SLAE–CPS: Smart Lean Automation Engine Enabled by Cyber-Physical Systems Technologies

Abstract

:1. Introduction

- (1)

- Human-centered systems: Among existing production management philosophies and methods, lean production focuses on human-centered production systems [6,7]. Lean production can enable the operators to perform different work tasks, especially assembly tasks. The benefits of lean production, such as waste reduction, human optimization, distributed design, and supply chain management, are well documented and have fully served many companies. However, lean production has the following limitations when applied in Industry 4.0:

- When dealing with complex production tasks, human-centered systems cannot stabilize production and therefore suffer from inconsistent operations, defects, and other problems.

- Lean production aims to eliminate waste and effectively manage personnel such that each stage of production is done the best way possible. Therefore, lean production eliminates much of the creativity necessary for innovations [3], thereby making enterprises miss advanced technology-push opportunities. Lean production also does not maximize the potential of Industry 4.0 technologies [5].

- (2)

- Automation systems: Automation systems are more stable than human-centered production systems in terms of operation efficiency, quality control, and other factors. Nowadays, robots, automated guided vehicles, automated warehouses, and other high-end automation equipment are widely used in factories to strengthen the said advantages. However, implementing new production systems is a systematic engineering process that integrates all aspects of enterprises. Simply applying high automation technologies to improve production system flexibility will cause problems, such as high investment costs, low investment returns, and investment transformation failure [9,10,11,12]. Although automation technologies are more advanced than human-centered ones, only humans can accomplish some complex and special tasks, especially in assembly operations.

- (3)

- Lean automation: Whether companies can apply lean automation in a shrinking economy while focusing on innovations needed for survival is unclear [3]. Lean automation is emphasized to address this contradictory situation. In the early 1990s, the first approaches for integrating automation technology into lean production arose and were called lean automation. Lean automation is the key pillar of the lean production system and is also called Jidoka or autonomation (collectively called Jidoka hereinafter). The emergence of certain Industry 4.0 technologies (e.g., IoT, CPS, and cloud) has recently widened the application range of Jidoka. Lean production and Industry 4.0 favor decentralized structures over large, complex machines and both aim for small modules with low levels of complexity [8,12]. Therefore, Jidoka is a cost-efficient and effective way to improve production system flexibility in the context of Industry 4.0.

- CPS-based Jidoka is a hybrid system (physical, conversion, and cyber automation) composed of diverse components, including analog and digital parts, actuators, controllers, ICT, software, and Jidoka rules. CPS-based Jidoka is distributed, such as network-embedded systems that can decouple centralized control and support distributed control. IoT has the power to achieve seamless connections, and each network-connected resource is easily controlled. Cloud technology can support remote and distributed applications. Therefore, a comprehensive architecture should be proposed to support the application of smart Jidoka before CPS-enabled Jidoka is studied. However, this area is yet to be explored.

- Under IoT, networks and protocols are heterogeneous and complex; thus, the data analysis and decision support capability of Jidoka are limited. Therefore, the second stage of CPS-based Jidoka application is converting heterogeneous network or protocols into uniform communication services. This issue is also not addressed by the related studies.

- IoT connects much resource to the production networks, thereby enabling the collection of various states of resources. This function allows Jidoka to detect abnormalities (e.g., operational sequence for operators, material shortage, and buffer capacity). However, existing research incomprehensively present production abnormalities.

- The potential of CPS has led to new fields of application for Jidoka. However, existing approaches are individualized solutions that are tailored to different needs. Thus, modularization and changeability are not supported.

2. Related Works

2.1. Related Architectures in the Context of Industry 4.0

- Industry 4.0 architectures: The Zentralverband Elektrotechnik (ZVEI) of Germany defined the reference architectural model Industry 4.0 (RAMI 4.0) [22], which consisted of a three-dimensional coordinate system that describes all crucial aspects of Industry 4.0. Based on RAMI 4.0, Industry 4.0 technologies can be classified and further developed.

- CPS architectures: Lee and Bagheri proposed a five-level CPS structure (smart connection, data-to-information conversion, cyber, cognition, and configuration levels), namely, the 5C architecture, and provided a guideline for developing and deploying a CPS for manufacturing application [13]. Hu et al. presented a generic CPS architecture based on SOA to improve the integration flexibility and process composability of CPS [25]. Lin et al. put forward a semantic agent framework for CPS to enable distributed intelligence and knowledge sharing [26].

- CPPS architectures: Jakovljevic et al. described the IEC-61499 which can be used for modeling a distributed CPPS. The scope of this standard is the reference architecture for utilization of FB for effective system integration in distributed control systems [27]. Pérez et al. proposed a general CPPS architecture, which is composed of production process, information exchange, and plant information models to represent the physical world, the information exchange, and the information to be accessed [28].

- Jidoka architectures: Jidoka is a functional production system that detects abnormalities and controls feedback. Therefore, a simple or incomplete functional architecture cannot support a standardized Jidoka application. As mentioned in Section 1, the existing studies do not provide a comprehensive architecture that presents a hybrid and distributed Jidoka in the context of Industry 4.0. This question has been highlighted in 2015 [8]. Although standardized solutions are preferred to individualized solutions to date, some individualized solutions containing architectures and mechanisms for Jidoka are also significant and are discussed in Section 2.3.

2.2. Smart Capacity of CPS Technologies

- IoT enables CPS by connecting all distributed resources in the industrial environment to gain rich data and a deep knowledge of the environment; accordingly, operators and machines can perform complex tasks with fewer defects. For example, machine vision can be used for quality inspection, assembly verification, and device guidance [30]. For the necessary identification of performed tasks and the individualization of displayed information, the German Research Center for Artificial Intelligence successfully demonstrated a smart manual working station based on augmented reality [8]. Based on the smart manual working station, a continuous flow of pieces can be supported by assisting systems based on augmented reality for employees. Information about cycle times within the visual field of employees supports just-in-time (JIT) manufacturing of goods. In addition, new operators can obtain individualized information about necessary tasks to participate in timed productions. Quick Response (QR) codes, Radio Frequency Identification (RFID), or specific sensors are used to assist operators in identifying a wide variety of materials accurately. Moreover, other kinds of IoT technologies can make operators and machines perform complex tasks with fewer defects.

- Agents are used to achieve distributed intelligence and adaptation for production systems [26,31]. FBs are used to achieve effective component integration in distributed agents [27]. In such distributed and heterogeneous systems, knowledge sharing can be a problem. Therefore, CPS also uses semantics to represent the structure of the shared knowledge, thereby allowing distributed agents to understand themselves during the cooperation processes [26,32,33].

- CPS needs to deal with the problem posed by heterogeneous networks and protocols when integrating components of different natures from different sources. Services can be positioned as higher-level abstractions to allow CPS to mediate the interactions among devices, software, information, humans, and applications within the existing technologies. Currently, SOA has been adopted in various industrial systems due to its integration flexibility and process composability [34,35,36]. Integrating agents and SOAs using agents to embed the intelligent logic control that is exposed as services to the other agents enables the adoption of a unifying technology for all levels of the enterprise [37,38].

- Each engineered system or component must be deployed to support performance. Currently, a large number of resources and services are allowed to deploy to different decentralized locations. Recently, the cloud emerged as a new way to develop and deploy sophisticated applications. Therefore, for supporting centralized and distributed implementations, a complete CPS may be specified as a single model composed of multiple components; the components may be executed or deployed at different locations locally and into the cloud [39]. Cloud-based CPS will be a distributed and intelligent system in the IoT environment [40].

2.3. Jidoka: The Application of Automation Technologies to Lean Production

- Individualized solutions for Jidoka: Danielsson et al. described a flexible lean automation concept for a robotized manufacturing industry [48]. Jackson et al. developed a possible Jidoka solution for increased reconfigurability of robotic systems to enable the production of different products, and simple configuration to allow future product variants to be handled without large additional investments [10]. Mashaei and Lennartson investigated the lean design and control of an automated material handling system and introduced a universal framework for modeling and analysis of different types of material handling mechanisms to obtain a minimum number of resources in a system design and fulfill a desired throughput [49]. Similarly, Yamazaki et al. proposed a design method of material handling systems for lean automation; this method focuses on the low utilization rates of mechanisms, such as MUDA, at the equipment level rather than the station level, and devises a method for increasing the utilization rates of the equipment by aggregating the same kind of operations distributed across different stations [18]. Kolberg et al. presented an ongoing work on an interface for digitizing lean production methods using CPS. A model-view-controller-based architecture is proposed for realizing the interface [20]. Karadayi et al. proposed a design methodology for hybrid feeding systems in lean production-based assembly lines [17].

