A Modified Lamb Wave Time-Reversal Method for Health Monitoring of Composite Structures

Abstract

:1. Introduction

2. Lamb Waves in a Composite Plate

2.1. Excitability and Detectability

2.2. Wave Attenuation

3. Modified Time Reversal Method (MTRM)

- (i)

- An input signal is emitted from transducer A, and the response is captured by transducer B;

- (ii)

- The received signal is reversed in time domain;

- (iii)

- The time reversed signal is reemitted from B, and the response (“reconstructed signal”) is recorded at A;

- (iv)

- The reconstructed signal is time reversed and compared to the original input signal (both signals are normalized by their peak amplitudes).

- (i)

- An input signal is emitted from PZT A, and an output signal is recorded at PZT B;

- (ii)

- The output signal is reversed in time domain;

- (iii)

- The time reversed signal is re-emitted from PZT B, and the reconstructed signal is recorded at PZT A;

- (iv)

- The final signal is obtained as the time-reversed version of the reconstructed signal;

- (v)

- The modulated input signal is calculated from Equation (12) by using the estimated amplitude of transfer function (in the undamaged case) as a prior knowledge;

- (vi)

- Damage detection is accomplished by comparing the final signal to the modulated input signal (both signals are normalized by their peak amplitudes).

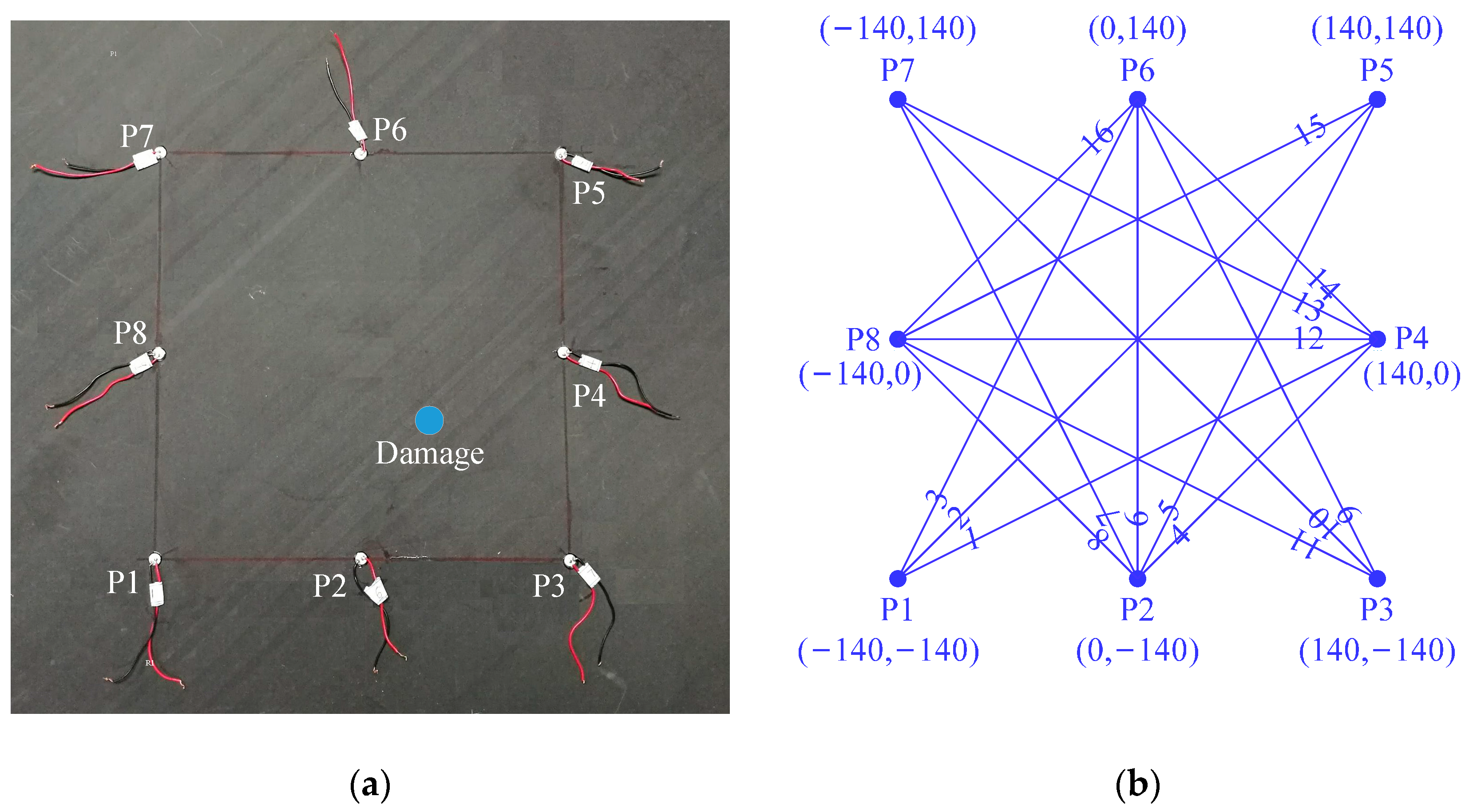

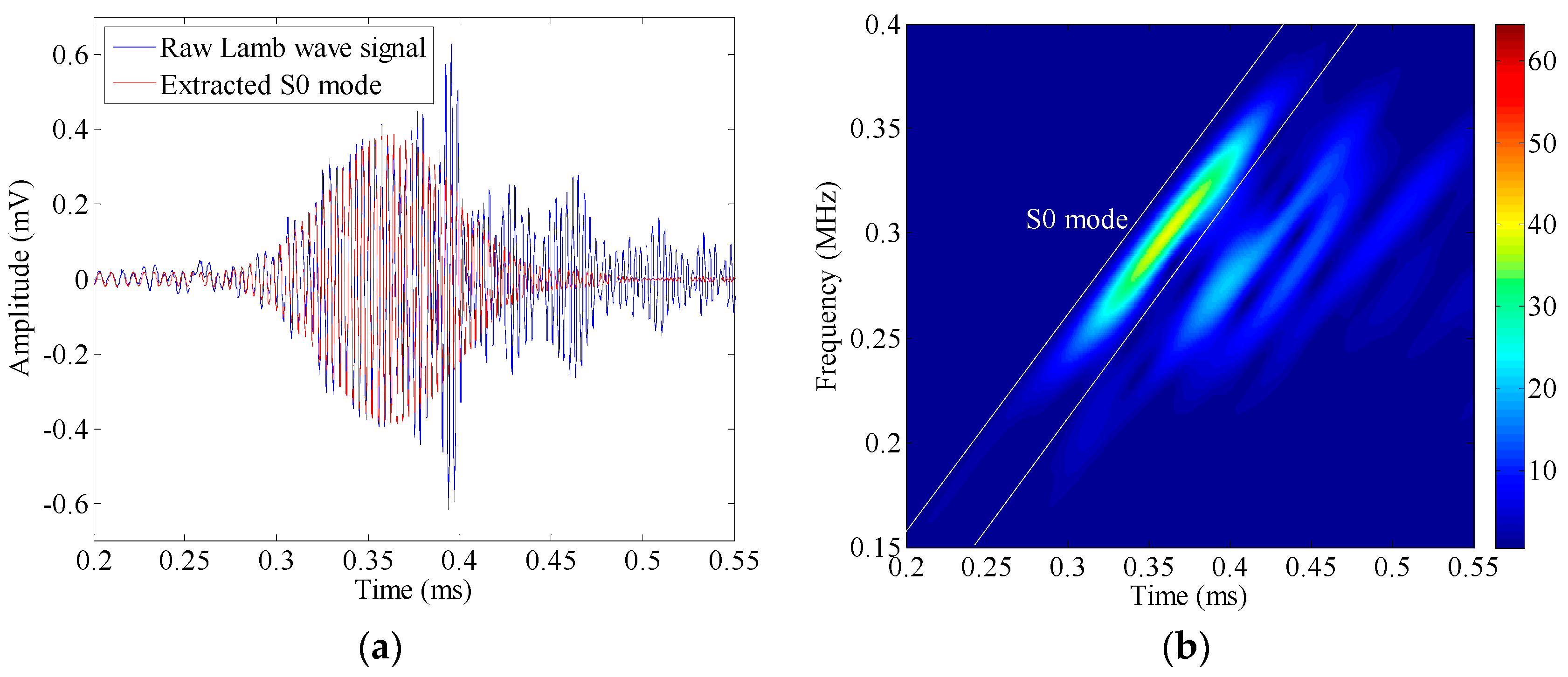

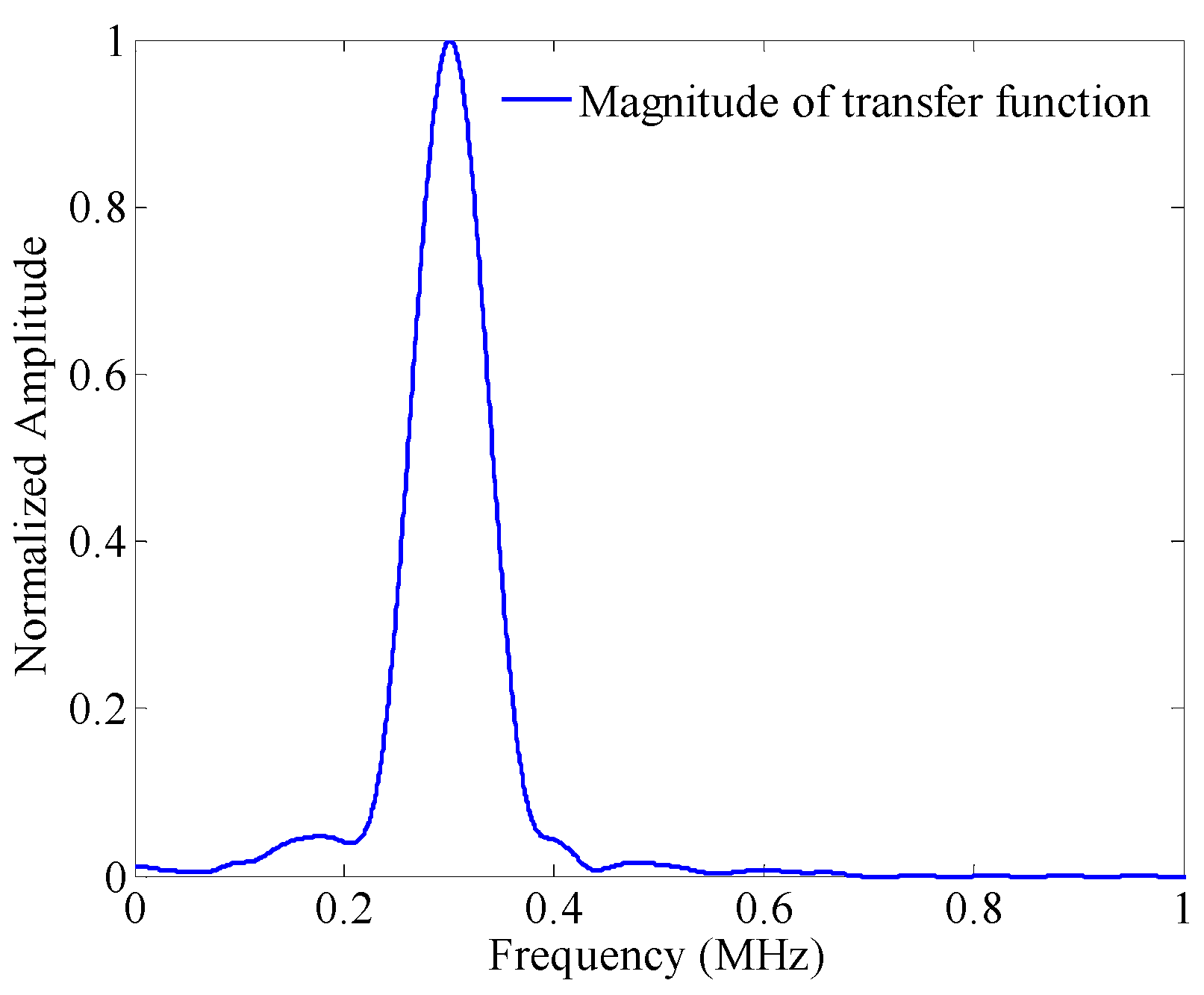

4. Experimental Setups

5. Results and Discussions

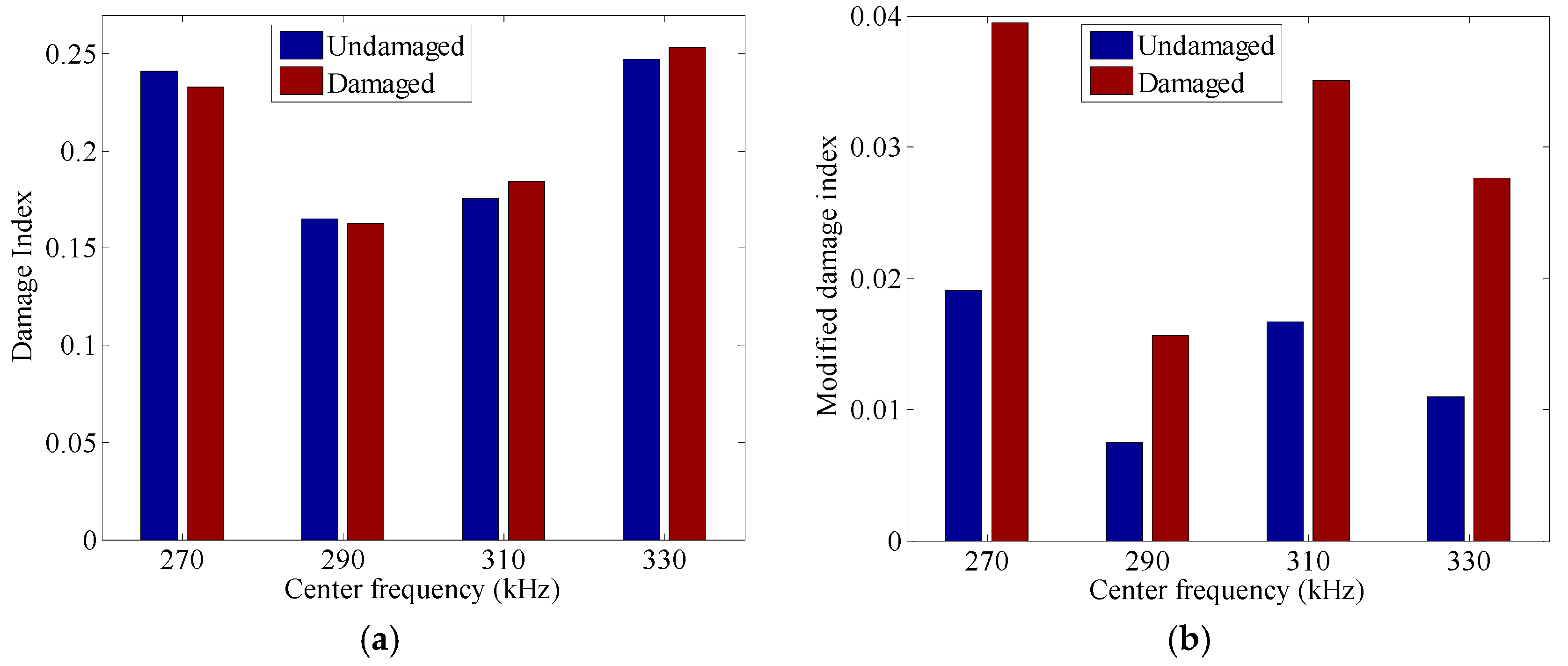

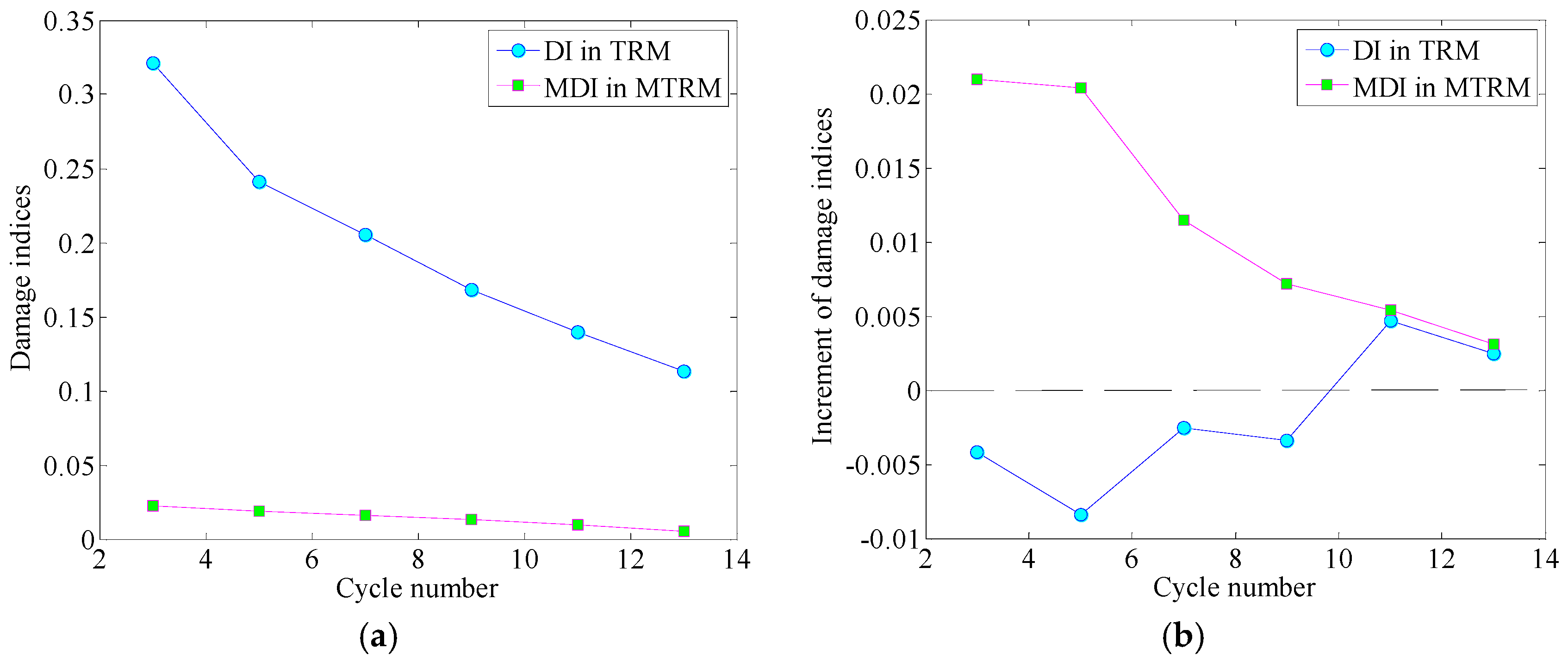

5.1. Identification Presence of Damage

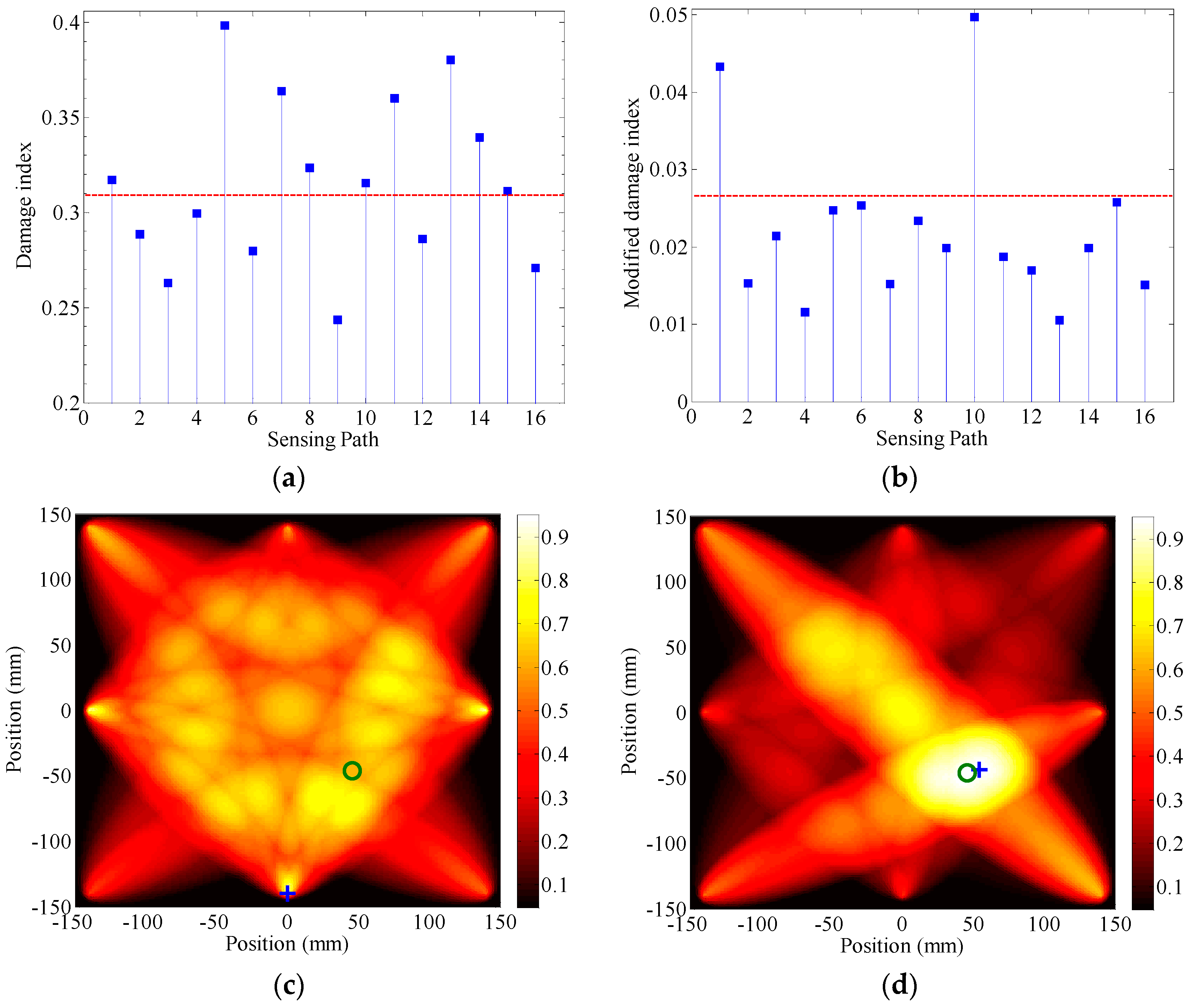

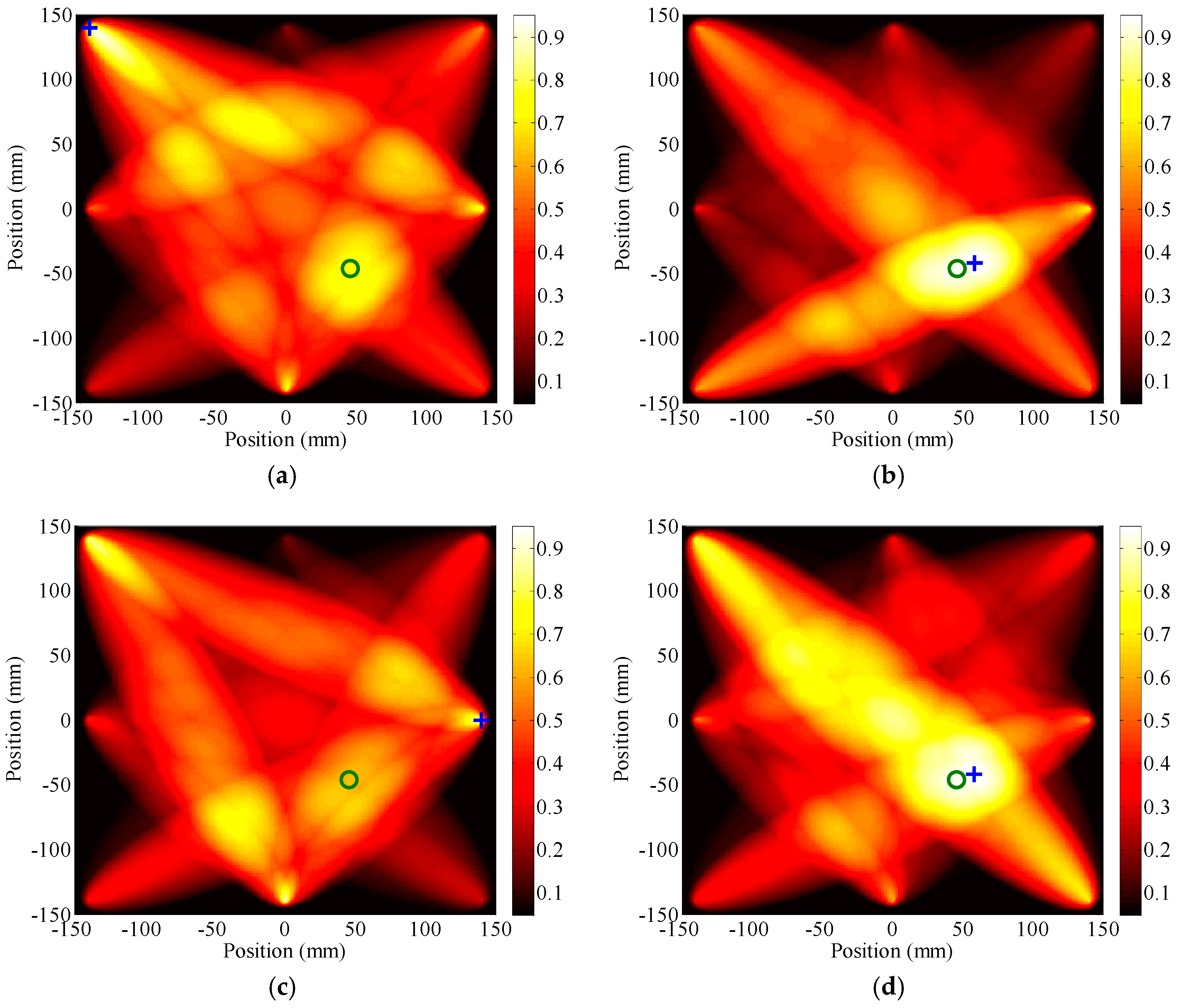

5.2. Damage Identification

6. Conclusions

- (1)

