Virtual Sensor for Kinematic Estimation of Flexible Links in Parallel Robots

Abstract

:1. Introduction

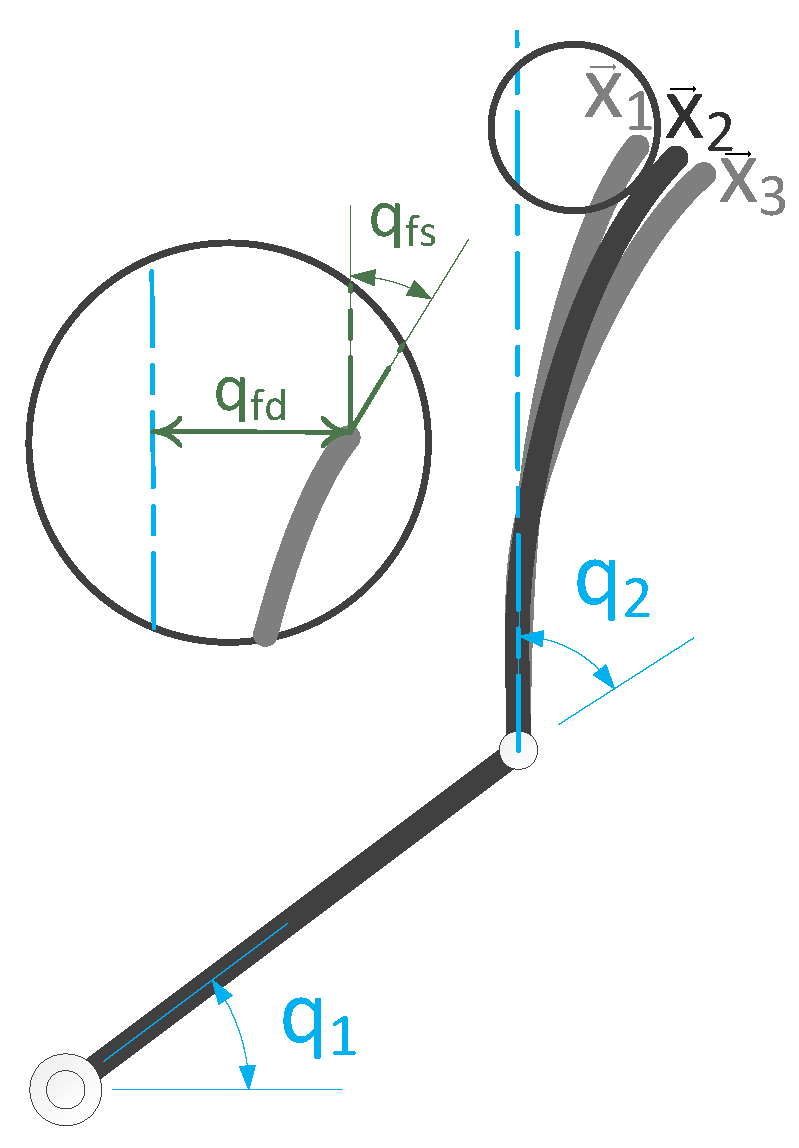

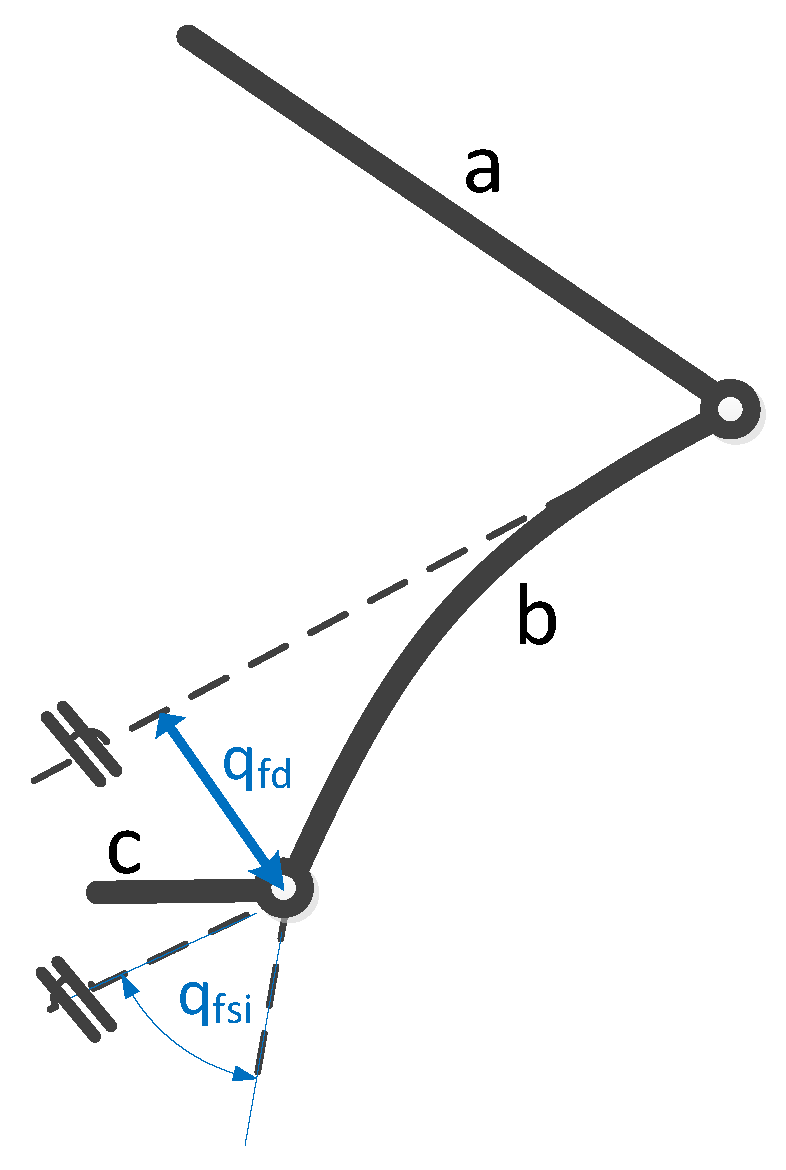

2. Theoretical Development of the Kinematic Virtual Sensor

2.1. Fundamentals of the Virtual Sensor

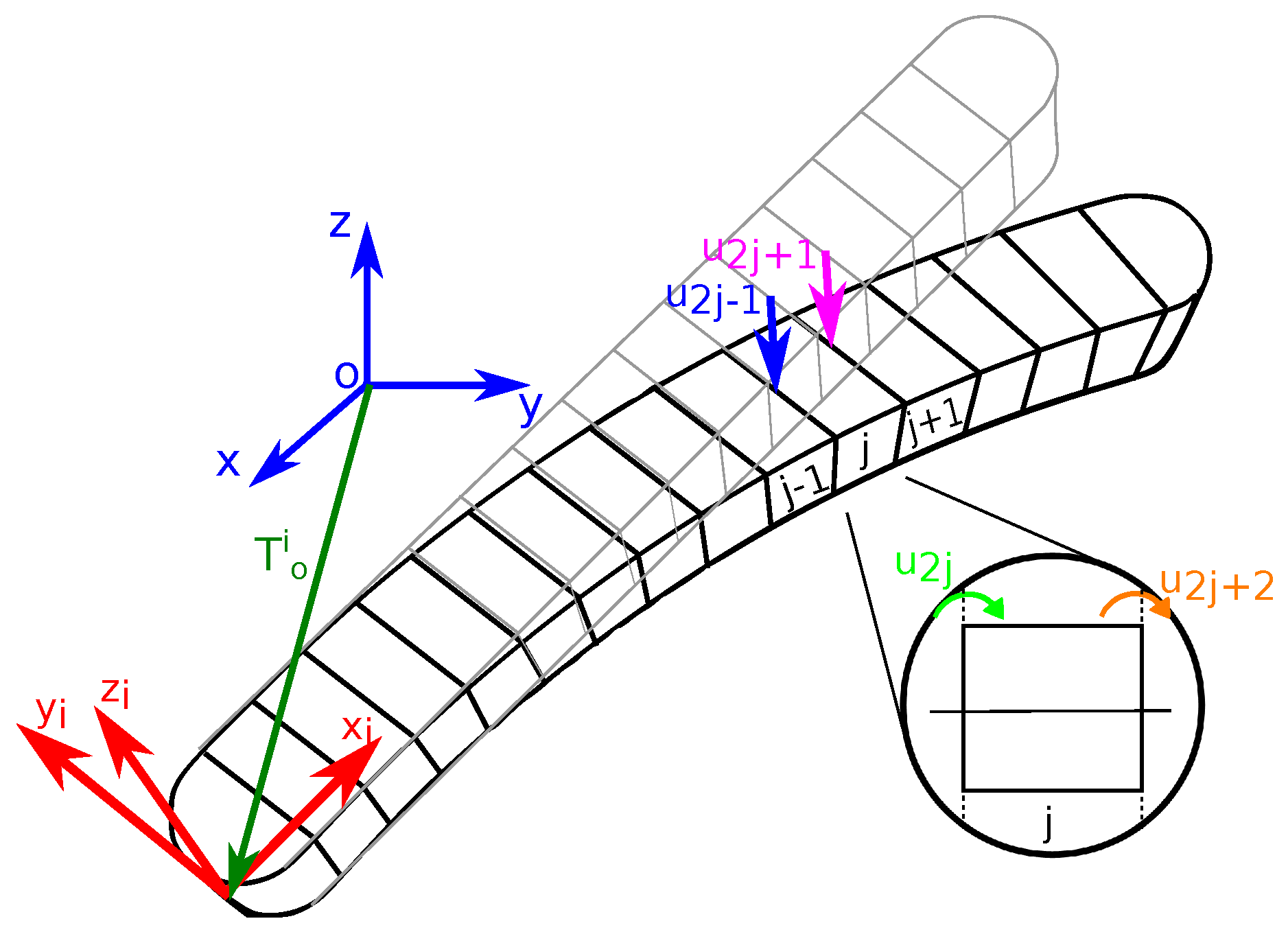

2.2. Modelling of Flexible Links

2.3. Modal Analysis of the Flexible Links

- If , then the solution isThis is a trivial solution, which does not provide any valuable information from a physical point of view, since it represents the case of no motion.

- If , the result of the eigenproblem is reduced to solve Equation (30).The determinant defined in Equation (30) can only be zero at a set of discrete eigenvalues . Furthermore, there is an eigenvector which satisfies the equation Equation (27). Therefore, Equation (27) can be rewritten as:where the number of eigenvalues and eigenvectors is equal to the number of DOF of the discretised limb has. Moreover, the ith eigenvalue is related to the ith natural frequency, , by

