Fibre Bragg Gratings in Embedded Microstructured Optical Fibres Allow Distinguishing between Symmetric and Anti-Symmetric Lamb Waves in Carbon Fibre Reinforced Composites

Abstract

:1. Introduction

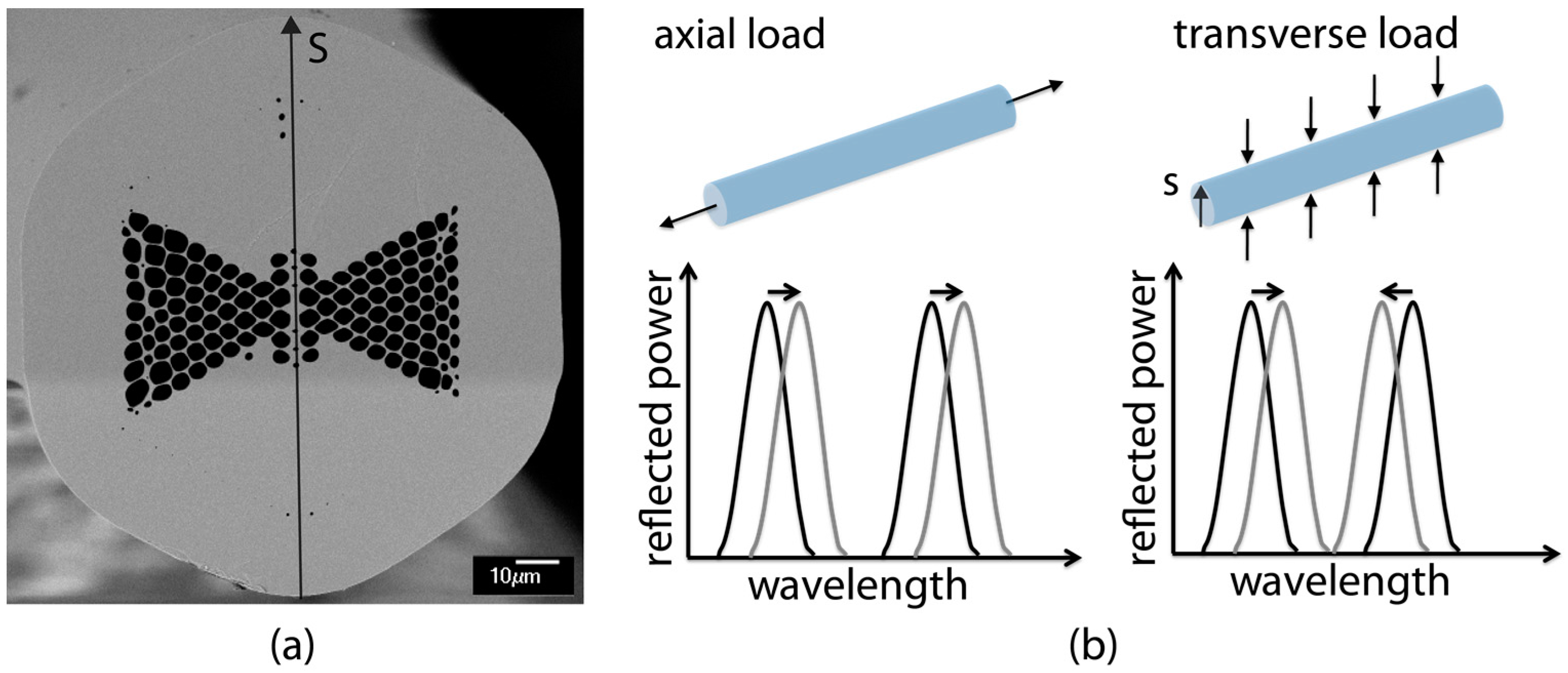

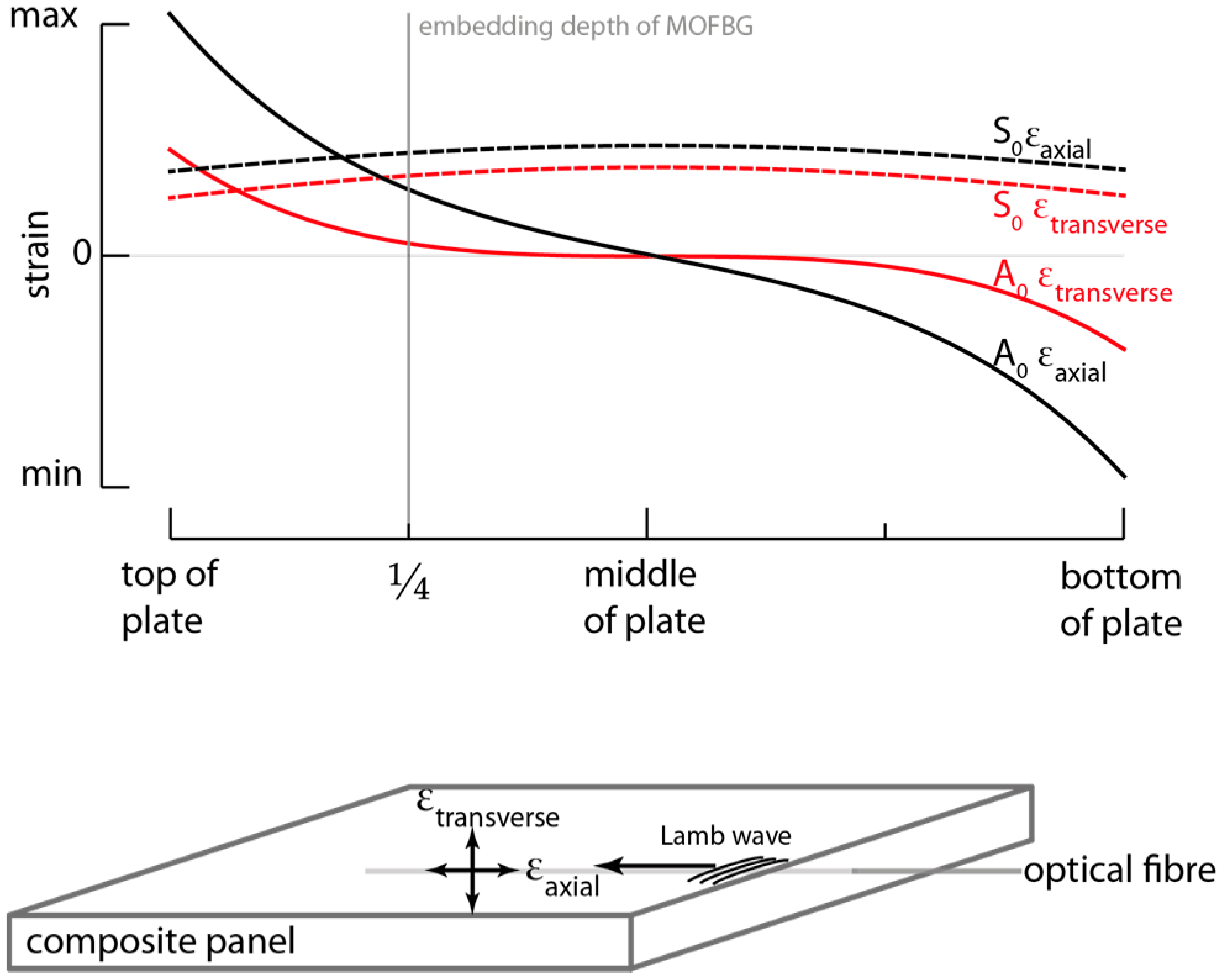

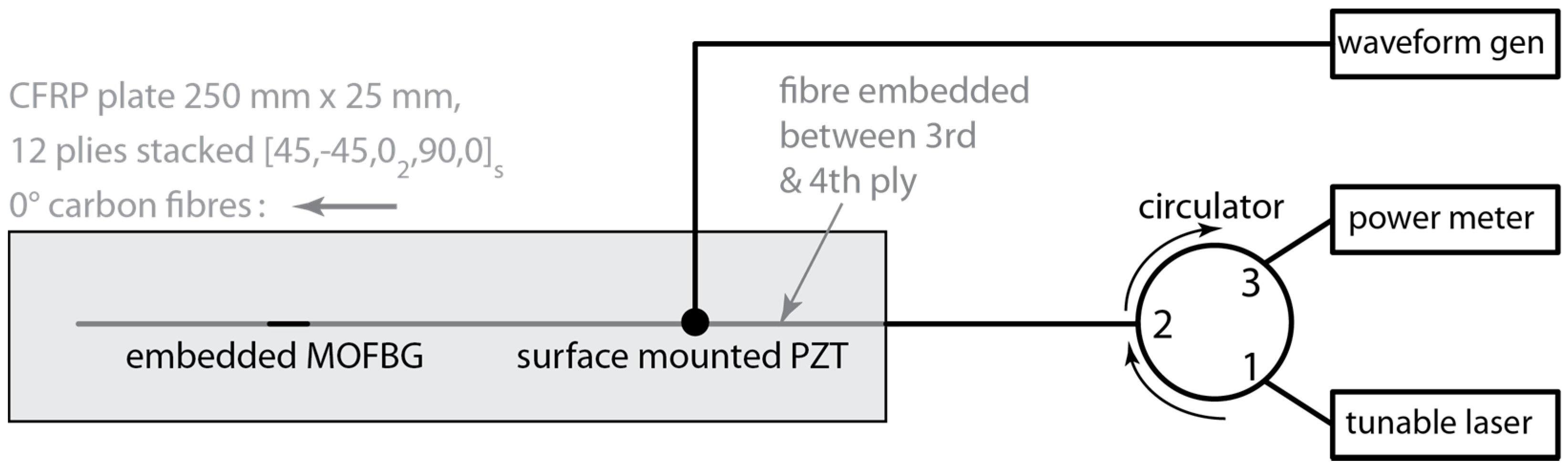

2. MOFBG Sensors and Measurement Strategy

3. Experimental Results

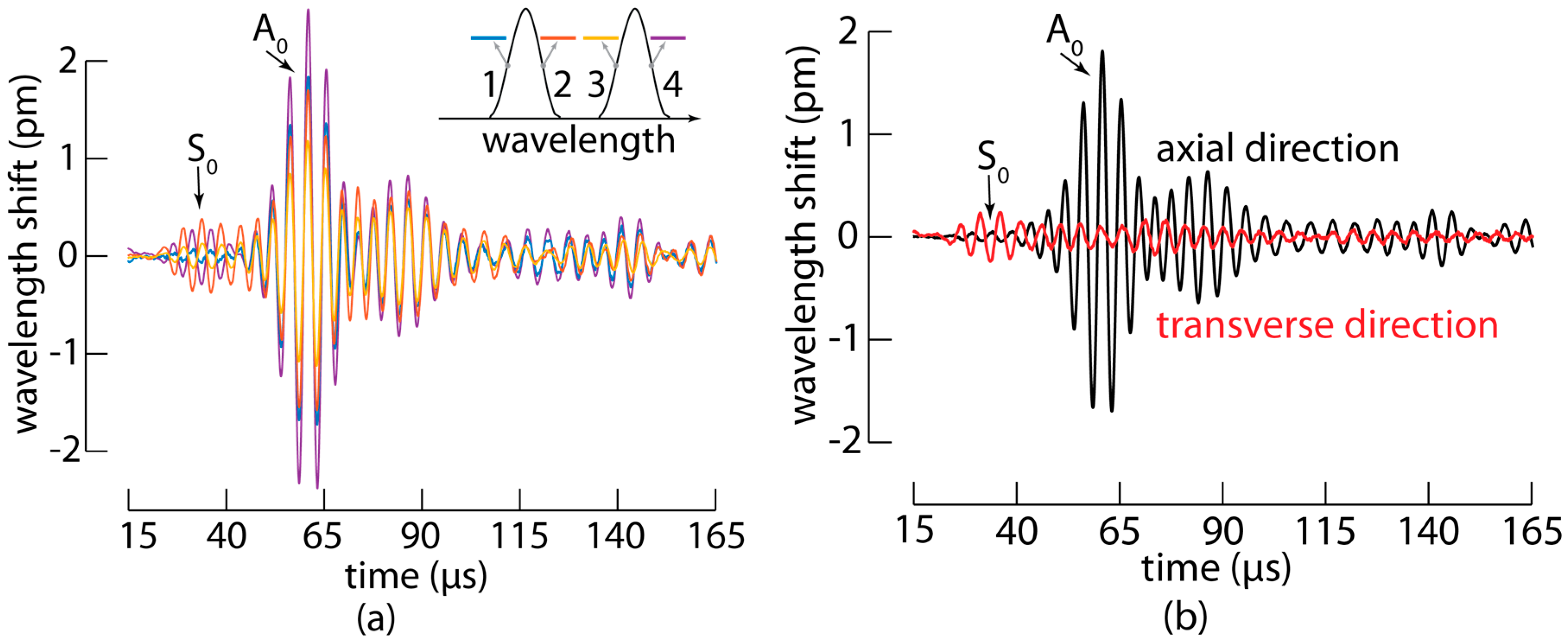

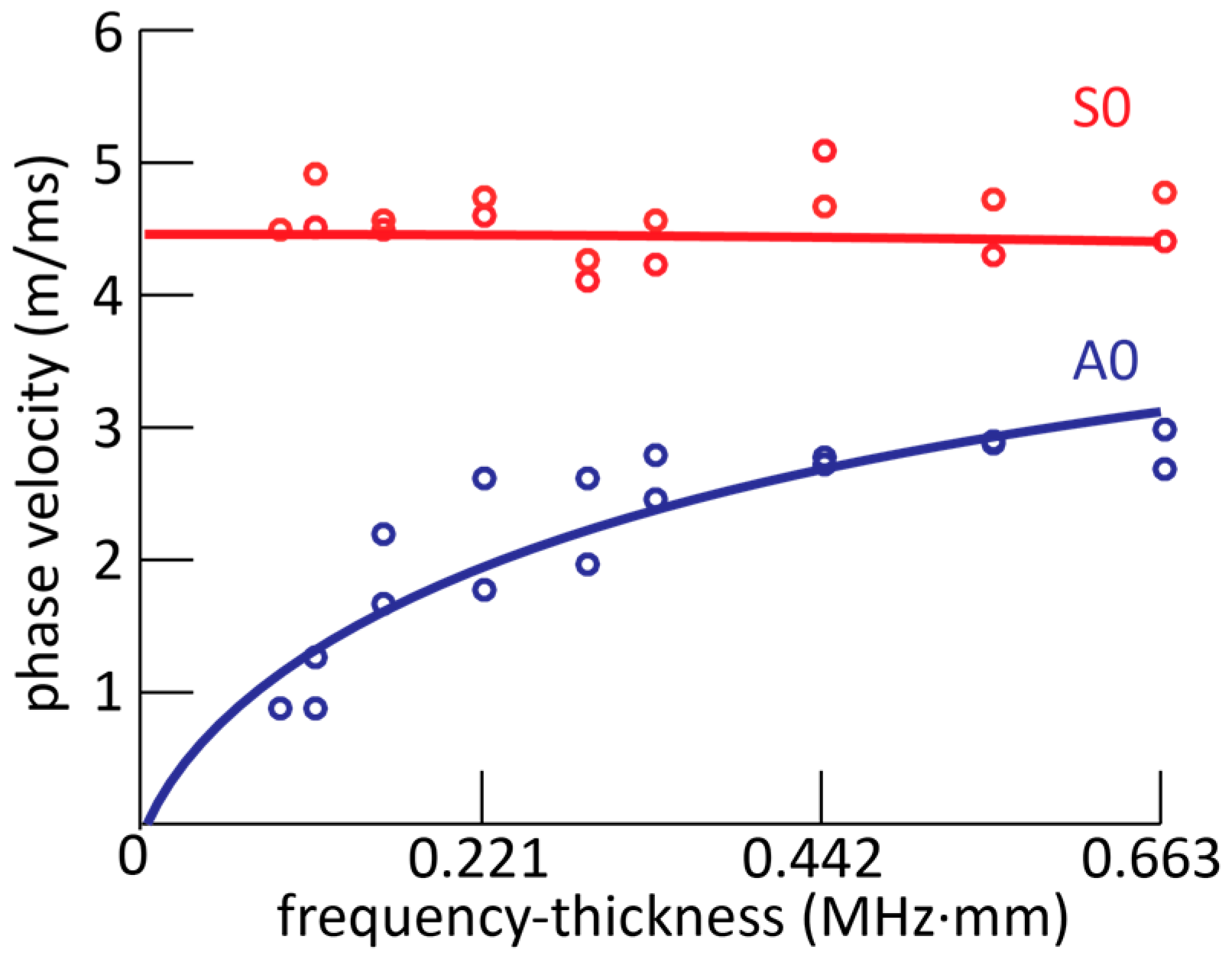

