A New Electromagnetic Acoustic Transducer Design for Generating and Receiving S0 Lamb Waves in Ferromagnetic Steel Plate

Abstract

:1. Introduction

2. Lamb Waves

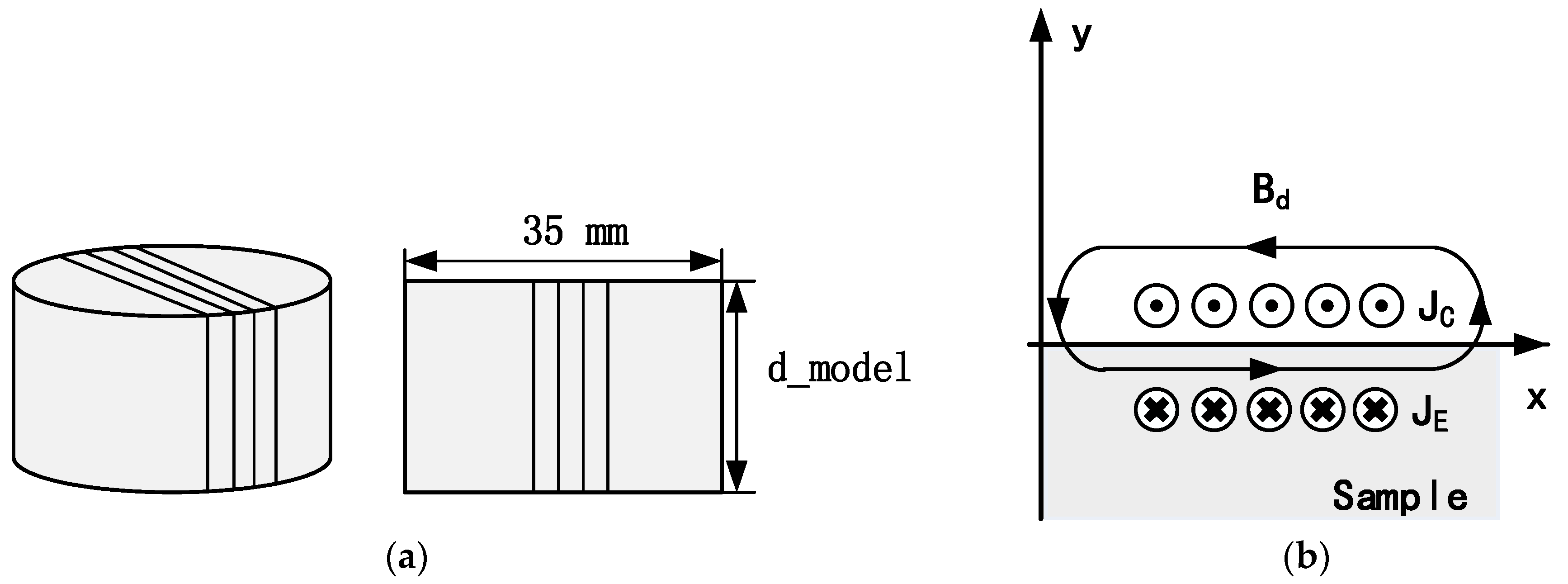

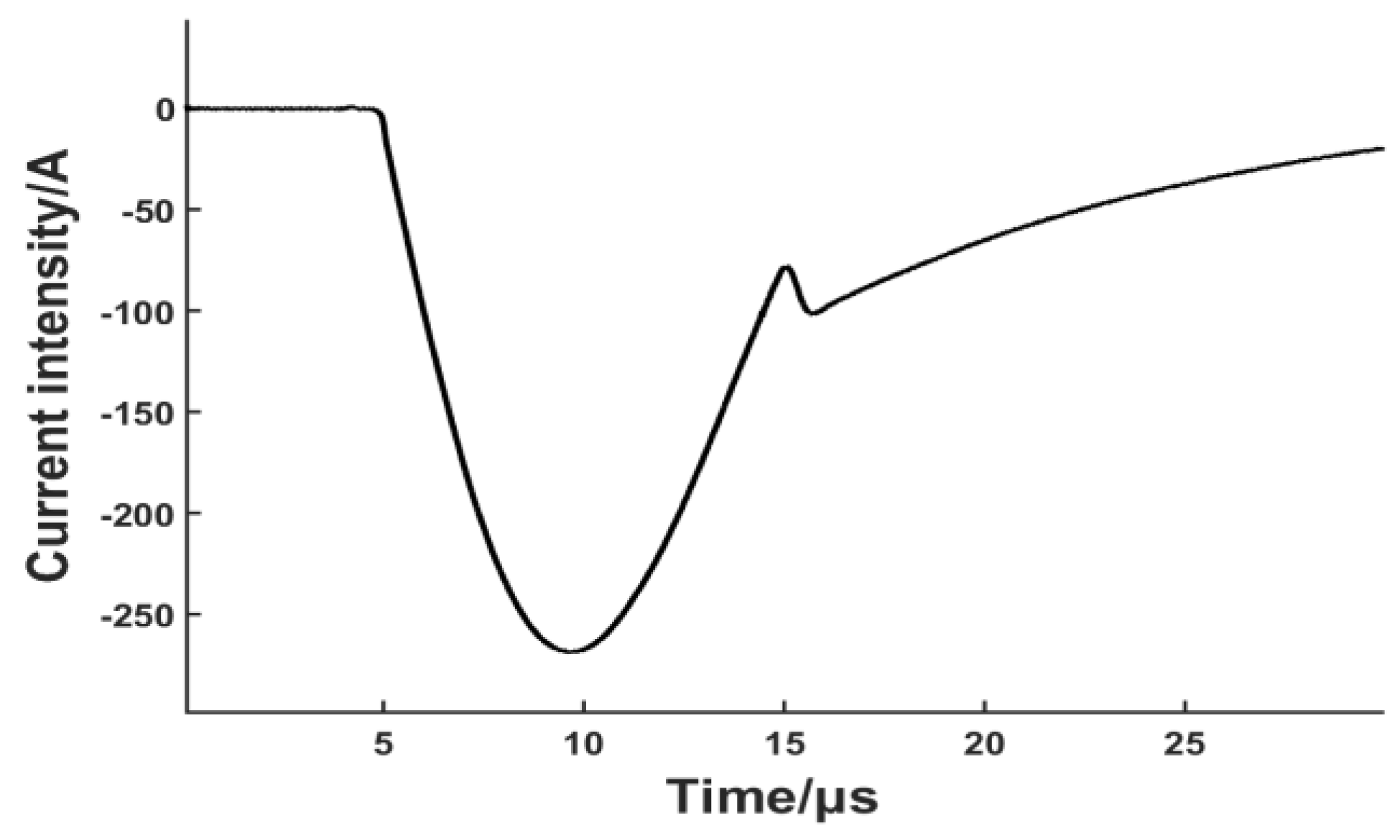

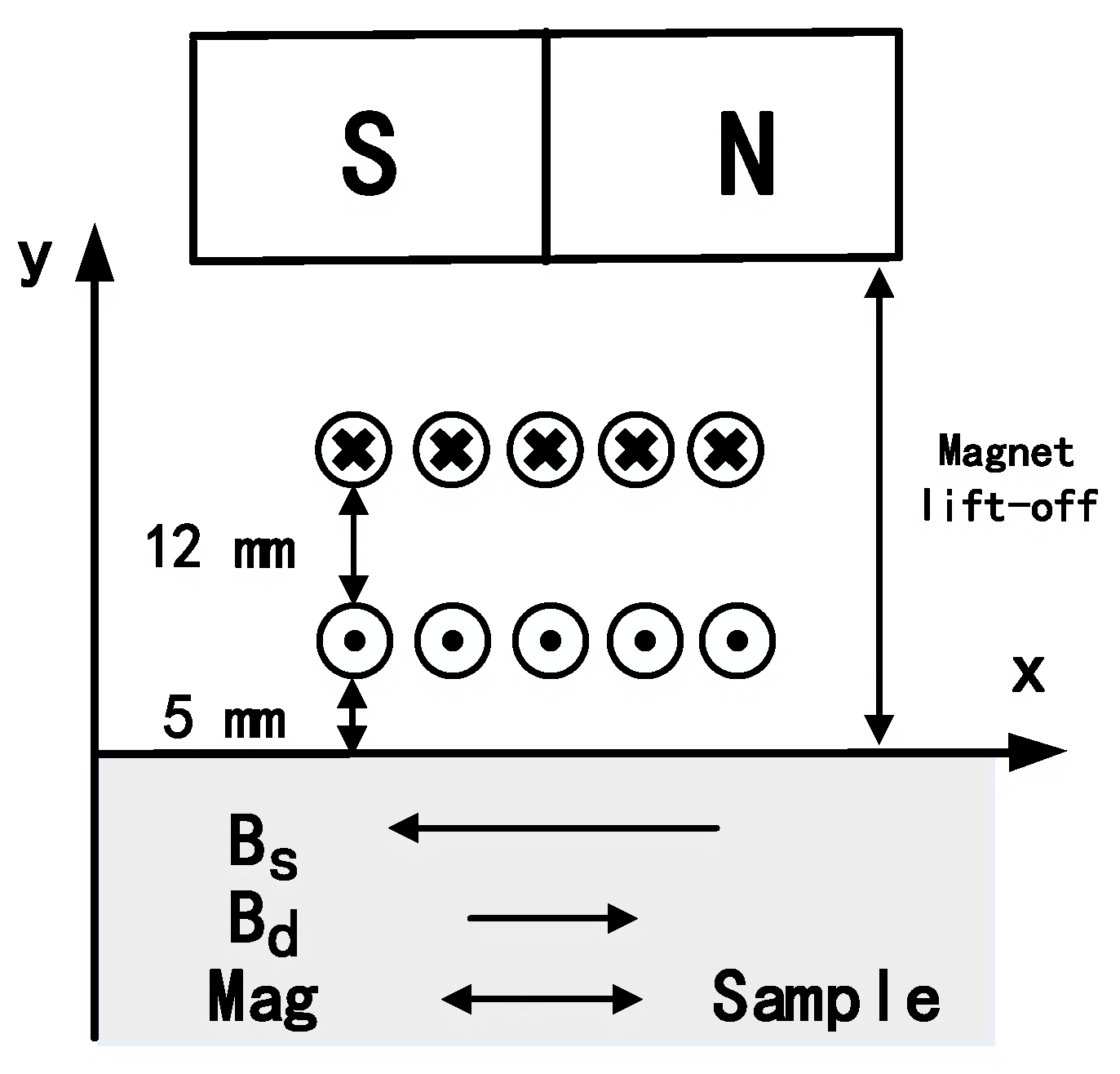

3. Design of a Coil-Only EMAT

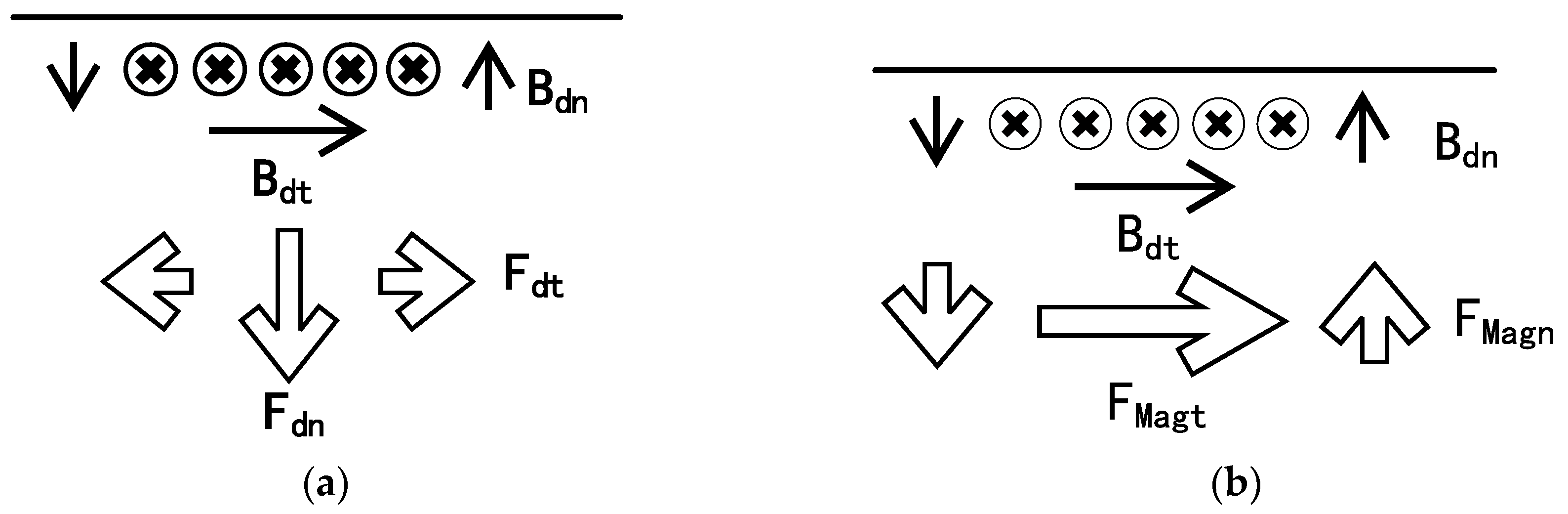

