Highly Sensitive Hot-Wire Anemometry Based on Macro-Sized Double-Walled Carbon Nanotube Strands

Abstract

:1. Introduction

2. Theoretical Analysis

3. Experimental Details

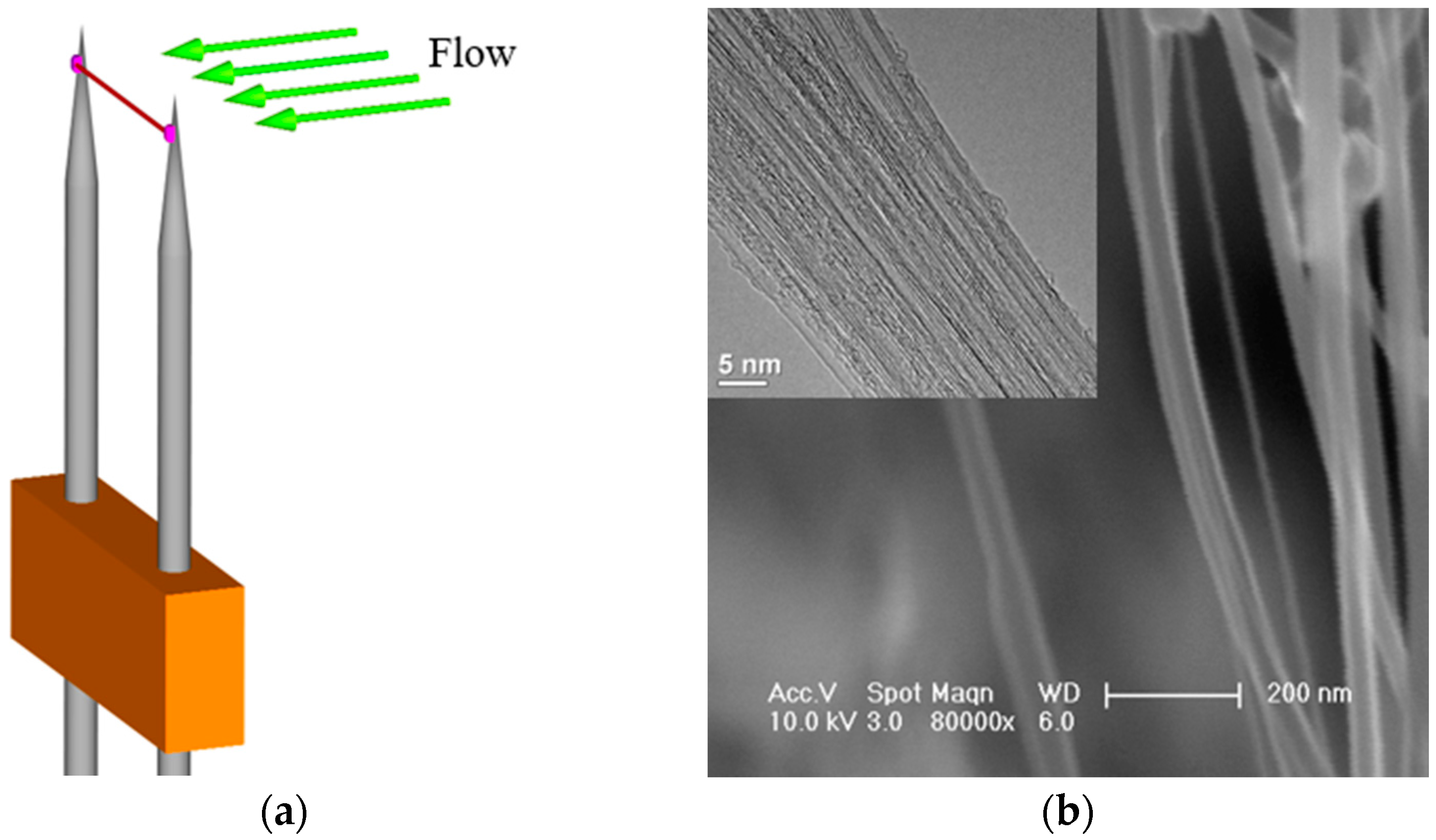

3.1. Assembly Process

3.2. Hot-Wire Anemometry Test Facility

4. Results and Discussion

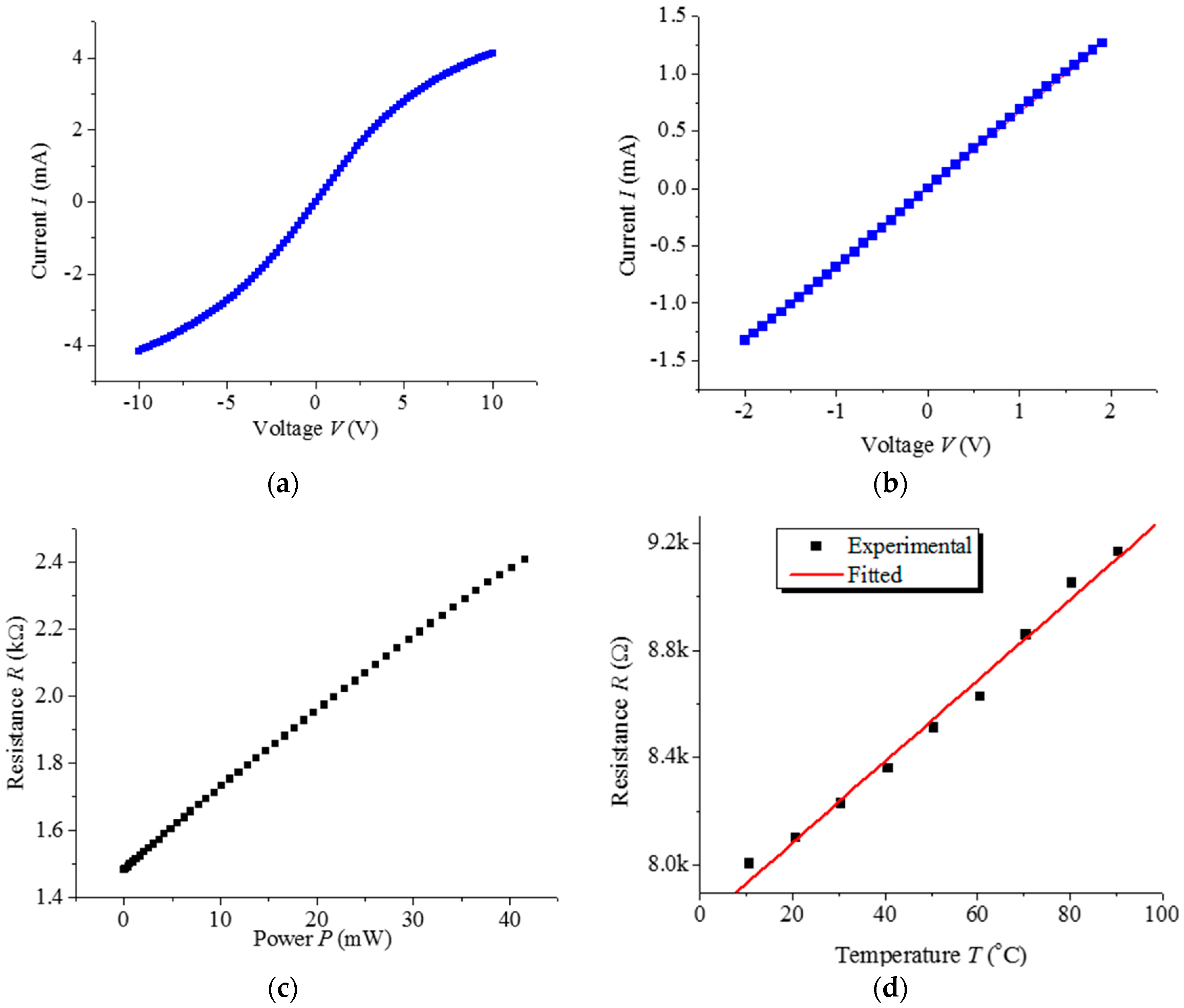

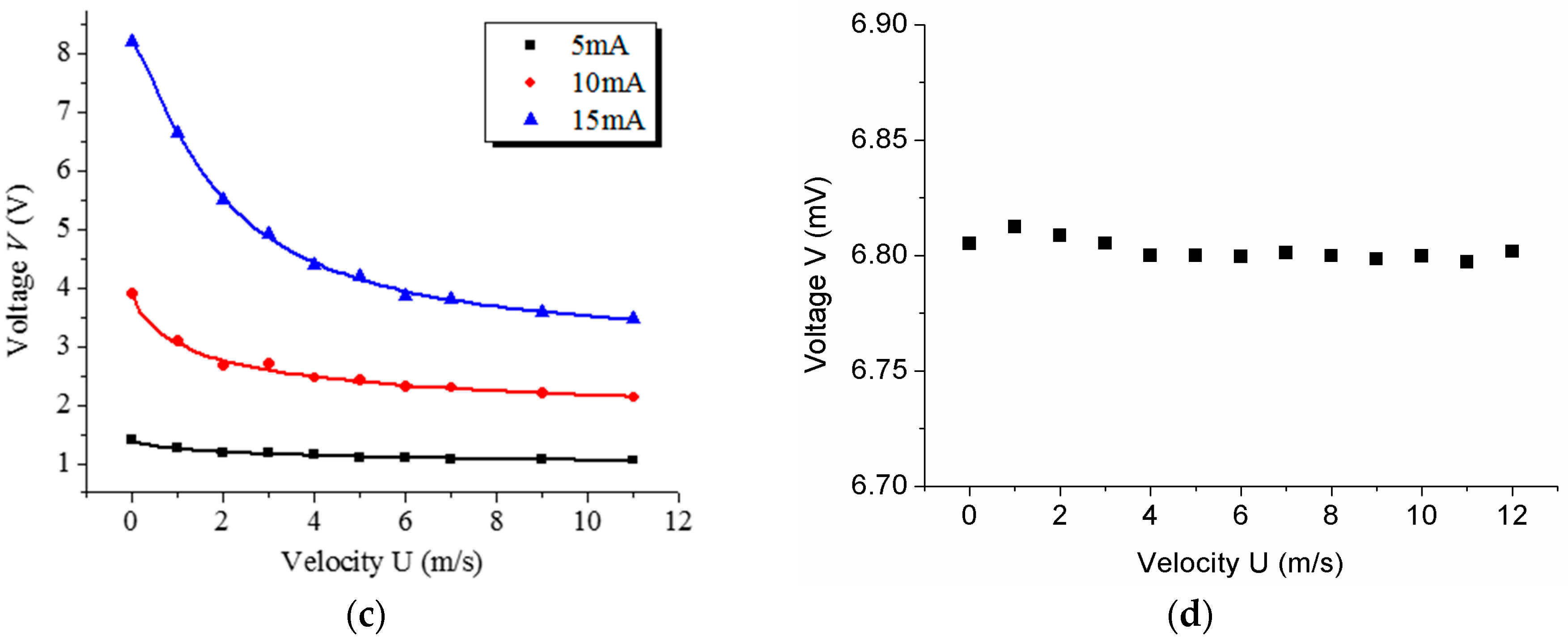

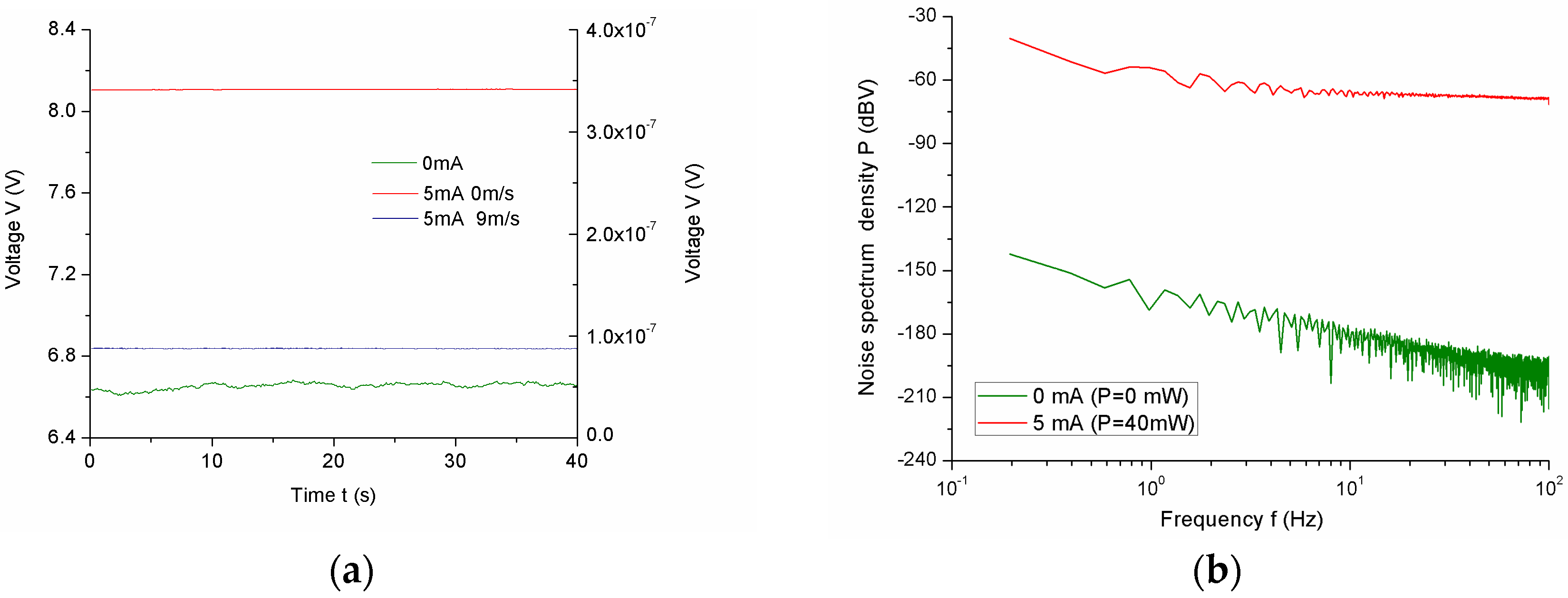