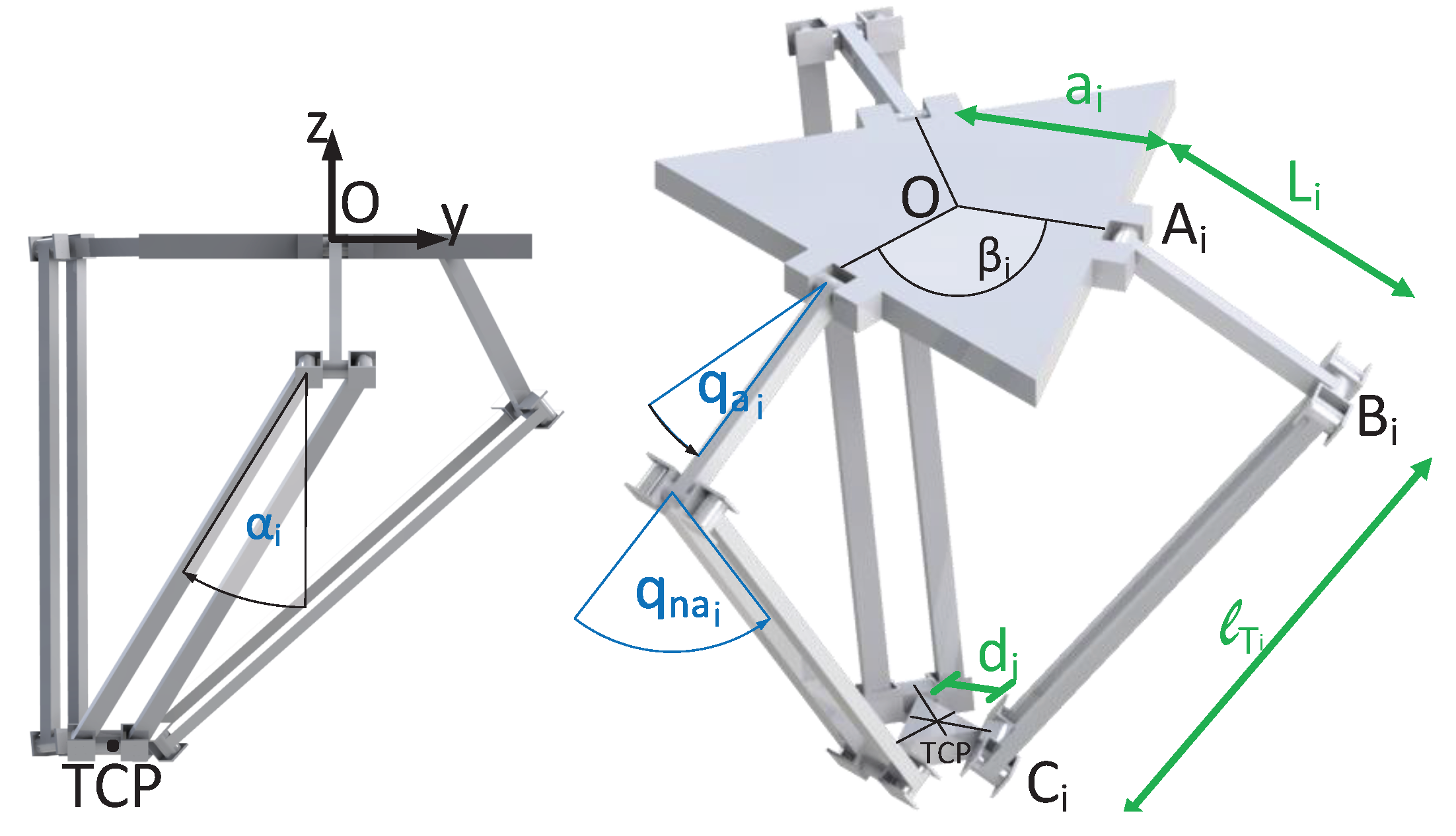

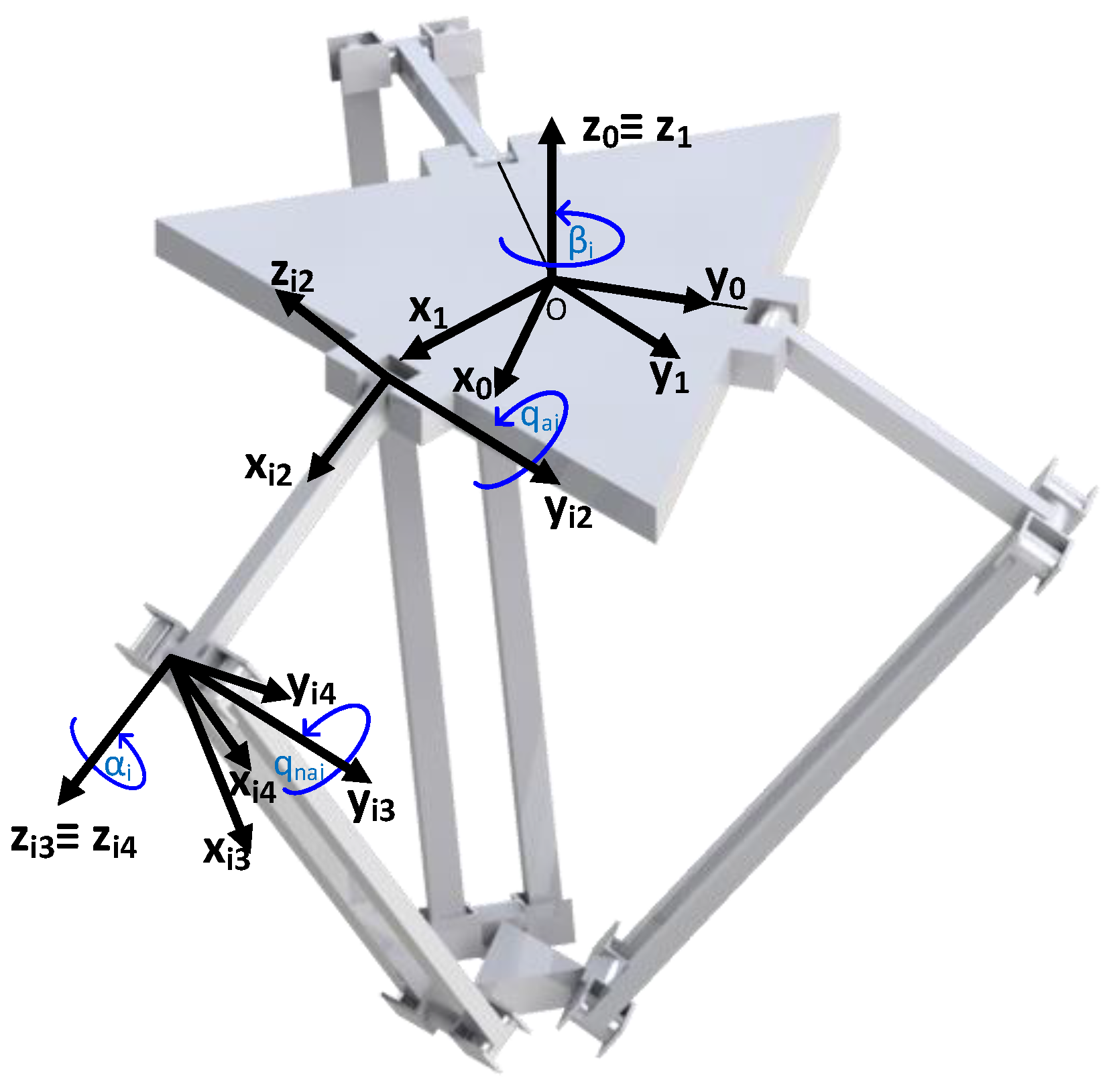

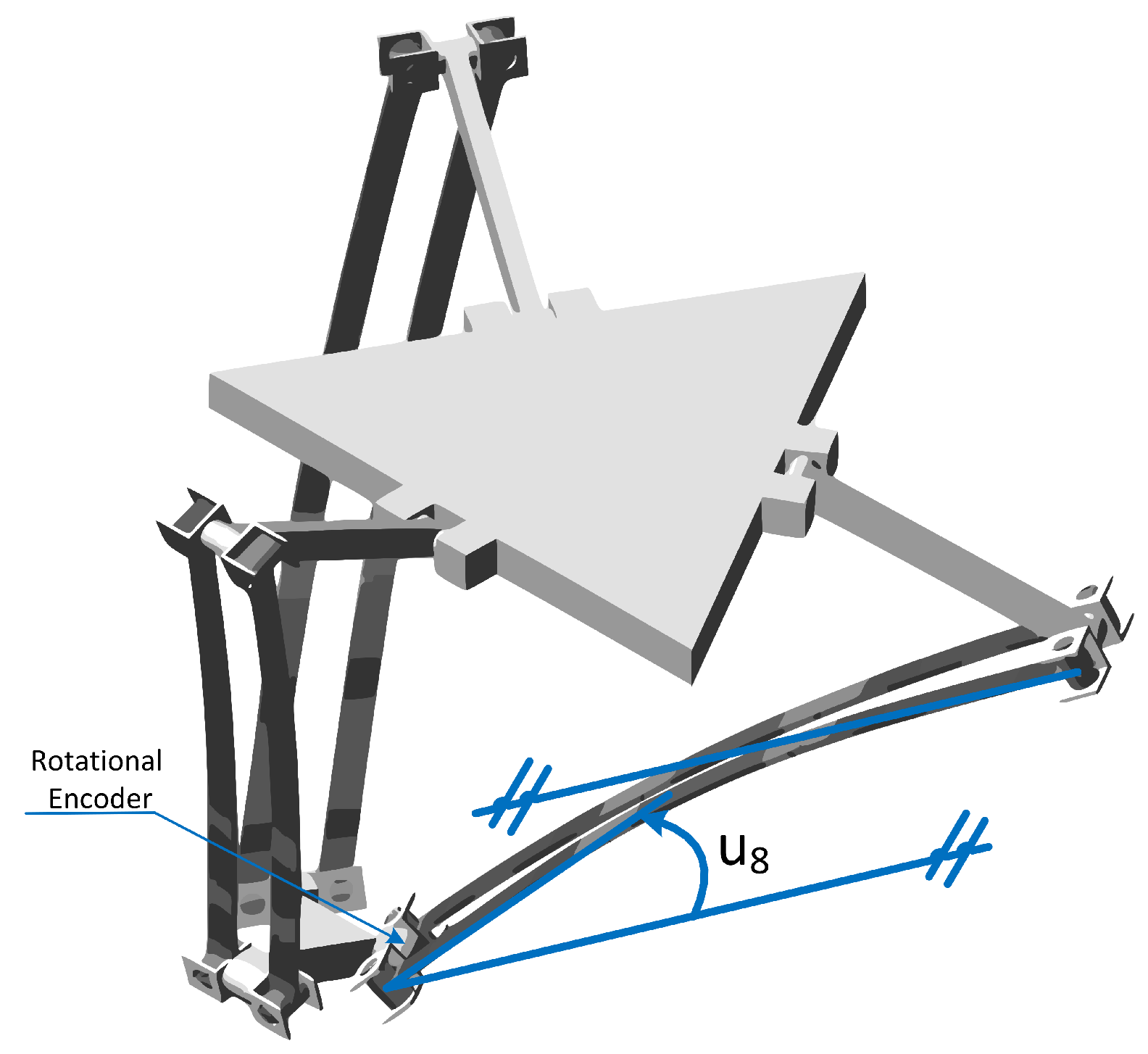

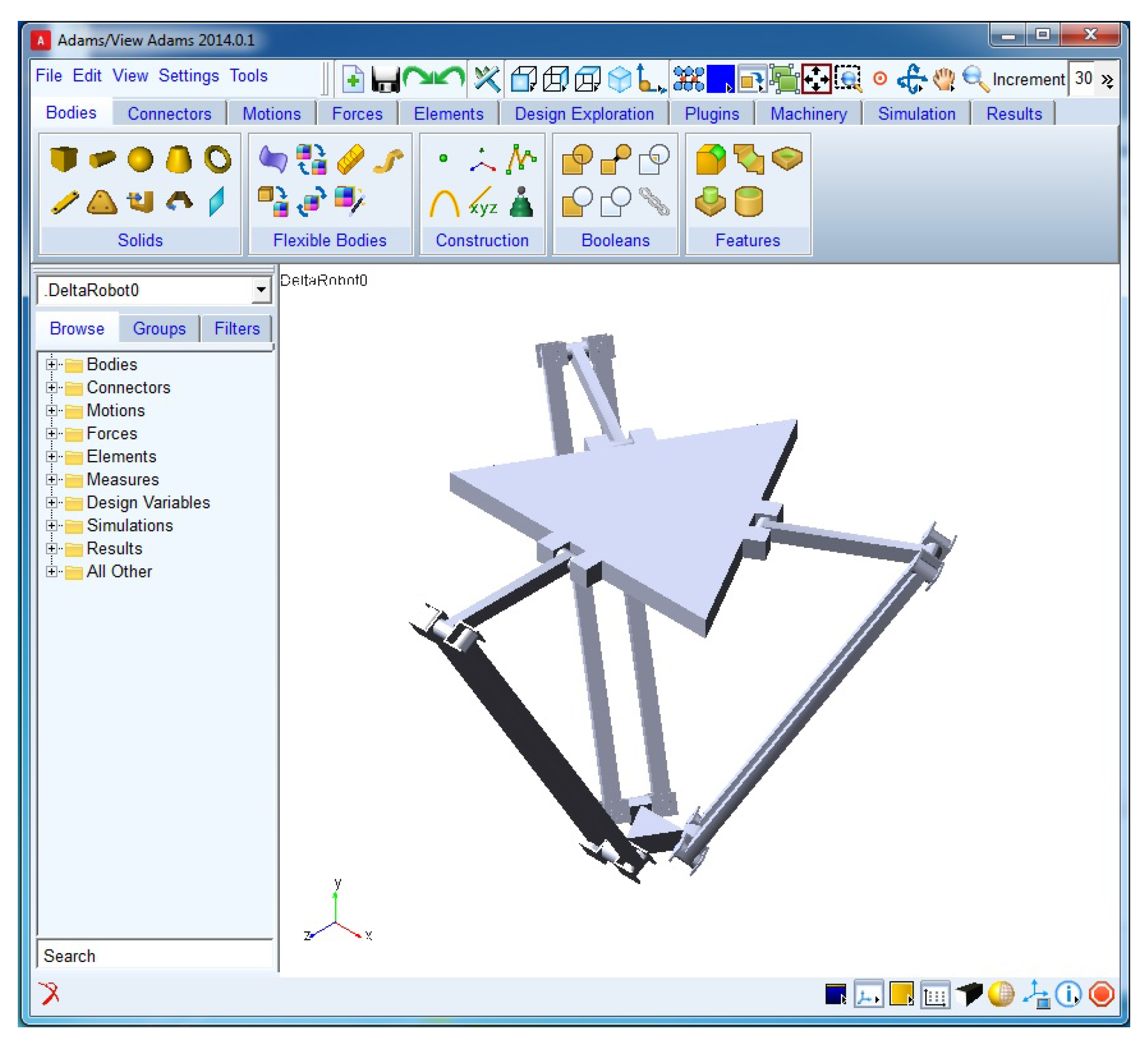

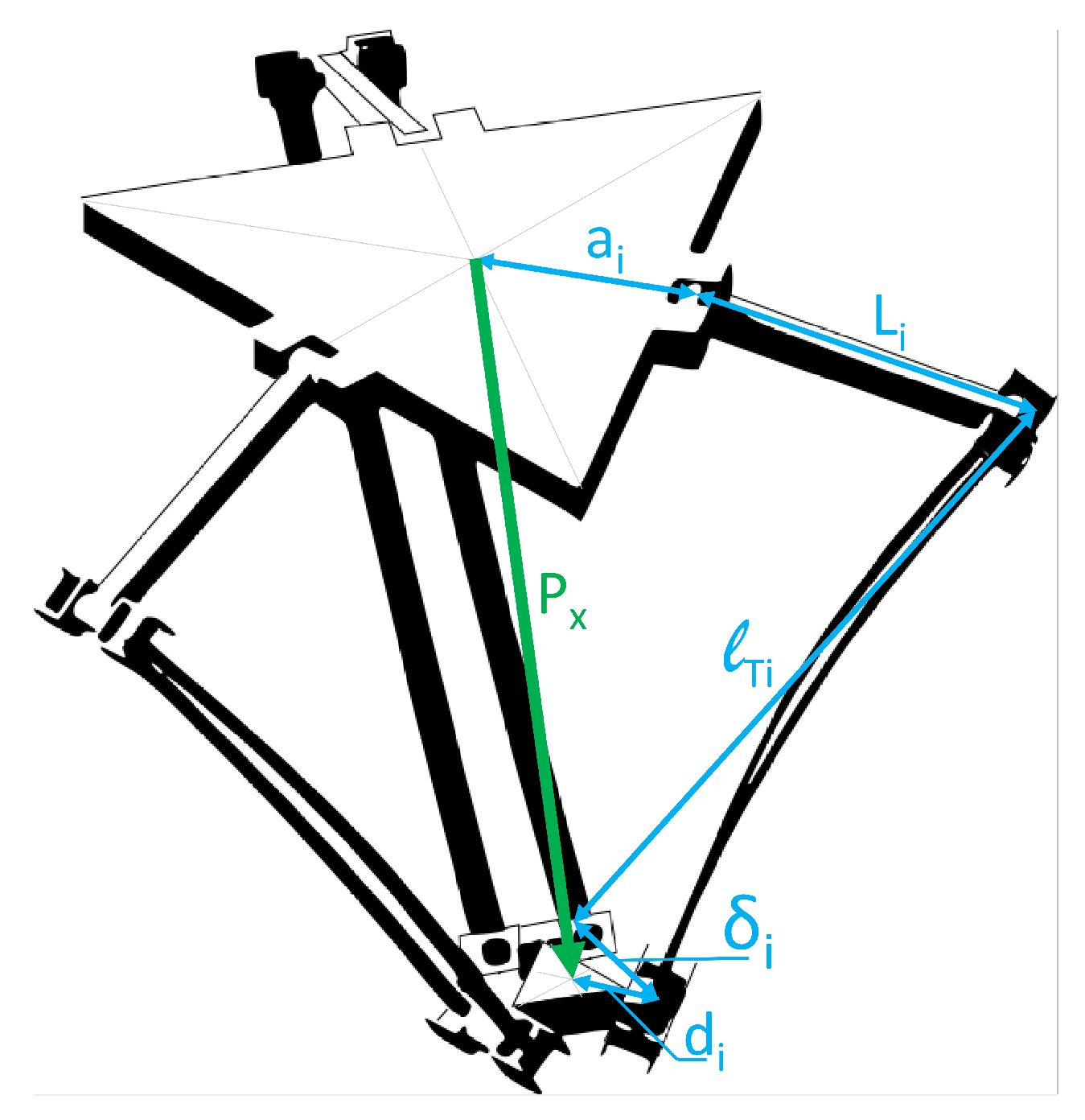

3. Case of Study: Delta Robot

3.1. The Delta Robot

3.2. Numeric Implementation of the Kinematic Virtual Sensor Applied to the Delta Robot

- The base of the link does not experience any deflection: .

- The link at the base has no deformation, so that the derivative of the deflection function is zero at that point: .

- There is no bending moment at the end of the link: .

- There is no shearing force acting at the end of the link: .

- If then .

- If then .

