A Pulsed Thermographic Imaging System for Detection and Identification of Cotton Foreign Matter

Abstract

:1. Introduction

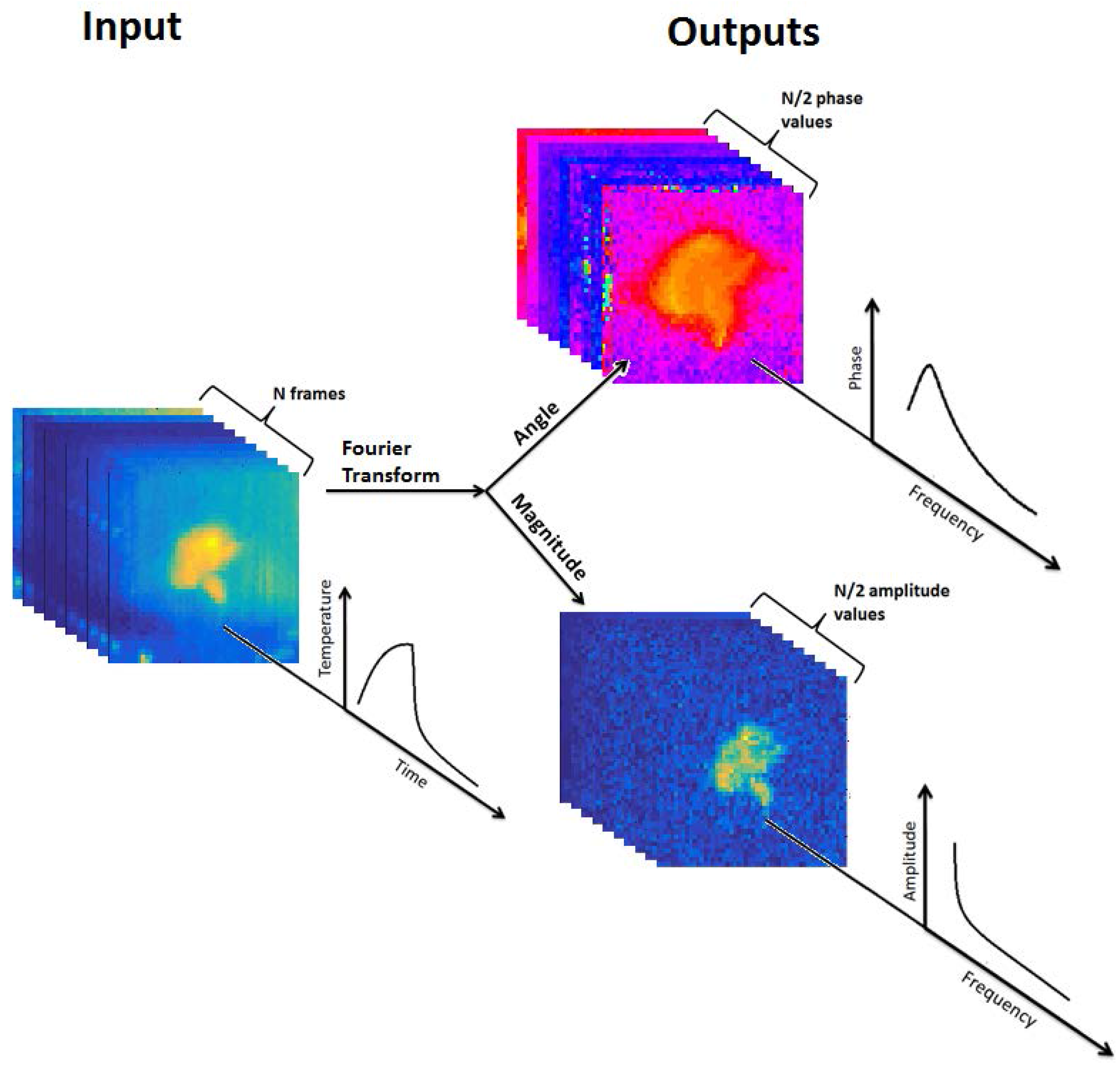

Pulse-Phase Thermography

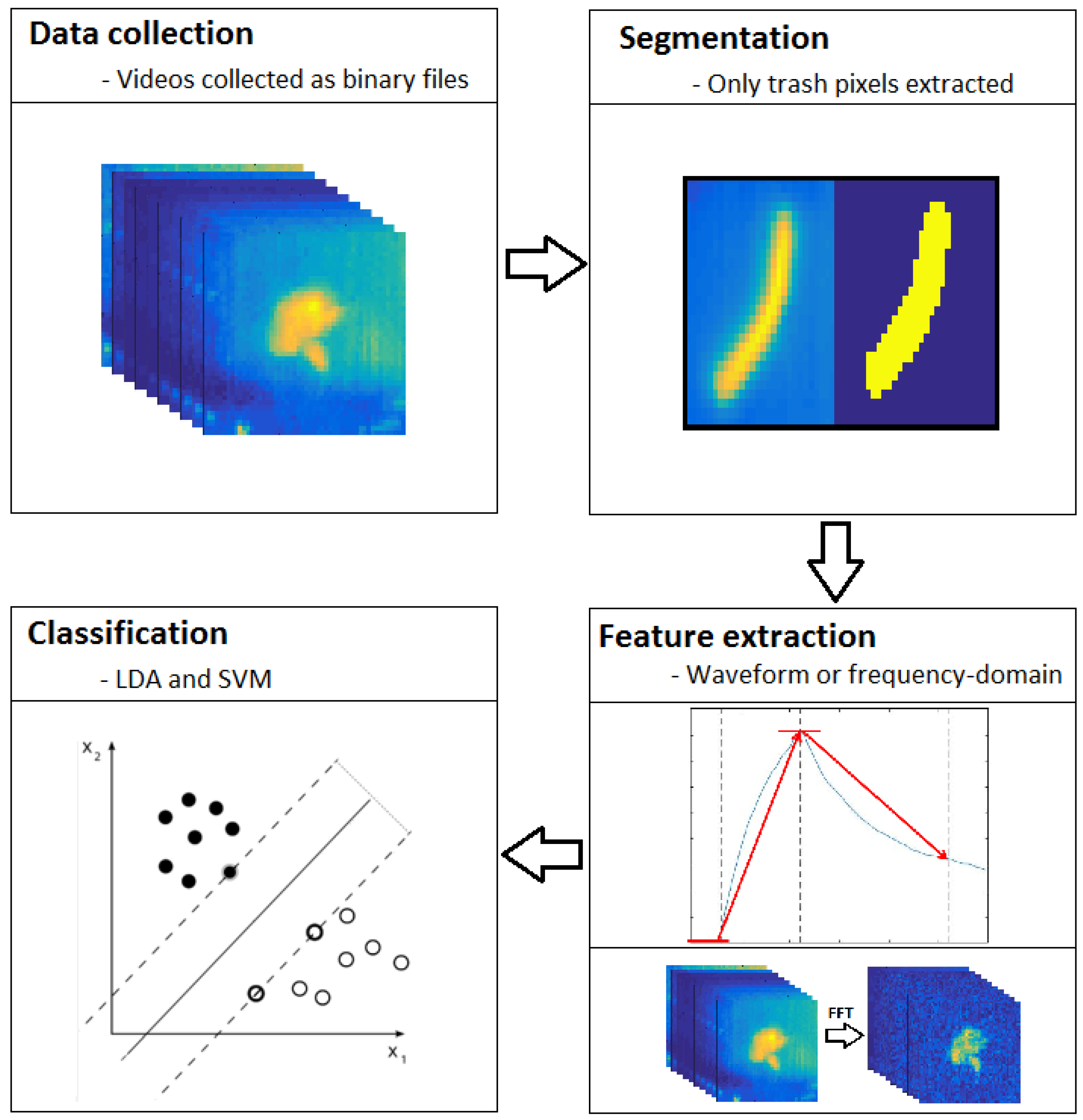

2. Materials and Methods

2.1. Samples

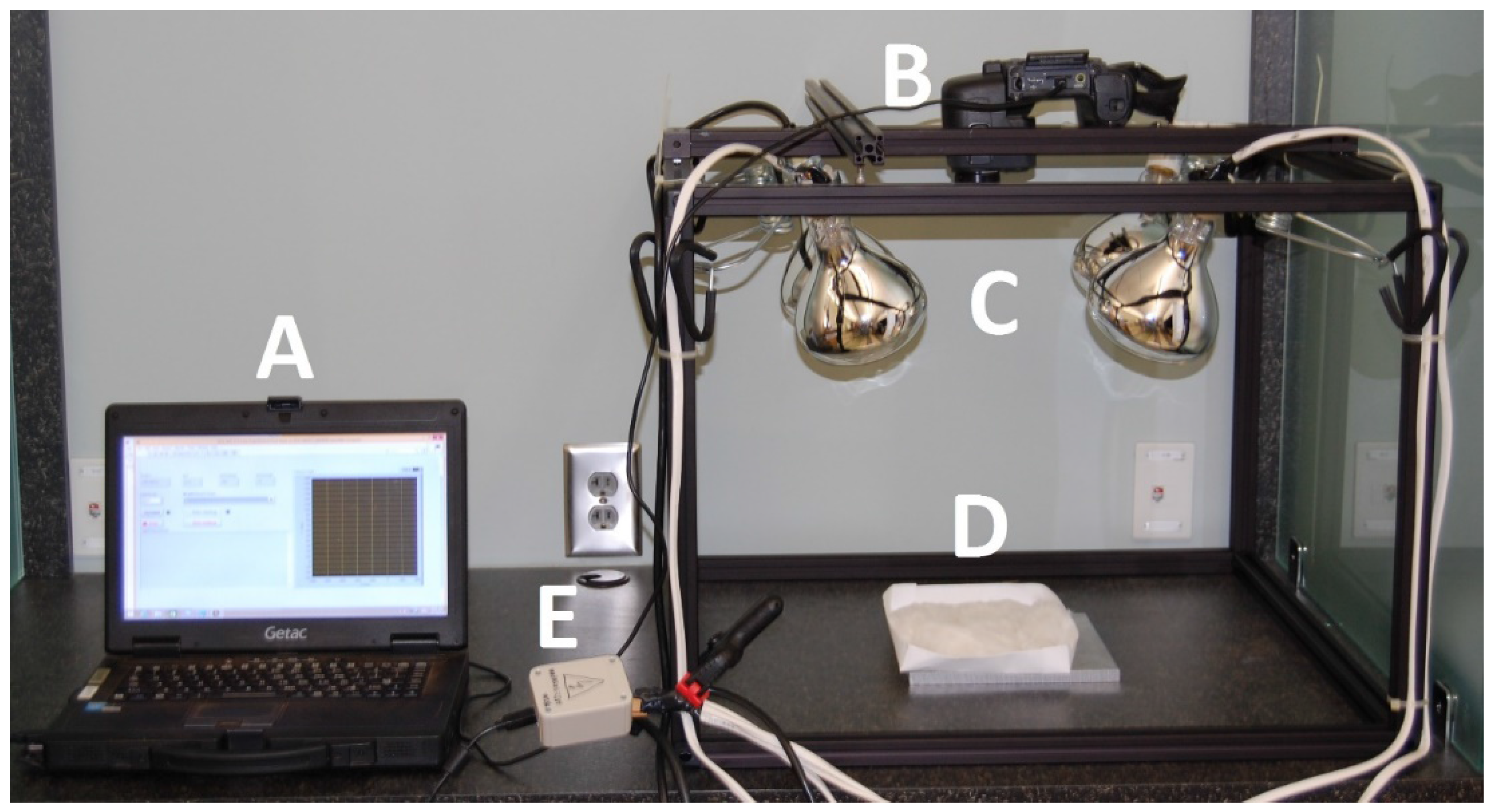