4.1. Overheating Characteristics

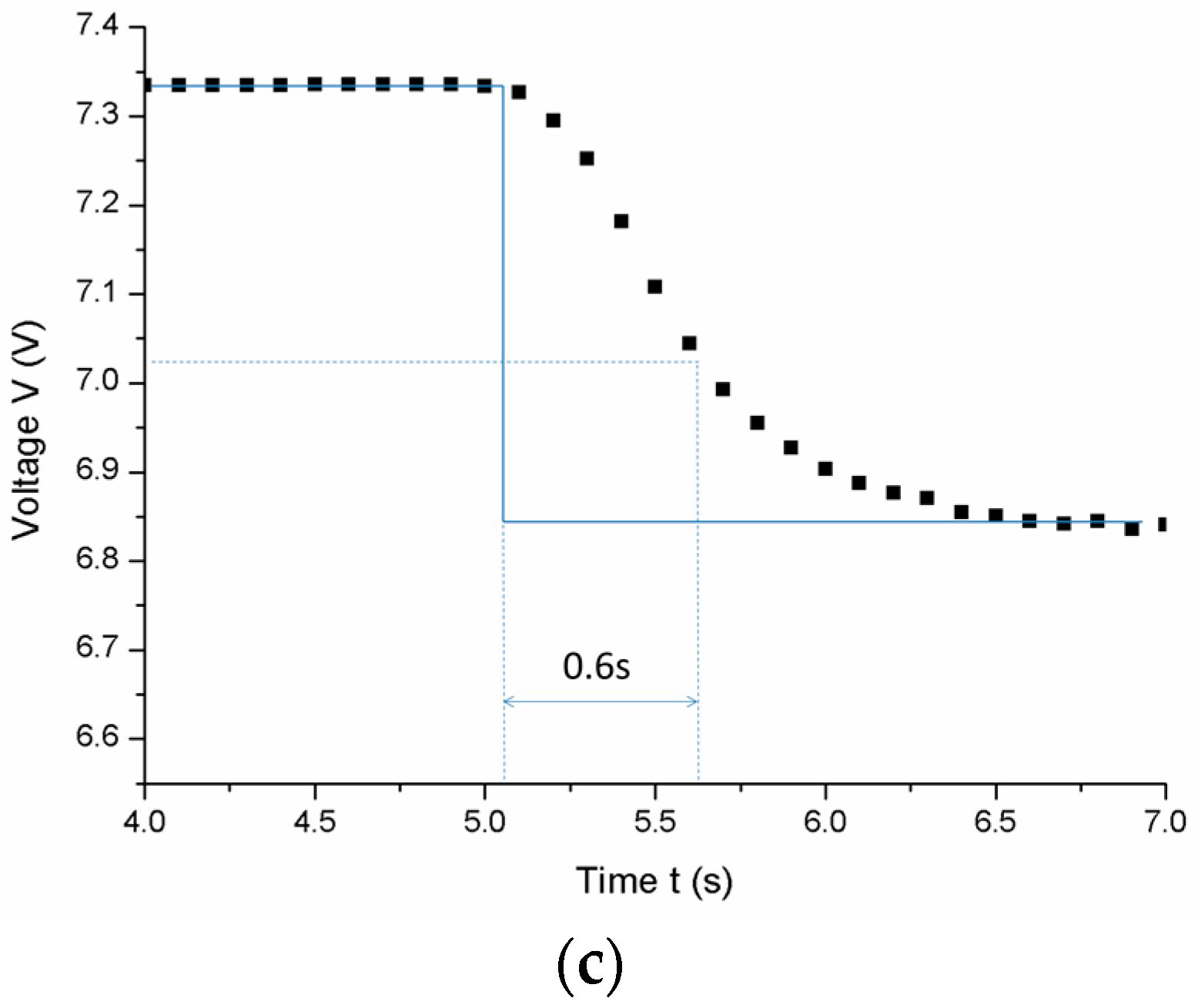

4.2. Performance of Hot-Wire Flow Sensors

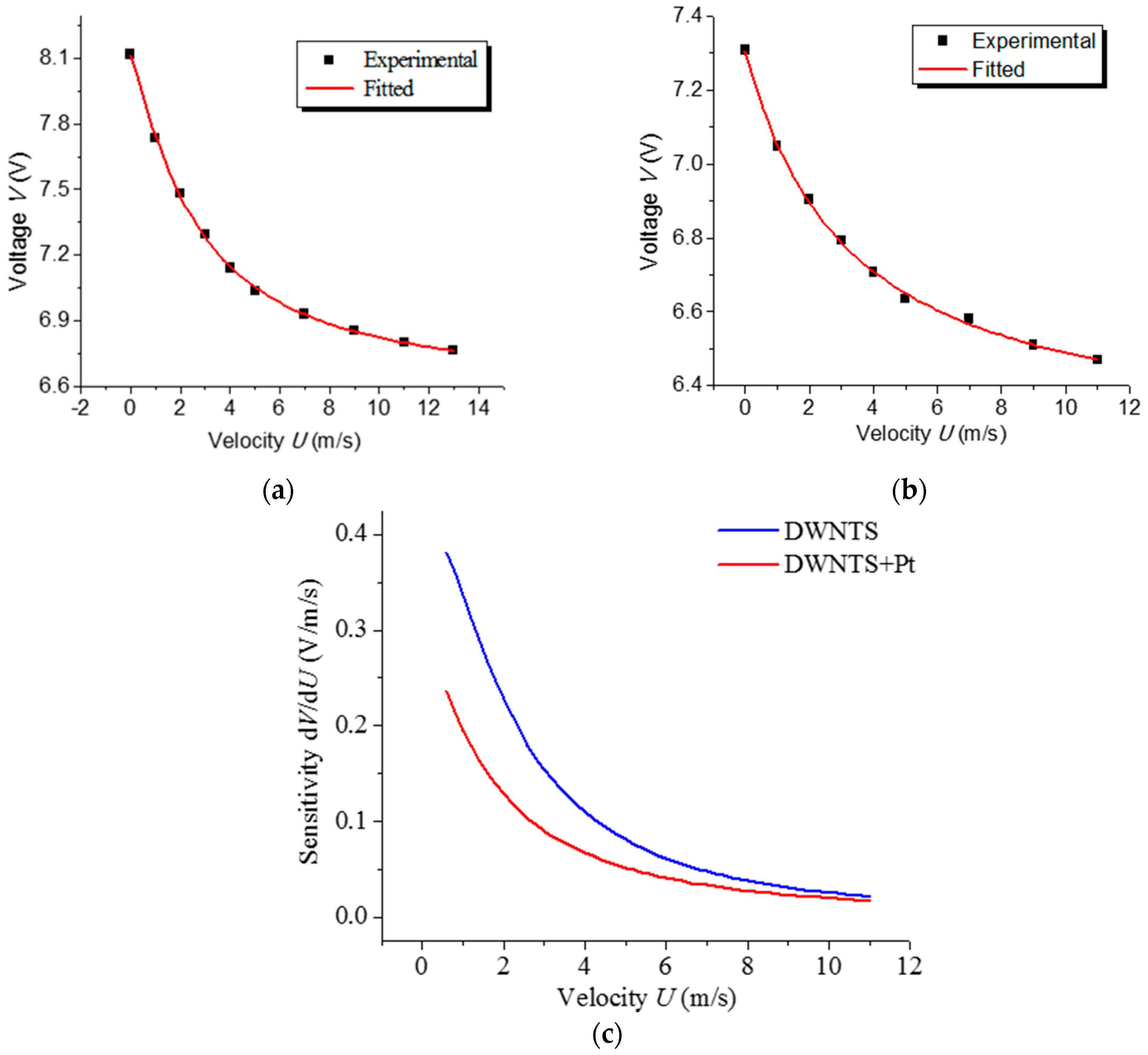

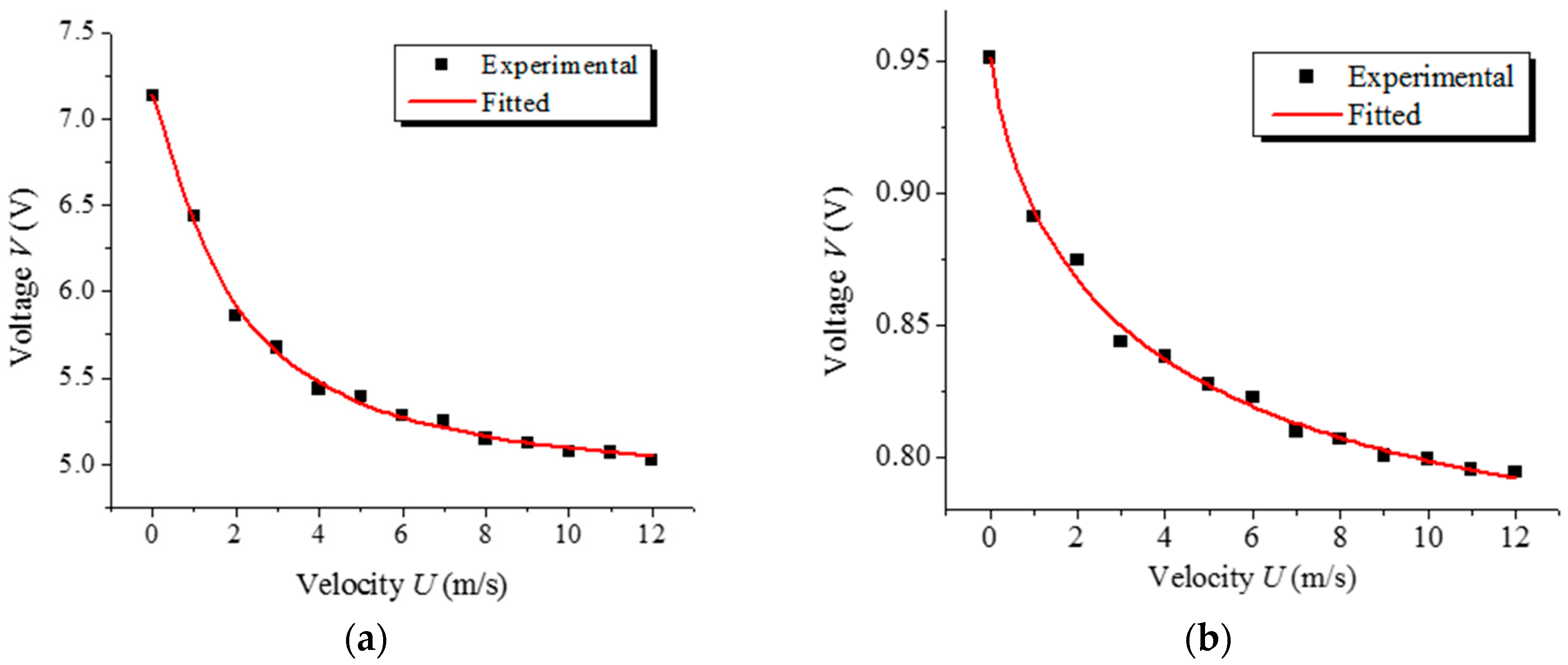

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Perry, A.E. Hot-wire filaments and simple models. In Hot-Wire Anemometer, 1st ed.; Oxford University Press: New York, NY, USA, 1982; pp. 7–32. [Google Scholar]