3.3. Simulation Setup

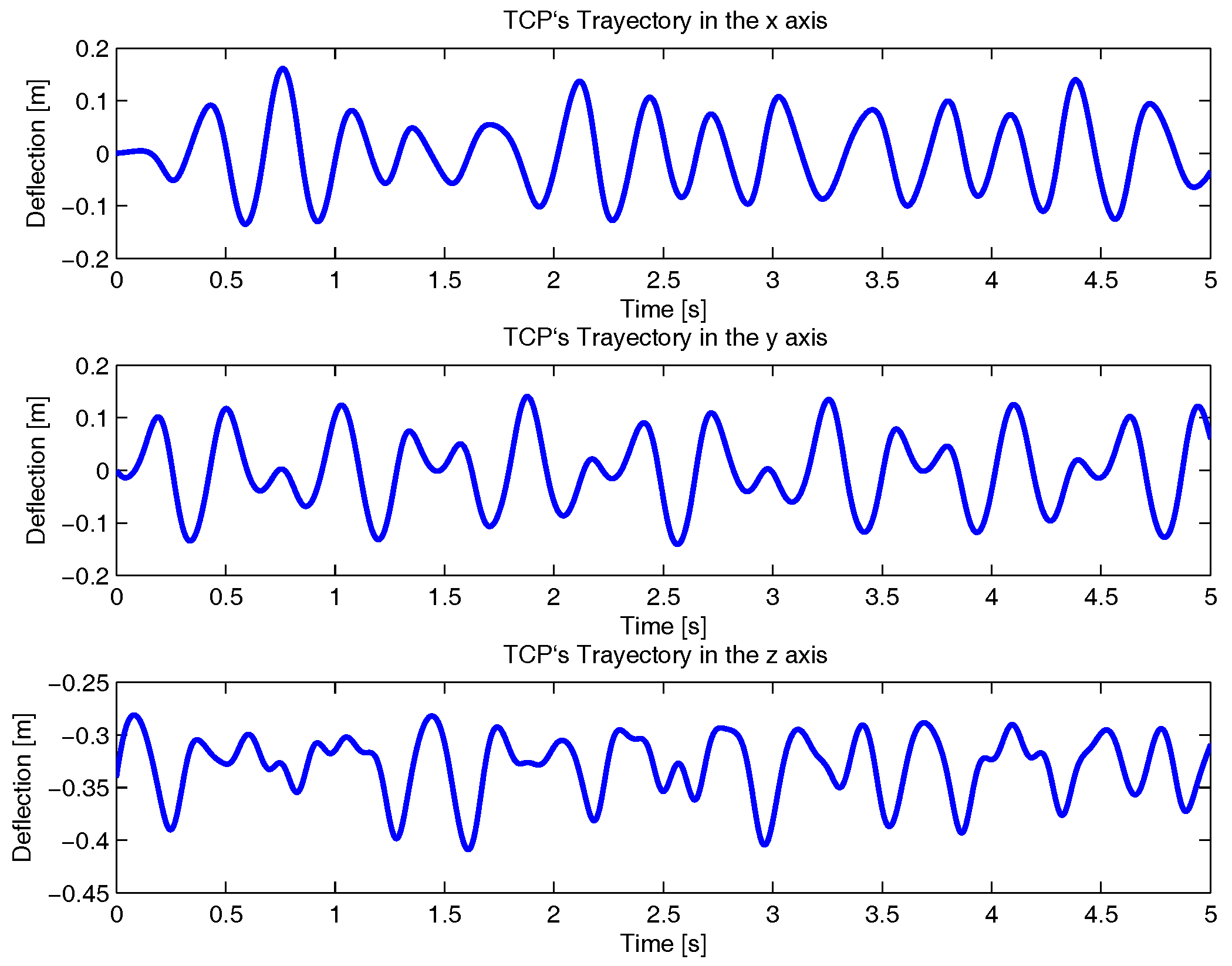

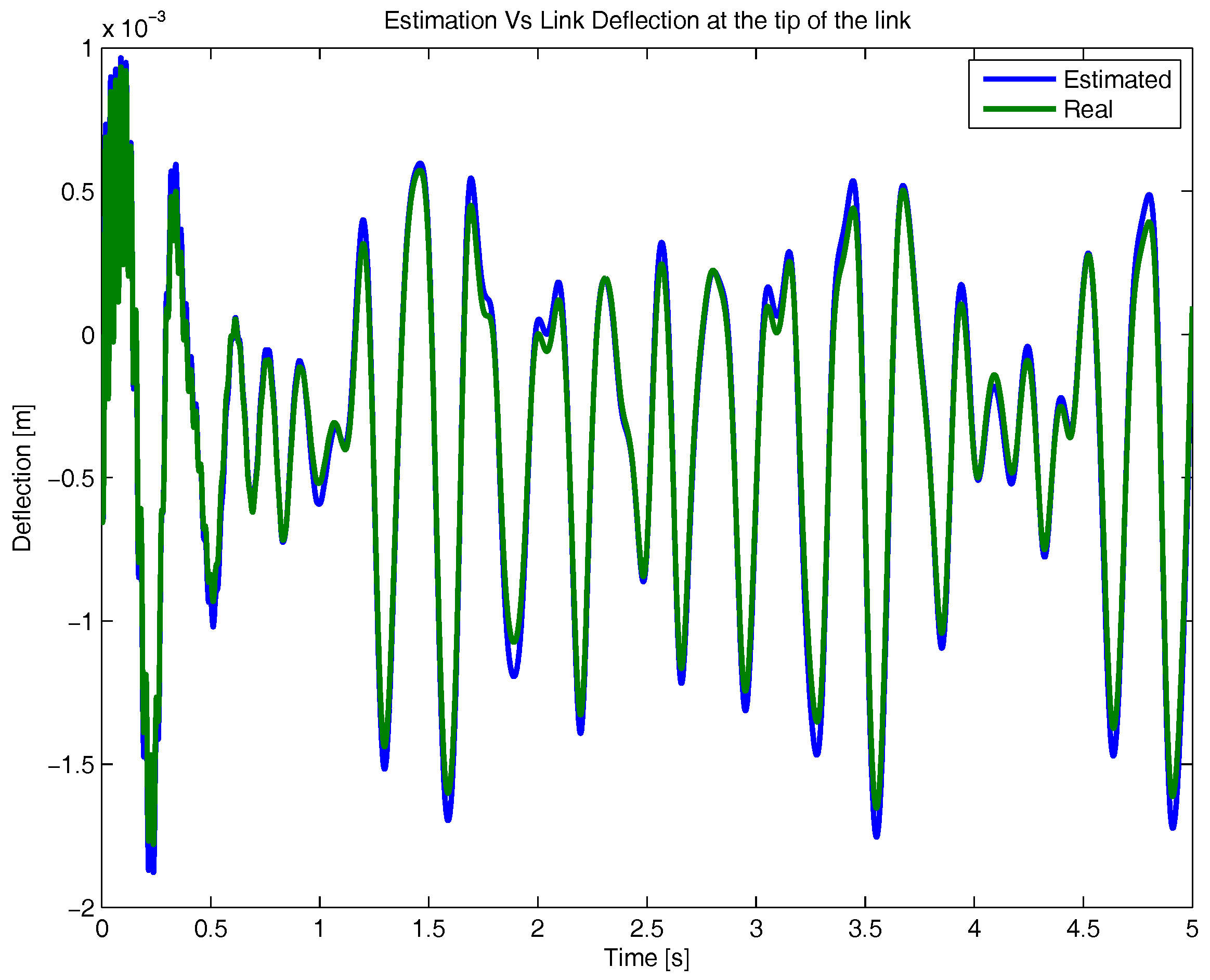

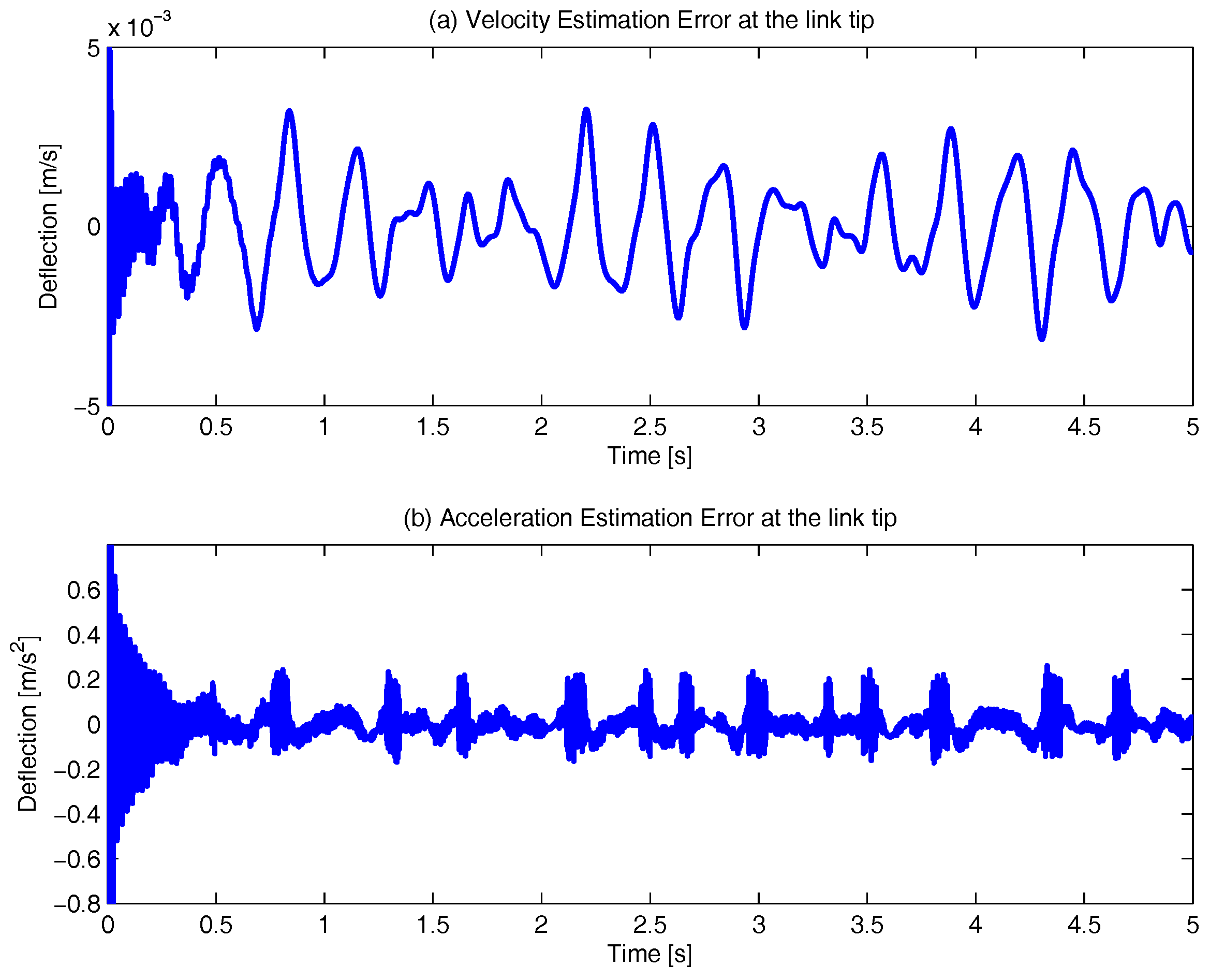

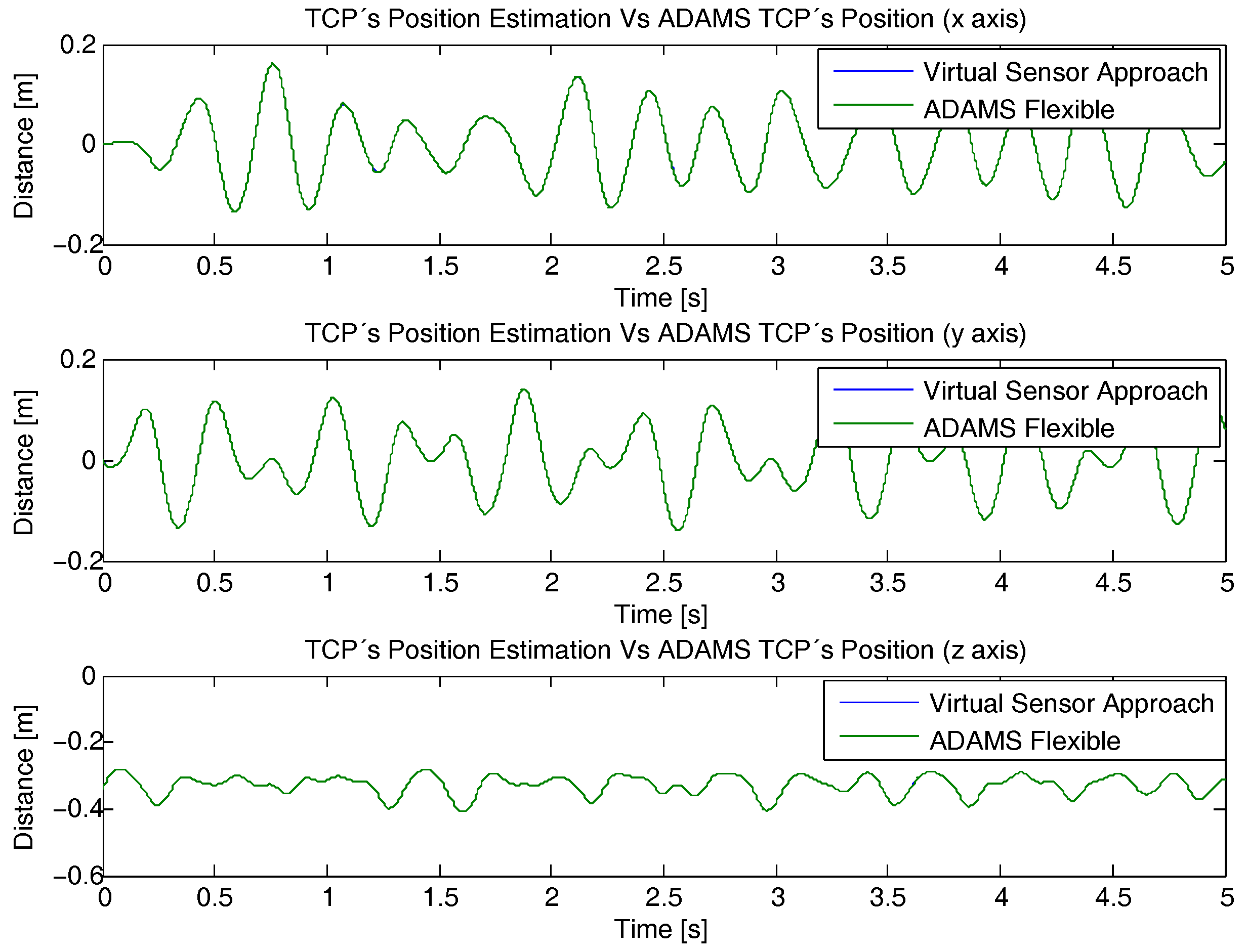

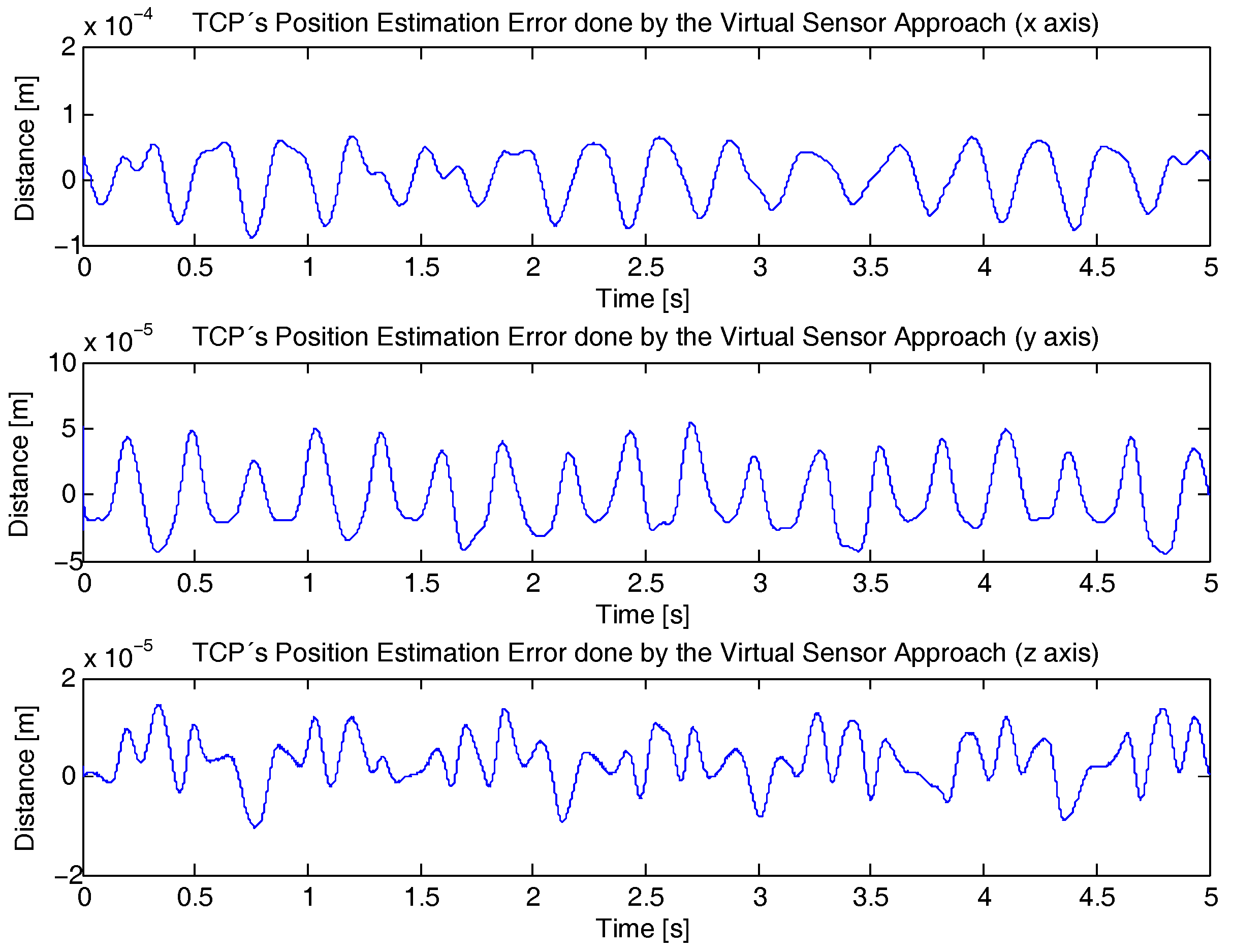

4. Results and Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PKR | Parallel Kinematic Robot |

| TCP | Tool Centre Point |

| DOF | Degree of Freedom |

| AMM | Assumed Modes Method |

| FEM | Finite Element Method |

| ERLS | Equivalent Rigid Link System |

| BC | Boundary Condition |

| DKP | Direct Kinematic Problem |

References

- Merlet, J.P. Parallel Robots, 2nd ed.; Springer Science & Business Media: Dordrecht, The Netherlands, 2006; p. 394. [Google Scholar]

- Chen, X.; Li, Y.; Deng, Y.; Li, W.; Wu, H. Kinetoelastodynamics Modeling and Analysis of Spatial Parallel Mechanism. Shock Vib. 2015, 2015, 1–10. [Google Scholar] [CrossRef]

- Rognant, M.; Courteille, E.; Maurine, P. A Systematic Procedure for the Elastodynamic Modeling and Identification of Robot Manipulators. IEEE Trans. Robot. 2010, 26, 1085–1093. [Google Scholar] [CrossRef] [Green Version]

- Mcguire, S. Control of Kinematically Redundant Robotic Manipulators for Orthopedic Surgery. Ph.D. Thesis, Intituto Superior Tecnico, Universidade Tecnica de Lisboa, Lisboa, Portugal, 2010. [Google Scholar]

- Kiang, C.T.; Spowage, A.; Yoong, C.K. Review of Control and Sensor System of Flexible Manipulator. J. Intell. Robot. Syst. Theory Appl. 2014, 77, 187–213. [Google Scholar] [CrossRef]