3.1. Theoretical Analysis

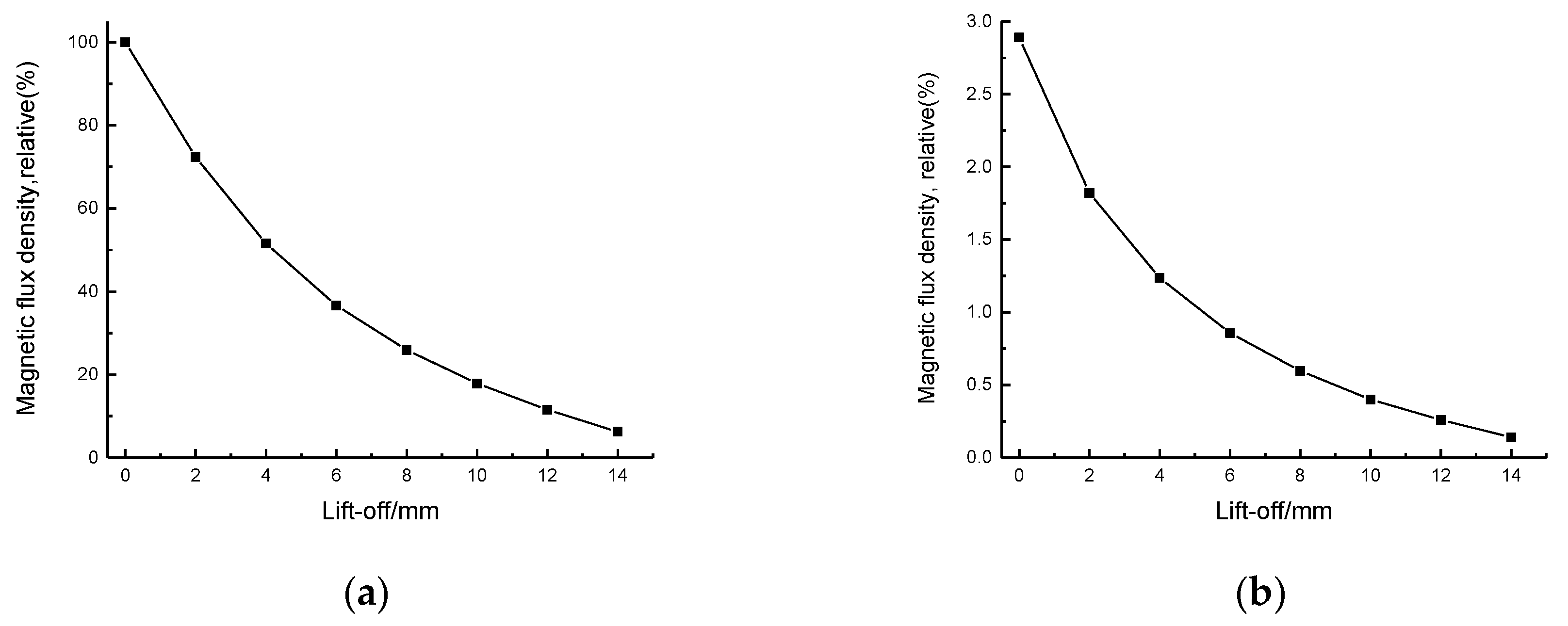

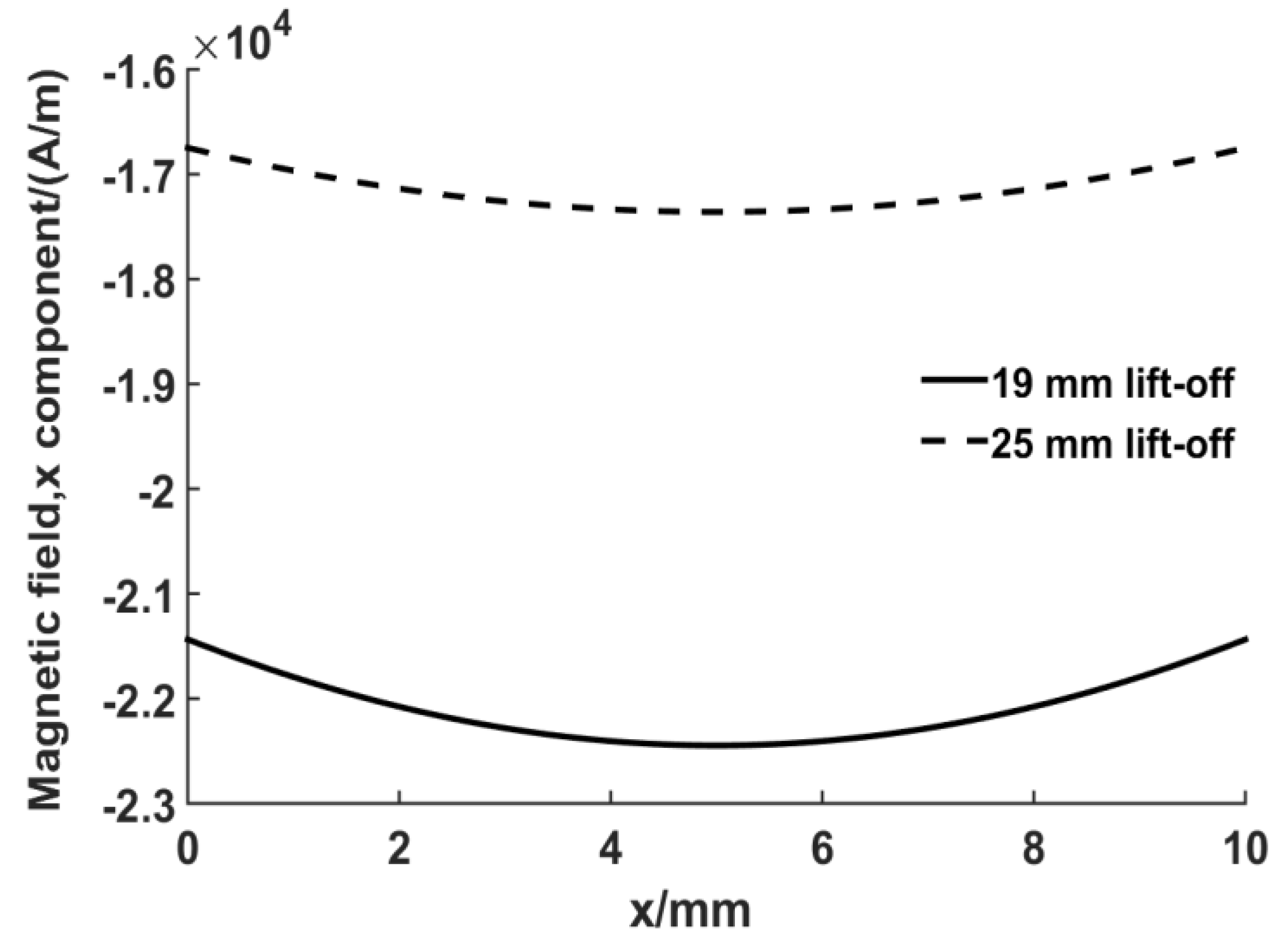

3.2. Simulation of Magnetic Flux Density with Lift-Off

3.3. Experimental Procedure

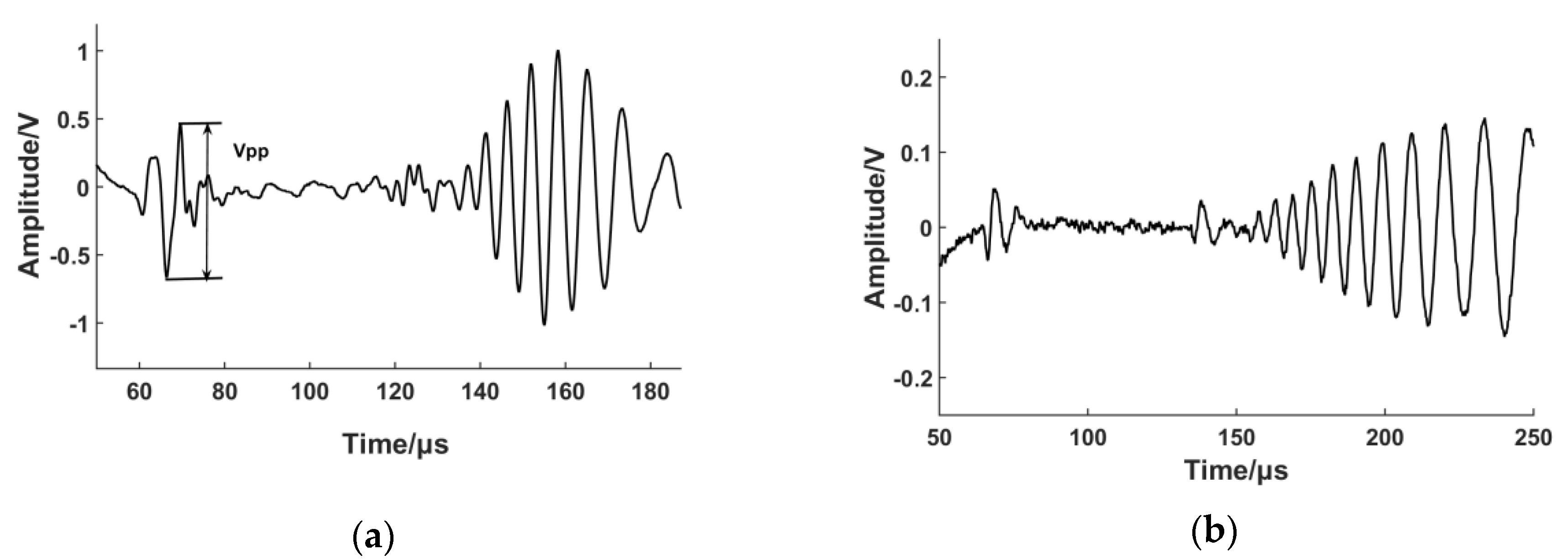

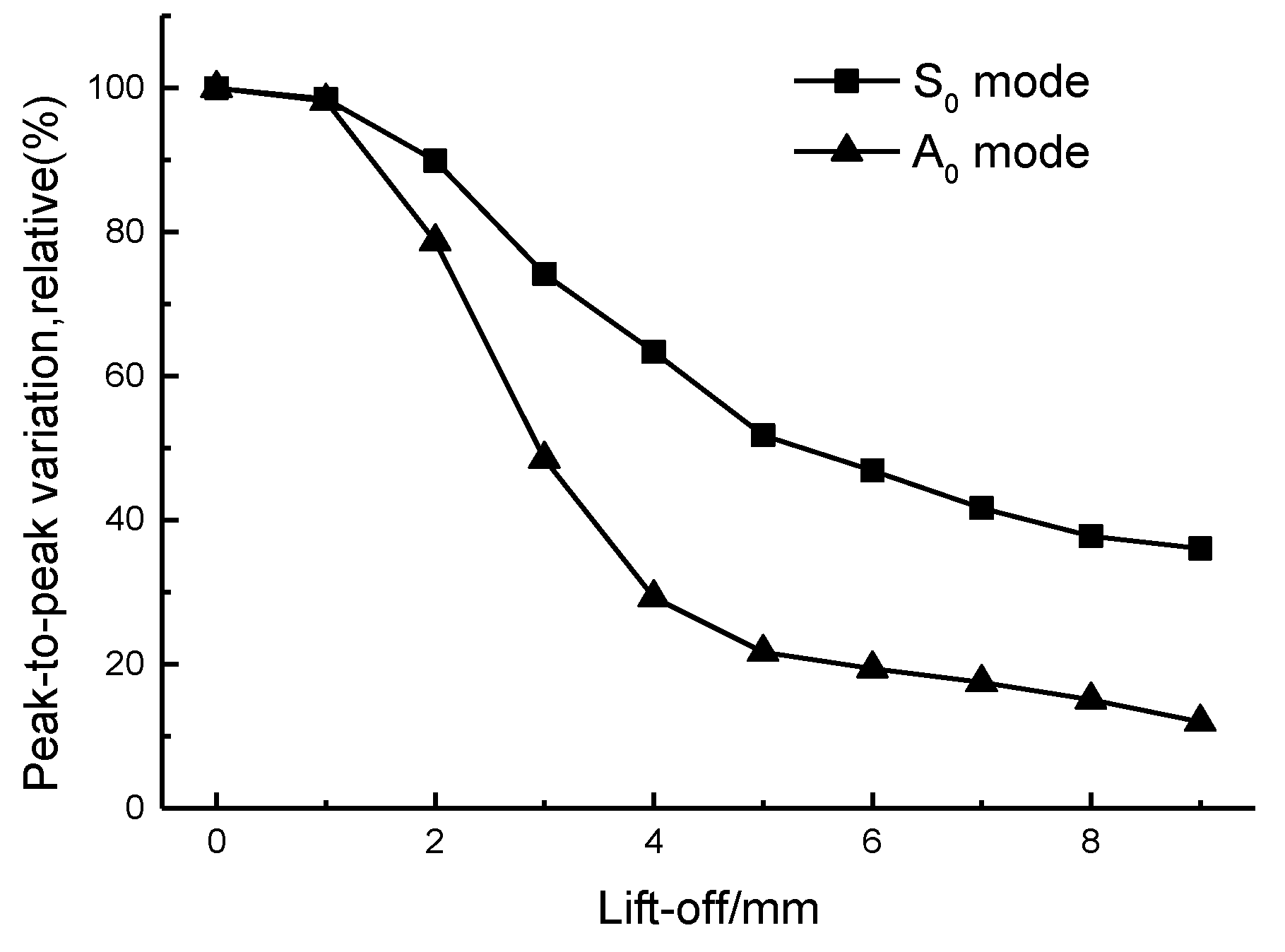

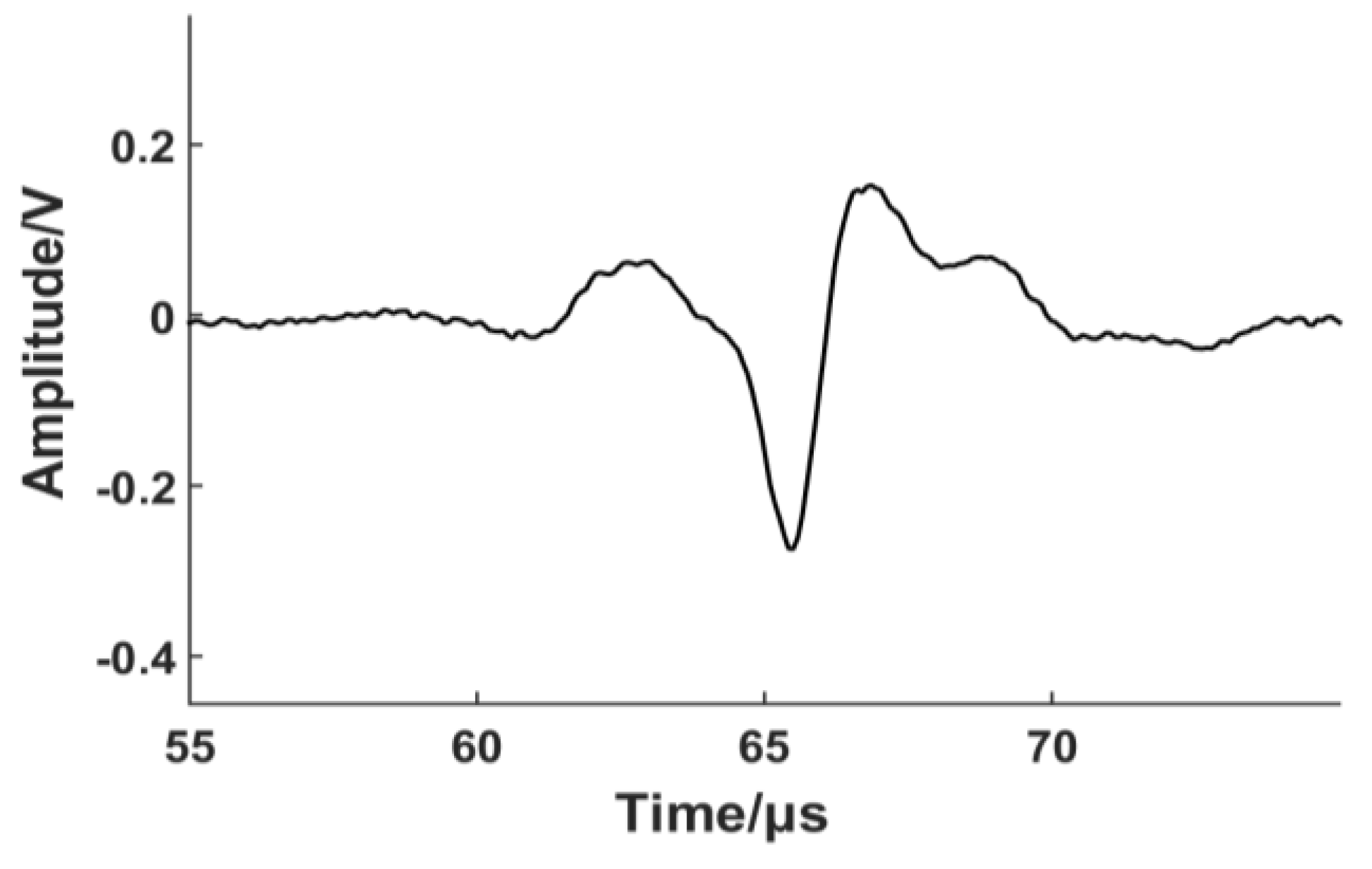

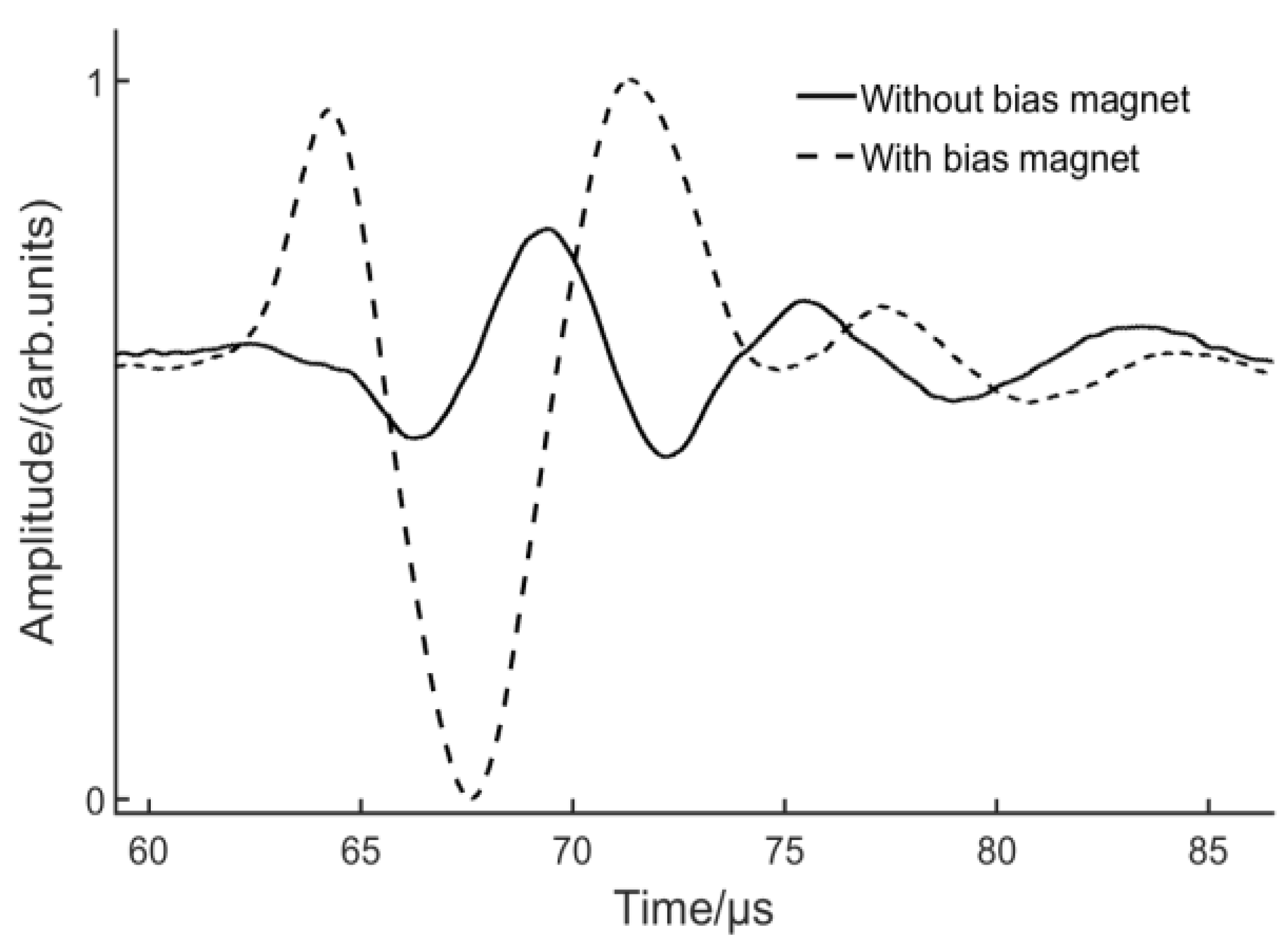

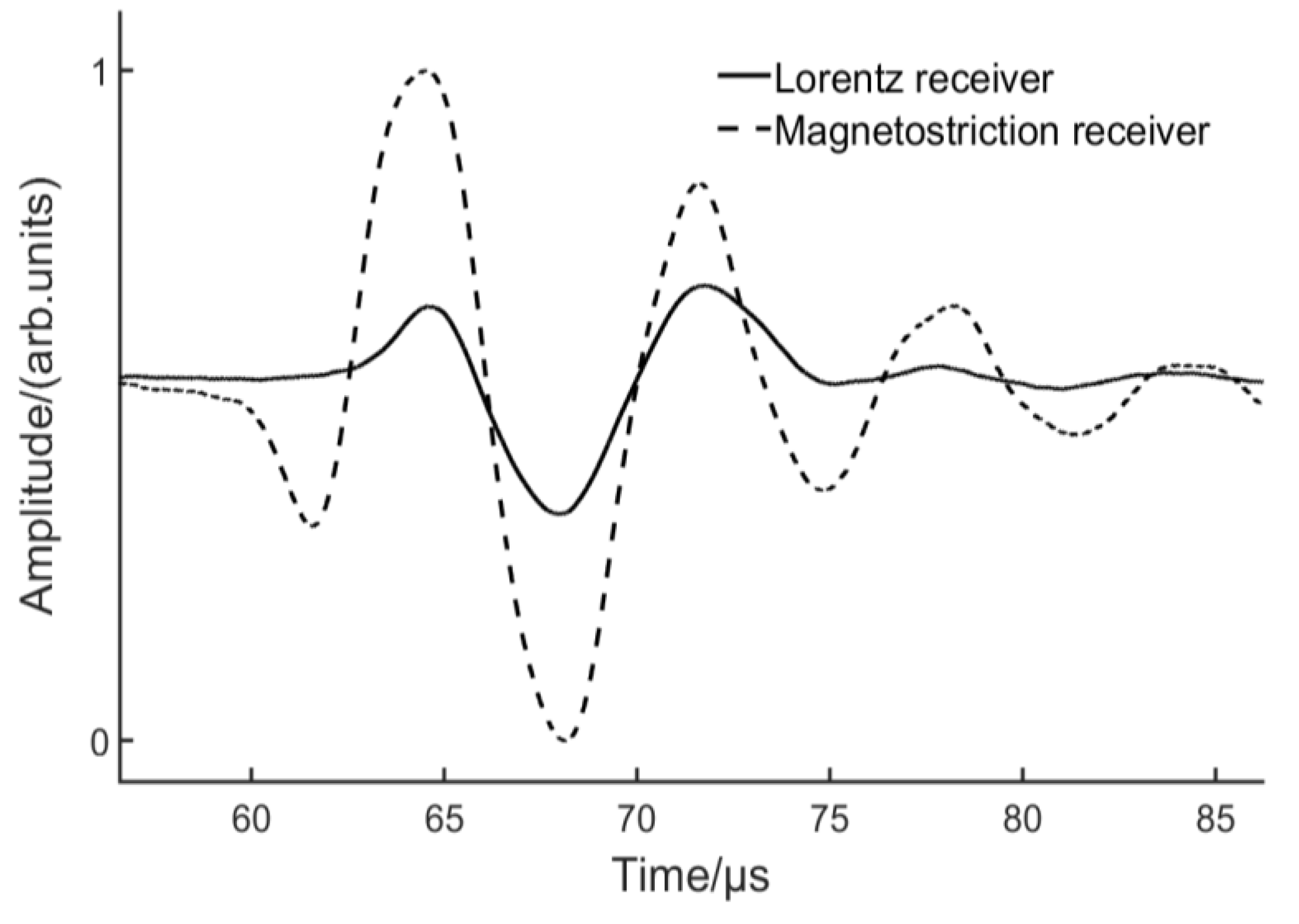