- MOP methods: Individualized Jidoka solutions are supported by related MOP methods. For example, Berk et al. proposed a Jidoka quality control method that combines the conventional use of control charts and randomly occurring system stoppages for inspection or repair decisions [16]. Gao et al. demonstrated an in-process sensing technique for online product quality assessment, and this technique can be used to improve quality detection capability [50]. Królczyk et al. presented a case study of material flow analysis in the production process and proposed a material flow optimization project [51,52]. This project requires creating a program of internal transportation and optimizing the location of the working stands. Aside from monitoring and optimization approaches, prediction technologies are gaining increased attention nowadays. For example, Nadai et al. proposed an equipment failure prediction approach based on neural network analysis incorporated with maintainer inspection findings [53]. A machinery condition prediction based on wavelet and support vector machine can be found in [54]. Jiang et al. designed an early warning model based on time series data for production safety [55]. Dean et al. researched the prediction of manufacturing resource requirements in mass customization production [56]. However, other kinds of MOP approaches can be embedded in the Jidoka system to detect abnormalities based on a comprehensive architecture and standardized key technologies.

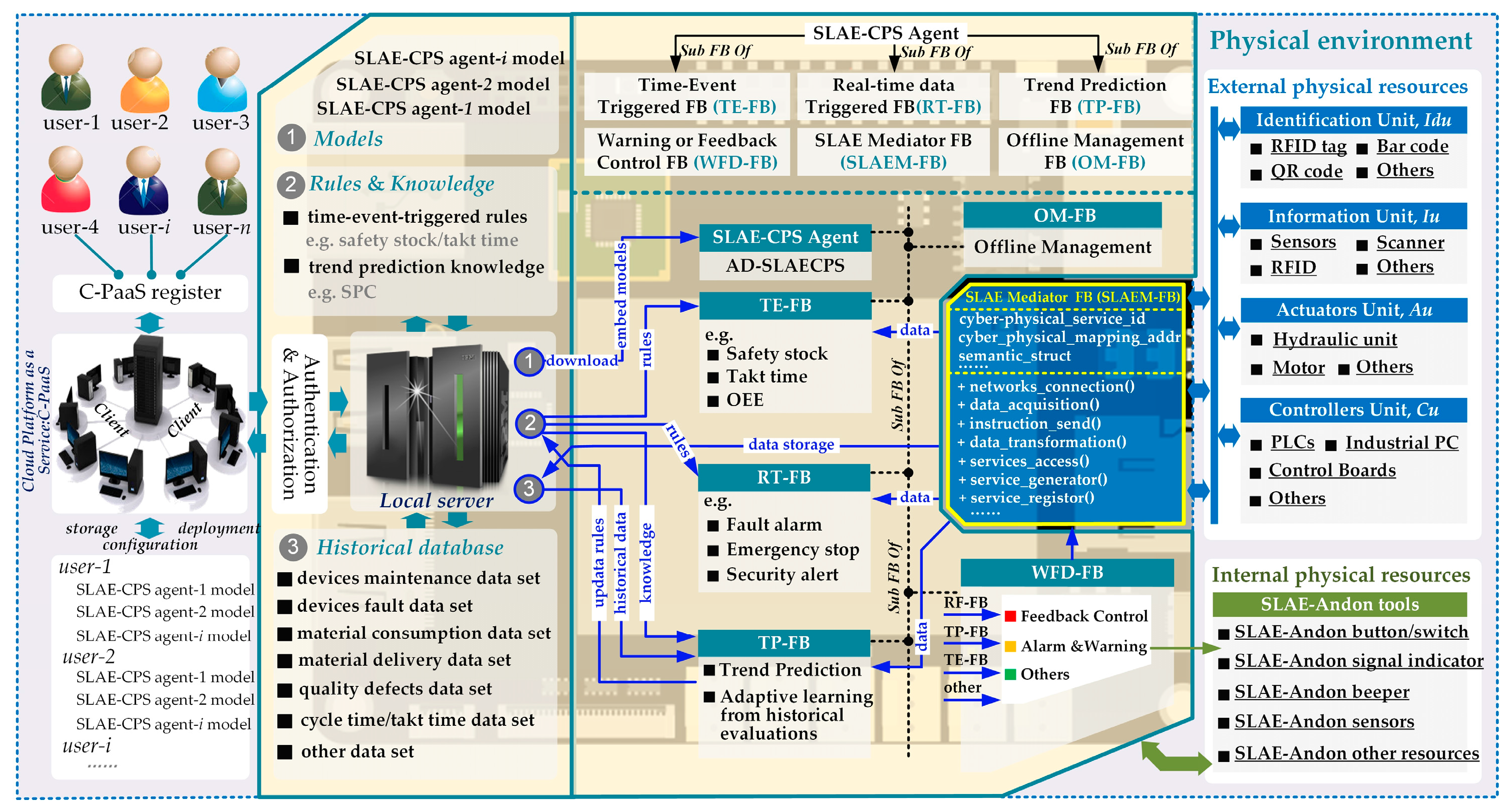

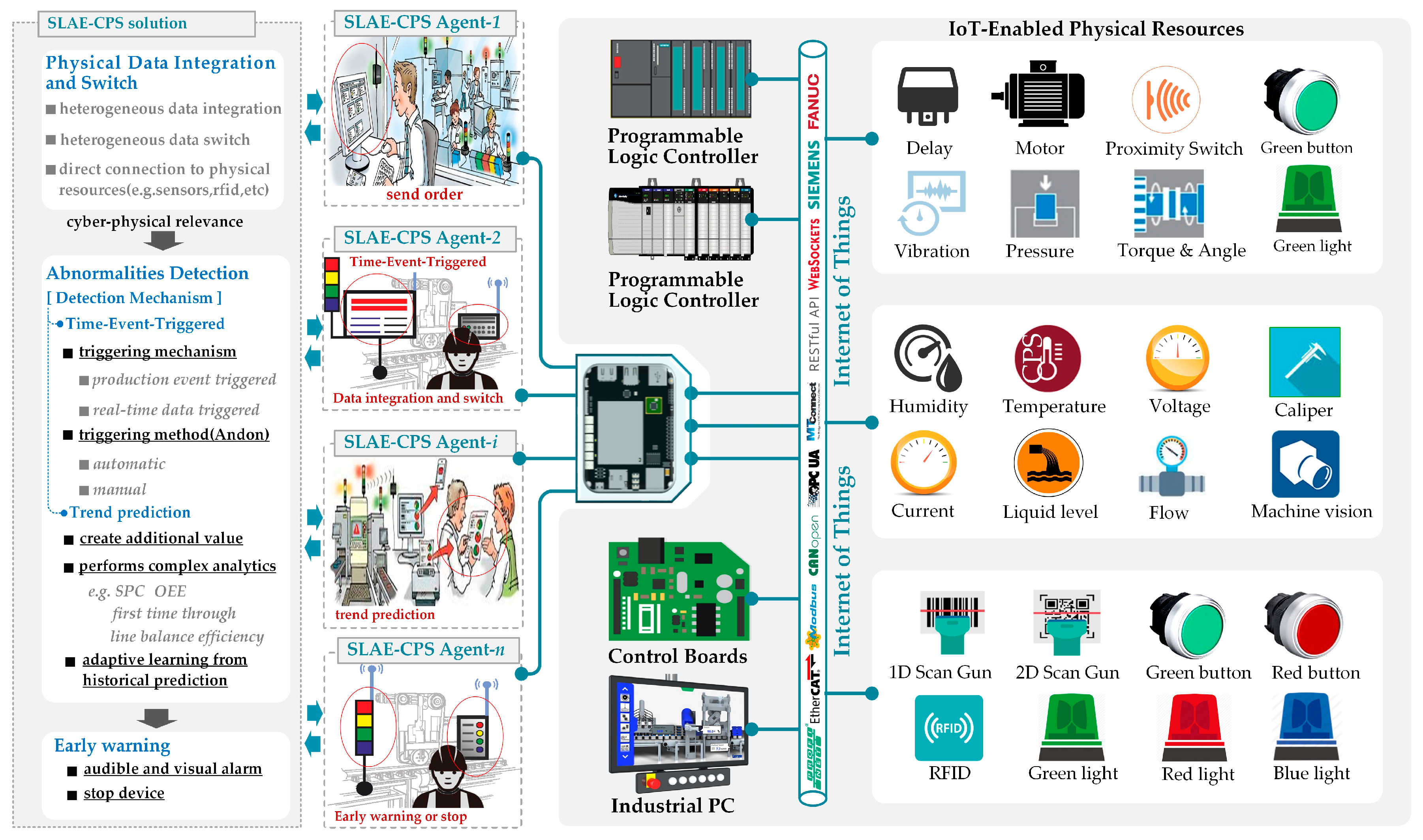

3. Definition and Architecture of SLAE–CPS

- (1)

- IoT-Enabled Physical Unit (IoT-Pu): CPS presents a high combination and coordination between physical and computational elements. In CPS, physical and software components are deeply intertwined. In this study, physical elements are called IoT-Pu. In Figure 2, the entire IoT-Pu can be classified into Identifying Unit (Idu), Information Unit (Iu), Actuators Unit (Au), and Controllers Unit (Cu).

- Idu: This part is responsible for addressing the sensing of normal assembly resources (e.g., Materials, WIP, product, and material-handling devices) by Iu. The general approach is to attach some identifying units (e.g., RFID tags, barcodes, GPS, and IC cards) to the assembly resources. These identified resources can be sensed and recognized by some Iu (e.g., RFID, scanning guns, and IC machines). Therefore, based on the identified resources, some Iu can collect resource data and capture abnormal production data automatically.