- The frequency dependence of the time reversal operator is associated with the excitability and detectability, and the attenuation with propagation. It is independent of the damage, and could be compensated to improve the performance of the time-reversed damage detection;

- (2)

- In the TRM, the deviation between the final signal and the original input signal may be attributed to both the frequency dependence of time reversal operator and the damage. In this case, the presence of damage may not always lead to an increase of damage index. Therefore, it may not be correctly identified;

- (3)

- Narrowing the excitation frequency bandwidth alleviates the frequency dependence of the time reversal operator at the cost of reducing the sensitivity to damage;

- (4)

- In the MTRM, the effects of frequency dependence of the time reversal operator are greatly compensated. A good waveform reconstruction can be achieved in the undamaged case, and the nonlinearity caused by the damage can be highlighted. Hence, it improves the reliability and applicability of the time-reversal based diagnostics;

- (5)

- While attractive results are obtained, the effectiveness of the MTRM under the varying environmental and operational conditions deserves further investigation in the future work. As in references [43,44,45,46], conducting researches on the nonlinear behavior of the damage and capturing more information for a damage indicator is an important and interesting aspect for achieving a more robust damage detection.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yu, X.; Ratassepp, M.; Rajagopal, P.; Fan, Z. Anisotropic effects on ultrasonic guided waves propagation in composite bends. Ultrasonics 2016, 72, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Hayat, K.; Ha, S.K. Low-velocity impact-induced delamination detection by use of the S0 guided wave mode in cross-ply composite plates: A numerical study. Mech. Sci. Technol. 2014, 28, 445–455. [Google Scholar] [CrossRef]