4. Generation and Reception of S0 Lamb Wave Based on the Magnetostrictive Mechanism

4.1. Design of the Magnetostrictive EMAT

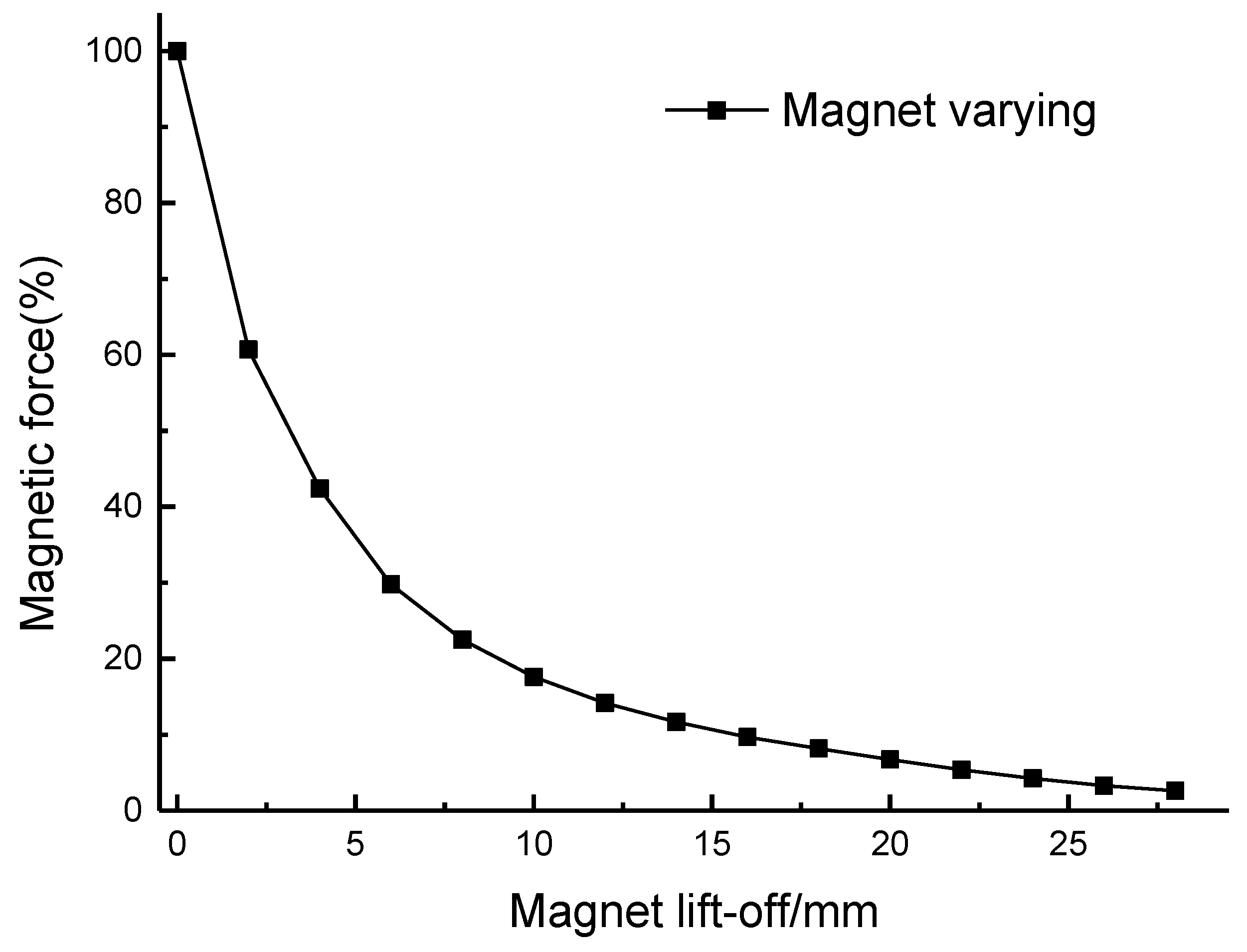

4.2. Experimental Study of Magnetostrictive EMAT Lift-Off

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Clough, M.; Fleming, M.; Dixon, S. Circumferential guided wave EMAT system for