3.1. MOFBGs Allow Distinguishing between A0 and S0 Waves

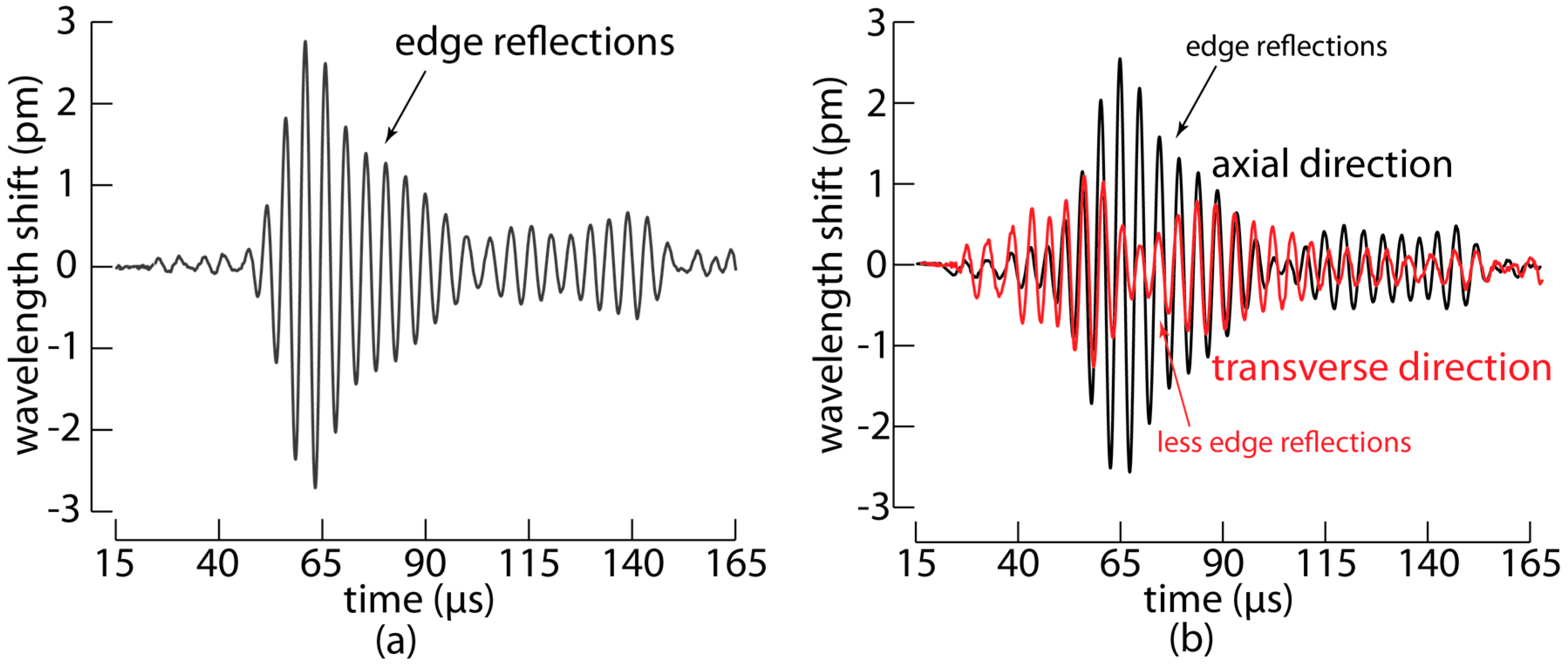

3.2. Selection of Preferential Directions Allow Filtering out Undesired Edge Reflections

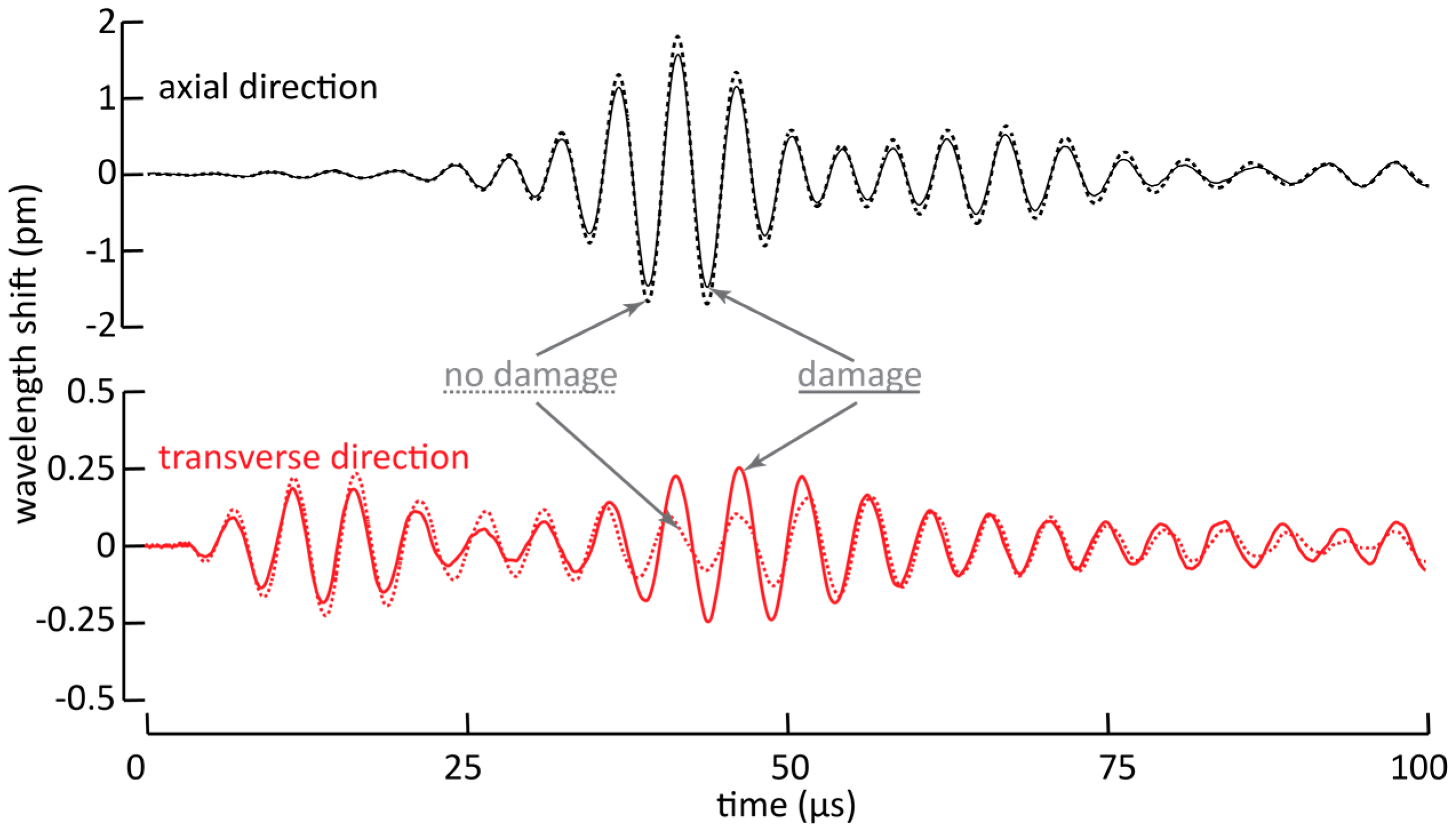

3.3. Consequences for Impact Damage Detection in CFRP

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhao, X.; Gao, H.; Zhang, G.; Ayhan, B.; Yan, F.; Kwan, C.; Rose, J.L. Active health monitoring of an aircraft wing with embedded piezoelectric sensor/actuator