Fabrication of Glass Microchannel via Glass Imprinting using a Vitreous Carbon Stamp for Flow Focusing Droplet Generator

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of A Vitreous Carbon Stamp

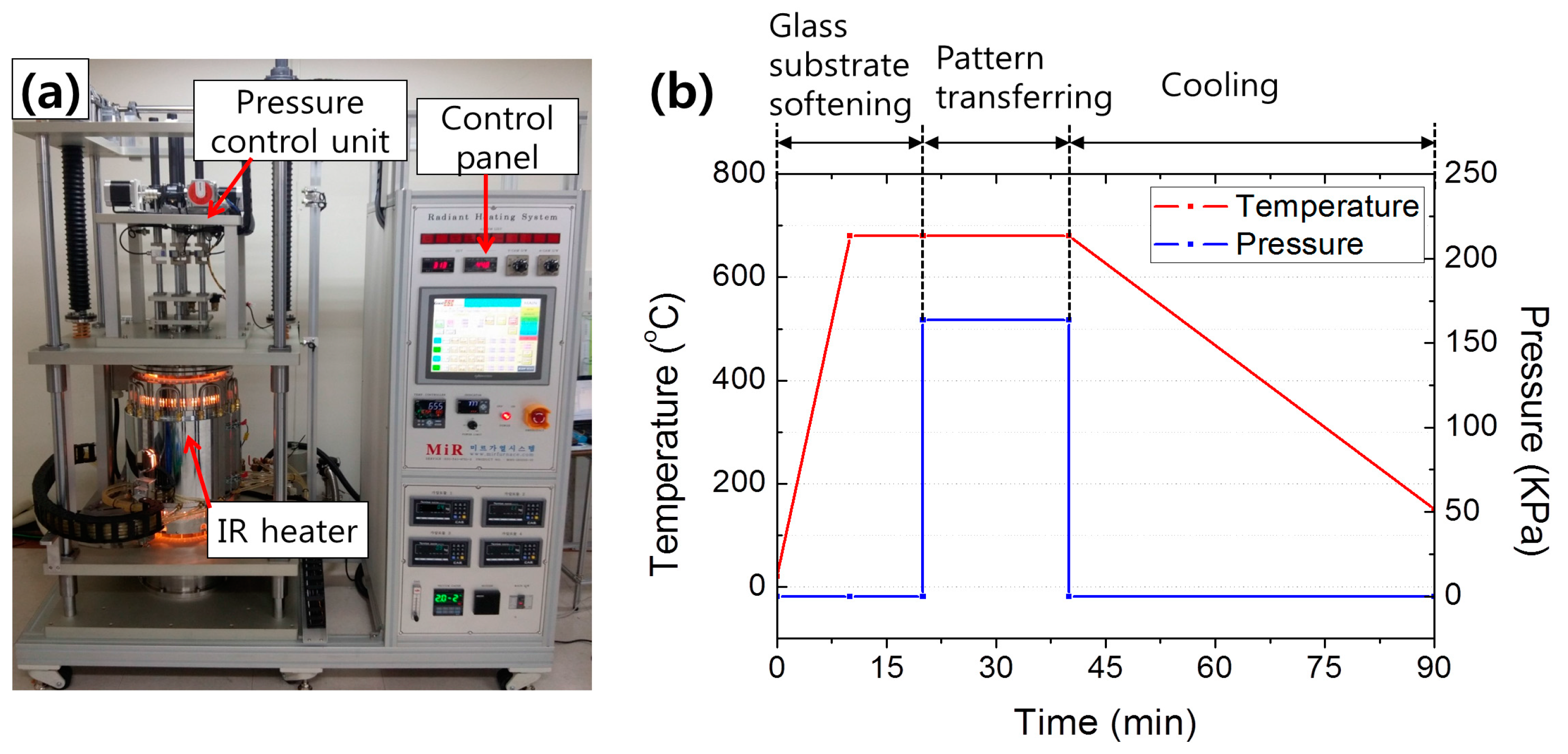

2.2. The Glass Imprinting Process

2.3. Sealing The Glass-Based, Droplet-Generating Microfluidic Chip

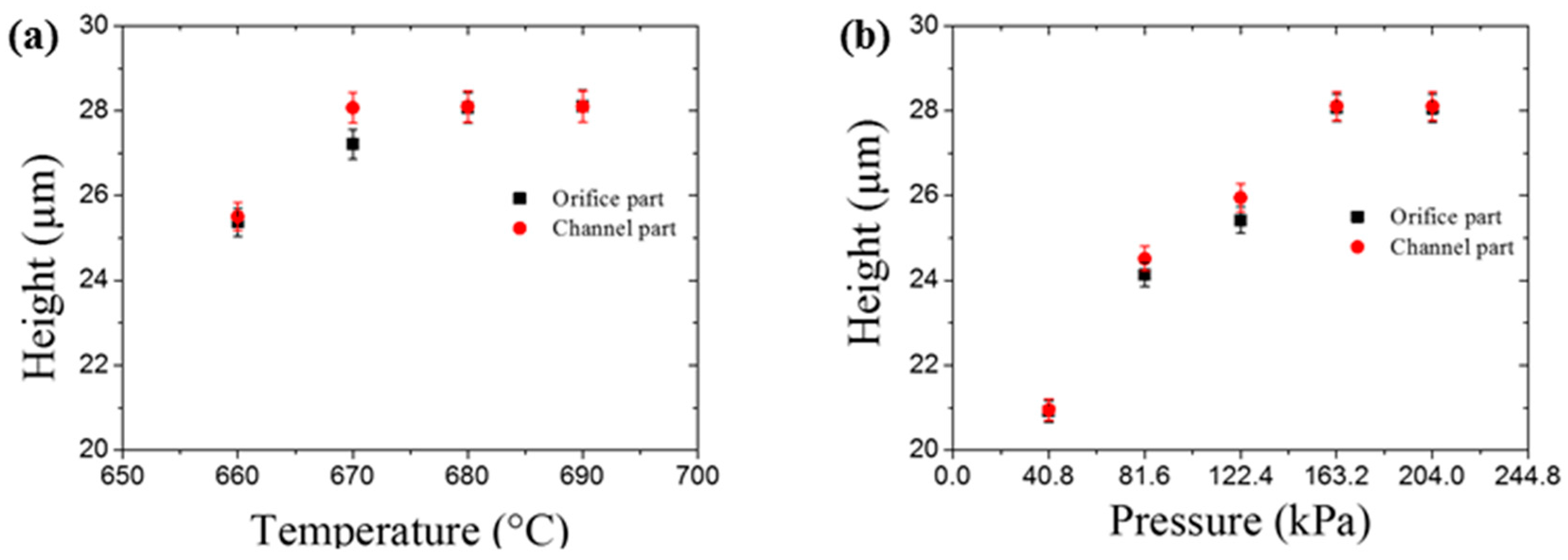

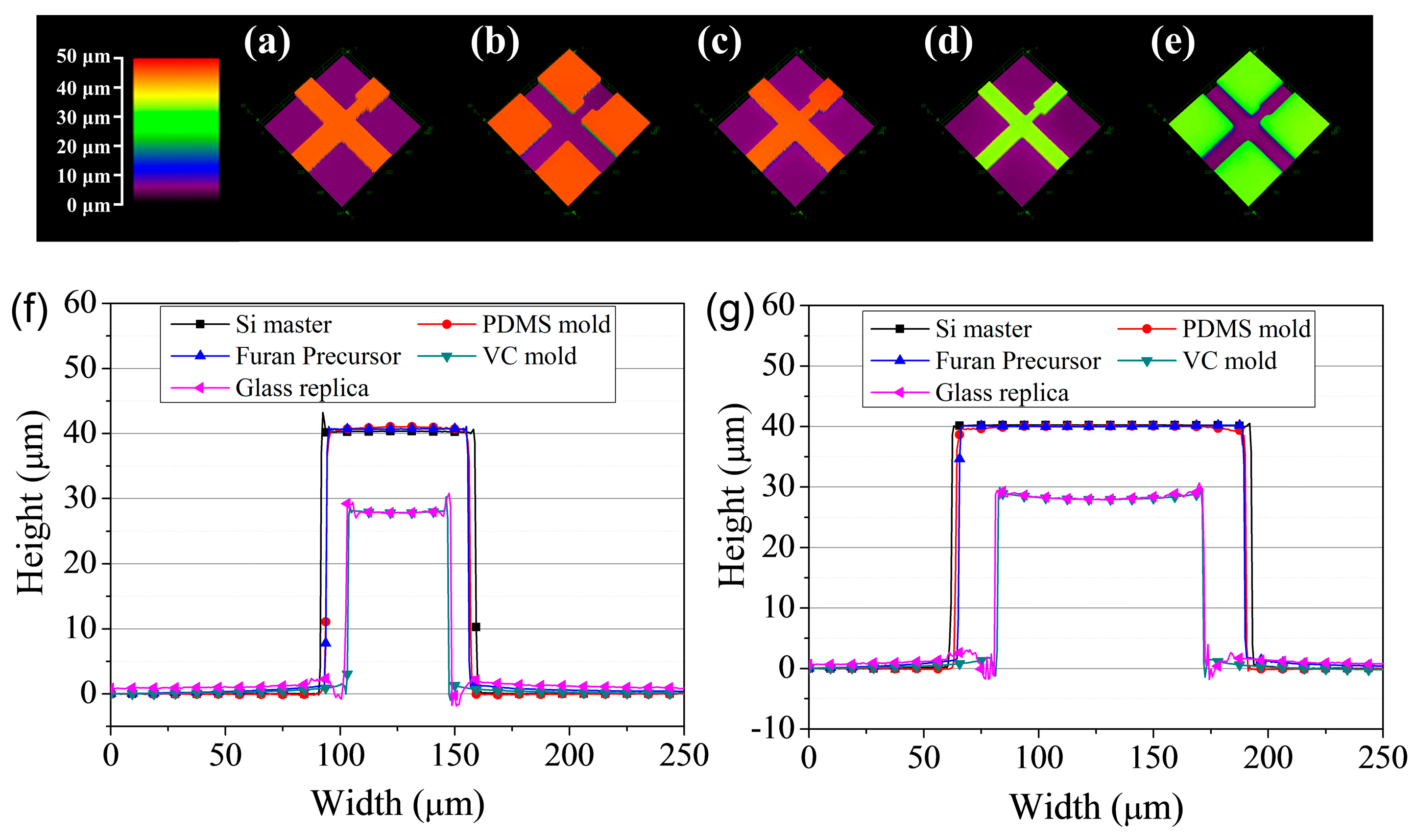

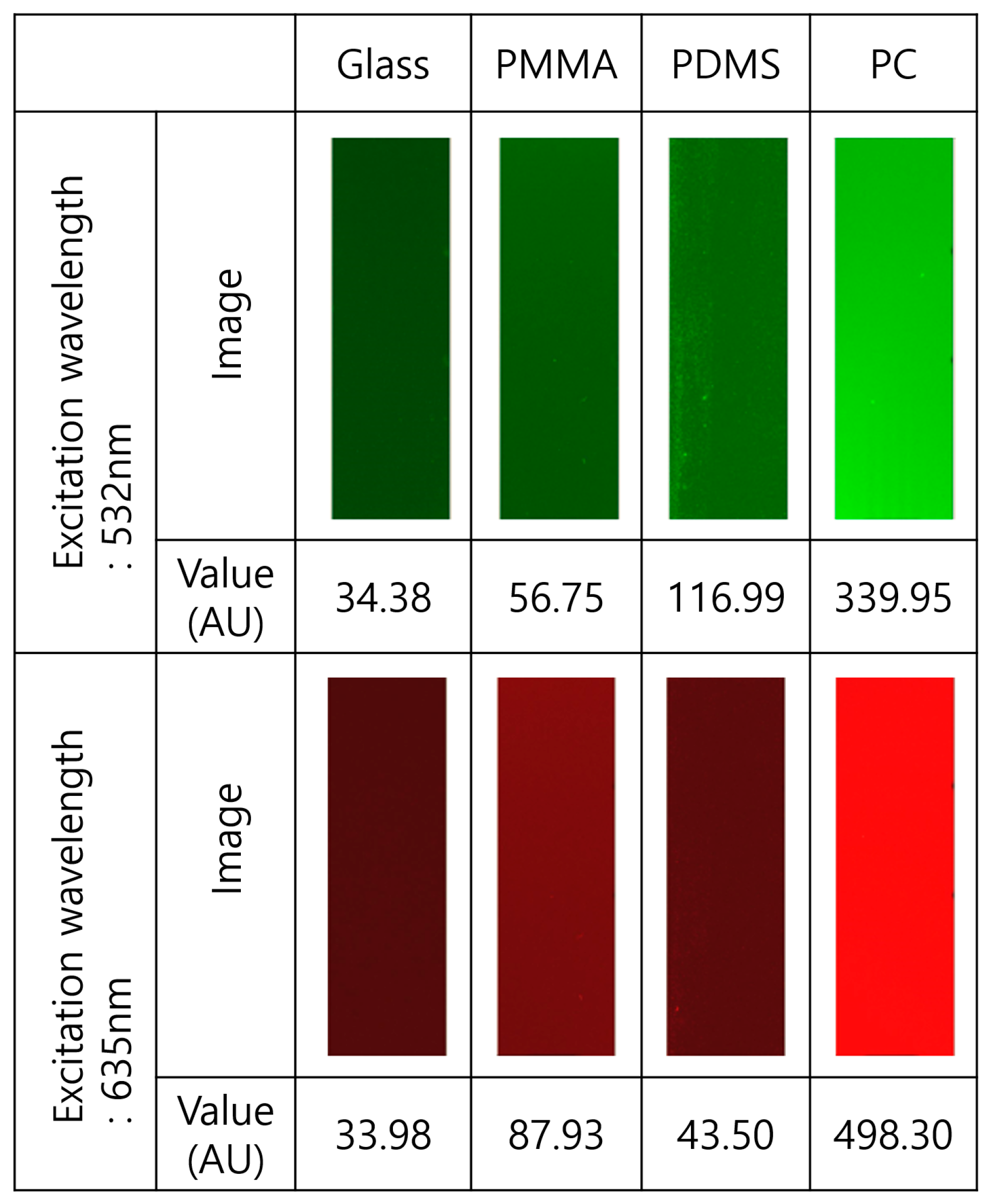

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Dittrich, P.S.; Manz, A. Lab-on-a-chip: Microfluidics in drug discovery. Nat. Rev. Drug Discov. 