- Bruun, H.H. Basic Principles of hot-wire anemometry. In Hot-Wire Anemometer Principles and Signal Analysis, 1st ed.; Oxford University Press: New York, NY, USA, 1995; pp. 19–62. [Google Scholar]

- Vadasz, P. Heat Conduction in Nanofluid Suspensions. J. Heat Transf. 2006, 128, 465–477. [Google Scholar] [CrossRef]

- Ito, Y.; Higuchi, T.; Takahashi, K. Submicroscale Flow Sensor Employing Suspended Hot Film with Carbon Nanotube Fins. J. Therm. Sci. Technol. 2010, 5, 51–60. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Charlier, J.C.; Hernández, E. Electronic, Thermal and Mechanical Properties of Carbon Nanotubes. Philos. Trans. R. Soc. A 2004, 362, 2065–2098. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.W. Mechanical Properties of suspended individual carbon nanotube studied by atomic force microscope. Synth. Met. 2016, 216, 88–92. [Google Scholar] [CrossRef]

- Li, Y.H.; Wei, J.Q.; Zhang, X.F.; Xu, C.; Wu, D.H.; Lu, L.; Wei, B.Q. Mechanical and electrical properties of carbon nanotube ribbons. Chem. Phys. Lett. 2002, 365, 95–100. [Google Scholar] [CrossRef]

- Al-Sharafi, A.; Sahin, A.Z.; Yilbas, B.S. Measurement of Thermal and Electrical Properties of Multiwalled Carbon Nanotubes-Water Nanofluid. J. Heat Transf. 2016, 138, 072401. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, W.J. A Picowatt Powered Carbon-Nanotube-Based Thermal Convective Motion Sensor. IEEE Trans. Nanotechnol. 2011, 10, 5. [Google Scholar] [CrossRef]

- Maruyama, H.; Kariya, R.; Arai, F. Evaluation of Thermal Conductivity of Single Carbon Nanotubes in Air and Liquid Using a Fluorescence Temperature Sensor. Appl. Phys. Lett. 2013, 103, 161905. [Google Scholar] [CrossRef]

- Hirotani, J.; Amano, J.; Ikuta, T.; Nishiyama, T.; Takahashi, K. Carbon Nanotube Thermal Probe for Quantitative Temperature Sensing. Sens. Actuators A 2013, 199, 1–8. [Google Scholar] [CrossRef]

- Yang, X.; Zhou, Z.Y.; Wang, D.Q.; Liu, X. High Sensitivity Carbon Nanotubes Flow-Rate Sensors and Their Performance Improvement by Coating. Sensors 2010, 10, 4898–4906. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.S.; Lou, L.; Park, W.T.; Lee, C.K. Characterization of a Silicon Nanowire-Based Cantilever Air-flow Sensor. J. Micromech. Microeng. 2012, 22, 095008. [Google Scholar] [CrossRef]

