Parametric Optimization of Lateral NIPIN Phototransistors for Flexible Image Sensors

Abstract

:1. Introduction

2. Simulation and Optimization of Single Device

2.1. Comparison between Photodiode and Phototransistor

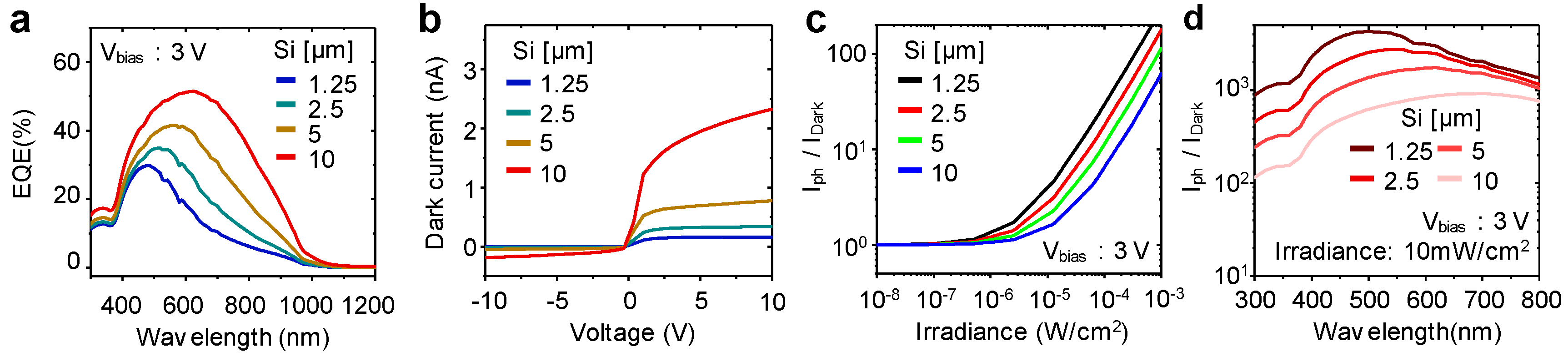

2.2. Thickness Simulation

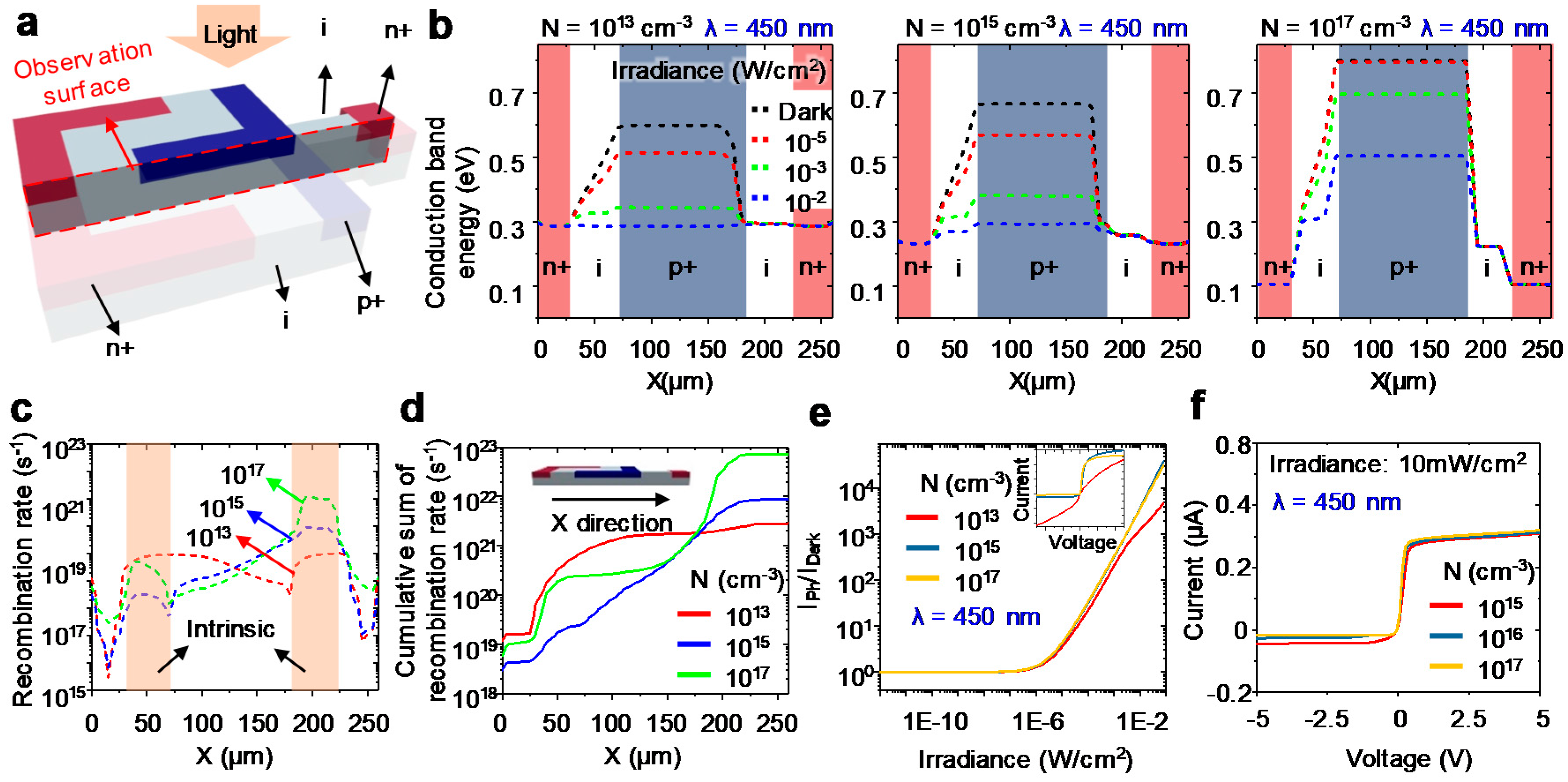

2.3. Doping Concentration Simulation

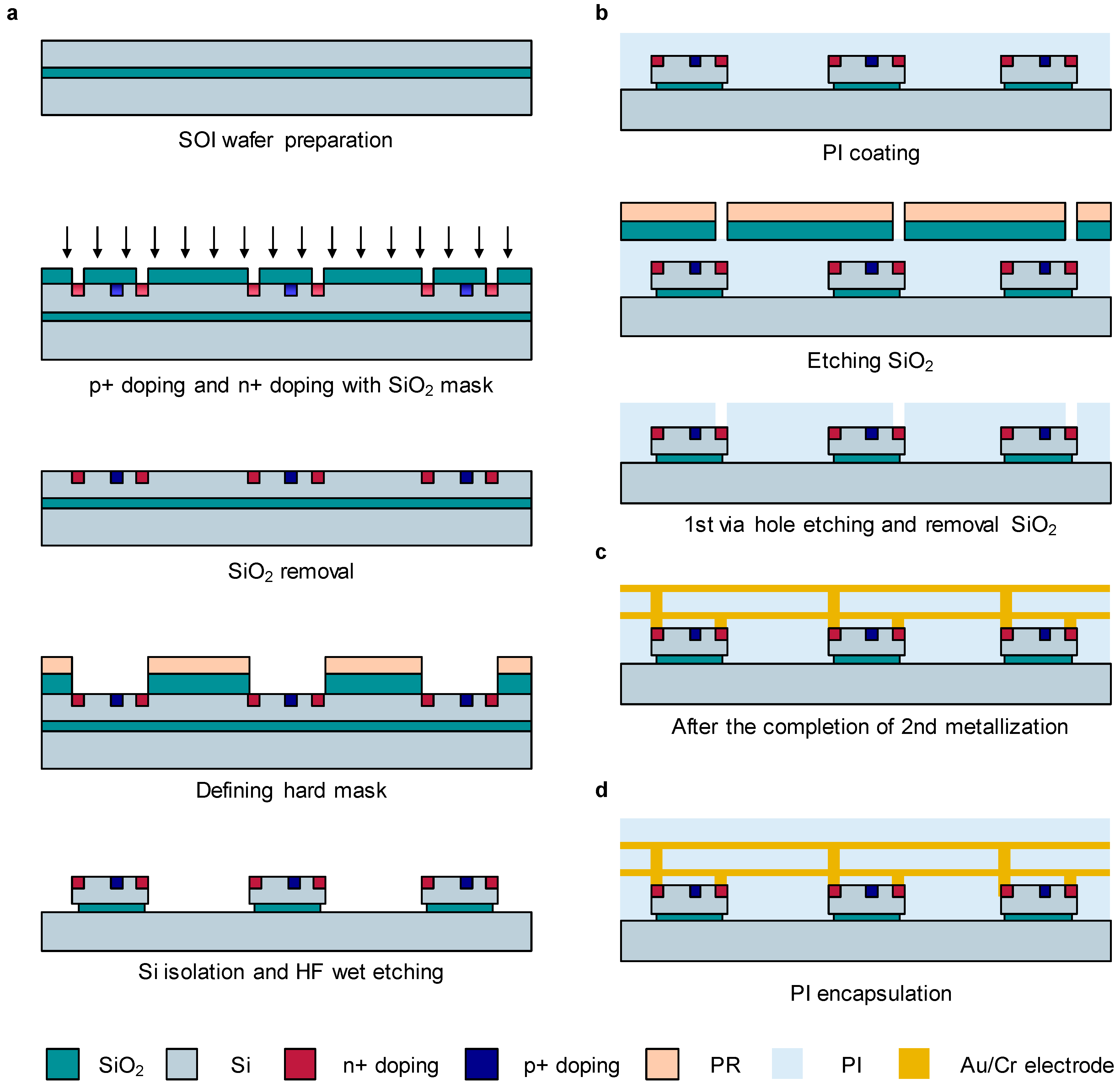

3. Fabrication of Phototransistor and Passive Matrix

4. Characterization of PTR Arrays with Passive Matrix Addressing

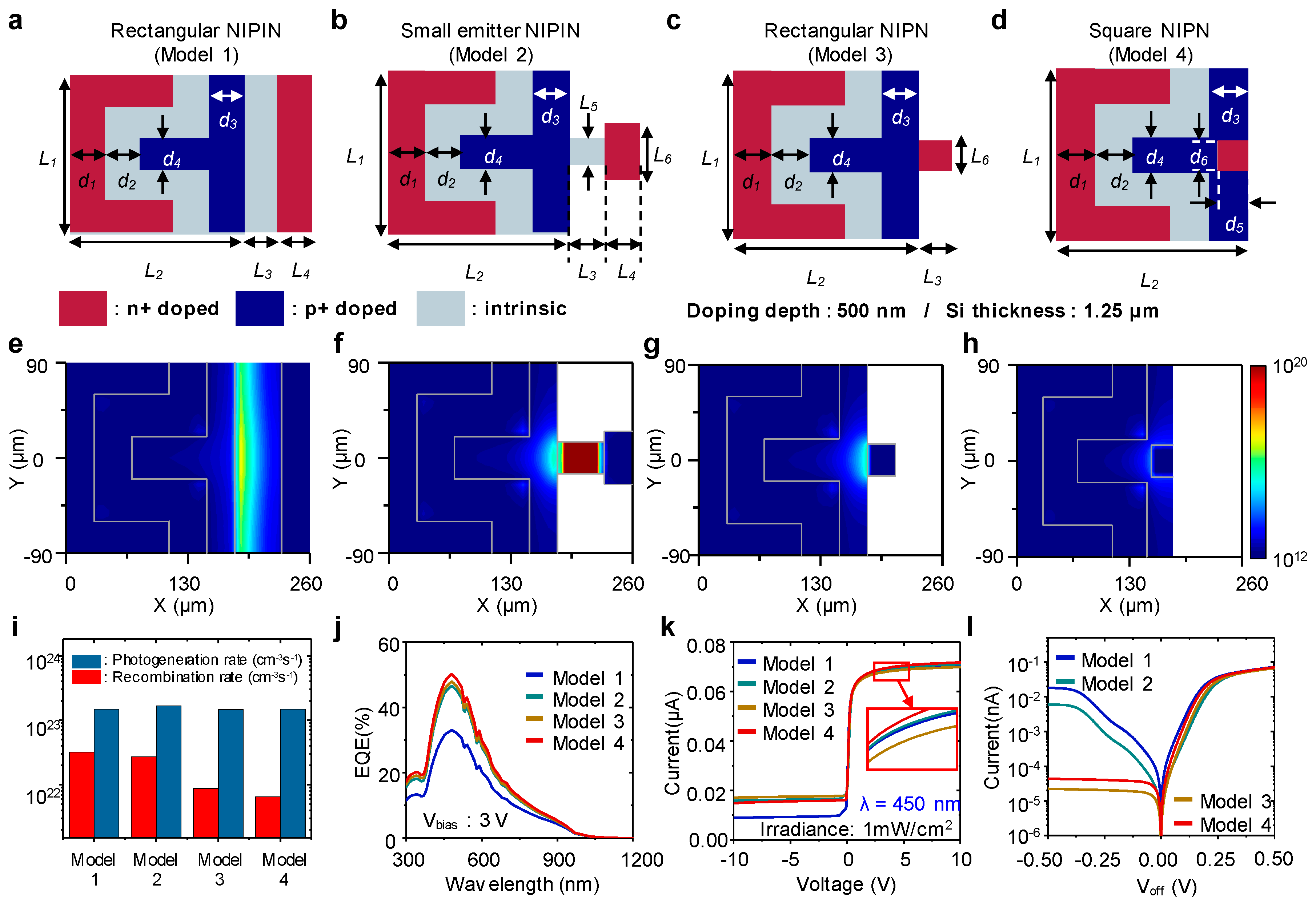

5. Geometry Optimization

