric. Food. Chem. 2016, 54, 2695–2704. [Google Scholar] [CrossRef] [PubMed]

- Yao, F.; Yi, B.; Shen, C.; Xu, P. Chemical analysis of the Chinese liquor Luzhoulaojiao by comprehensive two-dimensional gas chromatography/time-of-flight mass spectrometry. Sci. Rep. 2015, 5, 9553. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Han, B. Baijiu, Chinese liquor: History, classification and manufacture. J Ethn Foods. 2016, 3, 19–25. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, X.; Zhao, G.; Liu, H.; Gao, L.; Chen, L.; Tang, Y. Quality fingerprint expert discriminating system of Chinese famous white liquor. Chinese J. Anal. Chem. 2004, 32, 735–740. [Google Scholar]

- Wu, T.X.; Zheng, Y.; Tang, Q.L. Study on gas chromatography fingerprint map of maotai-flavor liquor. Chin. Liquor Making Sci. Tech. 2008, 10, 30–36. [Google Scholar]

- Huang, Y.; Lu, J.; Li, A.; Lv, C.; Wang, L.; Huang, G. Analysis of flavoring substances in Gujing Gongjiu Liquor by GC/MS. Chin. Liquor Making Sci. Tech. 2004, 7, 91–94. [Google Scholar]

- Qin, H.; Huo, D.; Zhang, L.; Yang, L.; Zhang, S.; Yang, M.; Shen, C.; Hou, C. Colorimetric artificial nose for identification of Chinese liquor with different geographic origins. Food. Res. Int. 2012, 45, 45–51. [Google Scholar] [CrossRef]

- Jing, Y.; Meng, Q.; Qi, P.; Zeng, M.; Li, W.; Ma, S. Electronic nose with a new feature reduction method and a multi-linear classifier for Chinese liquor classification. Rev. Sci. Instrum. 2014, 85, 055004. [Google Scholar] [CrossRef] [PubMed]

- Albert, K.J.; Lewis, N.S.; Schauer, C.L.; Sotzing, G.A.; Stitzel, S.E.; Vaid, T.P.; Walt, D.R. Cross-reactive chemical sensor arrays. Chem. Rev. 2000, 100, 2595–2626. [Google Scholar] [CrossRef] [PubMed]

- Shaffer, R.E.; Rose-Pehrsson, S.L.; Mcgill, R.A. A comparison study of chemical sensor array pattern recognition algorithms. Anal. Chim. Acta. 1999, 384, 305–317. [Google Scholar] [CrossRef]

- Peng, Q.; Tian, R.; Chen, F.; Li, B.; Gao, H. Discrimination of producing area of Chinese Tongshan kaoliang spirit using electronic nose sensing characteristics combined with the chemometrics methods. Food Chem. 2015, 178, 301–305. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Li, Q. Application of the new pattern recognition system in the new e-nose to detecting Chinese spirits. Chin. Phys. B 2014, 39, 330–334. [Google Scholar] [CrossRef]

- Zeng, H.; Li, Q.; Gu, Y. New pattern recognition system in the e-nose for Chinese spirit identification. Chin. Phys. B 2016, 2, 168–173. [Google Scholar] [CrossRef]

- Zhang, Q.; Xie, C.; Zhang, S.; Wang, A.; Zhu, B.; Wang, L.; Yang, Z. Identification and pattern recognition analysis of Chinese liquors by doped nano ZnO gas sensor array. Sens. Actuators B Chem. 2005, 110, 370–376. [Google Scholar] [CrossRef]

- Ema, K.; Yokoyama, Y.; Nakamoto, T.; Moriizumi, T. Odour-sensing system using a quartz-resonator sensor array and neural-network pattern recognition. Sens. Actuators B Chem. 1989, 18, 291–296. [Google Scholar] [CrossRef]

- Zheng, X.W.; Tabrizi, M.R.; Nout, M.J.R.; Han, B.Z. Daqu—A Traditional Chinese Liquor Fermentation Starter. J. Inst. Brew. 2011, 117, 82–90. [Google Scholar] [CrossRef]