- Iu: This part is responsible for perceiving (collecting) and transmitting production environmental data to Cu and activating corresponding SLAE–CPS scenes, such as scanning gun, RFID, machine vision, digital quantity and analog quantity sensor.

- Au: This part is responsible for executing Cu control commanders, responding to auto-stop commanders of SLAE–CPS Agent, and implementing corresponding logic actions (e.g., hardware with actual execution functions) or logic control functions (e.g., relay, servo motor, cylinder, and hydraulic equipment).

- Cu: This part is responsible for receiving cyber commands and controlling Idu, Iu, and Au to accomplish production tasks. Cu is composed of thing processing units with unified physical distributed logics (e.g., device clusters with independent transmission), data storage, and logical judgment capability (e.g., programmable processor, industrial personal computer, and embedded board card).

- (2)

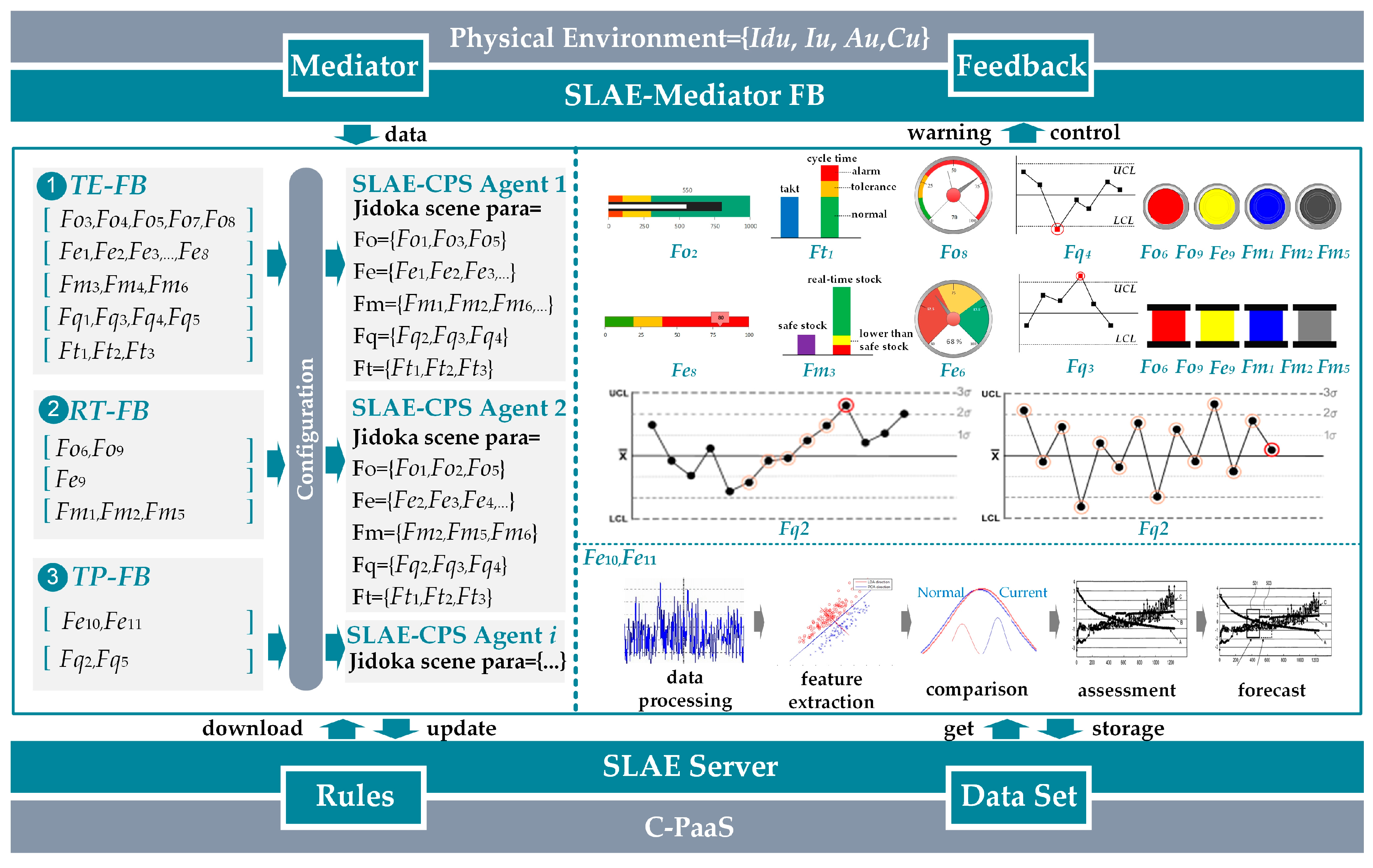

- SLAE–CPS Agent: The cyber-physical agent integrated with a hardware module and software component can access operating environmental data easily and execute poka-yoke (PY), anomaly detection (AD), trend forecast (TF), feedback (FED), and control and warning function (PY–AD–TF–FED function). An agent with independent communication, operation, and feedback control functions is called a SLAE–CPS agent. As an important component of the SLAE–CPS, the SLAE–CPS agent mainly consists of actuators for distributed SLAE–CPS scenarios (AD-SLAECPS) and six FBs with different functions, namely, SLAE-mediator FB (SLAEM-FB), real-time data-triggered FB (RT-FB), time-event-triggered FB (TE-FB), trend prediction FB (TP-FB), warning and feedback control FB (WFD-FB), and offline management FB (OM-FB).

- AD-SLAECPS: As the core part of the SLAE–CPS agent, AD-SLAECPS is mainly responsible for downloading SLAE–CPS scene models into the local platform and into the C-PaaS platform and controlling six types of FBs to execute SLAE–CPS scene models under multiple modes (e.g., event driving, real-time data driving, and trend prediction). Meanwhile, AD-SLAECPS executes corresponding feedback control (e.g., alarming and production termination) functions according to abnormality grade. According to the practical requirements, the scene models can be configured as services, applications (web or desktop), or other types of executable models (e.g., Petri net model [44,57,58]) based on the requirement of different Jidoka scene parameters (Table 1) for the SLAE–CPS agent. In this study, the scene models are programmed as desktop applications and are introduced in Section 5.