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ko, H.C.; Stoykovich, M.P.; Song, J.; Malyarchuk, V.; Choi, W.M.; Yu, C.-J.; Geddes, J.B., III; Xiao, J.; Wang, S.; Huang, Y.; et al. A hemispherical electronic eye camera based on compressible silicon optoelectronics. Nature 2008, 454, 748–753. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.M.; Xie, Y.; Malyarchuk, V.; Xiao, J.; Jung, I.; Choi, K.-J.; Liu, Z.; Park, H.; Lu, C.; Kim, R.-H.; et al. Digital cameras with designs inspired by the arthropod eye. Nature 2013, 497, 95–99. [Google Scholar] [CrossRef] [PubMed]

- Jung, I.; Xiao, J.; Malyarchuk, V.; Lu, C.; Li, M.; Liu, Z.; Yoon, J.; Huang, Y.; Rogers, J.A. Dynamically tunable hemispherical electronic eye camera system with adjustable zoom capability. Proc. Natl. Acad. Sci. USA 2011, 108, 1788–1793. [Google Scholar] [CrossRef] [PubMed]

- Floreano, D.; Pericet-Camara, R.; Viollet, S.; Ruffier, F.; Brückner, A.; Leitel, R.; Buss, W.; Menouni, M.; Expert, F.; Juston, R.; et al. Miniature curved artificial compound eyes. Proc. Natl. Acad. Sci. USA 2013, 110, 9267–9272. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, H.; Huang, Y.; Jiang, H. Artificial eye for scotopic vision with bioinspired all-optical photosensitivity enhancer. Proc. Natl. Acad. Sci. USA 2016, 113, 3982–3985. [Google Scholar] [CrossRef] [PubMed]

- Pang, K.; Fang, F.; Song, L.; Zhang, Y.; Zhang, H. Bionic compound eye for 3D motion detection using an optical freeform surface. J. Opt. Soc. Am. B 2017, 34, B28–B35. [Google Scholar] [CrossRef]

- Lee, G.J.; Nam, W.I.L.; Song, Y.M. Robustness of an artificially tailored fisheye imaging system with a curvilinear image surface. Opt. Laser Technol. 2017, 96, 50–57. [Google Scholar] [CrossRef]

- Dumas, D.; Fendler, M.; Berger, F.; Cloix, B.; Pornin, C.; Baier, N.; Druart, G.; Primot, J.; Le Coarer, E. Infrared camera based on a curved retina. Opt. Lett. 2012, 37, 653–655. [Google Scholar] [CrossRef] [PubMed]

- Dumas, D.; Fendler, M.; Baier, N.; Primot, J.; le Coarer, E. Curved focal plane detector array for wide field cameras. Appl. Opt. 2012, 51, 5419–5424. [Google Scholar] [CrossRef] [PubMed]