network: I. Defect detection, localization and growth monitoring. Smart Mater. Struct. 2007, 16. [Google Scholar] [CrossRef]

- Paget, C.A.; Levin, K.; Delebarre, C. Actuation performance of embedded piezoceramic transducer in mechanically loaded composites. Smart Mater. Struct. 2002, 11. [Google Scholar] [CrossRef]

- Su, Z.; Lin, Y.; Ye, L. Guided Lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295. [Google Scholar] [CrossRef]

- Betz, D.C.; Thursby, G.; Culshaw, B.; Staszewski, W.J. Advanced layout of a fiber Bragg grating strain gauge rosette. J. Lightwave Technol. 2006, 24. [Google Scholar] [CrossRef]

- Takeda, N.; Okabe, Y.; Kuwahara, J.; Kojima, S.; Ogisu, T. Development of smart composite structures with small-diameter fibre Bragg grating sensors for damage detection: Quantitative evaluation of delamination length in CFRP-laminates using Lamb wave sensing. Compos. Sci. Technol. 2005, 65. [Google Scholar] [CrossRef]

- Tsuda, H.; Toyama, N.; Urabe, K.; Takatsubo, J. Impact damage detection in CFRP using fiber Bragg gratings. Smart Mater. Struct. 2004, 13. [Google Scholar] [CrossRef]

- Takeda, S.; Okabe, Y.; Takeda, N. Delamination detection in CFRP laminates with embedded small-diameter fiber Bragg grating sensors. Compos. Part A 2002, 33. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L. Identification of Damage Using Lamb Waves; Springer: Hong Kong, China, 2009. [Google Scholar]