- Son, B.H.; Park, J.Y.; Lee, S.; Ahn, Y.H. Suspended single-walled carbon nanotube fluidic sensors. Nanoscale 2015, 7, 15421. [Google Scholar] [CrossRef] [PubMed]

- Hsu, M.C.; Lee, G.B. Carbon nanotube-based hot-film and temperature sensor assembled by optically-induced dielectrophoresis. IET Nanobiotechnol. 2014, 8, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Wong, V.T.S.; Li, W.J. Bulk Carbon Nanotubes as Sensing Element for Temperature and Anemometry Micro Sensing. In Proceedings of the IEEE the Sixteenth Annual International Conference on Micro Electro Mechanical Systems, Kyoto, Japan, 22–23 January 2003; pp. 41–44. [Google Scholar]

- Dinh, T.; Phan, H.P.; Nguyen, T.K.; Qamar, A.; Woodfield, P.; Zhu, Y.; Nguyen, N.T.; Dao, D.V. Solvent-free fabrication of biodegradable hot-film flow sensor for noninvasive respiratory monitoring. J. Phys. D Appl. Phys. 2017, 50, 215401. [Google Scholar] [CrossRef]

- Ericson, L.M.; Fan, H.; Peng, H.; Davis, V.A.; Zhou, W.; Sulpizio, J.; Wang, Y.; Booker, R.; Vavro, J.; Guthy, C.; et al. Macroscopic, neat, single-walled carbon nanotube fibers. Science 2005, 305, 1447–1450. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.Q.; Jiang, B.; Wu, D.H.; Wei, B.Q. Large Scale Synthesis of Long Double-Walled Carbon Nanotubes. J. Phys. Chem. B 2004, 108, 8844–8846. [Google Scholar] [CrossRef]

- Bartolomeo, A.D.; Sarno, M.; Giubileo, F. Multiwalled carbon nanotube films as small-sized temperature sensors. J. Appl. Phys. 2009, 105, 064518. [Google Scholar] [CrossRef]

- Kawabe, E.; Itaya, S.; Hirahara, K.; Nakayama, Y. Temperature Dependent Resistance of Multi-Wall Carbon Nanotube. Jpn. J. Appl. Phys. 2012, 51, 06FD25. [Google Scholar] [CrossRef]

- Lu, R.T.; Kamal, R.; Wu, J.Z. A comparative study of 1/f noise and temperature coefficient of resistance in multiwall and single-wall carbon nanotube bolometers. Nanotechnology 2011, 22, 265503. [Google Scholar] [CrossRef] [PubMed]

- Fung, C.K.M.; Li, W.J. Ultra-Low-Power and High-Frequency-Response Carbon Nanotube Based MEMS Thermal Sensors. In Proceedings of the 2003 IEEE/RSJ International Conference on Intelligent Robots and Systems, Las Vegas, NV, USA, 27–31 October 2003. [Google Scholar]

- Chen, J.; Liu, C. Development and characterization of surface micromachined, out-of-plane hot-wire anemometer. J. Microelectromech. Syst. 2003, 12, 979–988. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Xiong, W.; Zhou, Z.; Zhu, R.; Yang, X.; Li, W.; Jiang, Y.; Zhang, Y. Highly Sensitive Hot-Wire Anemometry Based on Macro-Sized Double-Walled Carbon Nanotube Strands. Sensors 2017, 17, 1756. https://doi.org/10.3390/s17081756

Wang D, Xiong W, Zhou Z, Zhu R, Yang X, Li W, Jiang Y, Zhang Y. Highly Sensitive Hot-Wire Anemometry Based on Macro-Sized Double-Walled Carbon Nanotube Strands. Sensors. 2017; 17(8):1756. https://doi.org/10.3390/s17081756

Chicago/Turabian StyleWang, Dingqu, Wei Xiong, Zhaoying Zhou, Rong Zhu, Xing Yang, Weihua Li, Yueyuan Jiang, and Yajun Zhang. 2017. "Highly Sensitive Hot-Wire Anemometry Based on Macro-Sized Double-Walled Carbon Nanotube Strands" Sensors 17, no. 8: 1756. https://doi.org/10.3390/s17081756