2006, 5, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Teo, A.J.T.; Tan, S.H.; Ai, Y.; Nguyen, N.T. Self-aligned interdigitated transducers for acoustofluidics. Micromachines 2016, 7, 216. [Google Scholar] [CrossRef]

- Xi, H.D.; Guo, W.; Leniart, M.; Chong, Z.Z.; Tan, S.H. AC electric field induced droplet deformation in a microfluidic T-junction. Lab Chip 2016, 16, 2982–2986. [Google Scholar] [CrossRef] [PubMed]

- Castro-Hernandez, E.; Garcia-Sanchez, P.; Tan, S.H.; Ganan-Calvo, A.M.; Baret, J.-C.; Ramos, A. Breakup length of AC electrified jets in a microfluidic flow-focusing junction. Microfluid. Nanofluid. 2016, 19, 787–794. [Google Scholar] [CrossRef]

- Link, D.; Anna, S.L.; Weitz, D.; Stone, H. Geometrically mediated breakup of drops in microfluidic devices. Phys. Rev. Lett. 2004, 92, 054503. [Google Scholar] [CrossRef] [PubMed]

- McDonald, J.C.; Whitesides, G.M. Poly(dimethylsiloxane) as a material for fabricating microfluidic devices. Acc. Chem. Res. 2002, 35, 491–499. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal. Chem. 2003, 75, 6544–6554. [Google Scholar] [CrossRef] [PubMed]

- Mukhopadhyay, R. When PDMS isn’t the best. Anal. Chem. 2007, 79, 3248–3253. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Kim, M.J.; Lee, H.H. Surface modification of poly(dimethylsiloxane) for retarding swelling in organic solvents. Langmuir 2006, 22, 2090–2095. [Google Scholar] [CrossRef] [PubMed]

- Abate, A.R.; Lee, D.; Do, T.; Holtze, C.; Weitz, D.A. Glass coating for PDMS microfluidic channels by sol-gel methods. Lab Chip. 2008, 8, 516–518. [Google Scholar] [CrossRef] [PubMed]

- Lim, J.; Gruner, P.; Konrad, M.; Baret, J.-C. Micro-optical lens array for fluorescence detection in droplet-based microfluidics. Lab Chip 2013, 13, 1472–1475. [Google Scholar] [CrossRef] [PubMed]

- Song, C.; Tan, S.H. A Perspective on the Rise of Optofluidics and the Future. Micromachines 2017, 8, 152. [Google Scholar] [CrossRef]