- Staszewski, W.J.; Mahzan, S.; Traynor, R. Health monitoring of aerospace composite structures—Active and passive approach. Compos. Sci. Technol. 2009, 69, 1678–1685. [Google Scholar] [CrossRef]

- Mustapha, S.; Ye, L.; Dong, X.; Alamdari, M.M. Evaluation of barely visible indentation damage (BVID) in CF/EP sandwich composites using guided wave signals. Mech. Syst.Signal Process. 2016, 76–77, 497–517. [Google Scholar]

- Giurgiutiu, V.; Bao, J. Embedded-ultrasonics structural radar for in situ structural health monitoring of thin-wall structures. Struct. Health Monit. 2004, 3, 121–140. [Google Scholar] [CrossRef]

- Roy, S.; Ladpli, P.; Chang, F.K. Load monitoring and compensation strategies for guided-waves based structural health monitoring using piezoelectric transducers. J. Sound Vib. 2015, 351, 206–220. [Google Scholar] [CrossRef]

- Cai, J.; Yuan, S.; Qing, X.P.; Chang, F.K.; Shi, L.; Qiu, L. Linearly dispersive signal construction of Lamb waves with measured relative wavenumber curves. Sens. Actuators A Phys. 2015, 221, 41–52. [Google Scholar] [CrossRef]

- Chen, X.; Michaels, J.E.; Michaels, T.E. A methodology for estimating guided wave scattering patterns from sparse transducer array measurements. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 208–219. [Google Scholar] [CrossRef] [PubMed]

- Su, Z.; Ye, L. Identification of Damage Using Lamb Waves: From Fundamentals to Applications; Springer: Berlin, Germany, 2009. [Google Scholar]

- Zhao, X.; Gao, H.; Zhang, G.; Ayhan, B.; Yan, F.; Kwan, C.; Rose, J.L. Active health monitoring of an aircraft wing with embedded piezoelectric sensor/actuator network: I. Defect detection, localization and growth monitoring. Smart Mater. Struct. 2007, 16, 1208–1217. [Google Scholar] [CrossRef]