- Shen, Y.F. Xiaoqu liquord a wonderful flow in Chinese traditional baijiu production techniques. Liquor Making. 2001, 28, 19–22. (In Chinese) [Google Scholar]

- Sauerbrey, G. Verwendung von Schwing quarzen zur Wagungdunner Schichten und zur Mikrowagung. Z. Phys. A Hadrons Nucl. 1995, 155, 206–222. [Google Scholar] [CrossRef]

- Gu, Y.; Li, Q. Preparation and characterization of PTFE coating of new polymer quartz piezoelectric crystal sensor for testing Chinese spirits. Chin. Phys. B 2015, 24, 544–547. [Google Scholar]

- Herve, A. Metric Multidimensional Scaling (MDS): Analyzing Distance Matrices. Encyclopedia Meas Stat. Sage. 2007. [Google Scholar] [CrossRef]

- Jain, Y.K.; Bhandare, S.K. Min max normalization based data perturbation method for privacy protection. Int. J. Comput Commun. Technol. 2011, 2, 45–50. [Google Scholar]

- Pardo, M.; Sberveglieri, G. Classification of electronic nose data with support vector machines. Sens. Actuators B. Chem. 2005, 107, 730–737. [Google Scholar] [CrossRef]

- Eberhart, R.; Kennedy, J. A new optimizer using particle swarm theory. In Proceedings of the Sixth International Symposium on Micro Machine and Human Science, Nagoya, Japan, 4–6 October 1995.

- Rodriguez-Lujan, I.; Fonollosa, J.; Vergara, A.; Homer, M.; Huerta, R. On the calibration of sensor arrays for pattern recognition using the minimal number of experiments. Chemom. Intell. Lab. Syst. 2013, 130, 123–134. [Google Scholar] [CrossRef]

| No. | Liquors | Main Raw Materials | Fermentation Starter | Fermentation Duration | Aging Duration | Proof | Date | Flavor Type | Place of Origin |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Fen Liquor | Sorghum | Daqu† | 28 days | 1 years | 106 | 2011 | Fen-flavor | Xinghua in Shanxi Province |

| 2 | GuoJiao1573 | Sorghum, rice | Daqu | 365 days | 5 years | 106 | 2011 | Strong-flavor | Luzhou in Sichuan Province |

| 3 | Jiannanchun | Rice, Sorghum | Daqu | 90 days | 2 years | 106 | 2011 | Strong-flavor | Mianyang in Sichuan Province |

| 4 | Jiugui Liquor | Sorghum, rice, glutinous rice, maize | Xiaoqu‡ | 50 days | 3 years | 106 | 2011 | Mixed-flavor | Jishou in Hunan Province |

| 5 | Kouzi Cellar | Sorghum, wheat, rice, pea | Daqu | 35 days | 2 years | 106 | 2011 | Mixed-flavor | Suixi in Anhui Province |

| 6 | Moutai | Sorghum, wheat, rice, | Daqu | 210 days | 3 years | 106 | 2011 | Moutai-flavor | Maotai in Guizhou Province |

| 7 | NiuLanshan | Sorghum, wheat | Daqu | 30 days | 1 year | 106 | 2011 | Strong-flavor | Beijing |

| 8 | Shuijingfang | Sorghum, wheat, maize, glutinous rice, rice, | Daqu | 180 days | 2 years | 106 | 2011 | Strong-flavor | Chengdu in Sichuan Province |

| 9 | Wuliangye | Sorghum, rice, glutinous rice, wheat, maize | Daqu | 70 days | 3 years | 106 | 2011 | Strong-flavor | Yibin city in Sichuan Province |

| 10 | XifengLiquor | Sorghum, wheat | Daqu | 18 days | 2 years | 106 | 2011 | Special-flavour | Baoji in Shanxi Province |

| Thin Coating | Composites | Thin Coating | Composites |

|---|---|---|---|

| Coating-1 | PVC | Coating-5 | AgCl |

| Coating-2 | Polyamide | Coating-6 | Azithromycin |

| Coating-3 | Polyethylene (PE) + AgCl | Coating-7 | CuCl2 + PE |

| Coating-4 | Polytef | Coating-8 | CuCl2 + AgCl + PE |

| No | 1 | 2 | 3 | 4 | 5 | 6 | 7 | … | 200 |

|---|---|---|---|---|---|---|---|---|---|

| Sensor-1 | 9,995,162 | 9,995,166 | 9,995,167 | 9,995,161 | 9,995,161 | 9,995,161 | 9,995,162 | … | 9,996,184 |