- Teo, A.J.; Li, K.H.H.; Nguyen, N.T.; Guo, W.; Heere, N.; Xi, H.D.; Tsao, C.W.; Li, W.; Tan, S.H. Negative Pressure Induced Droplet Generation in a Microfluidic Flow-Focusing Device. Anal. Chem. 2017, 89, 4387–4391. [Google Scholar] [CrossRef] [PubMed]

- Grover, W.H.; Skelley, A.M.; Liu, C.N.; Lagally, E.T.; Mathies, R.A. Monolithic membrane valves and diaphragm pumps for practical large-scale integration into glass microfluidic devices. Sens. Actuators B Chem. 2003, 89, 315–323. [Google Scholar] [CrossRef]

- Chen, Q.; Li, G.; Jin, Q.H.; Zhao, J.L.; Ren, Q.S.; Xu, Y.S. A Rapid and Low-Cost Procedure for Fabrication of Glass Microfluidic Devices. J. Microelectromech. Syst. 2007, 16, 1193–1200. [Google Scholar] [CrossRef]

- Ren, K.; Zhou, J.; Wu, H. Materials for microfluidic chip fabrication. Acc. Chem. Res. 2013, 46, 2396–2406. [Google Scholar] [CrossRef] [PubMed]

- Nge, P.N.; Rogers, C.I.; Woolley, A.T. Advances in microfluidic materials, functions, integration, and applications. Chem. Rev. 2013, 113, 2550–2583. [Google Scholar] [CrossRef] [PubMed]

- Fiorini, G.S.; Chiu, D.T. Disposable microfluidic devices: Fabrication, function, and application. Biol. Tech. 2005, 38, 429–446. [Google Scholar] [CrossRef]

- Tseng, S.-F.; Chen, M.-F.; Hsiao, W.-T.; Huang, C.-Y.; Yang, C.-H.; Chen, Y.-S. Laser micromilling of convex microfluidic channels onto glassy carbon for glass molding dies. Opt. Laser Eng. 2014, 57, 58–63. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, Q.; Maccioni, G. Fabrication of microfluidics structures on different glasses by simplified imprinting technique. Curr. Appl. Phys. 2013, 13, 256–261. [Google Scholar] [CrossRef]

- Chang, S.-H.; Lee, Y.-M.; Shin, K.-H.; Heo, Y.-M. A study on the aspheric glass tens forming analysis in the progressive gmp process. J. Opt. Soc. Korea 2007, 11, 85–92. [Google Scholar] [CrossRef]

- Choi, W.; Lee, J.; Kim, W.-B.; Min, B.-K.; Kang, S.; Lee, S.-J. Design and fabrication of tungsten carbide mould with micro patterns imprinted by micro lithography. J. Micromech. Microeng. 2004, 14, 1519. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Kuo, C.-H.; Hsiao, W.-T.; Huang, K.-C.; Tseng, S.-F.; Chou, C.-P. Glass biochip fabrication by laser micromachining and glass-molding process. J. Mater. Process. Technol. 2012, 212, 633–639. [Google Scholar] [CrossRef]

- Zhou, T.; Yan, J.; Liang, Z.; Wang, X.; Kobayashi, R.; Kuriyagawa, T. Development of polycrystalline Ni–P mold by heat treatment for glass microgroove forming. Precis. Eng. 2015, 39, 25–30. [Google Scholar] [CrossRef]

- Youn, S.W.; Takahashi, M.; Goto, H.; Maeda, R. A study on focused ion beam milling of glassy carbon molds for the thermal imprinting of quartz and borosilicate glasses. J. Micromech. Microeng. 2006, 16, 2576. [Google Scholar] [CrossRef]

- Komori, M.; Uchiyama, H.; Takebe, H.; Kusuura, T.; Kobayashi, K.; Kuwahara, H.; Tsuchiya, T. Micro/nanoimprinting of glass under high temperature using a CVD diamond mold. J. Micromech. Microeng. 2008, 18, 065013. [Google Scholar] [CrossRef]

- Ju, J.; Lim, S.; Seok, J.; Kim, S.-M. A method to fabricate low-cost and large area vitreous carbon mold for glass molded microstructures. Intl. J. Precis. Eng. Man. 2015, 16, 287–291. [Google Scholar] [CrossRef]