pipeline screening using shear horizontal ultrasound. NDT E Int. 2017, 86, 20–27. [Google Scholar] [CrossRef]

- Petcher, P.A.; Dixon, S. Weld defect detection using PPM EMAT generated shear horizontal ultrasound. NDT E Int. 2015, 74, 58–65. [Google Scholar] [CrossRef]

- Kang, L.; Zhang, C.; Dixon, S.; Zhao, H.; Hill, S.; Liu, M.H. Enhancement of Ultrasonic Signal Using a New Design of Rayleigh-Wave Electromagnetic Acoustic Transducer. NDT E Int. 2017, 86, 36–43. [Google Scholar] [CrossRef]

- Yi, P.X.; Zhang, K.; Li, Y.H.; Zhang, X.M. Influence of the lift-off effect on the cut-off frequency of the EMAT-generated Rayleigh wave signal. Sensors 2014, 14, 19687–19699. [Google Scholar] [CrossRef] [PubMed]

- Burrows, S.E.; Fan, Y.; Dixon, S. High temperature thickness measurements of stainless steel and low carbon steel using electromagnetic acoustic transducer. NDT E Int. 2014, 68, 73–77. [Google Scholar] [CrossRef]

- Petcher, P.A.; Burrows, S.E.; Dixon, S. Shear horizontal (SH) ultrasound wave propagation around smooth corners. Ultrasonics 2014, 54, 997–1004. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.L.; Wei, Z.; Zhao, W.; Wang, S. A new omni-directional EMAT for ultrasonic Lamb wave tomography imaging of metallic plate defects. Sensors 2014, 14, 3458–3476. [Google Scholar] [CrossRef] [PubMed]

- Hill, S.; Dixon, S. Frequency dependent directivity of periodic permanent magnet electromagnetic acoustic transducers. NDT E Int. 2014, 62, 137–143. [Google Scholar] [CrossRef]