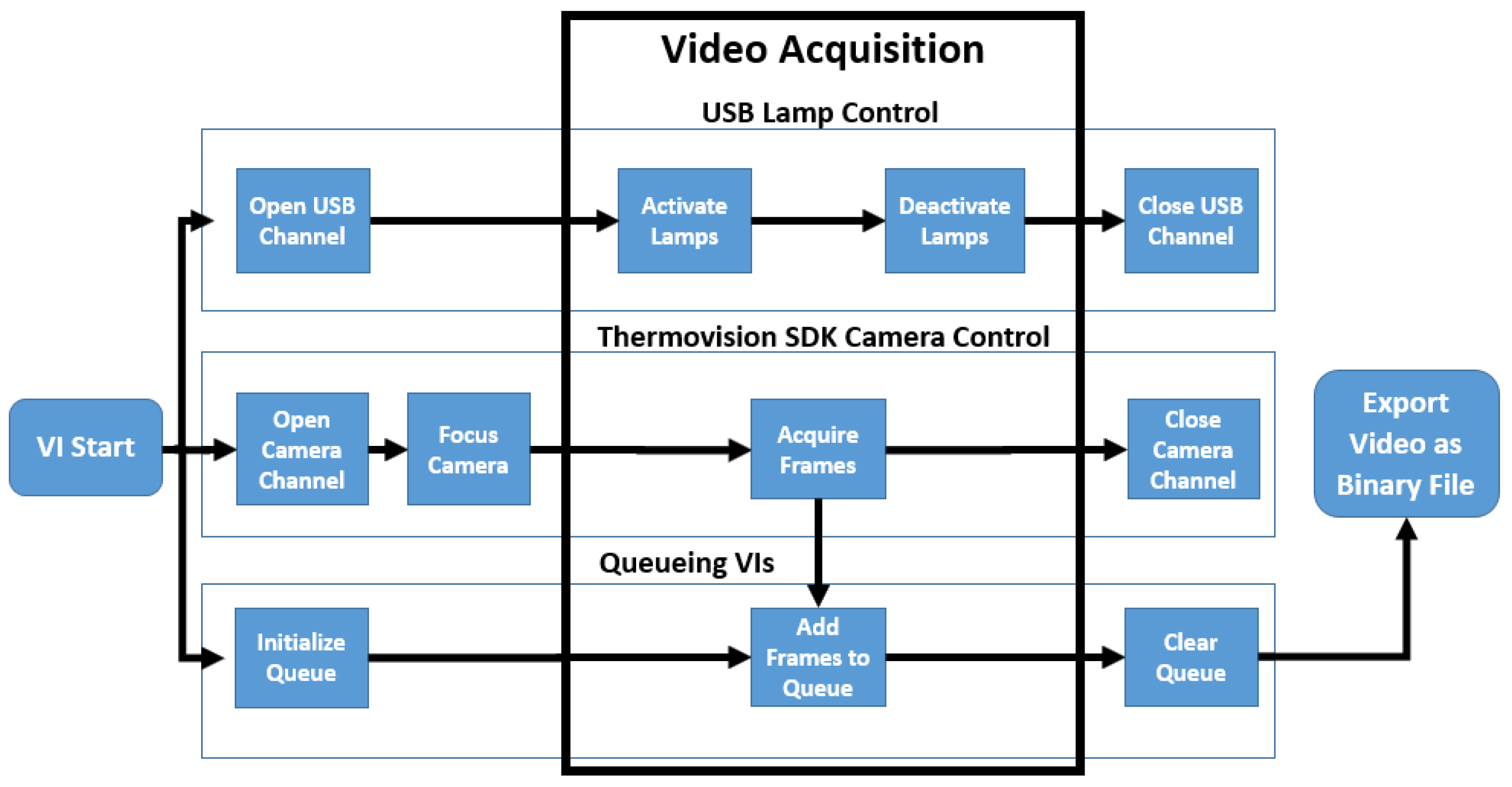

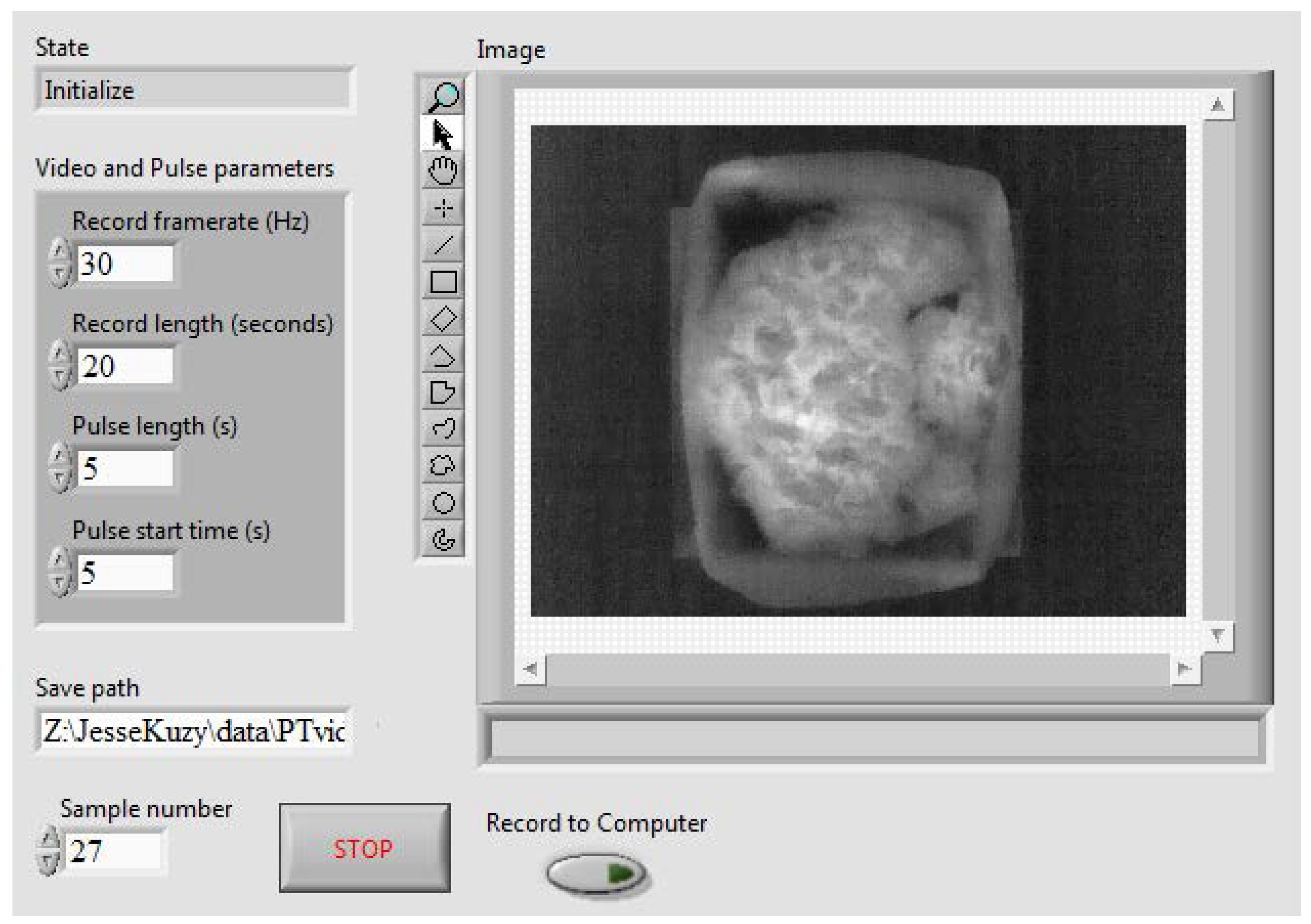

2.2. Pulsed Thermographic Imaging System and Data Acquisition

2.3. Segmentation

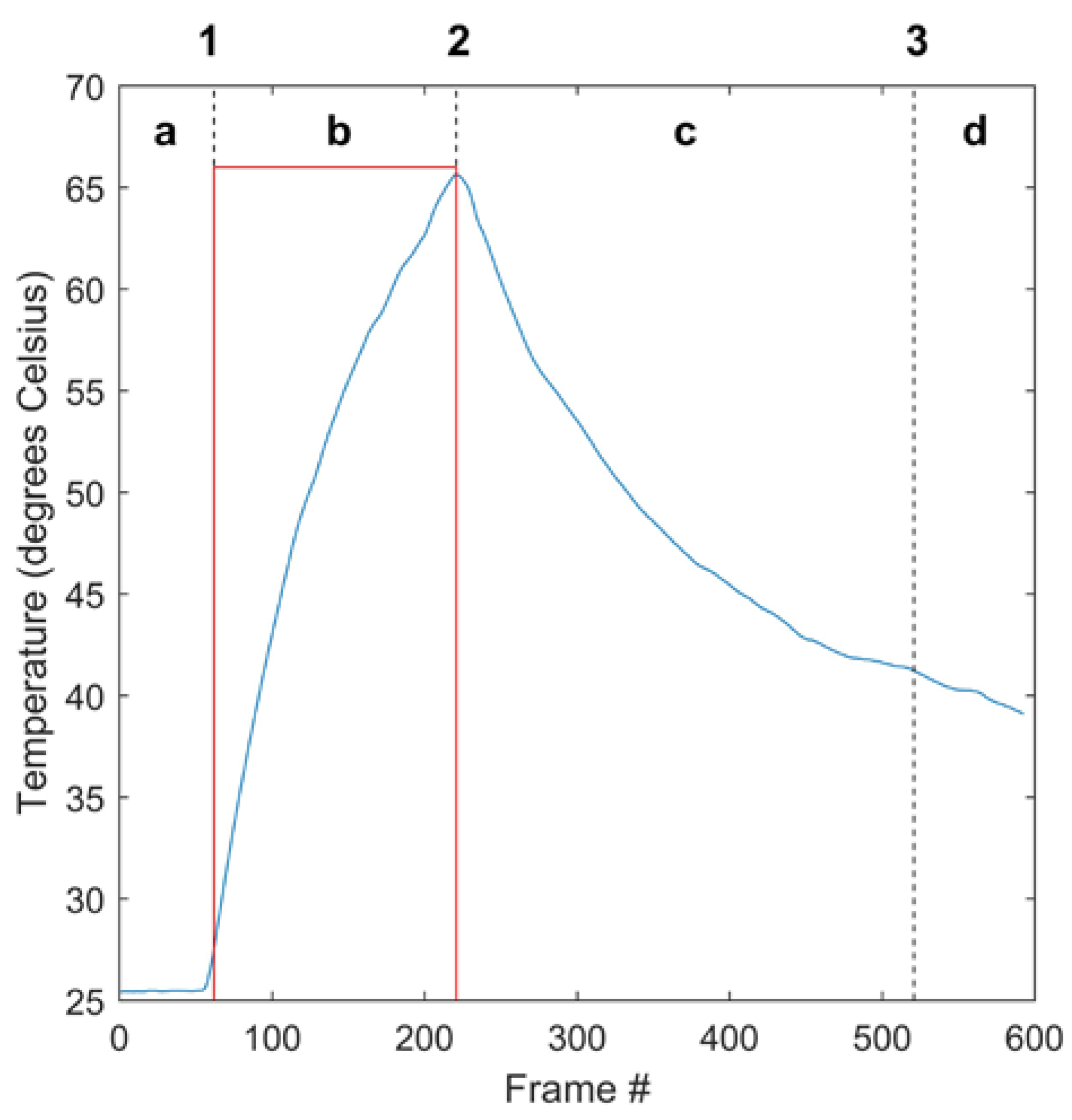

2.4. Feature Extraction

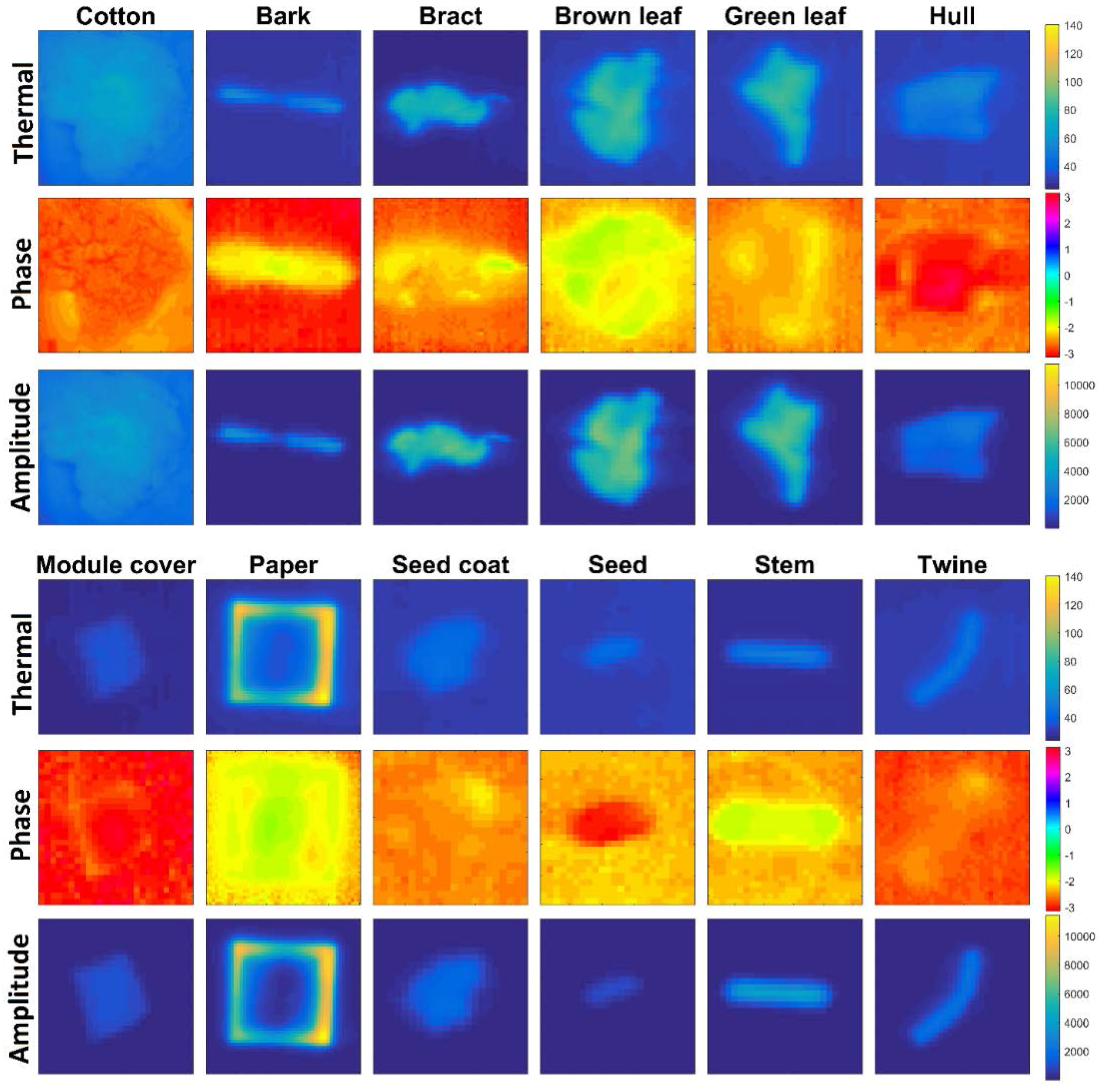