- Ju, J.; Han, Y.; Seok, J.; Kim, S.-M. Development of Low-cost and Large-area Nanopatterned Vitreous Carbon Stamp for Glass Nanoreplication. In Proceedings of the 2012 12th IEEE Conference on Nanotechnology (IEEE-NANO), Birmingham, UK, 20–23 August 2012; pp. 1–4. [Google Scholar]

- Mao, P.; Han, J. Fabrication and characterization of 20 nm planar nanofluidic channels by glass-glass and glass-silicon bonding. Lab Chip. 2005, 5, 837–844. [Google Scholar] [CrossRef] [PubMed]

- Rogers, T.; Kowal, J. Selection of glass, anodic bonding conditions and material compatibility for silicon-glass capacitive sensors. Sens. Actuators. A. Phys. 1995, 46, 113–120. [Google Scholar] [CrossRef]

| Si Master | PDMS Mold | Furan Precursor | VC Mold | Glass Replica | ||

|---|---|---|---|---|---|---|

| Orifice width | Mean (µm) | 62.53 | 61.83 | 61.33 | 43.50 | 43.54 |

| Standard deviation (µm) (coefficient of variance) | - (-) | 0.1559 (0.252%) | 0.1179 (0.192%) | 0.2700 (0.621%) | 0.2569 (0.590%) | |

| Total Shrinkage ratio (from master) | - | 0.98% | 1.91% | 30.43% | 30.30% | |

| Channel width | Mean (µm) | 127.35 | 126.22 | 125.06 | 88.93 | 88.87 |

| Standard deviation (µm) (coefficient of variance) | - (-) | 0.0236 (0.019%) | 0.2585 (0.207%) | 0.1671 (0.188%) | 0.2718 (0.306%) | |

| Shrinkage ratio (from master) | 0.89% | 1.80% | 30.17% | 30.22% | ||

| Height (µm) | Mean (µm) | 40.29 | 40.13 | 39.84 | 28.07 | 27.91 |

| Standard deviation (µm) (coefficient of variance) | - | 0.0125 (0.031%) | 0.0535 (0.134%) | 0.1337 (0.476%) | 0.1808 (0.648%) | |

| Shrinkage ratio (from master) | - | 0.41% | 1.12% | 30.33% | 30.74% | |

| Arithmetic Average of the Roughness (Ra, nm) | Root Mean Squared Roughness (Rq, nm) | |

|---|---|---|

| Si master | 1.67 ± 0.52 | 2.17 ± 0.41 |

| PDMS mold | 3.83 ± 1.47 | 5.17 ± 1.47 |

| Furan Precursor | 1.67 ± 0.52 | 2.17 ± 0.41 |

| VC mold | 2.83 ± 0.41 | 3.67 ± 0.52 |

| Glass replica | 5.50 ± 1.76 | 7.50 ± 3.02 |

| Flow Rate of Aqueous Phase (μL/min) | Flow Rate of Oil Phase (μL/min) | Generation Frequency (Hz) | Captured Image from the Movie Captured by High Speed Camera |

|---|---|---|---|

| 30 | 2.5 | 469 |  |

| 5 | 872 |  | |

| 10 | 1588 |  | |

| 15 | 2521 |  |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, H.; Refatul Haq, M.; Kim, Y.; Kim, J.; Oh, P.-h.; Ju, J.; Kim, S.-M.; Lim, J. Fabrication of Glass Microchannel via Glass Imprinting using a Vitreous Carbon Stamp for Flow Focusing Droplet Generator. Sensors 2018, 18, 83. https://doi.org/10.3390/s18010083

Jang H, Refatul Haq M, Kim Y, Kim J, Oh P-h, Ju J, Kim S-M, Lim J. Fabrication of Glass Microchannel via Glass Imprinting using a Vitreous Carbon Stamp for Flow Focusing Droplet Generator. Sensors. 2018; 18(1):83. https://doi.org/10.3390/s18010083

Chicago/Turabian StyleJang, Hyungjun, Muhammad Refatul Haq, Youngkyu Kim, Jun Kim, Pyoung-hwa Oh, Jonghyun Ju, Seok-Min Kim, and Jiseok Lim. 2018. "Fabrication of Glass Microchannel via Glass Imprinting using a Vitreous Carbon Stamp for Flow Focusing Droplet Generator" Sensors 18, no. 1: 83. https://doi.org/10.3390/s18010083