- Dubus, G. On-line estimation of time varying capture delay for vision-based vibration control of flexible manipulators deployed in hostile environments. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 3765–3770. [Google Scholar]

- Dubus, G.; David, O.; Measson, Y. A vision-based method for estimating vibrations of a flexible arm using on-line sinusoidal regression. In Proceedings of the IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 4068–4075. [Google Scholar]

- Liu, H.; Huang, Y.; Shi, W.; Xu, H. Design of adaptive fuzzy controller for flexible link manipulator. In Proceedings of the IEEE International Conference on Industrial Technology, Chengdu, China, 21–24 April 2008; pp. 1–4. [Google Scholar]

- Traslosheros, A.; Sebastian, J.M.; Torrijos, J.; Carelli, R.; Castillo, E. An inexpensive method for kinematic calibration of a parallel robot by using one hand-held camera as main sensor. Sensors 2013, 13, 9941–9965. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nguyen, H.N.; Zhou, J.; Kang, H.J. A new full pose measurement method for robot calibration. Sensors 2013, 13, 9132–9147. [Google Scholar] [CrossRef] [PubMed]

- Corke, P.I.; Hutchinson, S.A. Real-time vision, tracking and control. In Proceedings of the IEEE International Conference on Robotics and Automation, San Francisco, CA, USA, 24–28 April 2000; pp. 622–629. [Google Scholar]

- Hutchinson, S.; Hager, G.; Corke, P. A tutorial on visual servo control. IEEE Trans. Robot. Autom. 1996, 12, 651–670. [Google Scholar] [CrossRef]