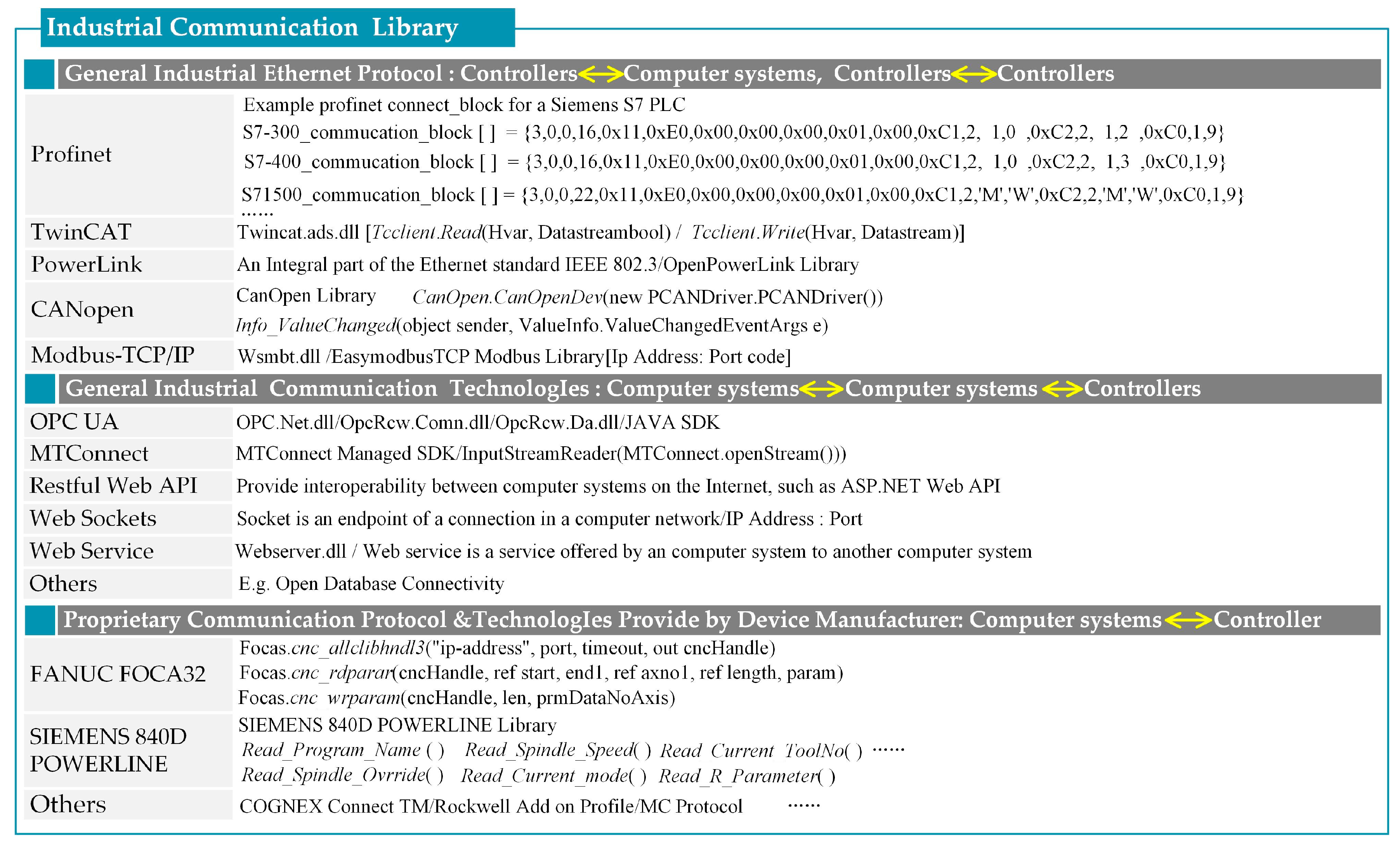

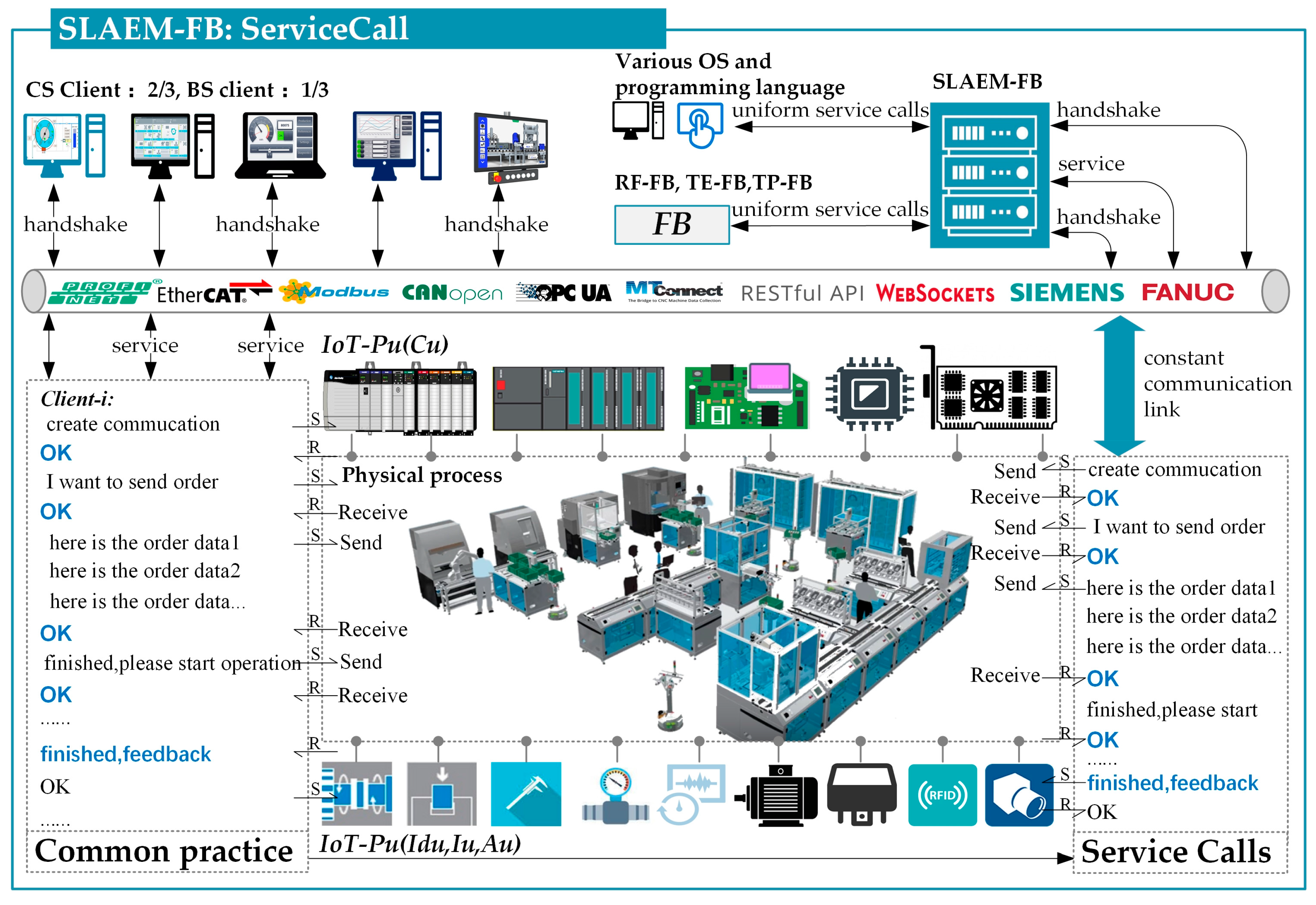

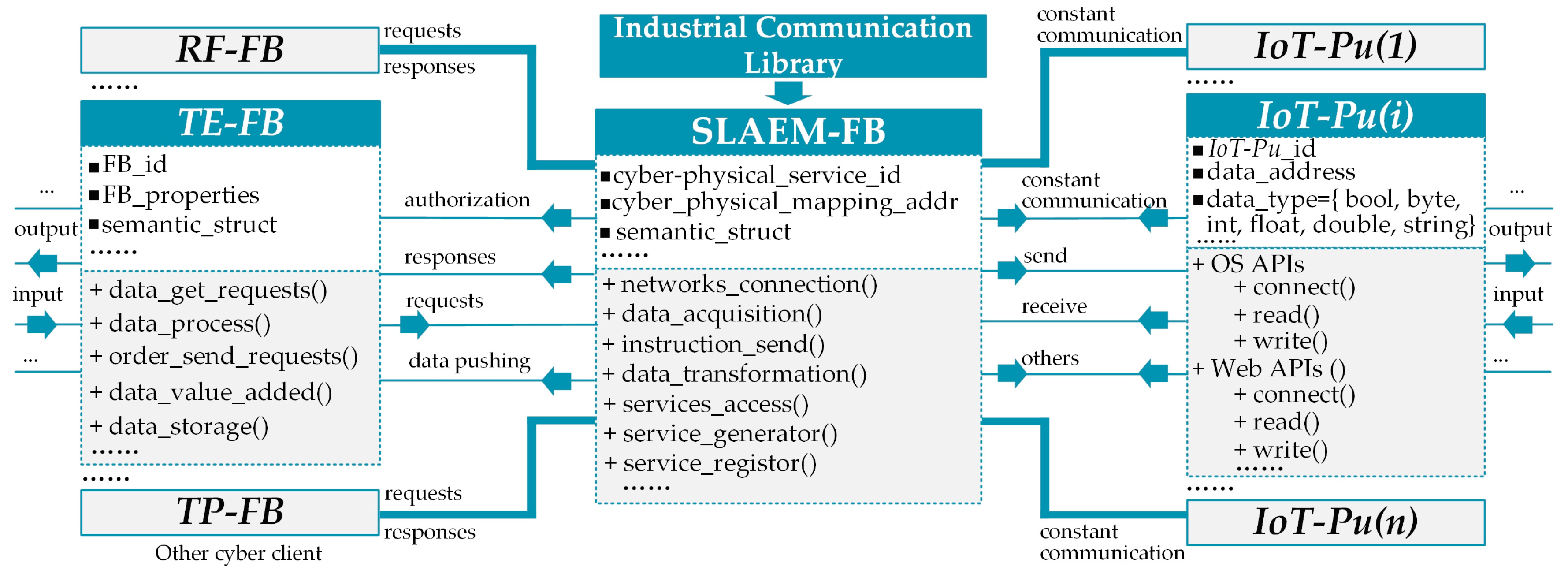

- SLAEM-FB: This FB provides a service-call function that can acquire heterogeneous data, manage the connections among various types of networks through various industrial Ethernet protocols and communication technologies, and uniformize the heterogeneous data. Through this function, SLAEM-FB provides uniform CPS access to the SLAE–CPS agent.

- RT-FB: As one of the basic software FBs of the SLAE–CPS agent, RT-FB mainly executes the SLAE–CPS scene activation function under the real-time data triggering category. RT-FB registers the desired data request services according to scene configuration and triggers the corresponding SLAE–CPS scenes based on real-time data. Examples of these scenes include alarms when operating personnel enter a dangerous operation region, equipment alarms, and Andon alarms (e.g., team Andon, quality defect Andon, equipment exception Andon, and quality defect Andon).

- TE-FB: This FB is one of the basic software FBs of the SLAE–CPS agent and mainly performs SLAE–CPS scene tests and time-event triggering. Embedded time and events in TE-FB cannot be triggered by real-time data and can only be triggered when the set threshold is met. Examples of this threshold include safety stocks for preventing store deficiencies, station timers for preventing imbalance in production lines, overall equipment efficiency, employee efficiency, and planned shut-down clocks.

- TP-FB: TP-FB combines historical running data of the system to analyze and mine potential abnormal factors in the production process that TE-FB and RT-FB fail to detect. As a basic software functional block of the SLAE–CPS agent, TP-FB analyzes abnormalities on the basis of mature data statistical analyses and mining algorithms and by setting knowledge rules to predict possible system anomalies and sending pre-alarms. These pre-alarms include those for quality anomaly decision rules based on statistical process control (SPC), curves based on mass historical data (material delivery timing of different production batches and different products) for the predicted material delivery timing of the current production batch, and for fluctuations in operating personnel’s competency index. TP-FB can offer predictive device maintenance with a relatively mature failure prediction algorithm. In addition, TP-FB is the learning part of the SLAE–CPS agent and can make deep statistical analyses on abundant SLAE–CPS scene running data and produce new engine activation rules, such as statistics, updates in scene word frequency indexes, updates in SPC anomaly decision rules, and updates in competency index evaluation models. TP-FB can automatically update scene activation rules and trend prediction to some extent.