2.4.1. Frequency-Domain Features

2.4.2. Waveform Features

2.5. Statistical Analyses and Classification

3. Results

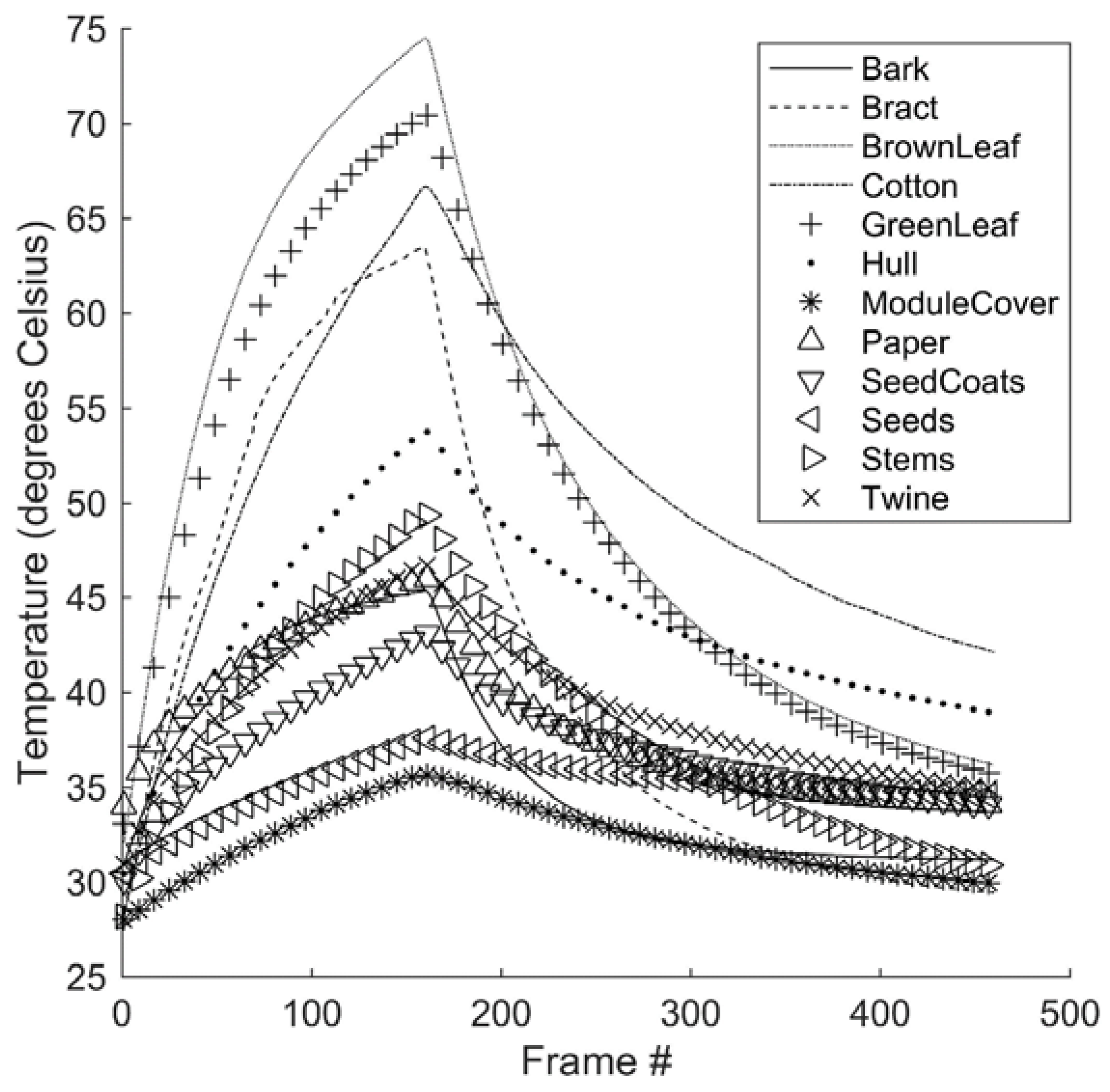

3.1. Waveform Feature Analysis

3.2. Frequency-Domain Feature Analysis

3.3. Statistical Analyses

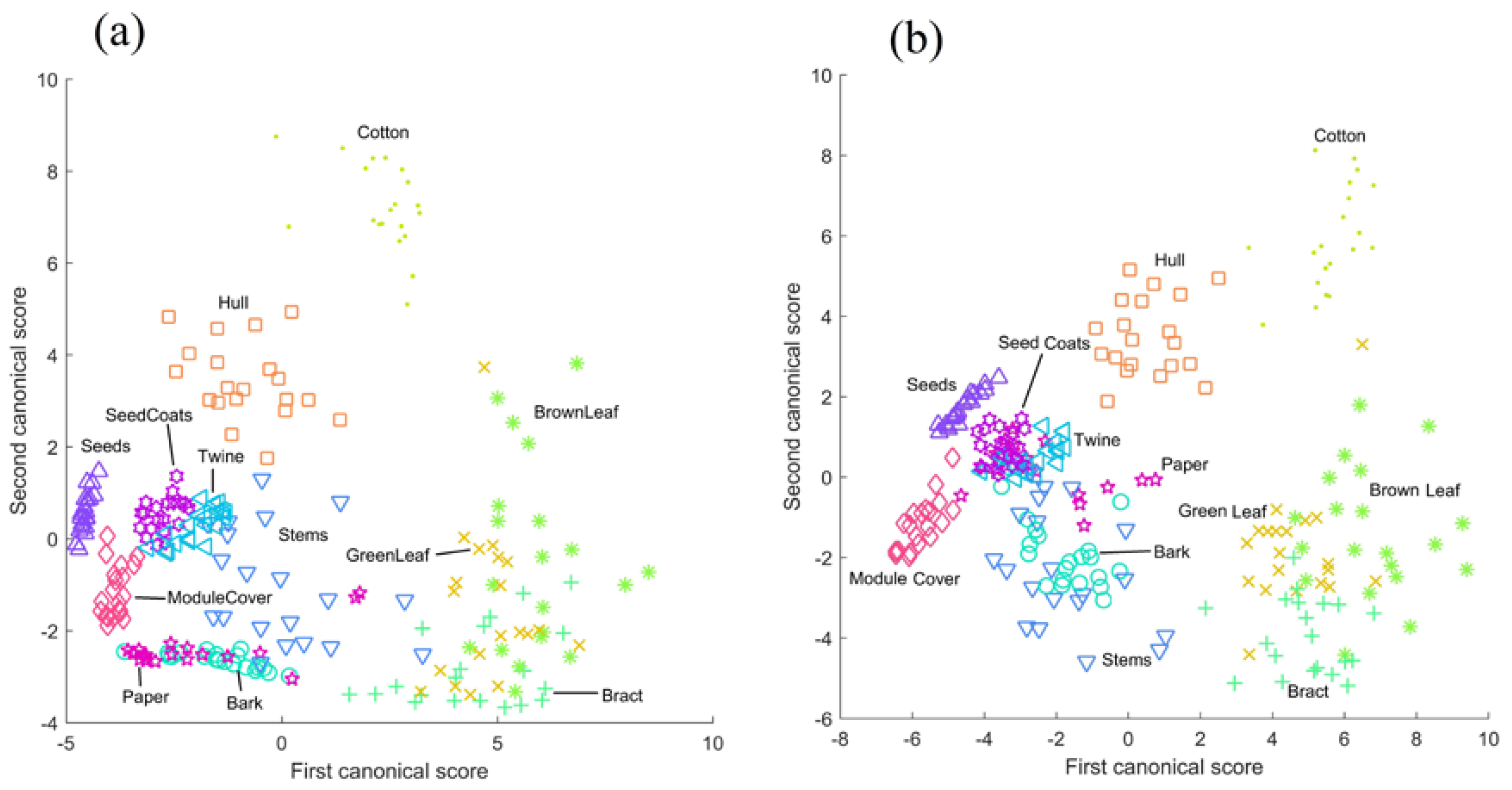