- Piedboeuf, J.C. The jacodian matrix for a flexble manipulator. J. Robot. Syst. 1995, 12, 709–726. [Google Scholar] [CrossRef]

- Gu, M.; Piedboeuf, J.C. A flexible-link as an endpoint position and force detection unit. IFAC Proc. Vol. 2002, 15, 361–366. [Google Scholar] [CrossRef]

- Rodriguez-Donate, C.; Morales-Velazquez, L.; Osornio-Rios, R.A.; Herrera-Ruiz, G.; Romero-Troncoso, R.D.J. FPGA-based fused smart sensor for dynamic and vibration parameter extraction in industrial robot links. Sensors 2010, 10, 4114–4129. [Google Scholar] [CrossRef] [PubMed]

- Gu, M.; Asokanthan, S.F. Combined Discrete-Distributed Control of a Single-Link Flexible Manipulator Using a Lyapunov Approach. J. Dyn. Syst. Meas. Control 1999, 121, 448. [Google Scholar] [CrossRef]

- Feliu, V.; Garcia, A.; Somolinos, J.A. Gauge-based tip position control of a new three-degree-of-freedom flexible robot. Int. J. Robot. Res. 2001, 20, 660–675. [Google Scholar] [CrossRef]

- Piedboeuf, J.C.; Miller, S. Estimation of endpoint position and orientation of a flexible link using strain gauges. IFAC Proc. Vol. 1994, 20, 675–680. [Google Scholar] [CrossRef]

- Bascetta, L.; Rocco, P. End-point vibration sensing of planar flexible manipulators through visual servoing. Mechatronics 2006, 16, 221–232. [Google Scholar] [CrossRef]

- Zheng, J.; Fu, M. A Reset State Estimator Using an Accelerometer for Enhanced Motion Control with Sensor Quantization. IEEE Trans. Control Syst. Technol. 2010, 18, 79–90. [Google Scholar] [CrossRef]