- WFD-FB: The SLAE–CPS agent is a cyber-physical agent integrated with a hardware module and software component. WFD–FB is the alarm and feedback control FB of the SLAE–CPS agent. This FB can control the built-in hardware module (e.g., warning light and buzzer) of the SLAE–CPS agent and establish the feedback control communication channel with IoT-Pu through SLAEM-FB. WFD-FB executes alarm and control functions according to abnormality grade after receiving feedback commands from TE-FB, RT-FB, and TP-FB.

- OM-FB: This FB is the knowledge localization and offline data management part of the SLAE–CPS agent. To prevent SLAE–CPS agent failure caused by linkage interruption between the SLAE–CPS agent at the workshop’s upper and lower servers, OM-FB automatically updates the desired data and knowledge rules for the operation of the current SLAE–CPS agent regularly or after the SLAE–CPS agent is started. Moreover, OM-FB can offer offline storage of SLAE–CPS agent running data and transmission of SLAE–CPS agent running data to the server after communication restoration and updating of knowledge rules. As a result, completeness of global data and knowledge rules is ensured.

- (3)

- SLAE Server: This server provides SLAE–CPS agent applications for enterprise knowledge rule storage, historical data storage, and model configuration and storage. Based on the certification of the C-PaaS platform, SLAE–CPS agent application models that are authorized and configured in the C-PaaS platform can be downloaded and updated.

- (4)

- C-PaaS: C-PaaS register functions are needed for SLAE–CPS agent applications for different types of customers and factories. A system supplier can perform SLAE–CPS agent application model configuration and deployment functions on the C-PaaS platform according to customer needs.

4. SLAE–CPS Agent

4.1. SLAEM-FB

- SLAEM-FB handles various network connections and data acquisition and transformation. Therefore, each cross-platform cyber client does not need to know the physical-level data structure. A cyber client only needs to register and call a corresponding CPS service.

- SLAEM-FB can handle real-time updates through constant communication links. Therefore, according to the real-time requirement of data acquisition and processing in practical applications, data request and pushing mode are available.