- Zhao, X.; Royer, R.L.; Owens, S.E.; Rose, J.L. Ultrasonic Lamb wave tomography in structural health monitoring. Smart Mater. Struct. 2011, 20, 105002. [Google Scholar] [CrossRef]

- Zeng, L.; Lin, J.; Hua, J.; Shi, W. Interference resisting design for guided wave tomography. Smart Mater. Struct. 2013, 22, 055017. [Google Scholar] [CrossRef]

- Konstantinidis, G.; Drinkwater, B.W.; Wilcox, P.D. The temperature stability of guided wave structural health monitoring systems. Smart Mater. Struct. 2006, 15, 967–976. [Google Scholar] [CrossRef]

- Croxford, A.J.; Moll, J.; Wilcox, P.D.; Michaels, J.E. Efficient temperature compensation strategies for guided wave structural health monitoring. Ultrasonics 2010, 50, 517–528. [Google Scholar] [CrossRef] [PubMed]

- Salmanpour, M.S.; Khodaei, Z.S.; Aliabadi, M.H. Guided wave temperature correction methods in structural health monitoring. J. Intell. Mater. Syst. Struct. 2016, 28, 1–15. [Google Scholar] [CrossRef]

- Park, H.W.; Kim, S.B.; Sohn, H. Understanding a time reversal process in Lamb wave propagation. Wave Motion 2009, 46, 451–467. [Google Scholar] [CrossRef]

- Gangadharan, R.; Murthy, C.R.L.; Gopalakrishnan, S.; Bhat, M.R. Time reversal technique for health monitoring of metallic structure using Lamb waves. Ultrasonics 2009, 49, 696–705. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.H.; Rose, J.T.; Chang, F.K. A synthetic time-reversal imaging method for structural health monitoring. Smart Mater. Struct. 2004, 13, 415–423. [Google Scholar] [CrossRef]

- Park, H.W.; Sohn, H.; Law, K.H.; Farrar, C.R. Time reversal active sensing for health monitoring of a composite plate. J. Sound Vib. 2007, 302, 50–66. [Google Scholar] [CrossRef]

- Poddar, B.; Kumar, A.; Mitra, M.; Mujumdar, M.P.M. Time reversibility of a Lamb wave for damage detection in a metallic plate. Smart Mater. Struct. 2011, 20, 025001. [Google Scholar] [CrossRef]

- Agrahari, J.K.; Kapuria, S. A refined Lamb wave time-reversal method with enhanced sensitivity for damage detection in isotropic plates. J. Intell. Mater. Syst. Struct. 2015, 27, 1–23. [Google Scholar] [CrossRef]

- Yu, L.; Tian, Z. Guided wave phased array beamforming and imaging in composite plates. Ultrasonics 2016, 68, 43–53. [Google Scholar] [CrossRef] [PubMed]

- Belanger, P.; Cawley, P. Lamb wave tomography to evaluate the maximum depth of corrosion patches. AIP Conf. Proc. 2008, 975, 1290–1297. [Google Scholar]

- Giurgiutiu, V. Structural Health Monitoring with Piezoelectric Wafer Active Sensors, 2nd ed.; Elsevier Academic Press: Waltham, MA, USA, 2014. [Google Scholar]

- Gresil, M.; Giurgiutiu, V. Prediction of attenuated guided waves propagation in carbon fiber composites using Rayleigh damping model. J. Intell. Mater. Syst. Struct. 2015, 26, 2151–2169. [Google Scholar] [CrossRef]

- Schubert, K.J.; Herrmann, A.S. On attenuation and measurement of Lamb waves in viscoelastic composites. Compos. Struct. 2011, 94, 177–185. [Google Scholar] [CrossRef]

- Draeger, C.; Cassereau, D.; Fink, M. Theory of the time-reversal process in solids. J. Acoust. Soc. Am. 1997, 102, 1289–1295. [Google Scholar] [CrossRef]

- Fink, M.; Prada, C. Acoustic time-reversal mirrors. Inverse Probl. 2001, 17, R1–R38. [Google Scholar] [CrossRef]

- Xu, K.; Ta, D.; Moilanen, P.; Wang, W. Mode separation of Lamb waves based on dispersion compensation method. J. Acoust. Soc. Am. 2012, 131, 2714–2722. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Ta, D.; Wang, W. Multiridge-based analysis for separating individual modes from multimodal guided wave signals in long bones. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 2480–2490. [Google Scholar] [PubMed]

- Li, F.; Su, Z.; Ye, L.; Meng, G.A. Correlation filtering-based matching pursuit (CF-MP) for damage identification using Lamb waves. Smart Mater. Struct. 2006, 15, 1585–1594. [Google Scholar] [CrossRef]

- Marchi, L.D.; Marzani, A.; Caporale, S.; Speciale, N. Ultrasonic guided-waves characterization with warped frequency transforms. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 2232–2240. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Peng, Z.K.; Zhang, W.M.; Meng, G.; Lang, Z.Q. Dispersion analysis for broadband guided wave using generalized warblet transform. J. Sound Vib. 2016, 367, 22–36. [Google Scholar] [CrossRef]