- Wang, Y.G.; Wu, X.J.; Sun, P.F.; Li, J. Enhancement of the Excitation Efficiency of a Torsional Wave PPM EMAT array for Pipe Inspection by Optimizing the Element Number of the array Based on 3-D FEM. Sensors 2015, 15, 3471–3490. [Google Scholar] [CrossRef] [PubMed]

- Edwards, R.S.; Dixon, S.; Jian, X. Enhancement of the Rayleigh wave signal at surface defects. J. Phys. D Appl. Phys. 2004, 37, 2291–2297. [Google Scholar] [CrossRef]

- Huang, S.L.; Zhao, W.; Zhang, Y.; Wang, S. Study on the lift-off effect of EMAT. Sens. Actuators A Phys. 2009, 153, 218–221. [Google Scholar] [CrossRef]

- Ashigwuike, E.C.; Ushie, O.J.; Mackay, R.; Balachandran, W. A study of the transduction mechanisms of electromagnetic acoustic transducers (EMATs) on pipe steel materials. Sens. Actuators A Phys. 2015, 229, 154–165. [Google Scholar] [CrossRef]

- Murayama, R. Study of driving mechanism on electromagnetic acoustic transducer for Lamb wave using magnetostrictive effect and application in drawability evaluation of thin steel sheets. Ultrasonics 1999, 37, 31–38. [Google Scholar] [CrossRef]

- Ribichini, R.; Cegla, F.; Nagy, P.B.; Cawley, P. Study and comparison of different EMAT configurations for SH wave inspection. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 2571–2581. [Google Scholar] [CrossRef] [PubMed]

- Seher, M.; Huthwaite, P.; Lowe, M.J.S.; Nagy, P.B. Model-based design of low frequency Lamb wave EMATs for mode selectivity. J. Nondestr. Eval. 2015, 34, 22. [Google Scholar] [CrossRef]

- Dixon, S.; Palmer, S.B. Wideband low frequency generation and detection of Lamb and Rayleigh waves using electromagnetic acoustic transducers (EMATs). Ultrasonics 2004, 42, 1129–1136. [Google Scholar] [CrossRef] [PubMed]

- Murayama, R. Driving mechanism on magnetostrictive type electromagnetic acoustic transducer for symmetrical vertical-mode Lamb wave and for shear horizontal-mode plate wave. Ultrasonics 1996, 34, 729–736. [Google Scholar] [CrossRef]

- Ribichini, R.; Cegla, H.; Nagy, P.B.; Cawley, P. Quantitative modeling of the transduction of electromagnetic acoustic transducers operating on ferromagnetic media. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 2808–2817. [Google Scholar] [CrossRef] [PubMed]

- Hirao, M.; Ogi, H. EMATs for Science and Industry: Noncontacting Ultrasonic Measurements; Springer Science & Business Media: Boston, MA, USA, 2003; pp. 13–31. [Google Scholar]

- Murayama, R.; Hoshihara, H.; Fukushige, T. Development of an Electromagnetic Acoustic Transducer that can Alternately Drive the Lamb Wave and Shear Horizontal Plate Wave. Jpn. J. Appl. Phys. 2003, 42, 3180–3183. [Google Scholar] [CrossRef]

- Murayama, R.; Mizutani, K. Development of an Electromagnetic Acoustic Transducer with Multi-Wavelength for Lamb Wave. Jpn. J. Appl. Phys. 2002, 41, 3534–3538. [Google Scholar] [CrossRef]

- Dixon, S.; Burrows, S.E.; Dutton, B.; Fan, Y. Detection of cracks in metal sheets using pulsed laser generated ultrasound and EMAT detection. Ultrasonics 2011, 51, 7–16. [Google Scholar] [CrossRef] [PubMed]

- Potter, M.D.G.; Dixon, S. Ultrasonic texture measurement of sheet metals: An integrated system combining Lamb and shear wave techniques. Nondestr. Test. Eval. 2005, 20, 201–210. [Google Scholar] [CrossRef]

- Nagy, P.B.; Simonetti, F.; Instanes, G. Corrosion and erosion monitoring in plates and pipes using constant group velocity Lamb wave inspection. Ultrasonics 2014, 54, 1832–1841. [Google Scholar] [CrossRef] [PubMed]

- Rosli, M.H.; Edwards, R.S.; Fan, Y. In-plane and out-of-plane measurements of Rayleigh waves using EMATs for characterising surface cracks. NDT E Int. 2012, 49, 1–9. [Google Scholar] [CrossRef]

- Potter, M.D.G; Dixon, S.; Davis, C. Development of an automated non-contact ultrasonic texture measurement system for sheet metal. Meas. Sci. Technol. 2004, 15, 1303–1308. [Google Scholar] [CrossRef]

- Wang, S.J.; Kang, L.; Li, Z.C.; Zhai, G.F.; Zhang, L. 3-D modeling and analysis of meander-line-coil surface wave EMATs. Mechatronics 2012, 22, 653–660. [Google Scholar] [CrossRef]

- Ogi, H.; Goda, E.; Hirao, M. Increase of efficiency of magnetostriction SH-wave electromagnetic acoustic transducer by angled bias field: Piezomagnetic theory and measurement. Jpn. J. Appl. Phys. 2003, 42, 3020–3024. [Google Scholar] [CrossRef]

- Thompson, R.B. Mechanisms of electromagnetic generation and detection of ultrasonic Lamb waves in iron-nickel alloy polycrystals. J. Appl. Phys. 1977, 48, 4942–4950. [Google Scholar] [CrossRef]

- Yamasaki, T.; Yamamoto, S.; Hirao, M. Effect of applied stresses on magnetostriction of low carbon steel. NDT E Int. 1996, 29, 263–268. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, J.; Dixon, S.; Hill, S.; Xu, K. A New Electromagnetic Acoustic Transducer Design for Generating and Receiving S0 Lamb Waves in Ferromagnetic Steel Plate. Sensors 2017, 17, 1023. https://doi.org/10.3390/s17051023

He J, Dixon S, Hill S, Xu K. A New Electromagnetic Acoustic Transducer Design for Generating and Receiving S0 Lamb Waves in Ferromagnetic Steel Plate. Sensors. 2017; 17(5):1023. https://doi.org/10.3390/s17051023

Chicago/Turabian StyleHe, Jianpeng, Steve Dixon, Samuel Hill, and Ke Xu. 2017. "A New Electromagnetic Acoustic Transducer Design for Generating and Receiving S0 Lamb Waves in Ferromagnetic Steel Plate" Sensors 17, no. 5: 1023. https://doi.org/10.3390/s17051023