4.2. TE-FB, RT-FB and TP-FB

5. Case Study

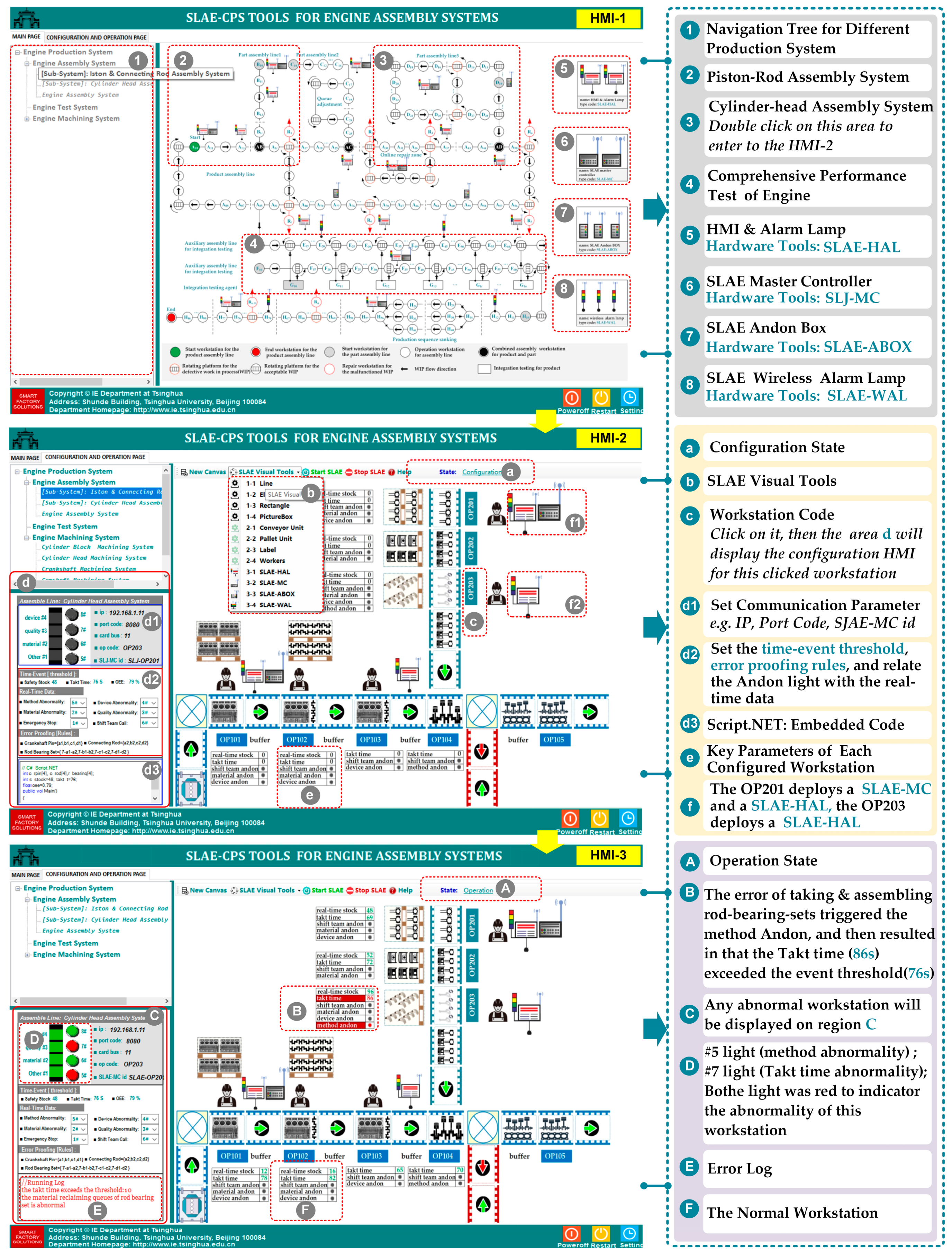

- SLAE Master Controller (SLAE-MC): Only one SLAE-MC is deployed in every production region or sub-production system. This module is used mainly to deploy AD-SLAECPS and download and execute the SLAE–CPS configuration scenes, including protocol adaptation, heterogeneous data integration and transmission, and different types of FBs running in the SLAE–CPS agent.

- Human Machine Interface (HMI) and Alarm Lamp (SLAE-HAL): This module receives the command of SLAE-MC and provides visual SLAE functions and human–computer interaction function for important production station.

- SLAE Andon Box (SLAE-ABOX): This module receives the command of SLAE-MC and provides relatively important stations of different types of production indication and anomaly alarm by combining different colors of indicator light and alarm light. Operators can trigger different types of SLAE-ABOX buttons manually according to the abnormality of station to execute corresponding Andon functions.

- Wireless Alarm Lamp (SLAE-WAL): This module receives the command of SLAE-MC and provides the most basic SLAE indication and alarm to stations with few production indications and anomaly alarm.

6. Conclusions and Future Works

- Compared with individualized solutions, SLAE–CPS presents a comprehensive architecture that joins SOA, agent, FB, cloud, and IoT to support flexible configuration, deployment, and smart performance of Jidoka systems.

- A standardized key technology for converting heterogeneous network or protocols into uniform communication services for a deep and varied abnormality analysis and detection is proposed to strengthen the data analysis and decision support capability of Jidoka.

- In the context of Industry 4.0, IoT can enable a collection of various states of resources. Thus, comprehensive Jidoka scene parameters (or Jidoka rules library) are necessary and useful for a flexible configuration and performance of Jidoka systems.

- Following the comprehensive and standardized approach of SLAE–CPS, a case study is conducted to demonstrate the practicality of the proposed SLAE–CPS. The advantages of SLAE–CPS are further illustrated by a comparison between integrated Jidoka and SLAE–CPS (Table 2).

- New SLAE–CPS tools based on C-PaaS should be developed to achieve agile implementation and remote data analysis.

- The design should be implemented with security protocols to fully benefit from the many application of CPS. Therefore, the overall security mechanism for SLAE–CPS should be considered, such as sensing security, communication security, actuation control security, and feedback security.

- Although the SLAE–CPS tools have been verified in laboratory, system stability needs to be further tested.

- New mature embedded technologies and human–machine interaction technologies (e.g., augmented reality) should be used to create a smart SLAE–CPS.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sendler, U. Industrie. 4.0: Beherrschung der Industriellen Komplexität Mit SysLM; Springer: Berlin, Germany, 2013; pp. 1–144. [Google Scholar]

- Lindeke, R.R.; Wyrick, D.A.; Chen, H. Creating change and driving innovation in highly automated and lean organizations: The Temporal Think Tank™ (T3™). Robot. Comput. Integr. Manuf. 2009, 25, 879–887. [Google Scholar] [CrossRef]

- Chen, H.; Lindeke, R.R.; Wyrick, D.A. Lean automated manufacturing: Avoiding the pitfalls to embrace the opportunities. Assem. Autom. 2010, 30, 117–123. [Google Scholar] [CrossRef]

- Akerman, M.; Fast-Berglund, A.; Karlsson, M.; Stahre, J. Introducing customized ICT for operators in manufacturing. Procedia CIRP 2016, 41, 490–495. [Google Scholar] [CrossRef]

- Yamazaki, Y.; Takata, S.; Onari, H.; Kojima, F.; Kato, S. Lean Automation System Responding to the Changing Market. Procedia CIRP 2016, 57, 201–206. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World: The Story of Lean Production; Macmillan: New York, NY, USA, 1990; pp. 1–352. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Simon & Shuster: New York, NY, USA, 1990; pp. 1–396. [Google Scholar]

- Kolberg, D.; Zühlke, D. Lean automation enabled by industry 4.0 technologies. IFAC-PapersOnLine 2015, 48, 1870–1875. [Google Scholar] [CrossRef]

- Parnaby, J. A systems approach to the implementation of JIT methodologies in Lucas Industries. Int. J. Prod. Res. 1988, 26, 483–492. [Google Scholar] [CrossRef]

- Jackson, M.; Hedelind, M.; Hellström, E.; Granlund, A.; Friedler, N. Lean automation: Requirements and solutions for efficient use of robot automation in the swedish manufacturing industry. Int. J. Eng. Res. Innov. 2011, 3, 36–43. [Google Scholar]

- Zühlke, D. Smart Factory-Towards a factory-of-things. Annu. Rev. Control 2010, 34, 129–138. [Google Scholar] [CrossRef]

- DeGarmo, E.P.; Black, J.T.; Ronaldo, A.K. Materials and Processes in Manufacturing, 8th ed.; Wiley Publishing Company: Hoboken, NJ, USA, 2003; pp. 1–1184. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.A. A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Lee, E.A. Cyber physical systems: Design challenges. In Proceedings of the 2008 11th IEEE International Symposium on Object Oriented Real-Time Distributed Computing (ISORC), Orlando, FL, USA, 5–7 May 2008; pp. 363–369. [Google Scholar]

- Kagermann, H.; Helbig, J.; Hellinger, A. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry; Forschungsunion: Berlin, Germany, 2013; pp. 1–82. [Google Scholar]