- Henriksson, R.; Norrlof, M.; Moberg, S.; Wernholt, E.; Schon, T.B. Experimental comparison of observers for tool position estimation of industrial robots. In Proceedings of the 48h IEEE Conference on Decision and Control (CDC) held jointly with 2009 28th Chinese Control Conference, Shanghai, China, 15–18 December 2009; pp. 8065–8070. [Google Scholar]

- Trejo-Hernandez, M.; Osornio-Rios, R.A.; Romero-Troncoso, R.d.J.; Rodriguez-Donate, C.; Herrera-Ruiz, G.; Dominguez-Gonzalez, A. FPGA-based fused smart-sensor for tool-wear area quantitative estimation in CNC machine inserts. Sensors 2010, 10, 3373–3388. [Google Scholar] [CrossRef] [PubMed]

- Siciliano, B. Kinematic control of redundant robot manipulators: A tutorial. J. Intell. Robot. Syst. 1990, 3, 201–212. [Google Scholar] [CrossRef]

- Maia, N.M.M.; Montalvao e Silva, J.M.J.M. Theoretical and Experimental Modal Analysis; Research Studies Press: Overijse, Belgium, 1997; p. 468. [Google Scholar]

- Singh, S.N.; Schy, A.A. Elastic Robot Control: Nonlinear Inversion and Linear Stabilization. IEEE Trans. Aerosp. Electron. Syst. 1986, AES-22, 340–348. [Google Scholar] [CrossRef]

- Hastings, G.; Book, W. Verification of a linear dynamic model for flexible robotic manipulators. In Proceedings of the IEEE International Conference on Robotics and Automation, San Francisco, CA, USA, 7–10 April 1986; Volume 3, pp. 1024–1029. [Google Scholar]

- Book, W. Modeling, design, and control of flexible manipulator arms: a tutorial review. In Proceedings of the 29th IEEE Conference on Decision and Control, Honolulu, HI, USA, 5–7 December 1990; Volume 2, pp. 500–506. [Google Scholar]

- Theodore, R.J.; Ghosal, A. Comparison of the Assumed Modes and Finite Element Models for Flexible Multilink Manipulators. Int. J. Robot. Res. 1995, 14, 91–111. [Google Scholar] [CrossRef]

- Cheng, G.; Wang, S.T.; Yang, D.H.; Yang, J.H. Finite Element Method for Kinematic Analysis of Parallel Hip Joint Manipulator. J. Mech. Robot. 2015, 7, 041010. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, F.; Dong, X.; Zhao, X. Dynamics analysis and characteristics of the 8-PSS flexible redundant parallel manipulator. Robot. Comput. Integr. Manuf. 2011, 27, 918–928. [Google Scholar] [CrossRef]

- Piras, G.; Cleghorn, W.; Mills, J. Dynamic finite-element analysis of a planar high-speed, high-precision parallel manipulator with flexible links. Mech. Mach. Theory 2005, 40, 849–862. [Google Scholar] [CrossRef]

- Ebrahimi, S.; Eshaghiyeh-Firoozabadi, A. Dynamic performance evaluation of serial and parallel RPR manipulators with flexible intermediate links. Iran. J. Sci. Technol. Trans. Mech. Eng. 2016, 40, 169–180. [Google Scholar] [CrossRef]

- Sharifnia, M.; Akbarzadeh, A. A constrained assumed modes method for dynamics of a flexible planar serial robot with prismatic joints. Multibody Syst. Dyn. 2016, 40, 1–25. [Google Scholar] [CrossRef]

- Briot, S.; Khalil, W. Recursive and symbolic calculation of the elastodynamic model of flexible parallel robots. Int. J. Robot. Res. 2013, 33, 469–483. [Google Scholar] [CrossRef]

- Sunada, W.; Dubowsky, S. The application of finite element methods to the dynamic analysis of flexible spatial and coplanar linkage systems. J. Mech. Des. 1981, 103, 643–651. [Google Scholar] [CrossRef]

- Jonker, B. A Finite Element Dynamic Analysis of Flexible Manipulators. Int. J. Robot. Res. 1990, 9, 59–74. [Google Scholar] [CrossRef]

- Meirovitch, L. Computational Methods in Structural Dynamics, 1980 ed.; Springer: Rockville, MD, USA, 1980; p. 456. [Google Scholar]

- Cook, R.D.; Saunders, H. Concepts and Applications of Finite Element Analysis. J. Press. Vessel Technol. 1984, 106, 127. [Google Scholar] [CrossRef]

- Zubizarreta, A.; Cabanes, I.; Marcos, M.; Pinto, C. A redundant dynamic model of parallel robots for model-based control. Robotica 2012, 31, 203–216. [Google Scholar] [CrossRef]

- Khalil, W.; Kleinfinger, J. A new geometric notation for open and closed-loop robots. In Proceedings of the IEEE International Conference on Robotics and Automation, San Francisco, CA, USA, 7–10 April 1986; Volume 3, pp. 1174–1179. [Google Scholar]

- Denavit, J. A kinematic notation for lower-pair mechanisms based on matrices. Trans. ASME. J. Appl. Mech. 1955, 22, 215–221. [Google Scholar]

- Tsujisawa, T.; Book, W. A reduced order model derivation for lightweight arms with a parallel mechanism. In Proceedings of the IEEE International Conference on Robotics and Automation, Scottsdale, AZ, USA, 14–19 May 1989; pp. 728–735. [Google Scholar]

- Przemieniecki, J. Theory of Matrix Structural Aanalysis; Dover Publication: New York, NY, USA, 1968; p. 480. [Google Scholar]

- Asada, H.; Ma, Z.D.; Tokumaru, H. Inverse Dynamics of Flexible Robot Arms: Modeling and Computation for Trajectory Control. J. Dyn. Syst. Meas. Control 1990, 112, 177. [Google Scholar] [CrossRef]

- Baruh, H.; Tadikonda, S.S.K. Issues in the dynamics and control of flexible robot manipulators. J. Guid. Control Dyn. 1989, 12, 659–671. [Google Scholar] [CrossRef]

- Book, W.J. Recursive Lagrangian Dynamics of Flexible Manipulator Arms. Int. J. Robot. Res. 1984, 3, 87–101. [Google Scholar] [CrossRef]

- Wang, D.; Vidyasagar, M. Transfer functions for a single flexible link. Int. J. Robot. Res. 1991, 10, 540–549. [Google Scholar] [CrossRef]

- Barbieri, E.; Ozguner, U. Unconstrained and Constrained Mode Expansions for a Flexible Slewing Link. J. Dyn. Syst. Meas. Control 1988, 110, 416. [Google Scholar] [CrossRef]

| Fixed Base | Upper Link | Lower Link | Mobile Platform | |

|---|---|---|---|---|

| Length (m) | 0.150 | 0.400 | ||

| Mass (kg) | 0.0365 | 0.1319 | 0.1278 | |

| Inertia (kg m2) | ||||

| Length | Width | Thickness | Young’s Modulus | Mass Density |

|---|---|---|---|---|

| 0.400 m | 0.015 m | 0.003 m | 71 GPa | 2740 kg/m3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bengoa, P.; Zubizarreta, A.; Cabanes, I.; Mancisidor, A.; Pinto, C.; Mata, S. Virtual Sensor for Kinematic Estimation of Flexible Links in Parallel Robots. Sensors 2017, 17, 1934. https://doi.org/10.3390/s17091934

Bengoa P, Zubizarreta A, Cabanes I, Mancisidor A, Pinto C, Mata S. Virtual Sensor for Kinematic Estimation of Flexible Links in Parallel Robots. Sensors. 2017; 17(9):1934. https://doi.org/10.3390/s17091934

Chicago/Turabian StyleBengoa, Pablo, Asier Zubizarreta, Itziar Cabanes, Aitziber Mancisidor, Charles Pinto, and Sara Mata. 2017. "Virtual Sensor for Kinematic Estimation of Flexible Links in Parallel Robots" Sensors 17, no. 9: 1934. https://doi.org/10.3390/s17091934