| Sensor-2 | 9,996,246 | 9,996,245 | 9,996,246 | 9,996,245 | 9,996,254 | 9,996,245 | 9,996,245 | … | 9,996,255 |

| Sensor-3 | 9,997,116 | 9,997,116 | 9,997,120 | 9,997,124 | 9,997,116 | 9,997,115 | 9,997,120 | … | 9,997,115 |

| Sensor-4 | 9,995,703 | 9,995,697 | 9,995,700 | 9,995,697 | 9,995,697 | 9,995,697 | 9,995,697 | … | 9,995,698 |

| Sensor-5 | 9,995,673 | 9,995,682 | 9,995,675 | 9,995,675 | 9,995,681 | 9,995,681 | 9,995,680 | … | 9,995,680 |

| Sensor-6 | 9,995,896 | 9,995,896 | 9,995,896 | 9,995,896 | 9,995,906 | 9,995,896 | 9,995,896 | … | 9,995,896 |

| Sensor-7 | 9,994,382 | 9,994,382 | 9,994,378 | 9,994,384 | 9,994,380 | 9,994,379 | 9,994,380 | … | 9,994,384 |

| Sensor-8 | 9,993,190 | 9,993,191 | 9,993,191 | 9,993,197 | 9,993,193 | 9,993,191 | 9,993,197 | … | 9,993,193 |