- Wu, W.; Yu, H.; Chen, W. Indentation responses of piezoelectric layered half-space. Smart Mater. Struct. 2013, 22. [Google Scholar] [CrossRef]

- Hayashi, T.; Kawashima, K. Single Mode Extraction from Multiple Modes of Lamb Wave and Its Application to Defect Detection. J. Solid Mech. Mater. Eng. 2003, 46. [Google Scholar] [CrossRef]

- Zhang, H.-Y.; Yu, J.-B. Piezoelectric transducer parameter selection for exciting a single mode from multiple modes of Lamb waves. Chin. Phys. B 2011, 20. [Google Scholar] [CrossRef]

- Frazao, O.; Santos, J.; Araujo, F.; Ferreira, L. Optical sensing with photonic crystal fibers. Laser Photonics Rev. 2008, 2. [Google Scholar] [CrossRef]

- Canning, J. Properties of Specialist Fibres and Bragg Gratings for Optical Fiber Sensors. J. Sens. 2009, 871580. [Google Scholar] [CrossRef]

- Canning, J.; Groothoff, N.; Cook, K.; Pohl, A.; Holdsworth, J.; Bandyopadhyay, S.; Stevenson, M. Grating Writing in Structured Optical Fibres. Laser Chem. 2008, 239417. [Google Scholar] [CrossRef]