- Gregory, J.A.; Smith, A.M.; Pearce, E.C.; Lambour, R.L.; Shah, R.Y.; Clark, H.R.; Warner, K.; Osgood, R.M.; Woods, D.F.; DeCew, A.E. Development and application of spherically curved charge-coupled device imagers. Appl. Opt. 2015, 54, 3072–3082. [Google Scholar] [CrossRef] [PubMed]

- Guenter, B.; Joshi, N.; Stoakley, R.; Keefe, A.; Geary, K.; Freeman, R.; Hundley, J.; Patterson, P.; Hammon, D.; Herrera, G. Highly curved image sensors: A practical approach for improved optical performance. Opt. Express 2017, 25, 13010–13023. [Google Scholar] [CrossRef]

- Xu, X.; Mihnev, M.; Taylor, A.; Forrest, S.R. Organic photodetector arrays with indium tin oxide electrodes patterned using directly transferred metal masks. Appl. Phys. Lett. 2009, 94, 1–3. [Google Scholar] [CrossRef]

- Deng, W.; Zhang, X.; Huang, L.; Xu, X.; Wang, L.; Wang, J.; Shang, Q.; Lee, S.; Jie, J. Aligned Single-Crystalline Perovskite Microwire Arrays for High-Performance Flexible Image Sensors with Long-Term Stability. Adv. Mater. 2016, 28, 2201–2208. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Lee, E.K.; Kim, D.Y.; Yu, H.; Oh, J.H. Flexible organic phototransistor array with enhanced responsivity via metal–ligand charge transfer. ACS Appl. Mater. Interfaces 2016, 8, 7291–7299. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yu, D.; Chen, J.; Wang, Y.; Cao, F.; Wei, Y.; Wu, Y.; Wang, L.; Zhu, Y.; Sun, Z. Constructing fast carrier tracks into flexible perovskite photodetectors to greatly improve responsivity. ACS Nano 2017, 11, 2015–2023. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Gu, L.; Lou, Z.; Fan, Z.; Shen, G. ZnO Quantum Dot Decorated Zn2SnO4 Nanowire Heterojunction Photodetectors with Drastic Performance Enhancement and Flexible Ultraviolet Image Sensors. ACS Nano 2017, 11, 4067–4076. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Hamann, S.S.; Ceballos, A.C.; Chang, C.E.; Solgaard, O.; Howe, R.T. Design and fabrication of silicon-tessellated structures for monocentric imagers. Microsyst. Nanoeng. 2016, 2, 16019. [Google Scholar] [CrossRef]

- Yoon, J.; Li, L.; Semichaevsky, A.V.; Ryu, J.H.; Johnson, H.T.; Nuzzo, R.G.; Rogers, J.A. Flexible concentrator photovoltaics based on microscale silicon solar cells embedded in luminescent waveguides. Nat. Commun. 2011, 2, 343. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-M.; Biswas, R.; Li, W.; Kang, D.; Chan, L.; Yoon, J. Printable nanostructured silicon solar cells for high-performance, large-area flexible photovoltaics. ACS Nano 2014, 8, 10507–10516. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Gai, B.; Thompson, B.; Lee, S.-M.; Malmstadt, N.; Yoon, J. Flexible Opto-Fluidic Fluorescence Sensors Based on Heterogeneously Integrated Micro-VCSELs and Silicon Photodiodes. ACS Photonics 2016, 3, 912–918. [Google Scholar] [CrossRef]

- Kim, J.; Lee, M.; Shim, H.J.; Ghaffari, R.; Cho, H.R.; Son, D.; Jung, Y.H.; Soh, M.; Choi, C.; Jung, S. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 2014, 5, 5747. [Google Scholar] [CrossRef] [PubMed]

- Song, J.-K.; Son, D.; Kim, J.; Yoo, Y.J.; Lee, G.J.; Wang, L.; Choi, M.K.; Yang, J.; Lee, M.; Do, K.; et al. Wearable force touch sensor array using a flexible and transparent electrode. Adv. Funct. Mater. 2016, 27, 1–9. [Google Scholar] [CrossRef]