3.4. Canonical Discriminant Analysis

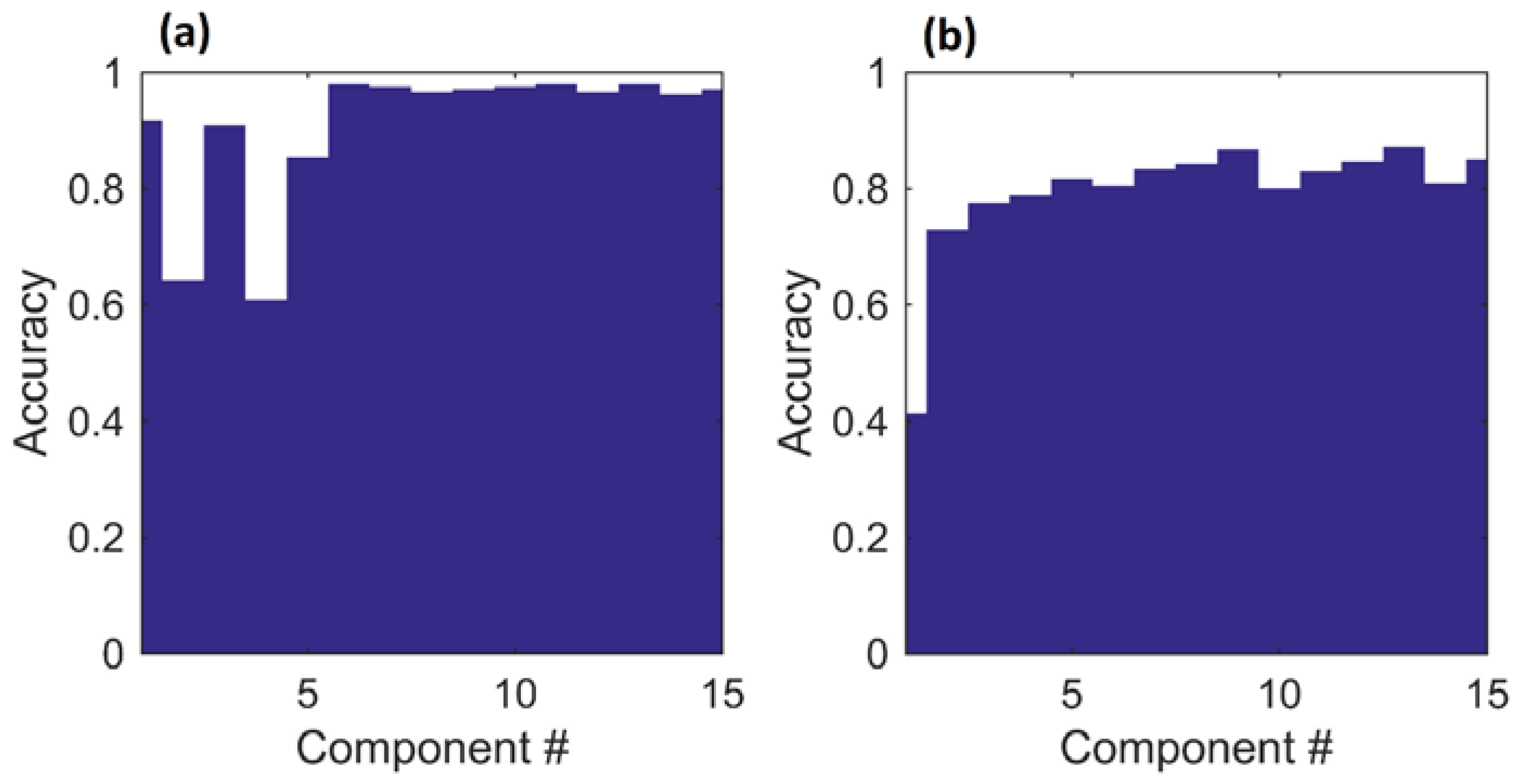

3.5. Classification Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- International Textile Manufacturers Federation. ITMF Cotton Contamination Survey; ITMF: Zurich, Switzerland, 2014. [Google Scholar]

- Himmelsbach, D.S.; Hellgeth, J.W.; McAlister, D.D. Development and use of an attenuated total reflectance/fourier transform infrared (ATR/FT-IR) spectral database to identify foreign matter in cotton. J. Agric. Food Chem. 2006, 54, 7405–7412. [Google Scholar] [CrossRef] [PubMed]

- Ghorashi, H. Uster® HVI Classic; Uster Technologies, Ed.; CI Singapore: Singapore, 2004. [Google Scholar]

- Frydrych, I.; Matusiak, M. Trends of afis application in research and industry. Fibres Text. East. Eur. 2002, 10, 35–39. [Google Scholar]

- Xu, B.; Fang, C.; Huang, R.; Watson, M.D. Chromatic image analysis for cotton trash and color measurements. Text. Res. J. 1997, 67, 881–890. [Google Scholar] [CrossRef]

- Yang, W.; Li, D.; Wei, X.; Kang, Y.; Li, F. An automated visual inspection system for foreign fiber detection in lint. In Proceedings of the 2009 IEEE WRI Global Congress on Intelligent Systems, Xiamen, China, 19–21 May 2009; pp. 364–368.