- Canning, J. Fibre Gratings & Devices for Sensors & Lasers. Lasers Photonics Rev. 2008, 2. [Google Scholar] [CrossRef]

- Pinto, A.; Lopez-Amo, M. Photonic Crystal Fibers for Sensing Applications. J. Sens. 2009, 598178. [Google Scholar] [CrossRef]

- Berghmans, F.; Geernaert, T.; Sonnenfeld, C.; Sulejmani, S.; Thienpont, H. Microstructured Optical Fibre-Based Sensors for Structural Health Monitoring Applications, Optofluidics, Sensors and Actuators in Microstructured Optical Fibres; Woodhead Publishing: Cambridge, UK, 2015; p. 139. [Google Scholar]

- Sonnenfeld, C.; Luyckx, G.; Sulejmani, S.; Geernaert, T.; Eve, S.; Gomina, M.; Chah, K.; Mergo, P.; Urbanczyk, W.; Thienpont, H.; et al. Microstructured optical fiber Bragg grating as an internal three-dimensional strain sensor for composite laminates. Smart Mater. Struct. 2015, 24. [Google Scholar] [CrossRef]

- Sonnenfeld, C.; Sulejmani, S.; Geernaert, T.; Eve, S.; Lammens, N.; Luyckx, G.; Voet, E.; Degrieck, J.; Urbanczyk, W.; Mergo, P.; et al. Microstructured optical fibre sensors embedded in laminate composite for smart material applications. Sensors 2011, 11, 2566. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sulejmani, S.; Sonnenfeld, C.; Geernaert, T.; Luyckx, G.; van Hemelrijck, D.; Mergo, P.; Urbanczyk, W.; Chah, K.; Caucheteur, C.; Mégret, P.; et al. Shear stress sensing with Bragg grating-based sensors in microstructured optical fibres. Opt. Express 2013, 21, 20404. [Google Scholar] [CrossRef] [PubMed]

- Rose, J. Ultrasonic Waves in Solid Media; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Cusano, A.; Cutolo, A. Fibre Bragg Grating Sensors: Recent Advancements, Industrial Applications and Market Exploitation; Bentham Science Publishers: Valencia, Spain, 2014. [Google Scholar]

- Sharif-Khodaei, Z.; Ghajari, M.; Aliabadi, M. Determination of impact location on composite stiffened panels. Smart Mater. Struct. 2012, 21, 105026. [Google Scholar] [CrossRef]

- Sharif-Khodaei, Z.; Aliabadi, M. Assessment of delay-and-sum algorithms for damage detection in aluminium and composite plates. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Lambinet, F.; Sharif-Khodaei, Z.; Aliabadi, M. Damage Detection in Composite Skin Stiffener with Hybrid PZT-FO SHM System. Key Eng. Mater. 2017, in press. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Pauw, B.; Goossens, S.; Geernaert, T.; Habas, D.; Thienpont, H.; Berghmans, F. Fibre Bragg Gratings in Embedded Microstructured Optical Fibres Allow Distinguishing between Symmetric and Anti-Symmetric Lamb Waves in Carbon Fibre Reinforced Composites. Sensors 2017, 17, 1948. https://doi.org/10.3390/s17091948

De Pauw B, Goossens S, Geernaert T, Habas D, Thienpont H, Berghmans F. Fibre Bragg Gratings in Embedded Microstructured Optical Fibres Allow Distinguishing between Symmetric and Anti-Symmetric Lamb Waves in Carbon Fibre Reinforced Composites. Sensors. 2017; 17(9):1948. https://doi.org/10.3390/s17091948

Chicago/Turabian StyleDe Pauw, Ben, Sidney Goossens, Thomas Geernaert, Dimitrios Habas, Hugo Thienpont, and Francis Berghmans. 2017. "Fibre Bragg Gratings in Embedded Microstructured Optical Fibres Allow Distinguishing between Symmetric and Anti-Symmetric Lamb Waves in Carbon Fibre Reinforced Composites" Sensors 17, no. 9: 1948. https://doi.org/10.3390/s17091948