- Berk, E.; Toy, A.Ö. Quality control chart design under Jidoka. Nav. Res. Logist. NRL 2009, 56, 465–470. [Google Scholar] [CrossRef]

- Karadayi Usta, S.; Oksuz, M.K.; Durmusoglu, M.B. Design methodology for a hybrid part feeding system in lean-based assembly lines. Assem. Autom. 2017, 37, 84–102. [Google Scholar] [CrossRef]

- Yamazaki, Y.; Shigematsu, K.; Kato, S.; Kojima, F.; Onari, H.; Takata, S. Design method of material handling systems for lean automation—Integrating equipment for reducing wasted waiting time. CIRP Ann. Manuf. Technol. 2017, in press. [Google Scholar] [CrossRef]

- Bulej, V.; Stoianovici, G.; Poppeova, V. Material flow improvement in automated assembly lines using lean logistics. In Proceedings of the Annals of DAAAM for 2011 & 22nd International DAAAM Symposium, Vienna, Austria, 23–26 November 2011; pp. 253–255. [Google Scholar]

- Kolberg, D.; Knobloch, J.; Zühlke, D. Towards a lean automation interface for workstations. Int. J. Prod. Res. 2017, 55, 2845–2856. [Google Scholar] [CrossRef]

- Guðlaugsson, T.V.; Ravn, P.M.; Mortensen, N.H.; Hvam, L. Modelling production system architectures in the early phases of product development. Concurr. Eng. 2017, 25, 136–150. [Google Scholar] [CrossRef]

- Hankel, M.; Rexroth, B. The Reference Architectural Model Industrie 4.0 (RAMI 4.0). Available online: http://www.control.lth.se/media/Education/EngineeringProgram/FRTN20/2016/ZVEI-Industrie-40-RAMI-40-English.pdf (accessed on 26 June 2017).

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Xu, L.D.; He, W.; Li, S. Internet of things in industries: A survey. IEEE Trans. Ind. Inform. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Hu, L.; Xie, N.; Kuang, Z.; Zhao, K. Review of cyber-physical system architecture. In Proceedings of the 2012 15th IEEE International Symposium on Object/Component/Service-Oriented Real-Time Distributed Computing Workshops: ISORCW, Shenzhen, China, 11 April 2012; pp. 25–30. [Google Scholar]

- Lin, J.; Sedigh, S.; Miller, A. A semantic agent framework for cyber-physical systems. In Semantic Agent Systems; Elçi, A., Tadiou Koné, M., Eds.; Springer: Berlin, Germany, 2011; Volume 344, pp. 189–213. [Google Scholar]

- Jakovljevic, Z.; Mitrovic, S.; Pajic, M. Cyber Physical Production Systems—An IEC 61499 Perspective. In Proceedings of the 5th International Conference on Advanced Manufacturing Engineering and Technologies, Belgrade, Serbia, 5–9 June 2017; pp. 27–39. [Google Scholar]

- Pérez, F.; Irisarri, E.; Orive, D.; Marcos, M.; Estevez, E. A CPPS Architecture approach for Industry 4.0. In Proceedings of the 2015 20th IEEE Conference on Emerging Technologies & Factory Automation (ETFA), Luxembourg, 8–11 September 2015; pp. 1–4. [Google Scholar]

- Leitão, P.; Colombo, A.W.; Karnouskos, S. Industrial automation based on cyber physical systems technologies: Prototype implementations and challenges. Comput. Ind. 2016, 81, 11–25. [Google Scholar] [CrossRef]

- Pérez, L.; Rodríguez, Í.; Rodríguez, N.; Usamentiaga, R.; García, D.F. Robot guidance using machine vision techniques in industrial environments: A comparative review. Sensors 2016, 16, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Leitao, P.; Karnouskos, S.; Ribeiro, L.; Lee, J.; Strasser, T.; Colombo, A.W. Smart Agents in Industrial Cyber–Physical Systems. Proc. IEEE 2016, 104, 1086–1101. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, Y.; Yang, Y.; Zhang, C.; Zhu, X.; Ji, Y. Towards a Semantic Web of Things: A Hybrid Semantic Annotation, Extraction, and Reasoning Framework for Cyber-Physical System. Sensors 2017, 17, 403. [Google Scholar] [CrossRef] [PubMed]

- Dillon, T.; Chang, E.; Singh, J.; Hussain, O. Semantics of Cyber-Physical Systems. In Proceedings of the 7th IFIP International Conference on Intelligent Information Processing, Guilin, China, 12–15 October 2012; pp. 3–12. [Google Scholar]

- Lin, K.J.; Panahi, M. A real-time service-oriented framework to support sustainable cyber-physical systems. In Proceedings of the 2010 8th IEEE International Conference on Industrial Informatics (INDIN), Osaka, Japan, 3–16 July 2010; pp. 15–21. [Google Scholar]

- Hoang, D.D.; Paik, H.Y.; Kim, C.K. Service-oriented middleware architectures for cyber-physical systems. Int. J. Comput. Sci. Netw. Secur. 2012, 12, 79–87. [Google Scholar]

- Wang, X.-L.; Huang, H.-B.; Su, D.; Chen, L.-N. A service-oriented architecture framework for cyber-physical systems. In Recent Advances in Computer Science and Information Engineering; Qian, Z., Cao, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; Volume 126, pp. 671–676. [Google Scholar]

- Colombo, A.W.; Bangemann, T.; Karnouskos, S.; Delsing, J.; Stluka, P.; Harrison, R.; Jammes, M.; Lastra, J.L. Industrial Cloud-Based Cyber-Physical Systems: The IMC-AESOP Approach; Springer: New York, NY, USA, 2014; pp. 1–261. [Google Scholar]

- Candido, G.; Colombo, A.W.; Barata, J.; Jammes, F. Service-oriented infrastructure to support the deployment of evolvable production systems. IEEE Trans. Ind. Inform. 2011, 7, 759–767. [Google Scholar] [CrossRef]

- Pereira, F.; Gomes, L. Combining Data-Flows and Petri Nets for Cyber-Physical Systems Specification. In Proceedings of the Doctoral Conference on Computing, Electrical and Industrial Systems, Costa de Caparica, Portugal, 11–13 April 2016; pp. 65–76. [Google Scholar]

- Colombo, A.W.; Karnouskos, S.; Mendes, J.M.; Leitão, P. Industrial agents in the era of service oriented architectures and cloud based industrial infrastructures. In Industrial Agents: Emerging Applications of Software Agents in Industry; Leitão, P., Karnouskos, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2015; Volume 13, pp. 67–87. [Google Scholar]

- Lee, E.A. The past, present and future of cyber-physical systems: A focus on models. Sensors 2015, 15, 4837–4869. [Google Scholar] [CrossRef] [PubMed]

- Kolberg, D.; Berger, C.; Pirvu, B.-C.; Franke, M.; Michnierica, J. CyProF–Insights from a Framework for Designing Cyber-physical Systems in Production Environments. Procedia CIRP 2016, 57, 32–37. [Google Scholar] [CrossRef]

- Lewandowski, M.; Gath, M.; Werthmann, D.; Lawo, M. Agent-based control for material handling systems in in-house logistics-towards cyber-physical systems in in-house-logistics utilizing real size. In Proceedings of the 2013 European IEEE Conference on Smart Objects, Systems and Technologies (SmartSysTech), Erlangen, Germany, 11–12 June 2013; pp. 1–5. [Google Scholar]

- Huang, J.; Zhu, Y.; Cheng, B.; Lin, C.; Chen, J. A PetriNet-Based Approach for Supporting Traceability in Cyber-Physical Manufacturing Systems. Sensors 2016, 16, 382. [Google Scholar] [CrossRef] [PubMed]

- Kaihara, T.; Yao, Y. A new approach on CPS-based scheduling and WIP control in process industries. In Proceedings of the 2012 Winter IEEE Simulation Conference (WSC), Berlin, Germany, 9–12 December 2012; pp. 1–11. [Google Scholar]

- Michniewicz, J.; Reinhart, G. Cyber-Physical-Robotics–Modelling of modular robot cells for automated planning and execution of assembly Tasks. Mechatronics 2016, 34, 170–180. [Google Scholar] [CrossRef]