- Yang, W.; Lu, S.; Wang, S.; Li, D. Fast recognition of foreign fibers in cotton lint using machine vision. Math. Comput. Model. 2011, 54, 877–882. [Google Scholar] [CrossRef]

- Xu, B.; Fang, C.; Watson, M. Clustering analysis for cotton trash classification. Text. Res. J. 1999, 69, 656–662. [Google Scholar] [CrossRef]

- Fortier, C.A.; Rodgers, J.E.; Cintron, M.S.; Cui, X.; Foulk, J.A. Identification of cotton and cotton trash components by fourier transform near-infrared spectroscopy. Text. Res. J. 2011, 81, 230–238. [Google Scholar] [CrossRef]

- Fortier, C.; Rodgers, J.; Foulk, J.; Whitelock, D. Near-infrared classification of cotton lint, botanical and field trash. J. Cotton Sci. 2012, 16, 72–79. [Google Scholar]

- Jiang, Y.; Li, C. Detection and discrimination of cotton foreign matter using push-broom based hyperspectral imaging: System design and capability. PLoS ONE 2015, 10, e0121969. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Ying, Y.; Li, J.; Rao, X.; Kang, Y.; Shi, Z. Detection of foreign materials on surface of ginned cotton by hyper-spectral imaging. Trans. Chin. Soc. Agric. Eng. 2012, 28, 126–134. [Google Scholar]

- Zhang, R.; Li, C.; Zhang, M.; Rodgers, J. Shortwave infrared hyperspectral reflectance imaging for cotton foreign matter classification. Comput. Electron. Agric. 2016, 127, 260–270. [Google Scholar] [CrossRef]

- Gamble, G.R.; Foulk, J.A. Quantitative analysis of cotton (gossypium hirsutum) lint trash by fluorescence spectroscopy. J. Agric. Food Chem. 2007, 55, 4940–4943. [Google Scholar] [CrossRef] [PubMed]

- Mustafic, A.; Li, C. Classification of cotton foreign matter using color features extracted from fluorescent images. Text. Res. J. 2015, 85, 1209–1220. [Google Scholar] [CrossRef]

- Pai, A.S. X-ray Microtomographic Image Analysis for Identification of Cotton Contaminants. Ph.D. Thesis, Texas Tech University, Lubbock, TX, USA, 2002. [Google Scholar]

- Hellebrand, H.; Linke, M.; Beuche, H.; Herold, B.; Geyer, M. Horticultural products evaluated by thermography. In Proceedings of the AgEng 2000, Warwick, UK, 2–7 July 2000; pp. 26–27.

- Veraverbeke, E.A.; Verboven, P.; Lammertyn, J.; Cronje, P.; De Baerdemaeker, J.; Nicolaï, B.M. Thermographic surface quality evaluation of apple. J. Food Eng. 2006, 77, 162–168. [Google Scholar] [CrossRef]

- Van Linden, V.; Labavitch, J.; De Baerdemaeker, J. Bruising mechanism in tomato fruit: Concerted biomechanical and enzymatic action. Commun. Agric. Appl. Biol. Sci. 2003, 68, 11. [Google Scholar] [PubMed]

- Manickavasagan, A.; Jayas, D.; White, N. Thermal imaging to detect infestation by cryptolestes ferrugineus inside wheat kernels. J. Stored Prod. Res. 2008, 44, 186–192. [Google Scholar] [CrossRef]

- Danno, A.; Miyazato, M.; Ishiguro, E. Quality evaluation of agricultural products by infrared imaging method. Mem. Fac. Agric. 1978, 14, 123–138. [Google Scholar]

- Varith, J.; Hyde, G.; Baritelle, A.; Fellman, J.; Sattabongkot, T. Non-contact bruise detection in apples by thermal imaging. Innov. Food Sci. Emerg. Technol. 2003, 4, 211–218. [Google Scholar] [CrossRef]

- Baranowski, P.; Mazurek, W.; Witkowska-Walczak, B.; Sławiński, C. Detection of early apple bruises using pulsed-phase thermography. Postharvest Biol. Technol. 2009, 53, 91–100. [Google Scholar] [CrossRef]

- Meinlschmidt, P.; Maergner, V. Detection of foreign substances in food using thermography. In AeroSense 2002; International Society for Optics and Photonics: Bellingham, WA, USA, 2002; pp. 565–571. [Google Scholar]

- Ginesu, G.; Giusto, D.D.; Märgner, V.; Meinlschmidt, P. Detection of foreign bodies in food by thermal image processing. IEEE Trans. Ind. Electron. 2004, 51, 480–490. [Google Scholar] [CrossRef]

- Gowen, A.; Tiwari, B.; Cullen, P.; McDonnell, K.; O’Donnell, C. Applications of thermal imaging in food quality and safety assessment. Trends Food Sci. Technol. 2010, 21, 190–200. [Google Scholar] [CrossRef]

- Maldague, X.; Marinetti, S. Pulse phase infrared thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Ishikawa, M.; Hatta, H.; Habuka, Y.; Fukui, R.; Utsunomiya, S. Detecting deeper defects using pulse phase thermography. Infrared Phys. Technol. 2013, 57, 42–49. [Google Scholar] [CrossRef]

- Mangialardi, G.J., Jr.; Anthony, W.S. Retrospective View of Cotton Gin Dryers; The Cotton Foundation, National Cotton Council: Cordova, TN, USA, 2004. [Google Scholar]

| Feature Set | Number of Features | Detection | Identification | ||

| LDA | SVM | LDA | SVM | ||

| Waveform features | 2 | 0.9833 | 0.9917 | 0.7375 | 0.7917 |

| Whole amp 1:10 | 10 | 0.9917 | 0.9792 | 0.9000 | 0.8667 |

| Rising amp 1:10 | 10 | 0.9500 | 0.9458 | 0.7292 | 0.7708 |

| Falling amp 1:10 | 10 | 0.9625 | 0.9375 | 0.7500 | 0.7708 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuzy, J.; Li, C. A Pulsed Thermographic Imaging System for Detection and Identification of Cotton Foreign Matter. Sensors 2017, 17, 518. https://doi.org/10.3390/s17030518

Kuzy J, Li C. A Pulsed Thermographic Imaging System for Detection and Identification of Cotton Foreign Matter. Sensors. 2017; 17(3):518. https://doi.org/10.3390/s17030518

Chicago/Turabian StyleKuzy, Jesse, and Changying Li. 2017. "A Pulsed Thermographic Imaging System for Detection and Identification of Cotton Foreign Matter" Sensors 17, no. 3: 518. https://doi.org/10.3390/s17030518