- Van den Brand, J.; de Kok, M.; Koetse, M.; Cauwe, M.; Verplancke, R.; Bossuyt, F.; Jablonski, M.; Vanfleteren, J. Flexible and stretchable electronics for wearable health devices. Solid State Electron. 2015, 113, 116–120. [Google Scholar] [CrossRef]

- Yu, K.J.; Kuzum, D.; Hwang, S.-W.; Kim, B.H.; Juul, H.; Kim, N.H.; Won, S.M.; Chiang, K.; Trumpis, M.; Richardson, A.G. Bioresorbable silicon electronics for transient spatiotemporal mapping of electrical activity from the cerebral cortex. Nat. Mater. 2016, 15, 782–791. [Google Scholar] [CrossRef] [PubMed]

- Lu, N. Mechanics, materials, and functionalities of biointegrated electronics. Bridge 2013, 43, 31–38. [Google Scholar]

- Burghartz, J.N.; Appel, W.; Harendt, C.; Rempp, H.; Richter, H.; Zimmermann, M. Ultra-thin chip technology and applications, a new paradigm in silicon technology. Solid State Electron 2010, 54, 818–829. [Google Scholar] [CrossRef]

- Shin, G.; Jung, I.; Malyarchuk, V.; Song, J.; Wang, S.; Ko, H.C.; Huang, Y.; Ha, J.S.; Rogers, J.A. Micromechanics and advanced designs for curved photodetector arrays in hemispherical electronic-eye cameras. Small 2010, 6, 851–856. [Google Scholar] [CrossRef] [PubMed]

- Jung, I.; Shin, G.; Malyarchuk, V.; Ha, J.S.; Rogers, J.A. Paraboloid electronic eye cameras using deformable arrays of photodetectors in hexagonal mesh layouts. Appl. Phys. Lett. 2010, 96, 021110. [Google Scholar] [CrossRef]

- Dang, M.; Yuan, H.-C.; Ma, Z.; Ma, J.; Qin, G. The fabrication and characterization of flexible single-crystalline silicon and germanium p-intrinsic-n photodetectors on plastic substrates. Appl. Phys. Lett. 2017, 110, 253104. [Google Scholar] [CrossRef]

- Chang, J.H.; Vygranenko, Y.; Nathan, A. Two-dimensional a-Si: H based nip sensor array. J. Vac. Sci. Technol. A 2004, 22, 971–974. [Google Scholar] [CrossRef]

- De Cesare, G.; Di Rosa, P.; La Monica, S.; Salotti, R.; Rita, R.; Schirone, L. Addressable Photosensing Elements for 2-Dimensional Image Sensors Using a-Si Alloy PIN Diodes. Mat. Res. Soc. Symp. Proc. 1993, 297. [Google Scholar] [CrossRef]

- Shin, K.-S.; Kim, Y.-H.; Paek, K.-K.; Park, J.-H.; Yang, E.-G.; Kim, T.-S.; Kang, J.-Y.; Ju, B.-K. Characterization of an integrated fluorescence-detection hybrid device with photodiode and organic light-emitting diode. IEEE Electron Device Lett. 2006, 27, 746–748. [Google Scholar] [CrossRef]

- Shive, J. The properties of germanium phototransistors. J. Opt. Soc. Am. 1953, 43, 239–244. [Google Scholar] [CrossRef]

- Sze, S.M. Physics of Semiconductor Devices, 3rd ed.; Wiley: New York, NY, USA, 2006. [Google Scholar]

- Deen, M.J.; Basu, P.K. Silicon Photonics: Fundamentals and Devices; Wiley: New York, NY, USA, 2012. [Google Scholar]

- Gong, X.; Tong, M.; Xia, Y.; Cai, W.; Moon, J.S.; Cao, Y.; Yu, G.; Shieh, C.-L.; Nilsson, B.; Heeger, A.J. High-Detectivity Polymer Photodetectors with Spectral Response from 300 nm to 1450 nm. Science 2009, 325, 1665–1667. [Google Scholar] [CrossRef] [PubMed]

- Shockley, W.; Sparks, M.; Teal, G.K. p−n Junction Transistors. Phys. Rev. 1951, 83, 151–162. [Google Scholar] [CrossRef]