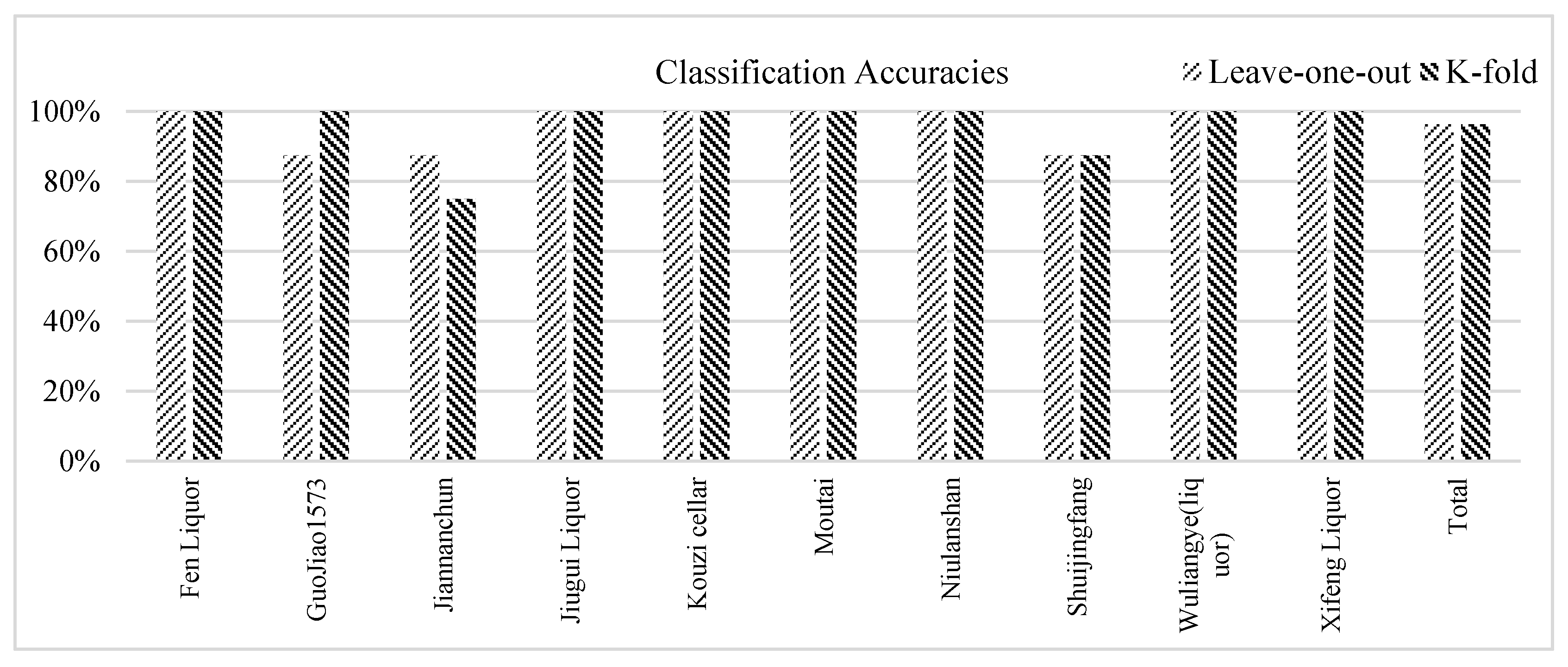

| No. | Liquor Name | Leave-One-Out Cross-Validation | 5-Fold Cross-Validation | ||||

|---|---|---|---|---|---|---|---|

| Num. of Errors | Num. of Samples | Accuracy | Num. of Errors | Num. of Samples | Accuracy | ||

| 1 | Fen Liquor | 0 | 8 | 100% | 0 | 8 | 100% |

| 2 | GuoJiao1573 | 1 | 8 | 87.5% | 0 | 8 | 100% |

| 3 | Jiannanchun | 1 | 8 | 87.5% | 2 | 8 | 75% |

| 4 | Jiugui Liquor | 0 | 8 | 100% | 0 | 8 | 100% |

| 5 | Kouzi cellar | 0 | 8 | 100% | 0 | 8 | 100% |

| 6 | Moutai | 0 | 8 | 100% | 0 | 8 | 100% |

| 7 | Niulanshan | 0 | 8 | 100% | 0 | 8 | 100% |

| 8 | Shuijingfang | 1 | 8 | 87.5% | 1 | 8 | 87.5% |

| 9 | Wuliangye(liquor) | 0 | 8 | 100% | 0 | 8 | 100% |

| 10 | Xifeng Liquor | 0 | 8 | 100% | 0 | 8 | 100% |

| Total | 3 | 80 | 96.25% | 3 | 80 | 96.25% | |

| Actual Brand (Liquor Name) | Mispredicted Brand (Liquor Name) | Num. of Errors | Num. of Samples | Accuracy |

|---|---|---|---|---|

| Fen Liquor | - | 0 | 30 | 100% |

| GuoJiao1573 | Shuijingfang | 2 | 30 | 93.4% |

| Jiannanchun | Shuijingfang/GuoJiao1573 | 1/1 | 30 | 93.4% |

| Jiugui Liquor | - | 0 | 30 | 100% |

| Kouzi cellar | - | 0 | 30 | 100% |

| Moutai | - | 0 | 30 | 100% |

| Niulanshan | - | 0 | 30 | 100% |

| Shuijingfang | Jiannanchun | 1 | 30 | 96.7% |

| Wuliangye | - | 0 | 30 | 100% |

| Xifeng Liquor | - | 0 | 30 | 100% |

| Total | 5 | 300 | 98.3% |

| Method | Classification Accuracy |

|---|---|

| MDS-SVM | 98.3% |

| PCA-BPNN | 93.3% |

| MA-LDA | 87.6% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Gu, Y.; Jia, J. Classification of Multiple Chinese Liquors by Means of a QCM-based E-Nose and MDS-SVM Classifier. Sensors 2017, 17, 272. https://doi.org/10.3390/s17020272

Li Q, Gu Y, Jia J. Classification of Multiple Chinese Liquors by Means of a QCM-based E-Nose and MDS-SVM Classifier. Sensors. 2017; 17(2):272. https://doi.org/10.3390/s17020272

Chicago/Turabian StyleLi, Qiang, Yu Gu, and Jing Jia. 2017. "Classification of Multiple Chinese Liquors by Means of a QCM-based E-Nose and MDS-SVM Classifier" Sensors 17, no. 2: 272. https://doi.org/10.3390/s17020272