- Zeng, L.; Zhao, M.; Lin, J.; Wu, W. Waveform separation and image fusion for Lamb waves inspection resolution improvement. NDT E Int. 2016, 79, 17–29. [Google Scholar] [CrossRef]

- Cowell, D.M.J.; Freear, S. Separation of overlapping linear frequency modulated (LFM) signals using the fractional Fourier transform. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 2324–2333. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Zeng, L.; Lin, J.; Wu, W. Mode identification and extraction of broadband ultrasonic guided waves. Meas. Sci. Technol. 2014, 25, 115005. [Google Scholar] [CrossRef]

- Ruzzene, M. Frequency-wavenumber domain filtering for improved damage visualization. Smart Mater. Struct. 2007, 16, 2116–2129. [Google Scholar] [CrossRef]

- Michaels, T.E.; Michaels, J.E.; Ruzzene, M. Frequency-wavenumber domain analysis of guided wavefields. Ultrasonics 2011, 51, 452–466. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.; Yu, L. Lamb wave frequency-wavenumber analysis and decomposition. J. Intell. Mater. Syst. Struct. 2014, 25, 1107–1123. [Google Scholar] [CrossRef]

- Kudela, P.; Radzieński, M.; Ostachowicz, W. Identification of cracks in thin-walled structures by means of wavenumber filtering. Mech. Syst. Signal Process. 2015, 50–51, 456–466. [Google Scholar] [CrossRef]

- Flynn, E.B.; Chong, S.Y.; Jarmer, G.J.; Lee, J. Structural imaging through local wavenumber estimation of guided waves. NDT E. Int. 2013, 59, 1–10. [Google Scholar] [CrossRef]

- Williams, G.; Trask, R.; Bond, I. A self-healing carbon fibre reinforced polymer for aerospace applications. Compos. Part A 2007, 38, 1525–1532. [Google Scholar] [CrossRef]

- Scalerandi, M.; Bruno, C.L.E.; Gliozzi, A.S.; Bocca, P.G. Break of reciprocity principle due to localized nonlinearities in concrete. Ultrasonics 2012, 52, 712–719. [Google Scholar] [CrossRef] [PubMed]

- Scalerandi, M.; Gliozzi, A.S.; Bruno, C.L.E.; Masera, D.; Bocca, P.G. A scaling method to enhance detection of a nonlinear elastic response. Appl. Phys. Lett. 2008, 92, 101912. [Google Scholar] [CrossRef]

- Hettler, J.; Tabatabaeipour, M.; Delrue, S.; Abeele, K.V.D. Linear and nonlinear guided wave imaging of impact damage in CFRP using a probabilistic approach. Materials 2016, 9, 901–917. [Google Scholar] [CrossRef]

- Monaco, E.; Boffa, N.D.; Memmolo, V.; Ricci, F.; Testoni, N.; Marchi, L.D.; Marzani, A.; Hettler, J.; Tabatabaeipour, M.; Delrue, S.; et al. Methodologies for Guided Wave-Based SHM System Implementation on Composite Wing Panels: Results and Perspectives from SARISTU Scenario 5. In Smart Intelligent Aircraft Structures (SARISTU); Wölcken, P.C., Papadopoulos, M., Eds.; Springer: Berlin, Germany, 2016. [Google Scholar]

| Material Properties | ρ (kg/m3) | E1 (GPa) | E2 (GPa) | G12 (GPa) | v12 | v23 |

|---|---|---|---|---|---|---|

| Value | 1560 | 135 | 10.9 | 4.7 | 0.285 | 0.4 |

| Cycle Number | Damage Index in TRM | Modified Damage Index in MTRM | ||||

|---|---|---|---|---|---|---|

| Undamaged | Damaged | Increment | Undamaged | Damaged | Increment | |

| 3 | 0.3212 | 0.3170 | −0.0042 | 0.0223 | 0.0433 | 0.0210 |

| 5 | 0.2412 | 0.2328 | −0.0084 | 0.0191 | 0.0395 | 0.0204 |

| 7 | 0.2057 | 0.2032 | −0.0025 | 0.0159 | 0.0274 | 0.0115 |

| 9 | 0.1684 | 0.1650 | −0.0034 | 0.0131 | 0.0203 | 0.0072 |

| 11 | 0.1398 | 0.1445 | 0.0047 | 0.0097 | 0.0151 | 0.0054 |

| 13 | 0.1129 | 0.1154 | 0.0025 | 0.0057 | 0.0088 | 0.0031 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, L.; Lin, J.; Huang, L. A Modified Lamb Wave Time-Reversal Method for Health Monitoring of Composite Structures. Sensors 2017, 17, 955. https://doi.org/10.3390/s17050955

Zeng L, Lin J, Huang L. A Modified Lamb Wave Time-Reversal Method for Health Monitoring of Composite Structures. Sensors. 2017; 17(5):955. https://doi.org/10.3390/s17050955

Chicago/Turabian StyleZeng, Liang, Jing Lin, and Liping Huang. 2017. "A Modified Lamb Wave Time-Reversal Method for Health Monitoring of Composite Structures" Sensors 17, no. 5: 955. https://doi.org/10.3390/s17050955