- Schlangenotto, H.; Scheuermann, U.; De Doncker, R. Pin-Diodes. In Semiconductor Power Devices: Physics, Characteristics, Reliability; Springer: Heidelberg/Berlin, Germany, 2010; pp. 159–224. [Google Scholar]

- Braun, D.; Yu, G. Simulations of Passive Matrix Polymer Image Sensors. MRS Proc. 1999, 558. [Google Scholar] [CrossRef]

- Seo, J.-H.; Zhang, K.; Kim, M.; Zhao, D.; Yang, H.; Zhou, W.; Ma, Z. Flexible phototransistors based on single-crystalline silicon nanomembrane. Adv. Opt. Mater. 2015, 4, 120–125. [Google Scholar] [CrossRef]

- Kim, M.; Seo, J.-H.; Yu, Z.; Zhou, W.; Ma, Z. Flexible germanium nanomembrane metal-semiconductor-metal photodiodes. Appl. Phys. Lett. 2016, 109, 051105. [Google Scholar] [CrossRef]

- Fan, D.; Lee, K.; Forrest, S.R. Flexible thin-film InGaAs photodiode focal plane array. ACS Photonics 2016, 3, 670–676. [Google Scholar] [CrossRef]

- Seo, J.-H.; Ling, T.; Gong, S.; Zhou, W.; Ma, A.L.; Guo, L.J.; Ma, Z. Fast flexible transistors with a nanotrench structure. Sci. Rep. 2016, 6, 24771. [Google Scholar] [CrossRef] [PubMed]

| Model | L1 | L2 | L3 | L4 | L5 | L6 | D1 | D2 | D3 | D4 |

|---|---|---|---|---|---|---|---|---|---|---|

| Photodiode | 180 | 180 | 50 | 30 | - | - | 30 | 40 | 30 | 40 |

| Phototransistor | 180 | 180 | 50 | 30 | 30 | 50 | 30 | 40 | 30 | 40 |

| Materials | Radius of Curvature | Deformability | Mechanism | Ref. |

|---|---|---|---|---|

| Si | 73 mm | Small | Thinning and bending | [8] |

| Si | ~19 mm | Small | Thinning and bending | [11] |

| Si | >15 mm | Cylindrical shape | Nanomembrane | [40] |

| Ge | 77.5 to 21 mm | Cylindrical shape | Nanomembrane | [41] |

| InGaAs | >2.5 mm | Cylindrical shape | Nanomembrane | [42] |

| Si | 28.5 mm | Cylindrical shape | Nanomembrane | [43] |

| Si | ~10 mm | Almost hemisphere | Photodetector array | [1] |

| Si | >11.4 mm | Almost hemisphere | Photodetector array | [3] |

| Si | ~6.96 mm | Hemisphere | Photodetector array | [2] 1 |

| Si | - | Hemisphere | Kirigami | [17] |

| Model | L1 | L2 | L3 | L4 | L5 | L6 | D1 | D2 | D3 | D4 | D5 | D6 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 180 | 180 | 50 | 30 | - | - | 30 | 40 | 30 | 40 | - | - |

| 2 | 180 | 180 | 50 | 30 | 30 | 50 | 30 | 40 | 30 | 40 | - | - |

| 3 | 180 | 180 | 30 | - | - | 30 | 30 | 40 | 30 | 40 | - | - |

| 4 | 180 | 180 | - | - | - | - | 30 | 40 | 30 | 40 | 25 | 30 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.S.; Lee, G.J.; Kim, H.M.; Song, Y.M. Parametric Optimization of Lateral NIPIN Phototransistors for Flexible Image Sensors. Sensors 2017, 17, 1774. https://doi.org/10.3390/s17081774

Kim MS, Lee GJ, Kim HM, Song YM. Parametric Optimization of Lateral NIPIN Phototransistors for Flexible Image Sensors. Sensors. 2017; 17(8):1774. https://doi.org/10.3390/s17081774

Chicago/Turabian StyleKim, Min Seok, Gil Ju Lee, Hyun Myung Kim, and Young Min Song. 2017. "Parametric Optimization of Lateral NIPIN Phototransistors for Flexible Image Sensors" Sensors 17, no. 8: 1774. https://doi.org/10.3390/s17081774