- Holweg, M. The genealogy of lean production. J. Oper. Manag. 2007, 25, 420–437. [Google Scholar] [CrossRef]

- Danielsson, F.; Svensson, B.; Gustavsson, S. A flexible lean automation concept for robotized manufacturing industry. In Proceedings of the 11th Middle Eastern Simulation Multiconference (MESM 2010), Alexandria, Egypt, 1–3 December 2010; pp. 101–104. [Google Scholar]

- Mashaei, M.; Lennartson, B. A universal framework for lean design and control of automated material handling systems. In Proceedings of the 2012 17th IEEE Conference on Emerging Technologies & Factory Automation, Krakow, Poland, 17–21 September 2012; pp. 1–8. [Google Scholar]

- Gao, R.X.; Tang, X.; Gordon, G.; Kazmer, D.O. Online product quality monitoring through in-process measurement. CIRP Ann. Manuf. Technol. 2014, 63, 493–496. [Google Scholar] [CrossRef]

- Królczyk, G.; Legutko, S.; Królczyk, J.; Tama, E. Materials flow analysis in the production process-case study. Appl. Mech. Mater. 2014, 474, 97–102. [Google Scholar] [CrossRef]

- Krolczyk, J.B.; Krolczyk, G.M.; Legutko, S.; Napiorkowski, J.; Hloch, S.; Foltys, J.; Tama, E. Material flow optimization—A case study in automotive industry. Tehnički Vjesnik 2015, 22, 1447–1456. [Google Scholar]

- Nadai, N.; Melani, A.H.; Souza, G.F.; Nabeta, S.I. Equipment failure prediction based on neural network analysis incorporating maintainers inspection findings. In Proceedings of the Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 23–26 January 2017; pp. 1–7. [Google Scholar]

- Liu, S.; Hu, Y.; Li, C.; Lu, H.; Zhang, H. Machinery condition prediction based on wavelet and support vector machine. J. Intell. Manuf. 2017, 28, 1045–1055. [Google Scholar] [CrossRef]

- Jiang, D.; Gong, J.; Garg, A. Design of early warning model based on time series data for production safety. Measurement 2017, 101, 62–71. [Google Scholar] [CrossRef]

- Dean, P.R.; Xue, D.; Tu, Y.L. Prediction of manufacturing resource requirements from customer demands in mass-customisation production. Int. J. Prod. Res. 2009, 47, 1245–1268. [Google Scholar] [CrossRef]

- Pereira, F.; Moutinho, F.; Gomes, L. IOPT-tools—Towards cloud design automation of digital controllers with Petri nets. In Proceedings of the 2014 International IEEE Conference on Mechatronics and Control (ICMC), Jinzhou, China, 3–5 July 2014; pp. 2414–2419. [Google Scholar]

- Liu, M.; Ma, J.; Zhao, Z.; Wang, Q.; Zhang, M. Modeling for management and control integrated intelligent assembly system for mechanical products based on Internet of things. Comput. Integr. Manuf. Syst. 2015, 21, 669–679. [Google Scholar]

- Dopico, M.; Gomez, A.; de la Fuente, D.; García, N.; Rosillo, R.; Puche, J. A vision of industry 4.0 from an artificial intelligence point of view. In Proceedings of the International Conference on Artificial Intelligence (ICAI), Las Vegas, NV, USA, 25–28 July 2016; pp. 407–412. [Google Scholar]

- Monostori, L. Cyber-physical production systems: Roots, expectations and R&D challenges. Procedia CIRP 2014, 17, 9–13. [Google Scholar]

| Factors | JDKSPA | FB Type | Feedback | |||

|---|---|---|---|---|---|---|

| RT | TE | TP | C | W | ||

| Operator (Foi) | Fo1: Actual personnel work time, APWT | ☐ | ☑ | ☐ | ☐ | ☑ |

| Fo2: Actual personnel attendance time, APAT | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fo3: Staff efficiency, STEF = APWT/APAT | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fo4: Workstation productivity, WOPR | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fo5: Workstation passed yield, WPAY | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fo6: Operational sequence, OPSE | ☑ | ☐ | ☐ | ☑ | ☑ | |

| Fo7: Standard work compliance rate, SWCR | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fo8: Mis-operation frequency, MOFR | ☐ | ☑ | ☐ | ☑ | ☑ | |

| Fo9: Operator entry in danger zone, OEDZ | ☑ | ☐ | ☐ | ☑ | ☑ | |

| Equipment (Fei) | Fe1: Equipment downtime, EQDO | ☐ | ☑ | ☐ | ☐ | ☑ |

| Fe2: Blocking time, BLTI | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fe3: Starving time, STTI | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fe4: Available rate, AVRA | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fe5: Performance Rate, PERA | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fe6: OEE = AVRA × PERA × Quality rate (QURA) | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fe7: Equipment alarm frequency, EAFR | ☐ | ☑ | ☐ | ☑ | ☑ | |

| Fe8: Change over time, COTI | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fe9: Equipment alarm (real-time), EQAL | ☑ | ☐ | ☐ | ☑ | ☑ | |

| Fe10: Tendency prediction in equipment failure, TPEF | ☐ | ☐ | ☑ | ☐ | ☑ | |

| Fe11: Equipment health forecast, EQHF | ☐ | ☐ | ☑ | ☐ | ☑ | |

| Material (Fmi) | Fm1: Neglected assembly, NEAS | ☑ | ☐ | ☐ | ☑ | ☑ |

| Fm2: Faulty assembly, FAAS | ☑ | ☐ | ☐ | ☑ | ☑ | |

| Fm3: Safety stock of workstation material, SSWM | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fm4: Stockout frequency (workstation), STOF | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Fm5: Material shortage (workstation), MASH | ☑ | ☐ | ☐ | ☑ | ☑ | |

| Fm6: Material qualified rate before assembly, MQRA | ☐ | ☑ | ☐ | ☐ | ☑ | |

| Quality (Fqi) | Fq1: QURA within workstation | ☐ | ☑ | ☐ | ☑ | ☑ |

| Fq2: Quality abnormality pre-warning, QAPW | ☐ | ☐ | ☑ | ☐ | ☑ | |

| Fq3: Exceed upper control limitation of detect, EUCL | ☐ | ☑ | ☐ | ☑ | ☑ | |

| Fq4: Exceed lower control limitation of detect, ELCL | ☐ | ☑ | ☐ | ☑ | ☑ | |

| Fq5: Other quality control rules, OQCR | ☐ | ☑ | ☑ | ☑ | ☑ | |

| Others (Fti) | Ft1: Job timeout, JOTI = Cycle time-Takt time | ☐ | ☑ | ☐ | ☐ | ☑ |

| Ft2: Work in process, WIPR | ☐ | ☑ | ☐ | ☑ | ☑ | |

| Ft3: Buffer capacity, BUCA | ☐ | ☑ | ☐ | ☑ | ☑ | |

| Items | Traditional Jidoka | SLAE–CPS |

|---|---|---|

| Integrated | Distributed | |

| Architecture |

|

|

| Data resources | • Data resources:

| • Data resources:

|

| Flexibility |

|

|

| Reliability |

|

|

| Cost | Jidoka hardware costs (project in 2012):

| SLAE–CPS hardware costs:

|

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Wang, Q.; Zhao, Z. SLAE–CPS: Smart Lean Automation Engine Enabled by Cyber-Physical Systems Technologies. Sensors 2017, 17, 1500. https://doi.org/10.3390/s17071500

Ma J, Wang Q, Zhao Z. SLAE–CPS: Smart Lean Automation Engine Enabled by Cyber-Physical Systems Technologies. Sensors. 2017; 17(7):1500. https://doi.org/10.3390/s17071500

Chicago/Turabian StyleMa, Jing, Qiang Wang, and Zhibiao Zhao. 2017. "SLAE–CPS: Smart Lean Automation Engine Enabled by Cyber-Physical Systems Technologies" Sensors 17, no. 7: 1500. https://doi.org/10.3390/s17071500